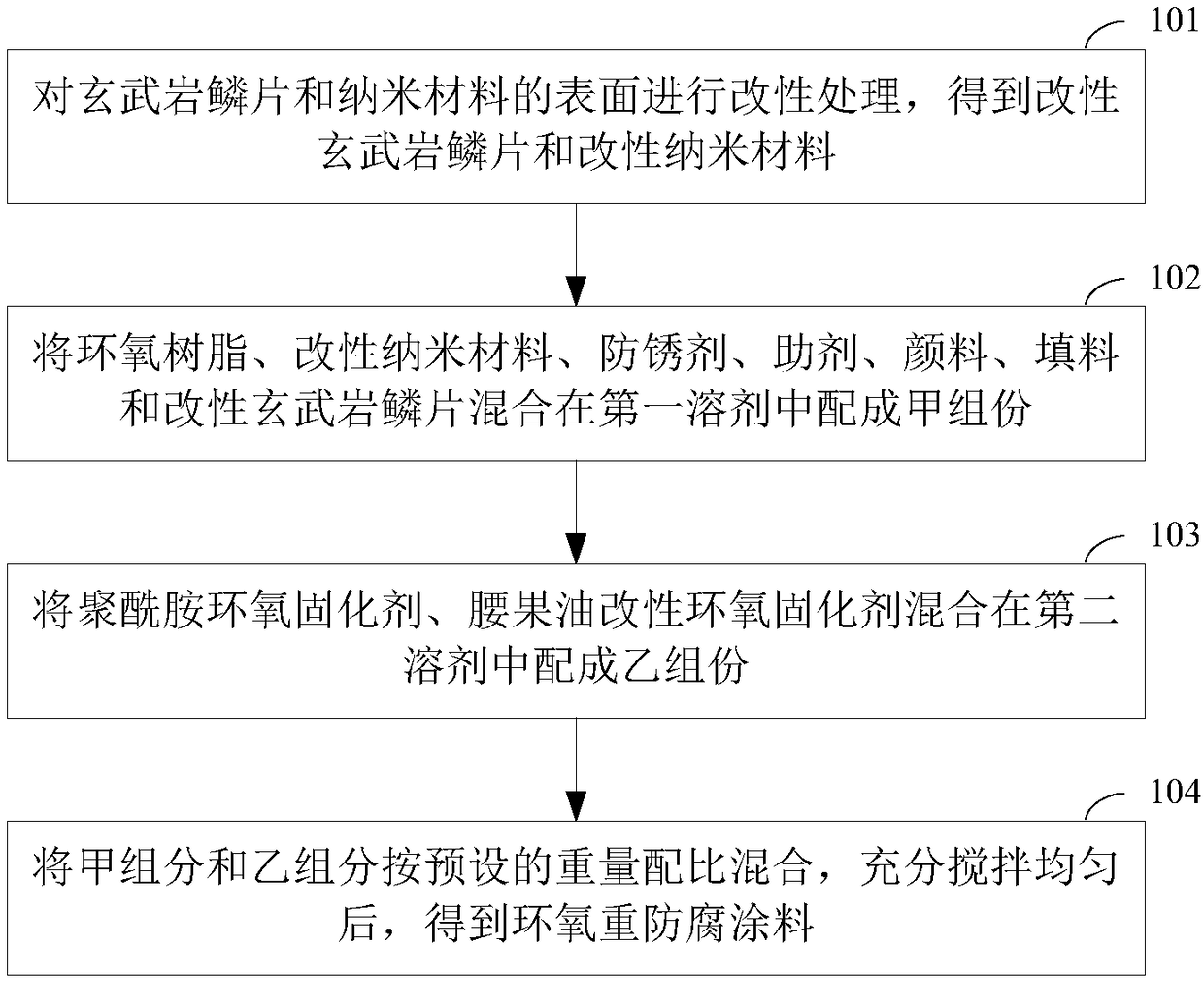

Preparation method of epoxy heavy duty anticorrosion coating

An anti-corrosion coating, epoxy heavy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as easy cracking, excess hardness, poor abrasion resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] In the technical solution of the present invention, the inventors have found through research and multiple tests that nano-scale particles can significantly improve the performance of epoxy resins. The reason is that the bonding between the nanoparticles and the matrix interface is strong And due to the small size effect of nanoparticles, the coating is conducive to stress transmission when it is stressed, and the surface of nanomaterials is severely insufficiently coordinated, showing extremely strong activity, thus further promoting the crosslinking reaction of the resin and improving the intermolecular strength. bond strength, while making the coating dense and wear-resistant. Moreover, the particle size of the micron particles is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com