Solvent-free epoxy primer for corrosion protection of 3 polypropylene (PP) at craters of steel pipelines

An epoxy primer, solvent-free technology, applied in the field of primers, can solve the problems of low surface energy and surface tension, poor adhesion performance, complex material sources, etc., to improve poor flexibility, strong adhesion, chemical good stability

Inactive Publication Date: 2012-03-07

JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

View PDF4 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As far as the 3PP anti-corrosion primer is concerned, due to the strong non-polarity of PP, its surface energy and surface tension are not large, resulting in poor bonding performance between many polymer materials and it. The bond strength is so small that the primer cannot adhere well to the PP substrate

The technology in this area is still blank in China at present, and there are not many mature products abroad, mainly Raychem and other companies. Due to its high price and complicated material sources, it has not been widely promoted, and the bonding is not perfect. Satisfactory, the corresponding technology is not perfect, and there are few reference data

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

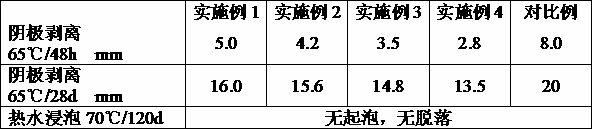

Effect test

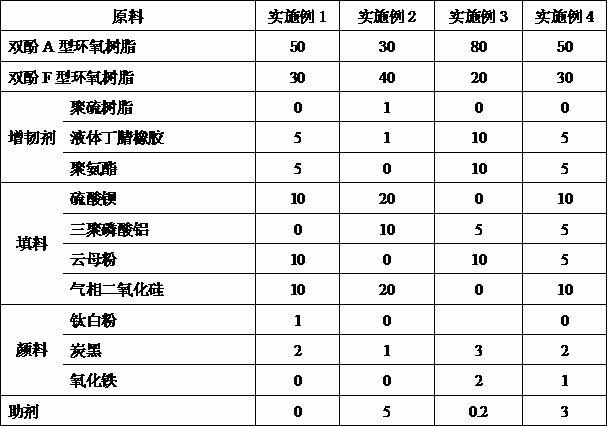

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a solvent-free epoxy primer for corrosion protection of 3 PP at craters of steel pipelines. The primer comprises, by mass, 50 to 80% of component A and 20 to 50% of component B, wherein, the component A comprises, by weight, 30 to 80 parts of a bisphenol A type epoxy resin, 20 to 40 parts of a bisphenol F type epoxy resin, 2 to 20 parts of a flexibilizer, 15 to 50 parts of a filling material and 1 part to 5 parts of pigments, and the component B is a polyamide epoxy hardener. According to the invention, the solvent-free epoxy primer for corrosion protection of 3 PP at craters of steel pipelines ensures good bond performance, i.e., high bonding strength, between the primer and PP, and good bond performance between 3 PP and a hot melt adhesive as well.

Description

technical field [0001] The invention relates to a primer, in particular to a solvent-free epoxy primer for 3PP anticorrosion at the welding joint of steel pipelines. Background technique [0002] With the increasing development of the petroleum industry, the corrosion of steel bears the brunt of the problem. Pipeline anticorrosion has received widespread attention. Solving the problem of pipeline anticorrosion is the most important thing related to people's livelihood and energy saving. At present, most anti-corrosion pipelines at home and abroad adopt the form of three-layer polyethylene (referred to as 3PE) pipes for external anti-corrosion, and the corresponding joints are also used in the same way. However, due to the long-term use temperature of polyethylene (referred to as PE) is not high, the anti-corrosion of 3PE loses its original efficiency and durability in some areas with high ambient temperature, such as tropical regions and deserts. A better solution to this ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/02C09D5/08

Inventor 饶学武赵秋峰

Owner JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com