Patents

Literature

34results about How to "Improve lithium intercalation capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

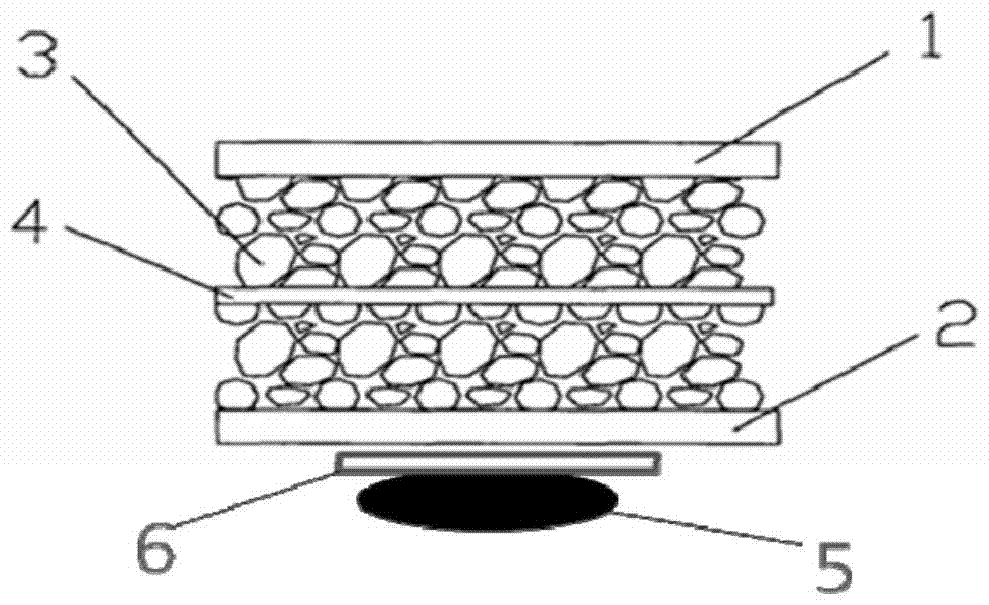

Multilayer positive plate with lithium/sodium supplementing function, battery and preparation method

ActiveCN111834622AMake up for irreversible consumptionReduce dosagePositive electrodesSecondary cells servicing/maintenanceElectrical batteryMaterials science

