Polyamide epoxy resin curing agent

A technology of epoxy resin curing and polyamide, applied in the field of curing agent, can solve the problems of low hardness, easy moisture absorption coating film, poor weather resistance of coating film, etc., and achieve the effect of good softness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, which are preferred embodiments of the present invention.

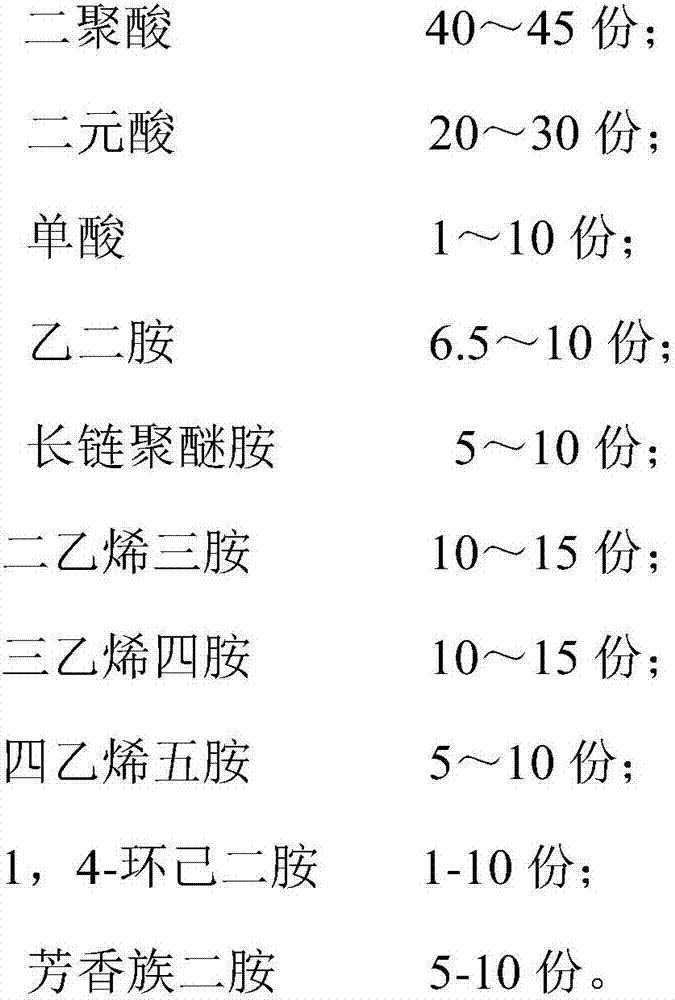

[0019] Polyamide epoxy resin curing agent comprises each component of following weight parts:

[0020]

[0021]

