Corrosion-resistant high-temperature insulation paint

A high-temperature insulation and corrosion-resistant technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor adhesion of coatings, poor resistance to organic solvents, high-temperature corrosion resistance, etc., and achieve good aging resistance, enhanced mutual connection, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

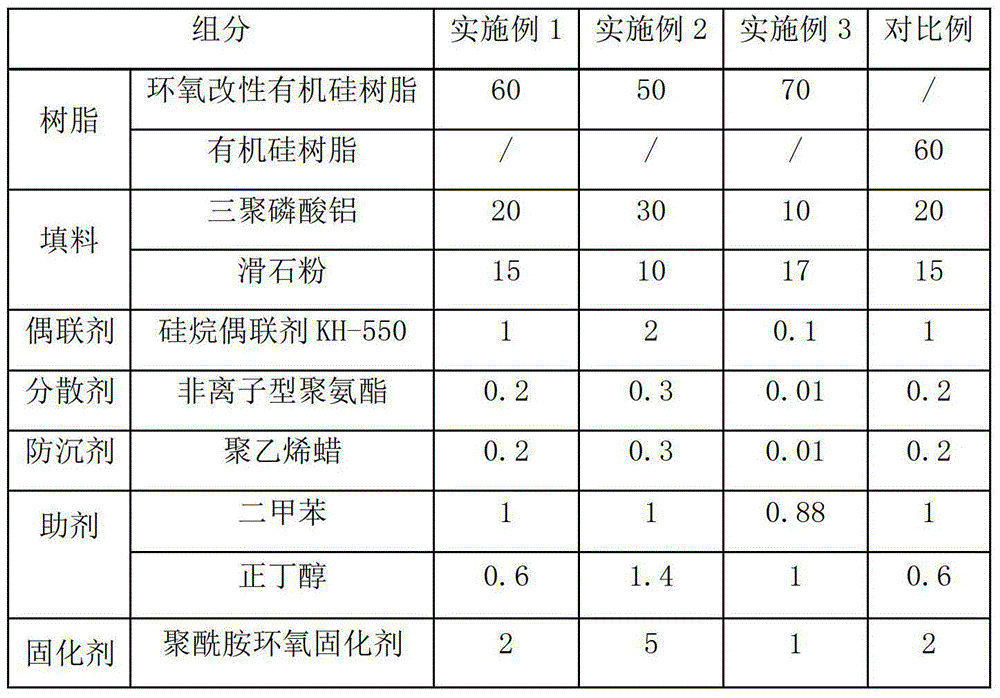

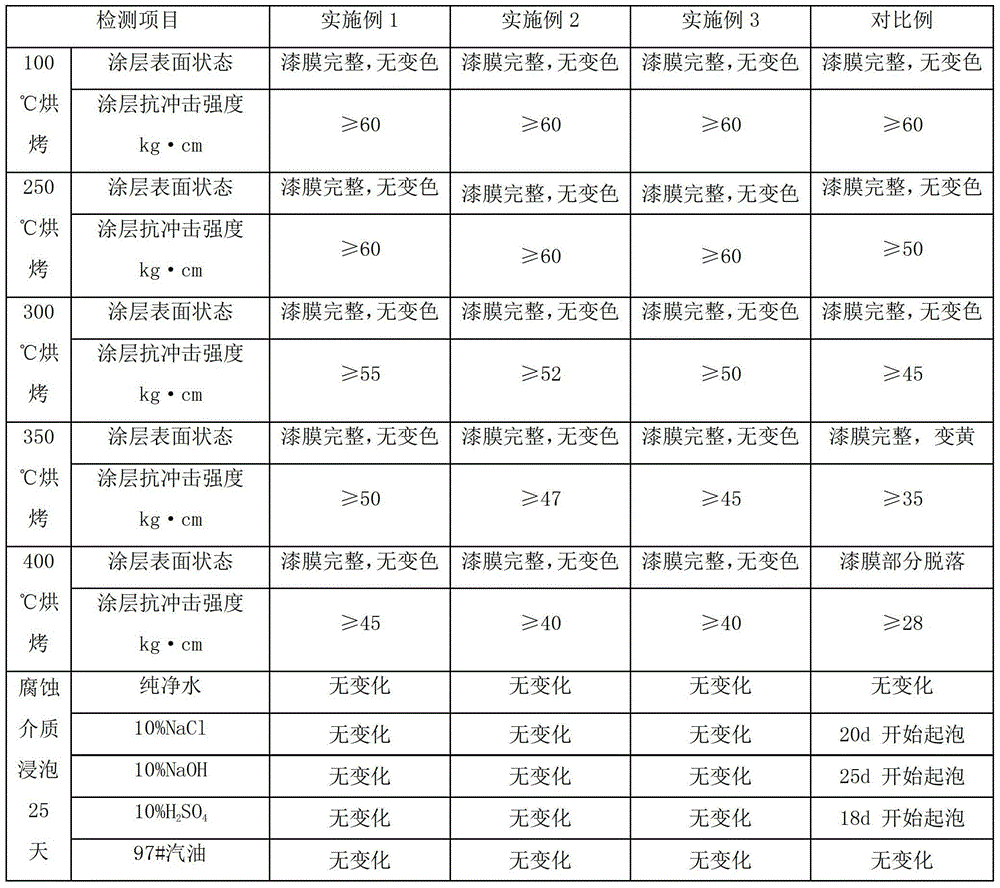

Examples

Embodiment 1

[0025] (1) Weigh the corresponding components according to the formula table 1 for later use;

[0026] (2) Mix the substances in component A and grind them in a ball mill until the particle size is ≤40 μm;

[0027] (3) Mix component A and component B in step (2) evenly to obtain the corrosion-resistant high-temperature insulating coating.

Embodiment 2-3

[0029] (1) Weigh the corresponding components according to the formula table 1 for later use; the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com