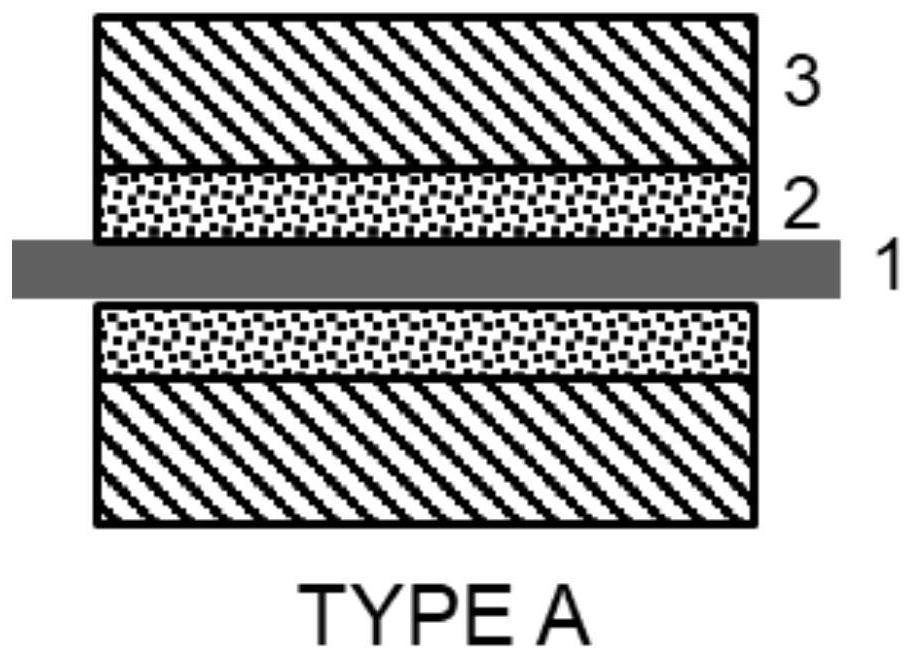

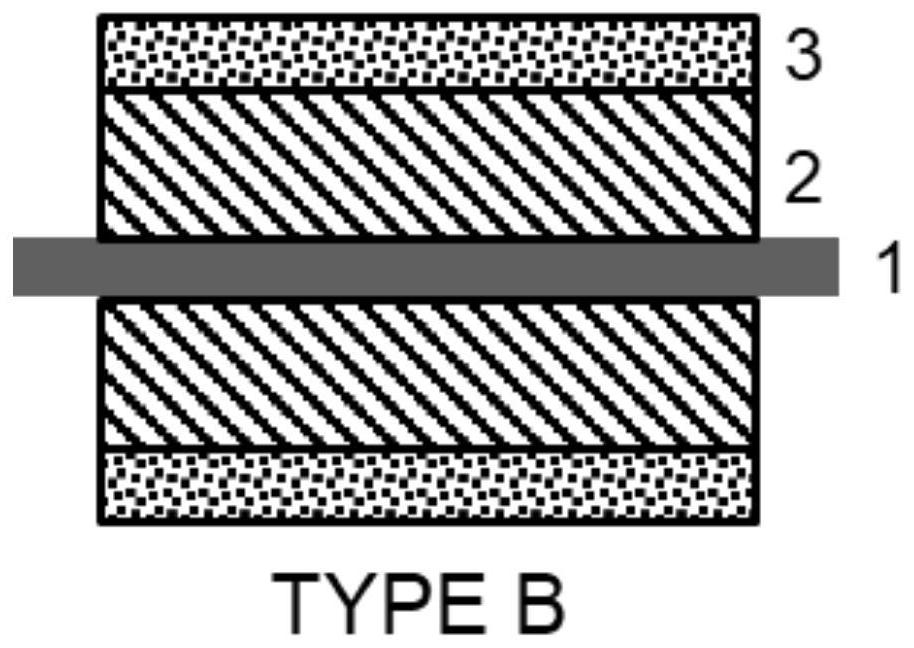

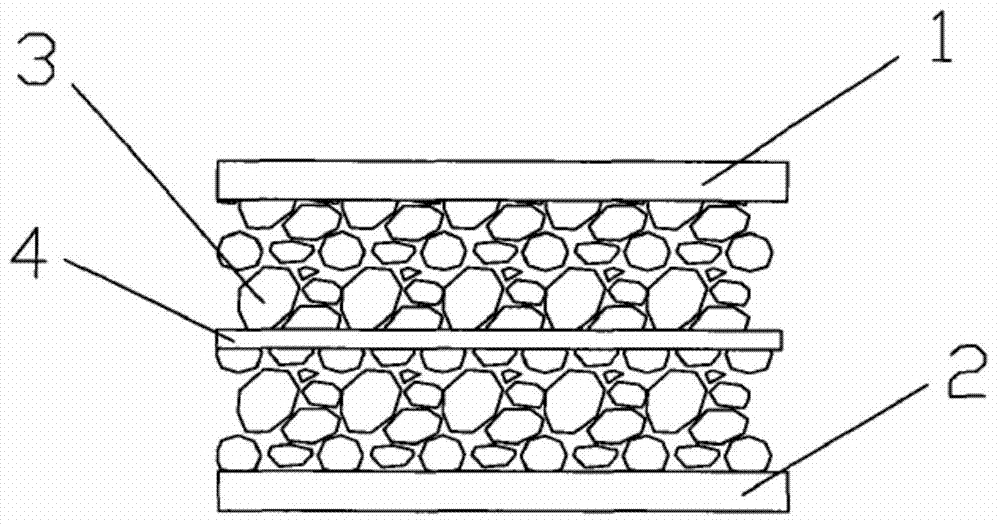

The invention discloses a multilayer positive plate with a lithium / sodium supplementing function, a battery and a preparation method, and belongs to the field of energy storage devices. The multilayerpositive plate comprises a current collector, a positive electrode material layer and a lithium / sodium supplement material layer. A positive electrode material layer and a lithium / sodium supplementing material layer are symmetrically arranged on the two sides of the current collector. The positive electrode material layer and the lithium / sodium supplementing material layer are laminated. The lithium / sodium supplementing material layer contains a special lithium / sodium-containing functional material. When the positive electrode is charged for the first time, a decomposition reaction occurs, sothat lithium / sodium ions in molecules of the positive electrode are irreversibly released into the battery, and the released lithium / sodium ions are supplemented into the negative electrode of the battery through an electrolyte, so that the problem of poor performance of the whole battery caused by low initial charge-discharge coulombic efficiency of an existing high-capacity negative electrode material is solved. The composite positive plate can efficiently supplement lithium / sodium to the negative electrode in the lithium / sodium ion total battery, has no adverse effect on the positive electrode material and the total battery, and can improve the energy density and the utilization rate of the positive electrode material of the battery, so that the cost of the battery can be reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

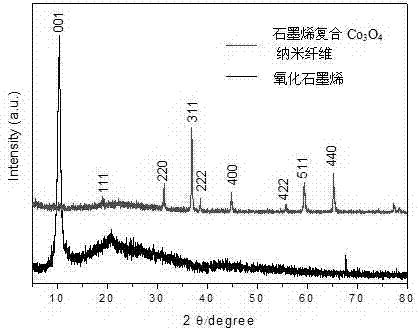

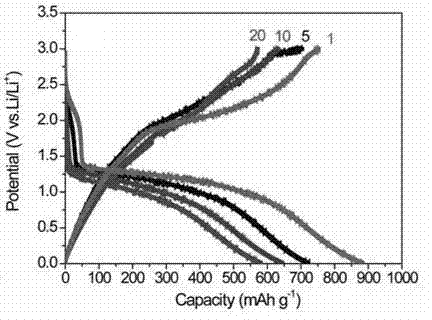

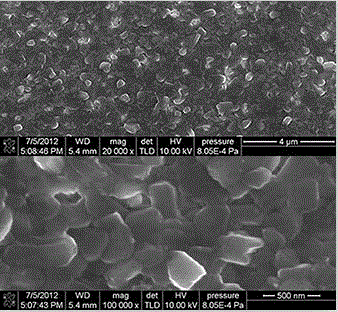

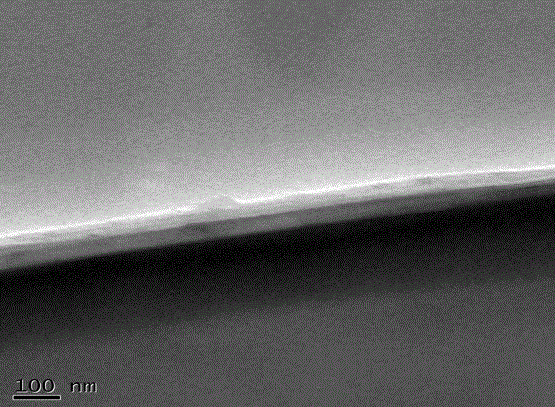

Graphene composite transition metal oxide nanofiber lithium ion battery electrode material and preparation method thereof

InactiveCN102931408AQuick releaseShorten migration distanceMaterial nanotechnologyCell electrodesLithium-ion batteryMaterials science

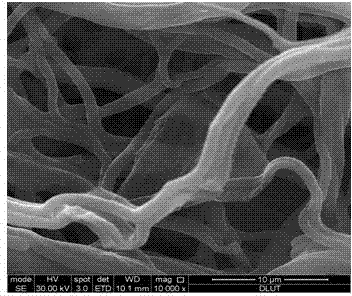

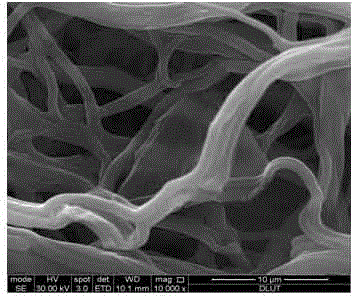

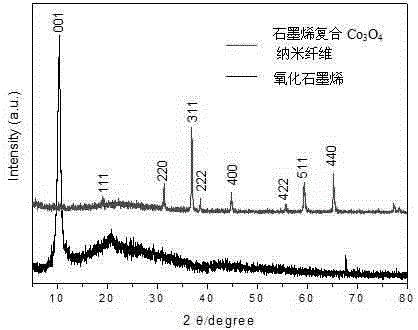

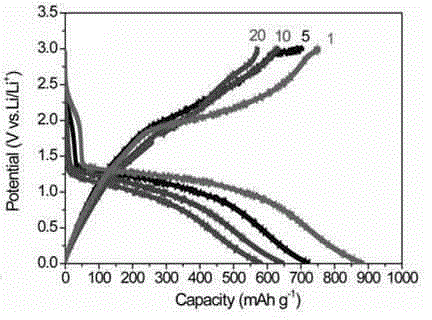

The invention discloses a graphene composite transition metal oxide nanofiber lithium ion battery electrode material and a preparation method thereof. The composite electrode material combines a function of a graphene laminated structure for embedding and binding transition metal oxide nanoparticles, a function of a micropore tunnel structure interconnected in graphene composite transition metal oxide nanofiber for quickly embedding and taking off lithium ions and a function of three-dimensional space structures wound with each other among nanofibers and used for effectively releasing greatly-changed stress when the volume in an electrode membrane is expanded or contracted. Due to the integration of the three functions, the volume effect of the transition metal oxide material in the process of embedding / taking off the lithium ions can be effectively restrained and buffered, the loss of the irreversible capacity can be reduced, and then, the capacity and the cycling stability performance of a lithium ion battery are further improved.