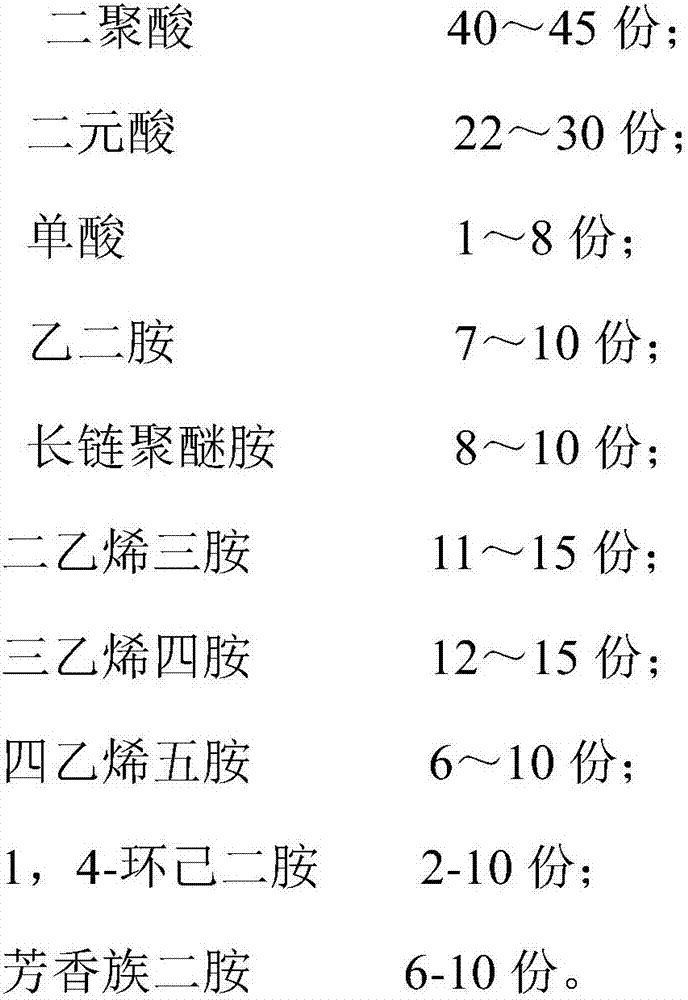

[0022] Further, each component including the following parts by weight:

[0023]

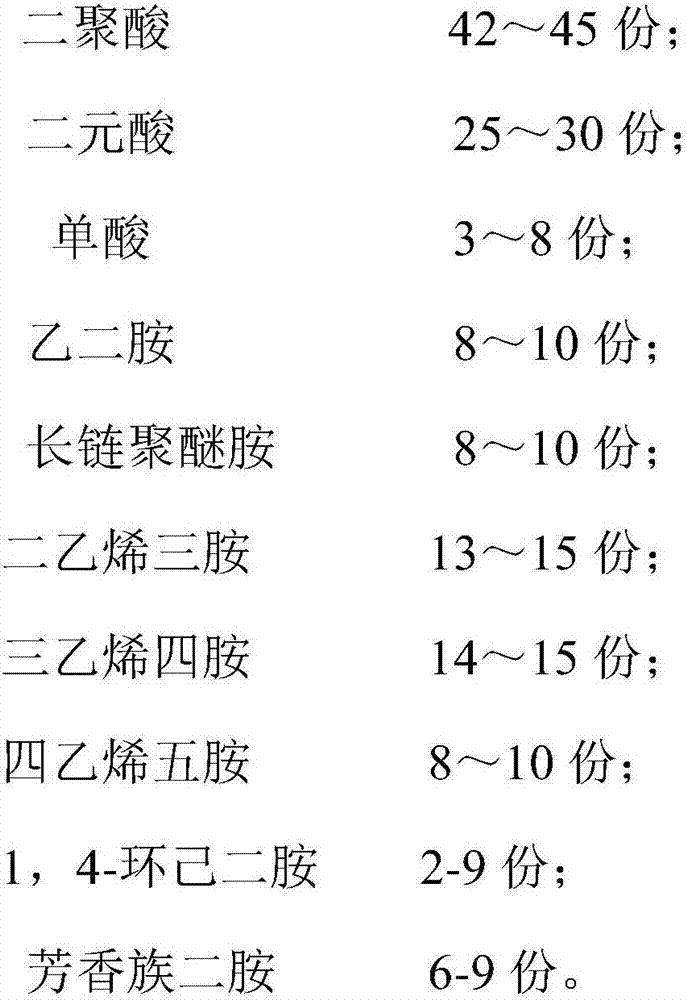

[0024] Further, each component including the following parts by weight:

[0025]

[0026]

[0027] Preferably, the dibasic acid is selected from any one or a combination of adipic acid or sebacic acid.

[0028] Preferably, the long-chain polyetheramine is polyetheramine D-4000.

[0029] Preferably, the monoacid is stearic acid.

[0030] Preferably, the aromatic diamine is p-xylylenediamine or m-xylylenediamine.

[0031] Compared with the prior art, the polyamide epoxy resin curing agent of the present invention has the following beneficial effects: particularly good in softness and toughness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com