Preparation method of permeation resistant addition agent with functions of reinforcing stiffness and wet-strength

A kind of anti-penetration aid, wet strength technology, applied in the field of papermaking aids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Synthesis of intermediate polyamide:

[0034] Add 35g of diethylenetriamine and 65g of water into a 500mL three-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser. Add 48 g of adipic acid and a small amount of catalyst under stirring. After the system automatically releases heat and heats up to 120°C, keep it warm for 30 minutes, change the condensing and reflux device to a distillation device, and control the distillate speed to distill one drop in 3 seconds. Slowly heat up to 200°C and keep at this temperature for 30min. Cool, and when the temperature drops below 110°C, slowly add water to adjust the solid content to 50%, and continue to stir until the reactant is homogeneous, and the intermediate polyamide is obtained.

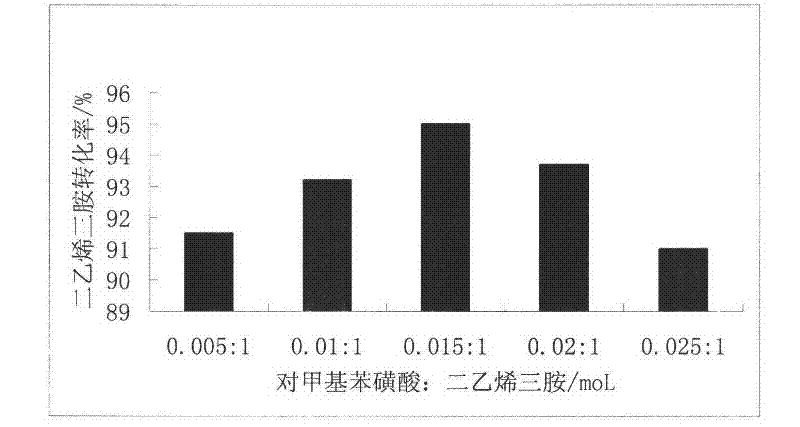

[0035] The applicant selected different catalysts to carry out the experiments in Example 1, and used the conversion rate of diethylenetriamine to represent the effect of each catalyst. The experimental results are...

Embodiment 2

[0041] Synthesis of intermediate polyamide (PPC):

[0042] Add 35g of diethylenetriamine and 65g of water into a 500mL three-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser. 48 g of adipic acid and 0.5 g of catalyst p-toluenesulfonic acid were added under stirring. After the system automatically releases heat and heats up to 120°C, keep it warm for 30 minutes, change the condensing and reflux device to a distillation device, and control the distillate speed to distill one drop in 3 seconds. Slowly heat up to 140°C to 200°C, and keep at this temperature for 30 minutes. Cool, and when the temperature drops below 110°C, slowly add water to adjust the solid content to 50%, and continue to stir until the reactant is homogeneous, and the intermediate polyamide is obtained.

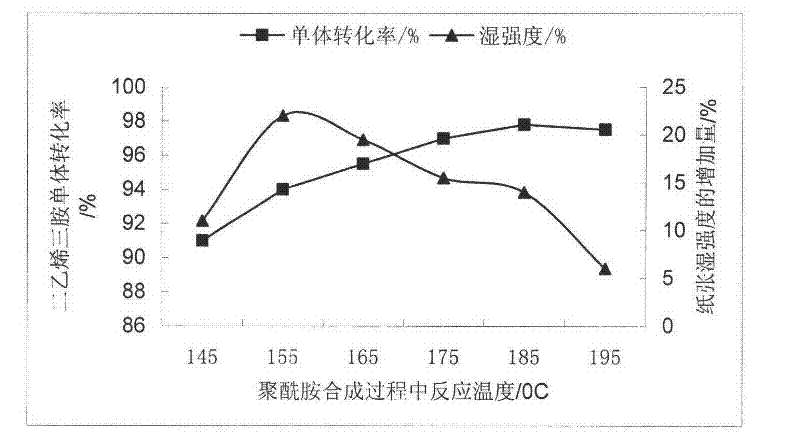

[0043] The applicant selected polymers in the synthesis temperature range of 140°C to 200°C to measure the conversion rate of diethylenetriamine monomer, and measured the w...

Embodiment 3

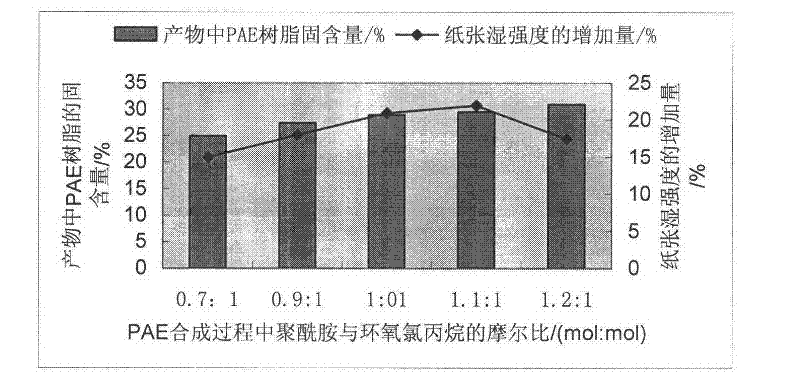

[0045] 1. Synthesis of polyamide polyamine epichlorohydrin (PAE)

[0046] (1) Synthesis of intermediate polyamide (PPC):

[0047] Add 35g of diethylenetriamine and 65g of water into a 500mL three-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser. 48 g of adipic acid and 0.5 g of catalyst p-toluenesulfonic acid were added under stirring. After the system automatically releases heat and heats up to 110°C, keep it warm for 30 minutes, change the condensation reflux device to a distillation device, and control the distillate speed to 3 seconds to distill one drop. Slowly heat up to 155°C and keep at this temperature for 30min. Cool, and when the temperature drops below 110°C, slowly add water to adjust the solid content to 50%, and continue to stir until the reactants are in a homogeneous phase to obtain an intermediate polyamide.

[0048] (2) Epoxidation reaction of polyamide and epichlorohydrin:

[0049] Take 50 g of the intermediate polyam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com