Owner:DALIAN OCEAN UNIV +1

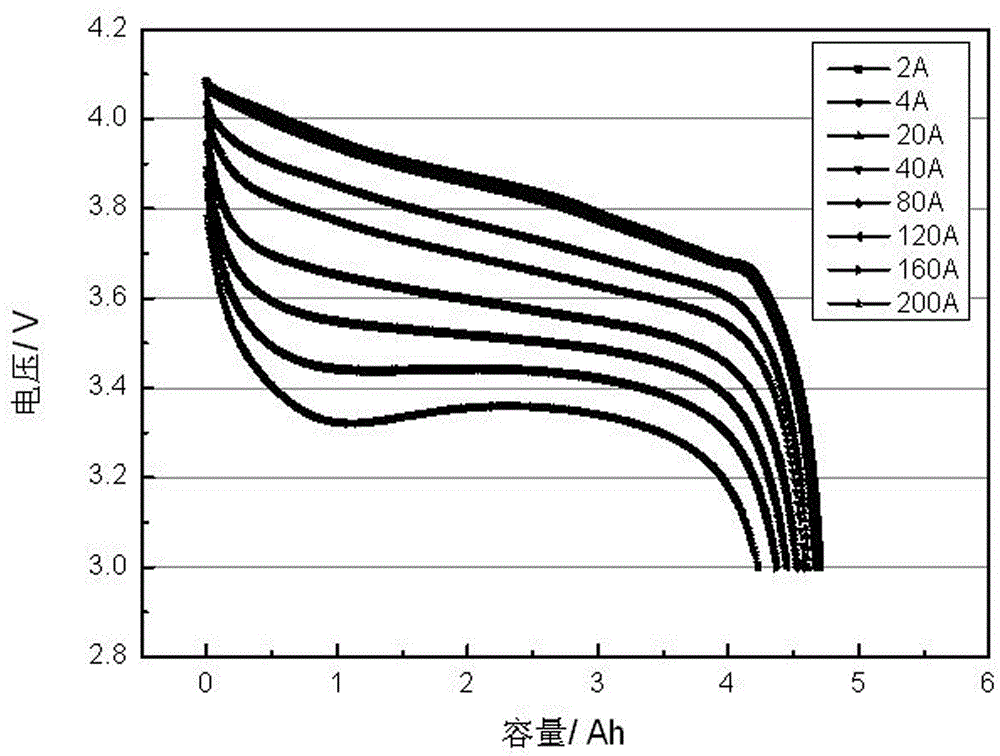

Lithium ion battery negative electrode material and preparation method thereof as well as lithium ion battery negative electrode plate and lithium ion battery

ActiveCN103682295AIncrease capacityImprove lithium intercalation capacityCell electrodesSecondary cellsOrganic solventBattery cell

The embodiment of the invention provides a lithium ion battery negative electrode material. The lithium ion battery negative electrode material comprises a negative electrode active material, a conductive agent, a bonding agent and an organic solvent, wherein the negative electrode active material comprises lithium titanate Li4Ti5O12 and transition metal sulfide; the lithium titanate Li4Ti5O12 accounts for 50%-95% of the total mass of the negative electrode active material; the transition metal sulfide is one or more of NiS, FeS2, FeS, TiS2, MoS and Co9S8; the negative electrode active material, the conductive agent and the bonding agent account for 70%-90%, 5%-20% ad 5%-10% of the total mass of the negative electrode active material, the conductive agent and the bonding agent respectively; the organic solvent accounts for 30%-70% of the total mass of the lithium ion battery negative electrode material. The lithium ion battery negative electrode material is high in capacity and has good cycling stability and durability. The embodiment of the invention further provides a preparation method of the lithium ion battery negative electrode material, a negative electrode plate containing the lithium ion battery negative electrode material and a lithium ion battery.

