Waterproof packing cardboard and producing method thereof

A technology for packaging cardboard and a production method, which is applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve problems affecting product packaging quality, rising packaging costs, deformation of plastic plates, etc., and achieves convenience for recycling and recycling, and is beneficial to environmental protection. The effect of stable packaging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 6 parts of alkyl ketene dimer with a solid content of 12% and 1 part of polyamide epoxy resin with a solid content of 15% by weight, mix them evenly at room temperature, and prepare a composite water repellent for later use;

[0018] The composite water repellent of 3.0% by weight (that is, 3.0% of the pulp pulp) is added to the pulp in the papermaking process to prepare waterproof paper 2;

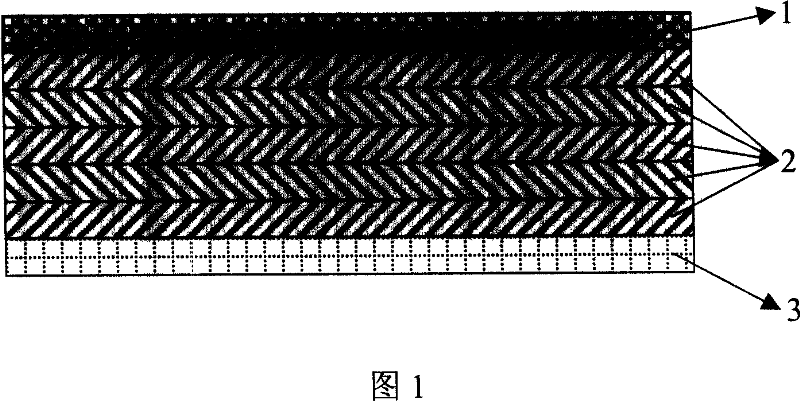

[0019] Take 3 layers of waterproof paper, glue them layer by layer with adhesive on the equipment, and dry them at 80-100℃ to make composite waterproof paperboard with a thickness of 1.5-2.0mm;

[0020] One side (outside) of the composite waterproof paperboard is coated with a layer of colored surface water repellent 1 (appropriate amount), and dried at 50-80°C;

[0021] A layer of vapor phase corrosion inhibitor 3 is coated on the other side (inner side) of the composite waterproof paperboard to prepare a waterproof and rust-proof packaging paperboard.

Embodiment 2

[0023] Take 5 parts of alkyl ketene dimer with a solid content of 15% and 1 part of polyamide epoxy resin with a solid content of 13% by weight, mix them evenly at room temperature, and prepare a composite water repellent for later use;

[0024] 2.25% of the composite water repellent is added to the pulp in the papermaking process to prepare waterproof paper 2 for later use;

[0025] Take 4 layers of waterproof paper, bond them layer by layer with adhesive on the equipment, and dry them at 80 to 100 °C to make composite waterproof paperboard with a thickness of 2.5 to 3.0 mm;

[0026] One side of the composite waterproof paperboard is coated with a layer of colored surface water repellent 1 (appropriate amount), and dried at 50-80°C.

[0027] A layer of vapor-phase corrosion inhibitor 3 can be coated on the other side of the composite waterproof paperboard to prepare a waterproof and rust-proof packaging paperboard.

Embodiment 3

[0029] Take 4 parts of alkyl ketene dimer with a solid content of 15% and 1 part of polyamide epoxy resin with a solid content of 15% by weight, mix them evenly at room temperature, and prepare a composite water repellent for later use;

[0030] 1.5% of the composite water repellent is added to the pulp in the papermaking process to prepare waterproof paper;

[0031] Take 6 layers of waterproof cardboard, glue them layer by layer with adhesive on the equipment, and dry them at a temperature of 80-100℃ to make a composite waterproof cardboard with a thickness of 3.5-4mm;

[0032] One side (outside) of the composite waterproof paperboard is coated with a layer of colored surface water repellent (appropriate amount), and dried at 50-80°C;

[0033] A layer of vapor phase corrosion inhibitor is coated on the other side (inner side) of the composite waterproof paperboard to prepare a waterproof and rust-proof packaging paperboard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com