Preparation method of environment-friendly low-chlorine wet strength agent

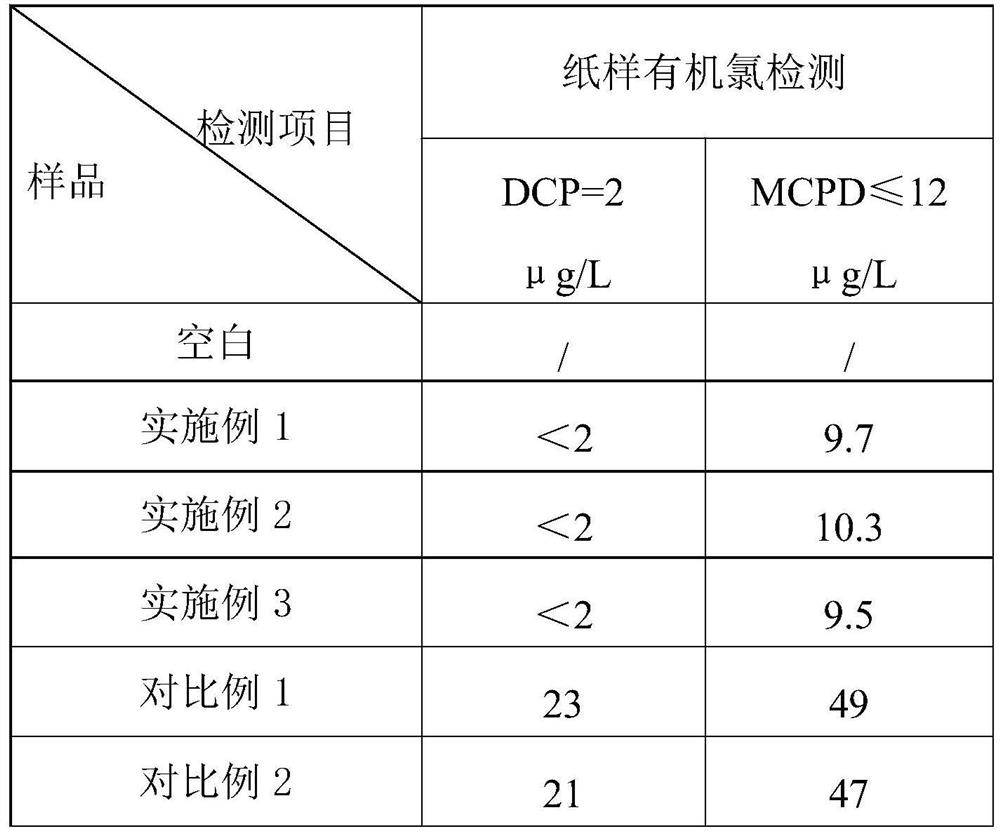

A wet strength agent and environmental protection technology, applied in the field of preparation of environmentally friendly low chlorine wet strength agent, to achieve the effects of reduced organic chlorine content, excellent application performance and good retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