Owner:厦门海辰新材料科技有限公司

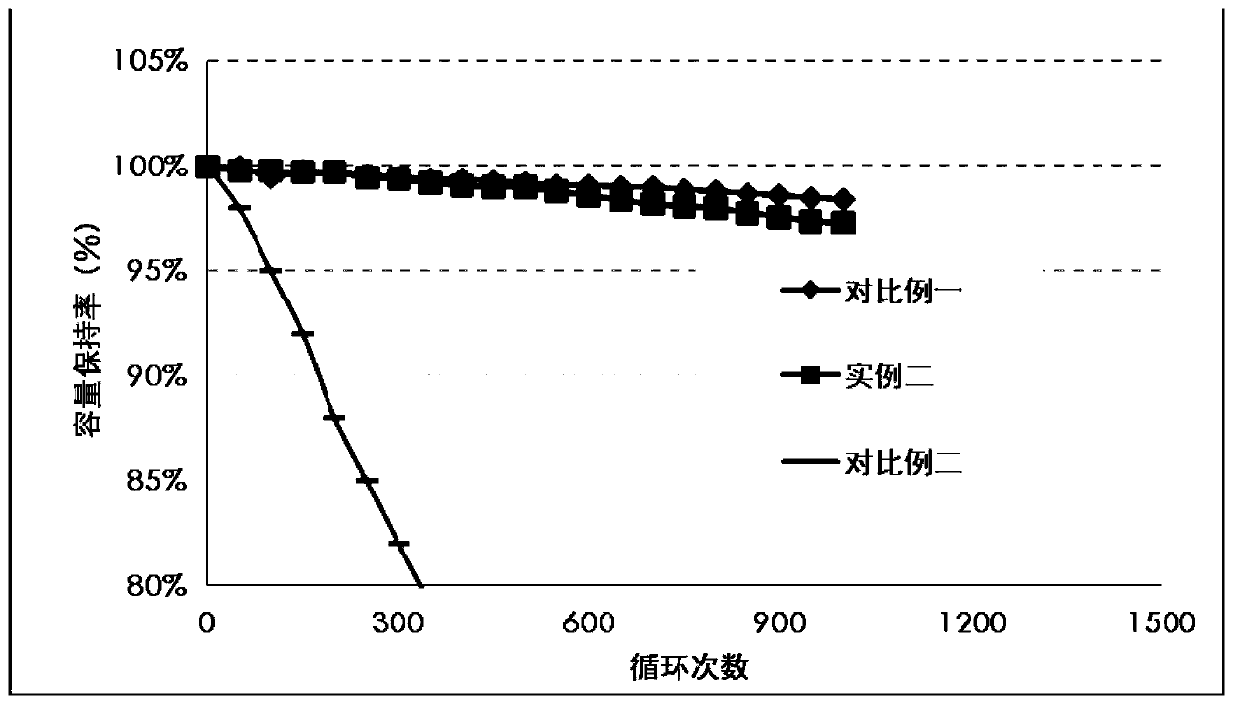

Aerospace safe and high-power lithium ion storage battery

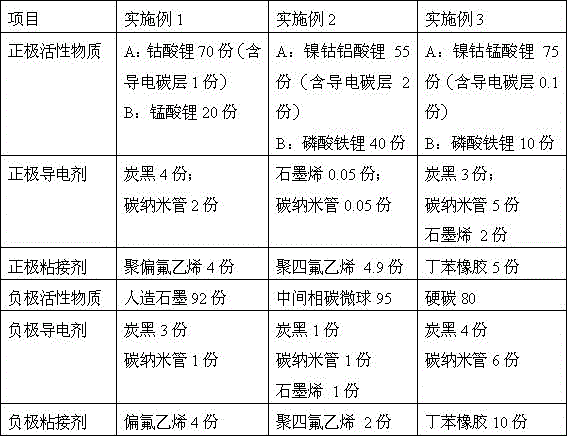

InactiveCN106169617AGood rate characteristicsImprove security featuresCell electrodesFinal product manufactureHybrid typeCarbon layer

The invention discloses an aerospace safe and high-power lithium ion storage battery, which comprises a positive electrode plate, a negative electrode plate, a separation membrane and electrolyte, wherein the positive and negative electrodes are separated by the separation membrane; the positive electrode plate comprises a positive electrode current collector and a positive electrode active coating layer coating the surface of the positive electrode current collector; the positive electrode active coating layer comprises positive electrode active substances; the positive electrode active substance is a mixed system formed by ingredients A and ingredients B; the ingredients A are at least one material from lithium cobalt oxides, nickel-cobalt lithium aluminate and nickel-cobalt lithium manganate; a conducting carbon layer coats the outer surfaces of materials of the ingredients A; the mass ratio of the conducting carbon layer to the ingredients A is (0.1 to 2):100; the thickness of the carbon layer is the nanometer level; the ingredients B are selected from at least one material from lithium manganate and lithium iron phosphate; and the mass percentage of the ingredients B accounting for the positive material active substances is 5 percent to 50 percent. Compared with the prior art, the aerospace safe and high-power lithium ion storage battery has the advantages that a mixed positive material system is used, so that the rate performance and the safety performance of an aerospace lithium ion battery can be greatly improved; and the application of the lithium ion battery to an aerospace power supply is expanded.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

