Double-component expansion type fireproof coating and preparation method thereof

A kind of technology of fireproof coating and expansion type, which is applied in the direction of fireproof coating, epoxy resin coating, coating, etc. It can solve the problems of poor water resistance and low mechanical strength, achieve good cohesion, improve fire resistance limit, and increase the effect of expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

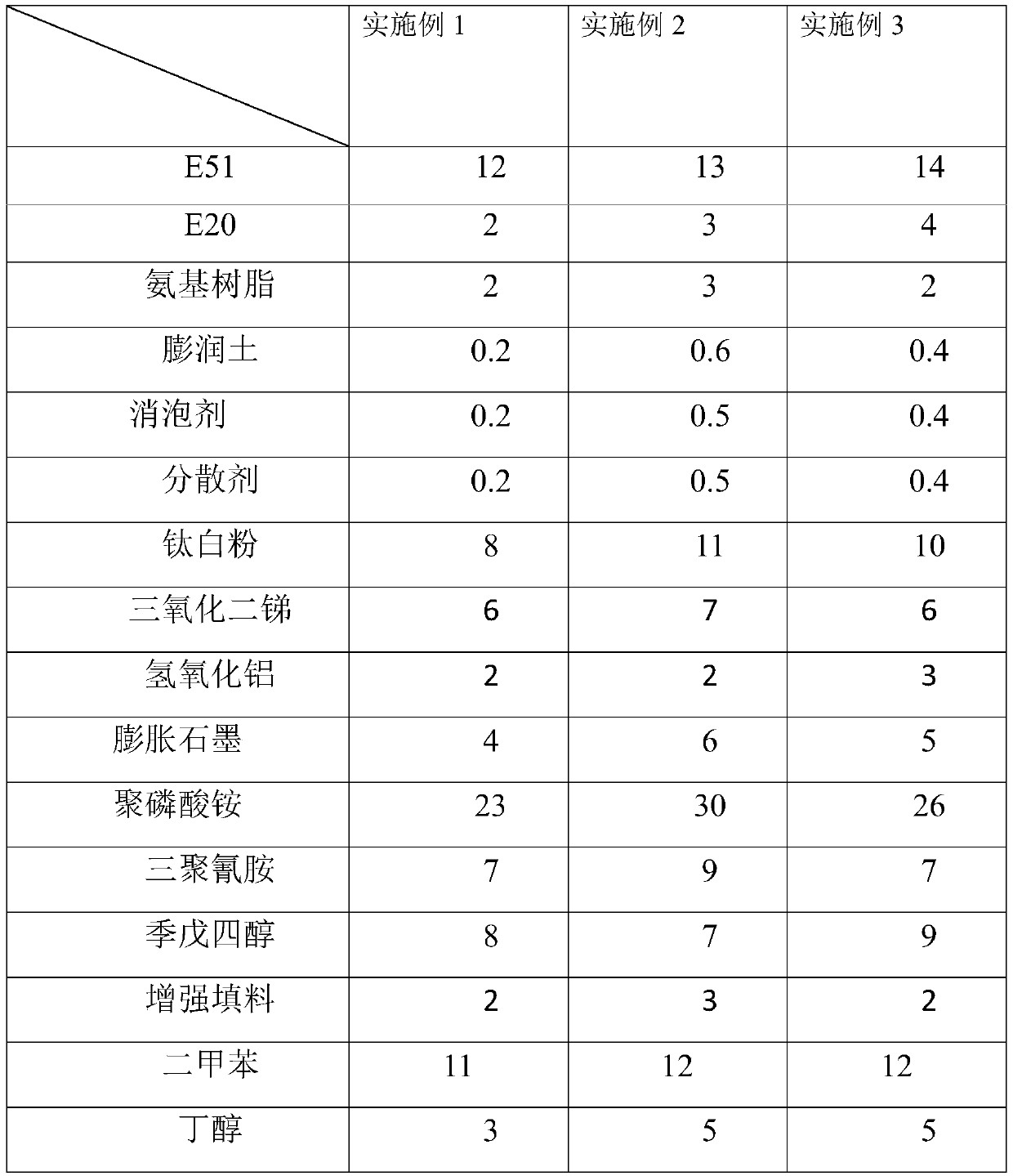

Embodiment 1-3

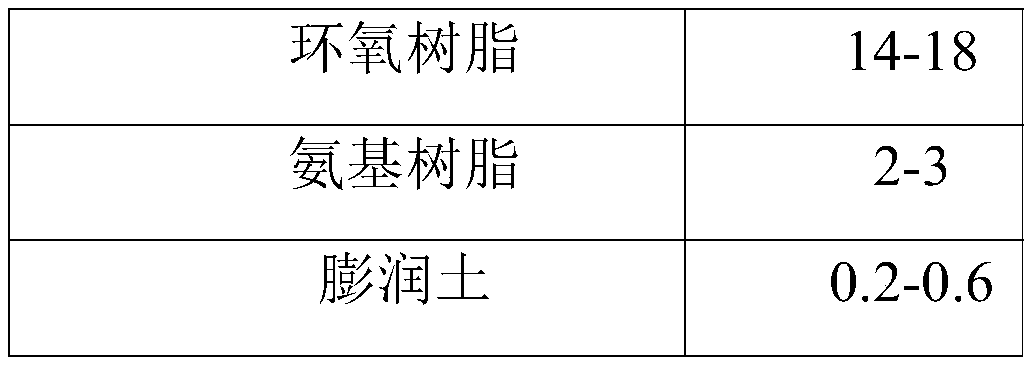

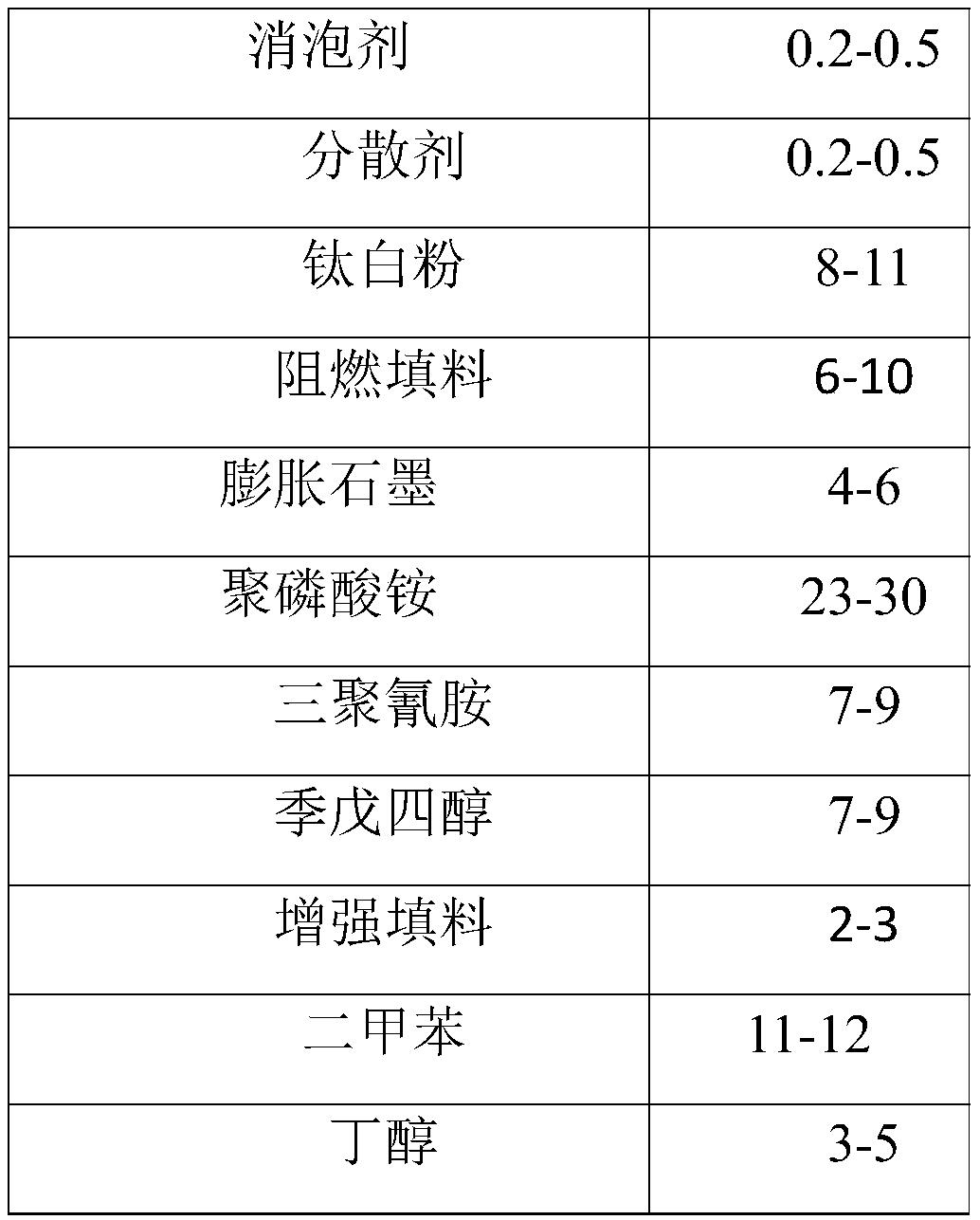

[0032] Component A of the two-component intumescent fire retardant coating is prepared by using the formula composition shown in the following table.

[0033]

Embodiment 1

[0034] The preparation method of above-mentioned embodiment 1-3 two-component intumescent fire retardant coating component A:

[0035] Dispersion: add epoxy resin, amino resin, defoamer, bentonite and dispersant to the batching tank in turn, and disperse at 1500r / min for 15 minutes;

[0036] Grinding: Add the dispersed materials into the grinding tank, add titanium dioxide, flame retardant fillers, melamine, pentaerythritol, and reinforcing fillers in sequence, and grind to a fineness of less than 80 μm;

[0037] After the fineness is qualified, stir in ammonium polyphosphate, expanded graphite, add toluene and butanol, stir evenly, and then obtain the component A of the two-component intumescent epoxy fireproof coating;

[0038] Component A of the two-component intumescent epoxy fireproof coating prepared in Example 1-3 and component B modified polyamide epoxy curing agent are mixed uniformly in a mass ratio of 4:1 to obtain a two-component intumescent ring. Oxygen fire reta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com