Emulsified asphalt cold-recycling layer interface bonding material as well as preparation method and application thereof

A technology of emulsified asphalt and adhesive materials, which is applied in the field of chemical construction materials, can solve the problems of affecting the performance of the regeneration layer and even other layers, reducing the effect of interfacial bonding and water release, and affecting the service life of the road, so as to reduce the shear damage between layers, Improve the application value, and the waterproof effect will continue to be effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

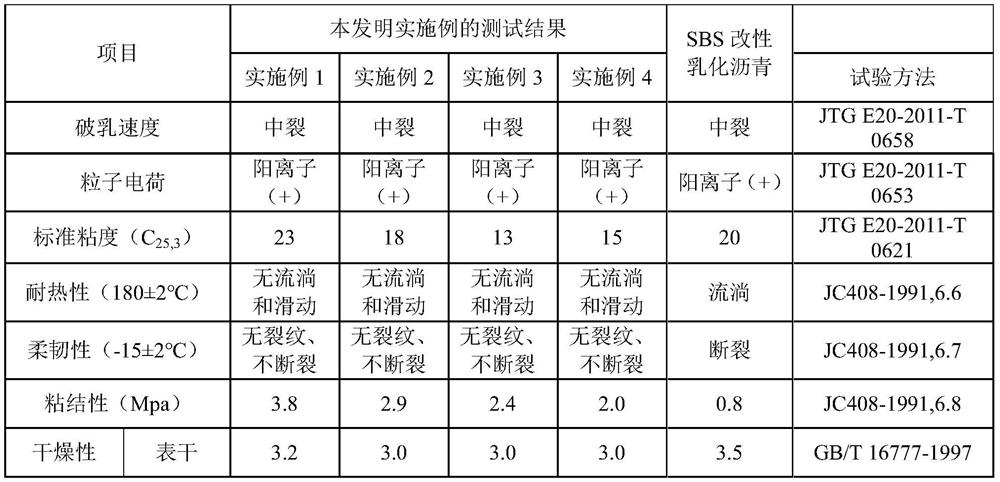

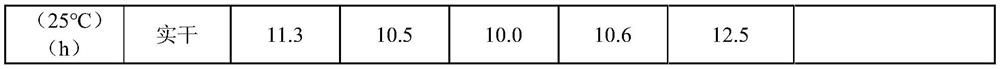

Examples

Embodiment 1

[0037] The preparation method of the emulsified asphalt cold regeneration layer interface bonding material of the present embodiment specifically comprises the following steps:

[0038] S1. Preparation of component C: add 1 part of polyvinyl alcohol particles to 9 parts of water, soak for 30 minutes first, and extend the soaking time appropriately according to the dissolution of polyvinyl alcohol. Then heat it to 80°C with a water bath to stop heating, and cool to room temperature for later use;

[0039] Preparation of components S2 and D: Grind 2 parts of solid SBS into a powder below 0.075 mm, dissolve it in xylene at room temperature until it becomes transparent, and use it as a precursor liquid SBS for later use; then use 0.082 parts of dibenzyl biphenyl polyoxyethylene ether Add 0.083 parts of fatty alcohol polyoxyethylene ether to 2.64 parts of water to make a compound emulsifier solution, heat it to 50-60°C; add the compound emulsifier solution to liquid SBS, and shear ...

Embodiment 2

[0043] The preparation method of the emulsified asphalt cold regeneration layer interface bonding material of the present embodiment specifically comprises the following steps:

[0044] Preparation of S1 and component C: add 0.7 parts of polyvinyl alcohol particles to 9.3 parts of water, soak for 30 minutes first, and extend the soaking time appropriately according to the dissolution of polyvinyl alcohol. Then heat to 80°C with a water bath, stop heating, and cool to room temperature for later use;

[0045]Preparation of components S2 and D: Grind 2 parts of solid SBS into powders below 0.075 mm, dissolve in xylene at room temperature until transparent, and use 0.082 parts of alkylphenol polyoxyethylene ether for sulfonation Add succinate and 0.083 parts of alkylphenol polyoxyethylene to 2.64 parts of water to make a composite emulsifier solution, and heat it to 50-60°C; add the composite emulsifier solution to liquid SBS and heat it at 7800-12000 rpm Under-shear emulsificati...

Embodiment 3

[0049] The preparation method of the emulsified asphalt cold regeneration layer interface bonding material of the present embodiment specifically comprises the following steps:

[0050] Preparation of S1 and component C: Add 0.5 parts of polyvinyl alcohol particles to 9.5 parts of water, soak for 30 minutes first, and extend the soaking time appropriately according to the dissolution of polyvinyl alcohol. Then heat to 80°C with a water bath, stop heating, and cool to room temperature for later use;

[0051] Preparation of components S2 and D: Grind 2 parts of solid SBS into powders below 0.075 mm, dissolve in xylene at room temperature until transparent, and use 0.055 parts of alkylphenol polyoxyethylene ether for sulfonation Add succinate, 0.055 parts of dibenzyl biphenyl polyoxyethylene ether and 0.055 parts of alkylphenol polyoxyethylene to 2.64 parts of water to make a composite emulsifier solution, and heat it to 50-60°C; add the composite emulsifier solution to In liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com