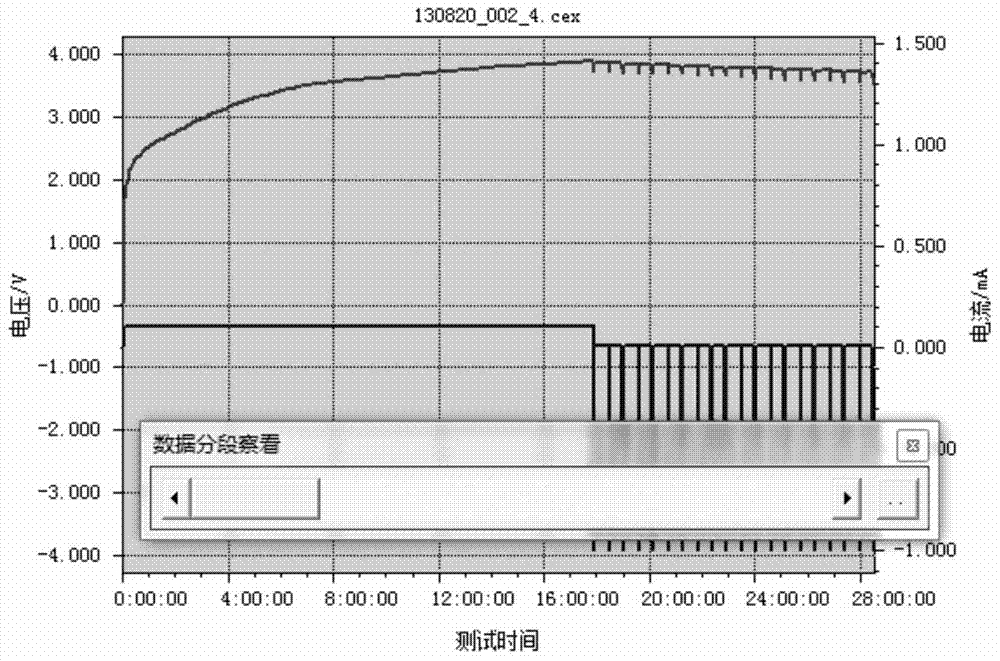

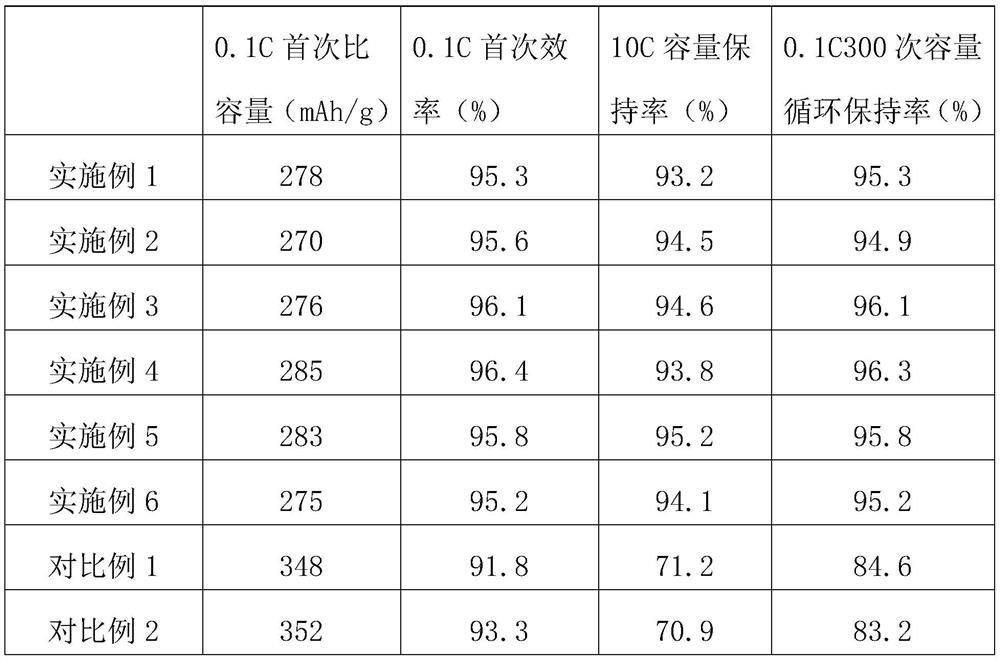

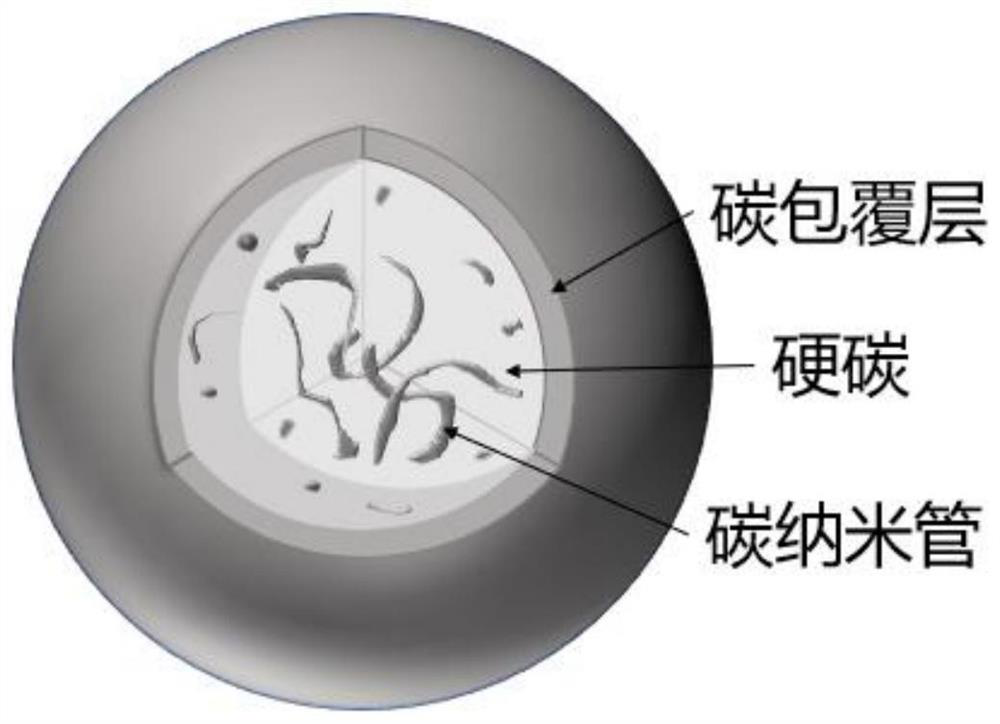

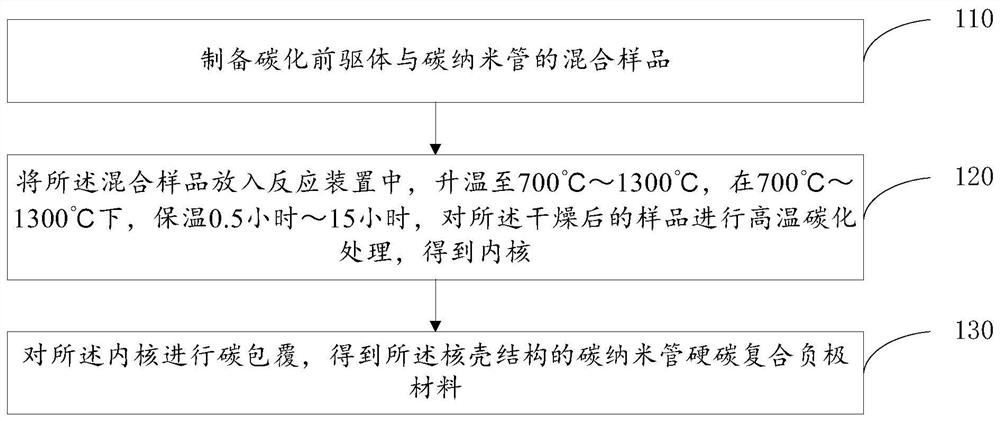

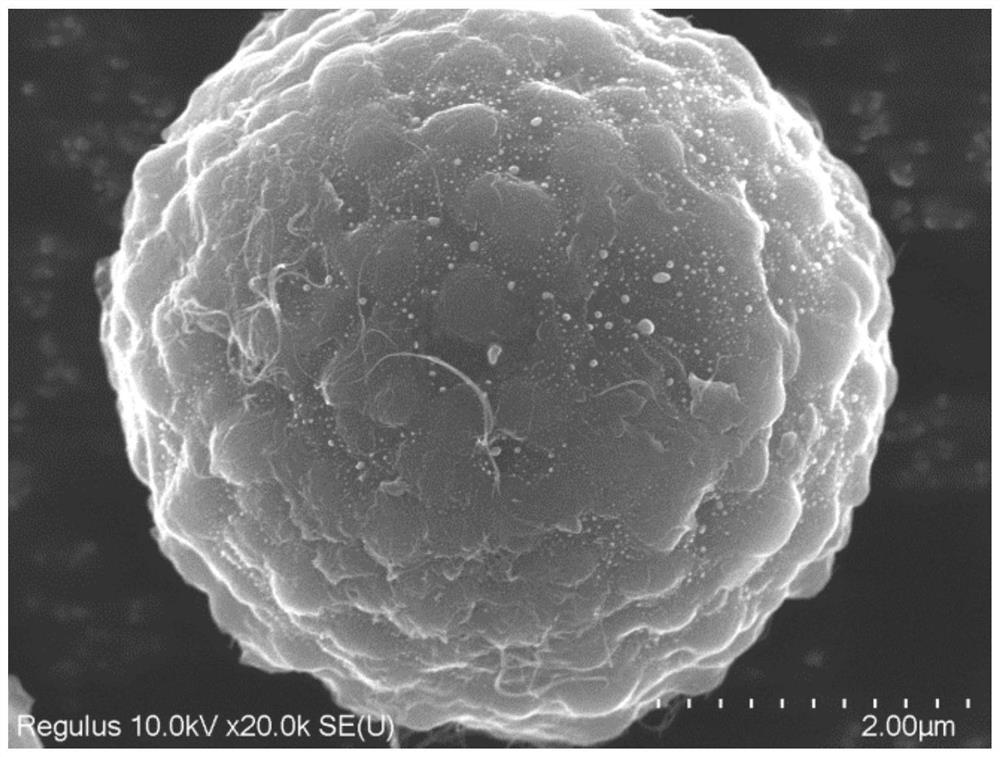

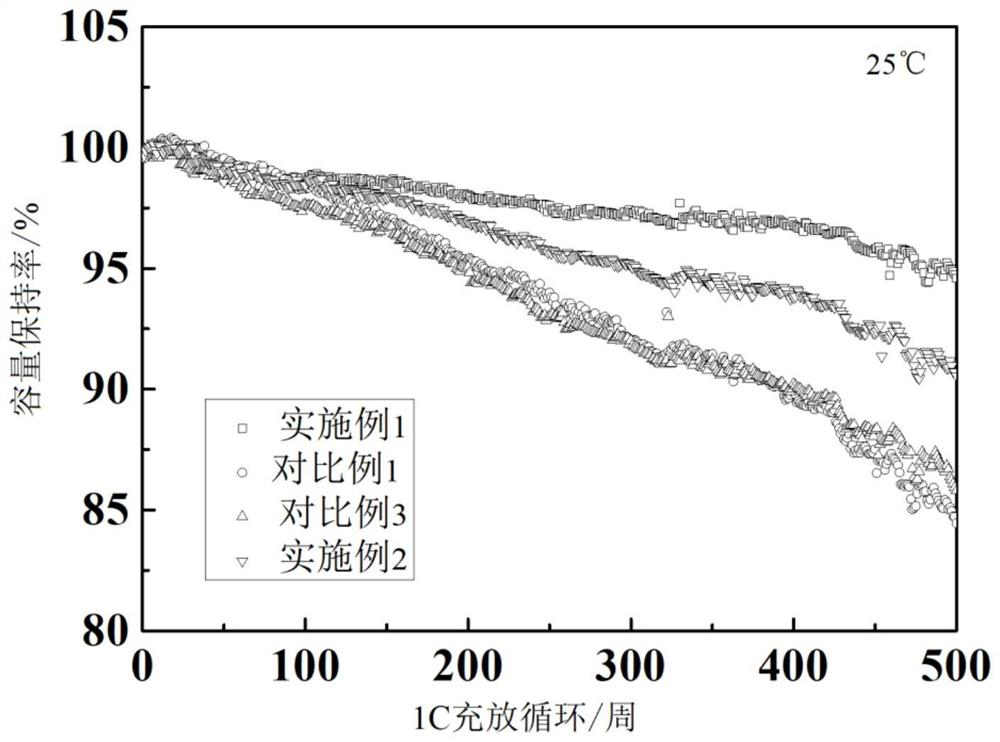

Carbon nanotube hard carbon composite negative electrode material with core-shell structure and preparation method and application

ActiveCN113328068AImprove first-week efficiencySmall specific surface areaCell electrodesSecondary cellsEpoxyCarbon composites

