Sizing agent and preparation method therefor

A technology of sizing agent and cross-linking agent, applied in the field of papermaking, can solve the problems of easy delamination, wear of sizing roller, insufficient stability, etc., and achieve the effects of improving printability, low cost and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] Sizing agent among the present invention is mainly made of starch, crosslinking agent and pigment, and the preparation method of this sizing agent mainly comprises the following steps:

[0013] (1) Take several starches, such as corn starch, tapioca starch, potato starch, potato starch, etc., or a mixture of several of them.

[0014] In practical applications, the sizing agent can better improve the physical properties of paper by selecting the morphology of starch granules and the ratio of straight chain and branched chain in starch. For example, the shape of the starch granules is preferably one or more of polygonal, oval, and round, and the starch is preferably a starch with a straight chain of 17-30% and a branched chain of 70-83%, or more preferably a straight chain. The chain is 18-25%, and the branched chain is 75-82% starch. In addition, the particle size of the starch is a commonly used starch particle size, such as 5-100 μm.

[0015] (2) Take 20-120% of the ...

Embodiment 1

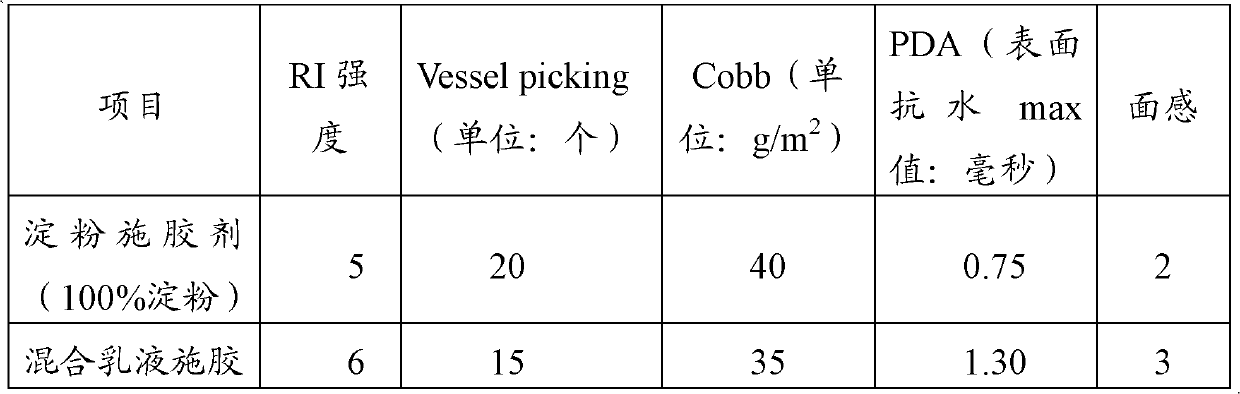

[0023] Take 100 grams of starch with 20% linear chain and 80% branched chain, 20 grams of heavy calcium carbonate pigment with a particle size of less than 2 μm and more than 60%, 0.5 grams of polyamide polyurea formaldehyde resin, add water to make the solid content reach 30% . On the basis of thorough mixing, cook at a temperature of 100-110°C for 40 minutes and a stirring speed of 70 rpm. Use this emulsion to sizing the paper, the paper used is base paper, and the basis weight of the paper is 67g / m 2 , the sizing amount is 8g / m 2 , the effect is as follows:

[0024]

[0025] Note: RI strength, paper surface strength, refers to the bonding strength between paper surface fibers, glue, fillers or between paper surface coating particles and between coating and paper base. It indicates the paper's resistance to ink splitting during printing. ability. The test method is as follows: cut the paper to be evaluated into a size of 1.5*21cm, use black ink No. 15, rotate 3 times ...

Embodiment 2

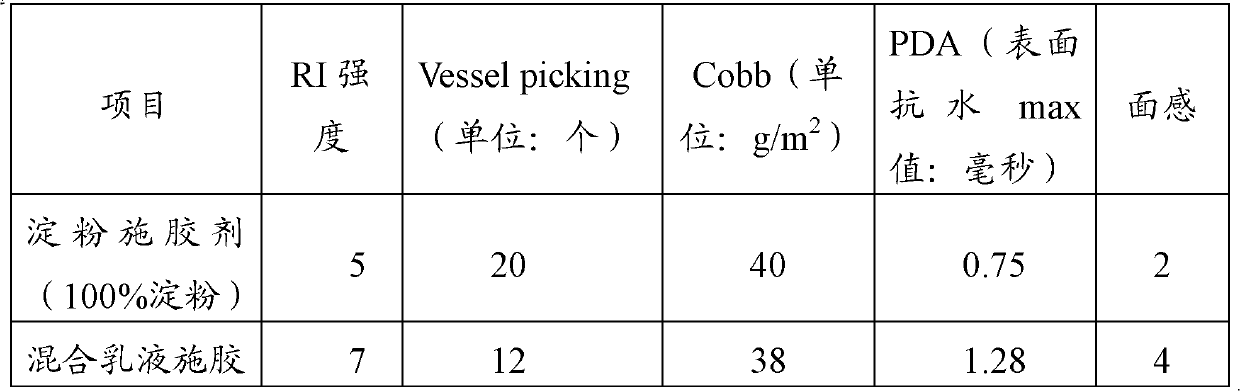

[0031] Select 80g of starch with 17% linear chain and 83% branched chain to cook, the temperature is controlled at 110-120°C, the time is 50min, the stirring speed is 90rpm, and 60g of light calcium carbonate pigment with an average particle size of less than 1.4μm, zirconium carbonate Ammonium 2g is added with water to adjust the solid content to 40%, fully mixed, and the obtained emulsion is used to sizing the paper. The paper used is base paper, and the basis weight of the paper is 82g / m 2 , sizing 10g / m 2 , the effect is as follows:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com