A kind of preparation method of hard carbon negative electrode material

A negative electrode material, hard carbon technology, applied in the preparation/purification of carbon, battery electrodes, structural parts, etc., can solve the problems of lithium intercalation capacity drop, peeling, low charge and discharge efficiency, etc., to increase safety and service life, Effect of improving strength and high lithium intercalation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

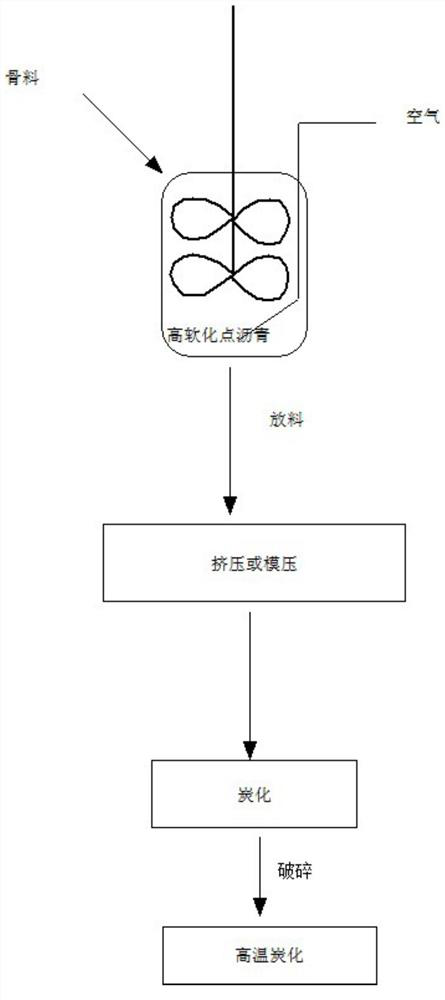

[0038] This embodiment relates to a preparation method of a hard carbon negative electrode material, such as figure 1 shown, including the following steps:

[0039] Using the mixture of green coke and calcined coke with a median diameter D50 of 3-5 μm needle coke produced in the negative electrode production process as the skeleton, the asphalt with a 20% ratio and a softening point of 240 ° C is fully mixed with air in the kneading chamber at 320 ° C Mixing, control a certain air flow rate and flow rate, wait until the material in the kneading pot is soft, and then mold it. After forming, the material is carbonized at 435 ° C. After the carbonized material is crushed, a negative electrode material with a median diameter D50 of 15 μm is obtained. Then carbonized at a high temperature of 1400°C, the obtained negative electrode material has a high initial Coulombic efficiency (95%), a stable charge-discharge platform, a low charge-discharge potential (0.25-0.5V), and a high lith...

Embodiment 2

[0041] This embodiment relates to a method for preparing a hard carbon negative electrode material, comprising the following steps:

[0042] Use the mixture of green coke and calcined coke with a median diameter D50 of 3-5 μm needle coke produced in the negative electrode production process as the skeleton, and use 15% pitch with a softening point of 280°C in the kneader to fully air at 370°C Mixing, control a certain air flow rate and flow rate, wait until the material in the kneading pot is soft, and then mold it. After forming, the material is carbonized at 425 ° C. After the carbonized material is crushed, a negative electrode material with a median diameter D50 of 15 μm is obtained. Then carbonized at a high temperature of 1400°C, the obtained negative electrode material has a high initial Coulombic efficiency (96%), a stable charge-discharge platform, a low charge-discharge potential (0.25-0.5V), and a high lithium-intercalation capacity (352mAh / g).

[0043] Therefore, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com