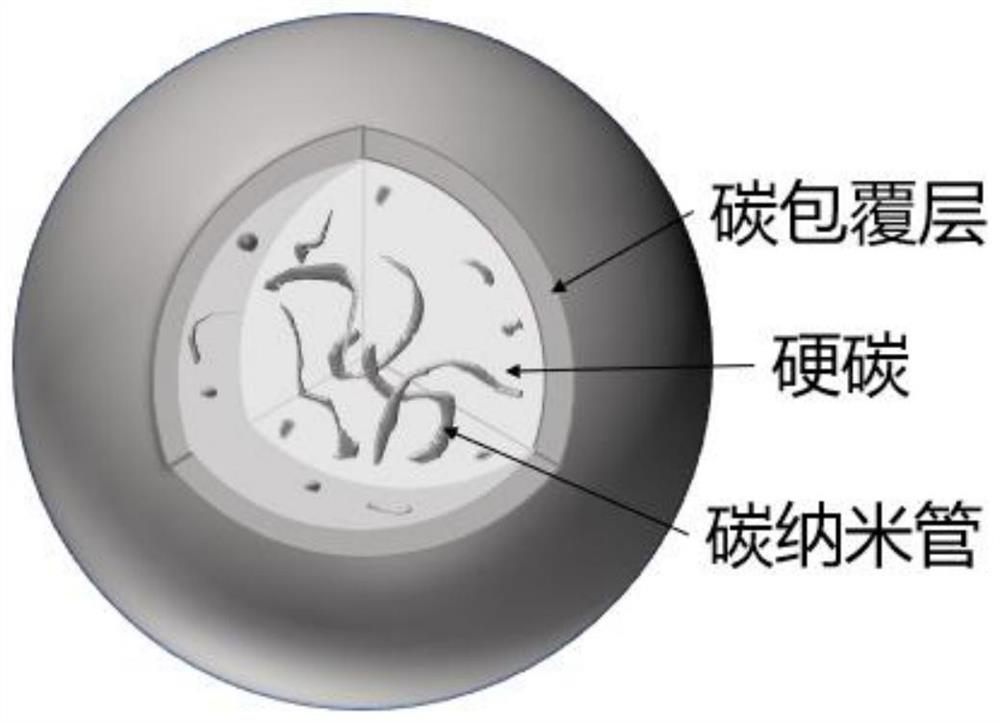

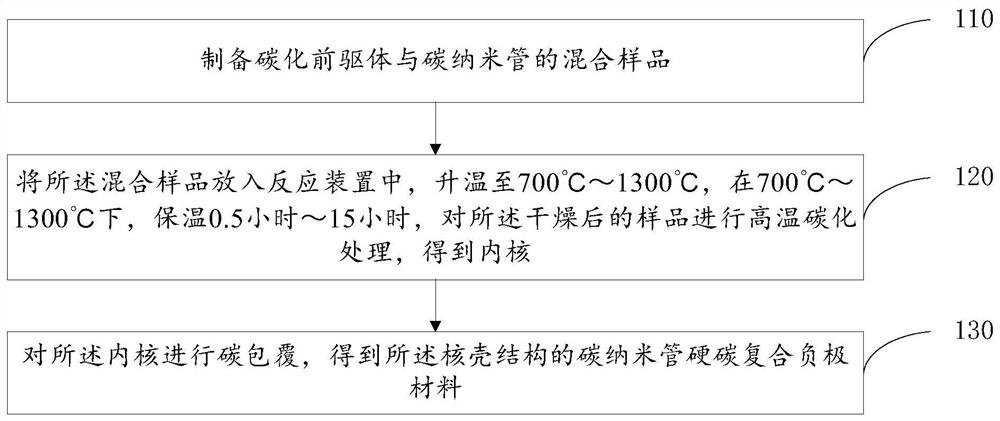

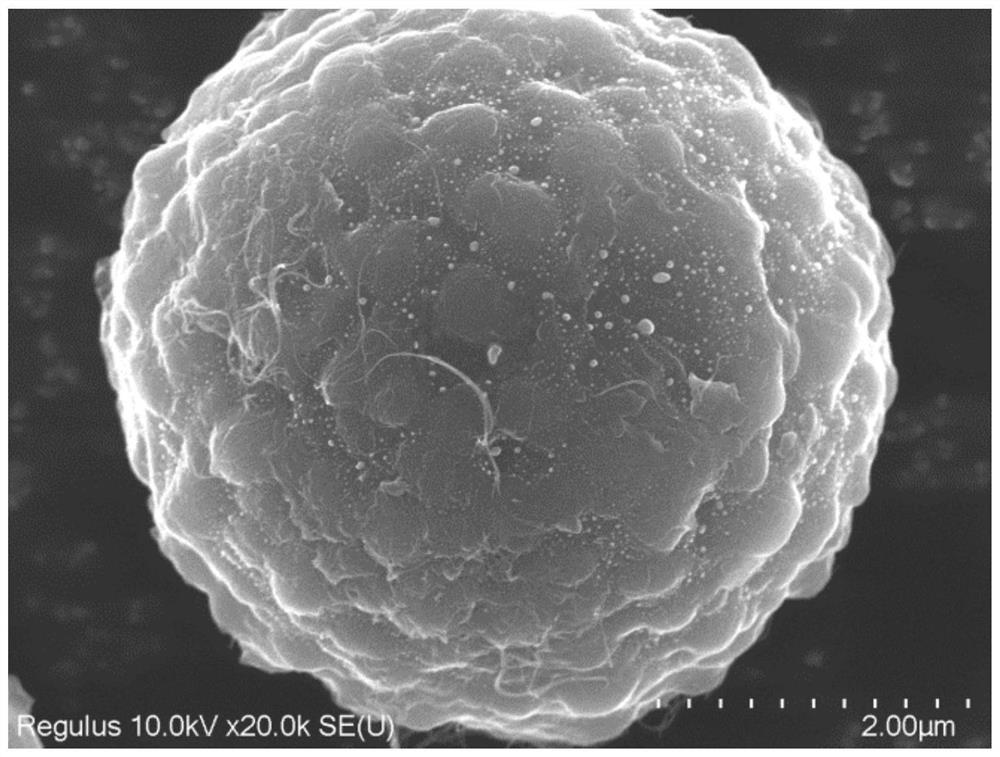

The embodiment of the invention relates to a carbon nanotube hard carbon composite negative electrode material with a core-shell structure and a preparation method and application. The size range of the carbon nanotube hard carbon composite negative electrode material is 1-50 mum, and the carbon nanotube hard carbon composite negative electrode material is composed of an inner core and a carbon coating layer coating the inner core; the inner core comprises a first phase and a second phase; the first phase is a hard carbon material prepared by taking one or a combination of several of glucose, cane sugar, polyvinylpyrrolidone, starch polyvinylidene fluoride, novolac epoxy resin or polyvinyl chloride as a carbonization precursor, the size range is 1-40 mum, and the Raman spectrum Id / Ig range is 0.7-0.9; the second phase is a carbon nanotube, and the size of the second phase is 1-50 nm; the carbon coating layer is prepared by a gas phase method, a liquid phase method or a solid phase method, and the Raman spectrum Id / Ig range is 0.7-1.3; in the carbon nanotube hard carbon composite negative electrode material, the mass fraction of the first phase to the second phase to the carbon coating layer is equal to (0, 100%) to (0, 60%) to (0, 40%).