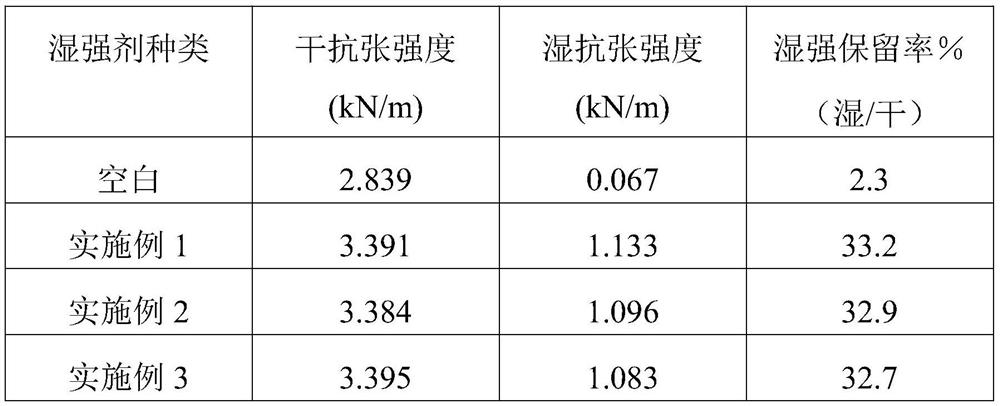

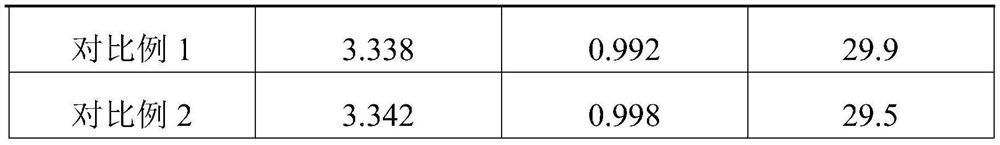

Examples

Embodiment 1

[0027](1) 132 grams of water under the reactor, 260 grams of adipic acid and 1.5 grams of citric acid, stirred at the stirring, and then add 180 grams of dicene triamine, stirred for 1 hour, add catalyst concentrated sulfuric acid 1.5 Gram, then stirred for 1 hour, then continued to heat up to 165 ° C (the reaction temperature was set according to actual needs) for 5 hours, and then dilute water was added after the effluent was added, and the polymer was diluted to a solid content of 50%. Take 160 g of the polymer solution, 400 grams of water, stirred and uniform, and then slowly drip to add epoxyoxropane, 40 min, and after the dropwater is added, the reaction is 60 min at 30 ° C, and the reaction is 90 min, then The temperature is heated to 65 ° C, and the reaction liquid is added after the viscosity of the design viscosity is added, and the pH is 3.7 to obtain a polyamide epoxy resin;

[0028](2) Weigh 50 grams of hydroxypropyleproluacuachen addition to a three-mouth flask with a the...

Embodiment 2

[0031](1) 100 grams of kettate, 250 grams of adipate and 1.5 grams of citric acid were added to 250 grams of citric acid, and stirred at 181 grams of diethylene triamine, stirred for 1 hour, and added to the catalyst concentratic acid 1.2 Gram, then stirred for 1 hour, then continued to warm to 170 ° C (the reaction temperature was set according to actual needs) for 4 hours, and then the amount of water reached the designed amount, dilution is diluted to a solid content of 50%. 200 grams of the polymer solution was taken, 400 g of water was added, and 64 grams of epoxy chloropropane was added, and the dropwish was 60 min. After the dropwise addition, the reaction was 50 min, and the reaction was 60 min at 50 ° C, while the subtraction temperature 70 ° C, when the reaction liquid viscosity reaches the design viscosity, add 50% dilute sulfate to 3.5, and the acid is adjusted to 3.5 to obtain a polyamide epoxy resin;

[0032](2) Weigh 100 grams of hydroxypropyleprium gum to add a three-mo...

Embodiment 3

[0035](1) 80 grams of kettate water, 146 g of adipate and 1.0 grams of citric acid were added, and stirred on stirring, 103 grams of diethylene triamine was slowly added, stirred for 1 hour, and the catalyst concentrated sulfuric acid was added. 1.0 Gram, then stirred for 1 hour, then continued to heat up to 190 ° C (the reaction temperature was set according to actual needs) for 2 hours, and then the amount of water was added to the designed amount, and the polymer was diluted to a solid content of 50%. 200 grams of the polymer solution was taken, 400 g of water was added, and 56 g of epoxy chloropropane was added, and the dropped time was 50 min. After the dropwater was added, the reaction was reacted at 35 ° C for 45min, while the subtracking temperature 67 ° C, when the reaction liquid viscosity reached the design viscosity, 50% dilute sulfate was added to the reaction, the acid or base regulation pH to 4.0 was added to obtain a polyamide epoxy resin.

[0036](2) Weighing 75 hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com