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

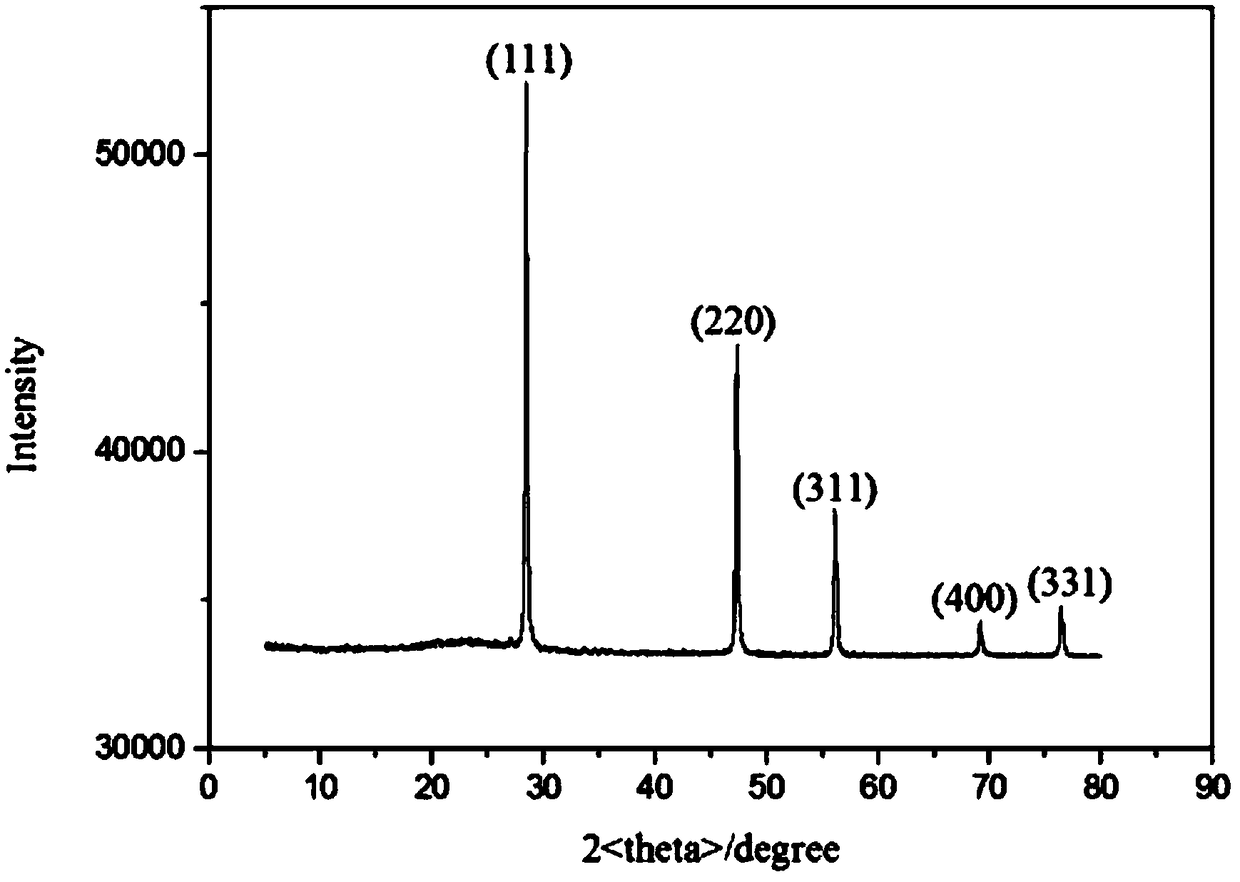

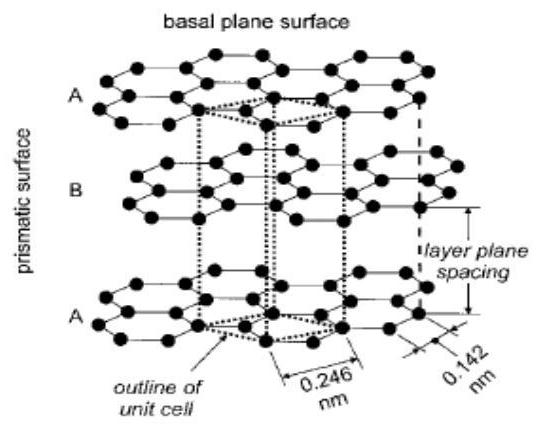

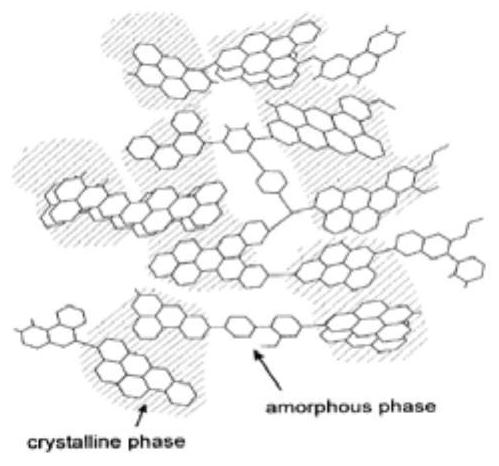

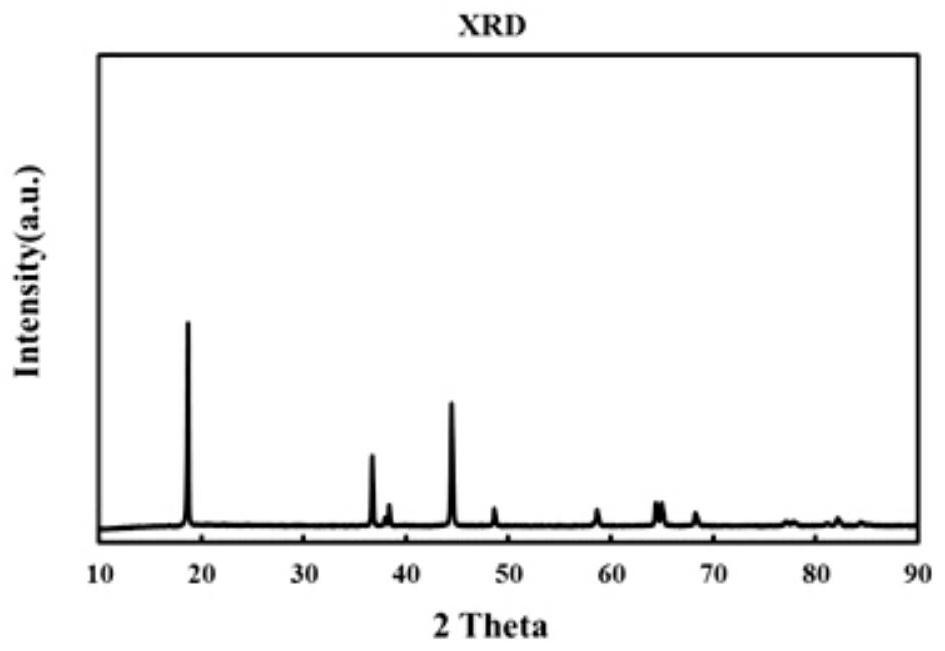

Amorphous carbon material with graphitizing characteristics and preparation method of amorphous carbon material

ActiveCN102751500AReduce the temperatureImprove lithium intercalation capacityCell electrodesOrganic solventGraphite

The invention discloses an amorphous carbon material with graphitizing characteristics. The amorphous carbon material with graphitizing characteristics comprises an amorphous carbon base body, wherein a graphitized microcrystalline area is distributed inside the amorphous carbon base body; furthermore, a transition metal element is also contained in the amorphous carbon material with graphitizing characteristics; and measured by an XRD (X-ray diffraction) method, the amorphous carbon material with graphitizing characteristics has a typical graphite characteristic diffraction peak d002 peak. The preparation method of the amorphous carbon material roughly comprises the steps of taking and uniformly mixing ultrafine powder containing a carbon precursor and / or the transition metal element and / or compound containing the transition metal element in water and / or an organic solvent to form a homogeneous dispersion system; drying the mixture at low temperature, sintering the mixture at high temperature, and cooling the mixture to room temperature to obtain the target product. According to the invention, partial graphitization temperature of the carbon material is reduced, so that the amorphous carbon material containing graphite crystallite is prepared; the defects that heavy current charging performance of the graphite material is poor and the structure is not stable can be overcome, and usable embedded lithium capacity of the amorphous carbon material is also improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

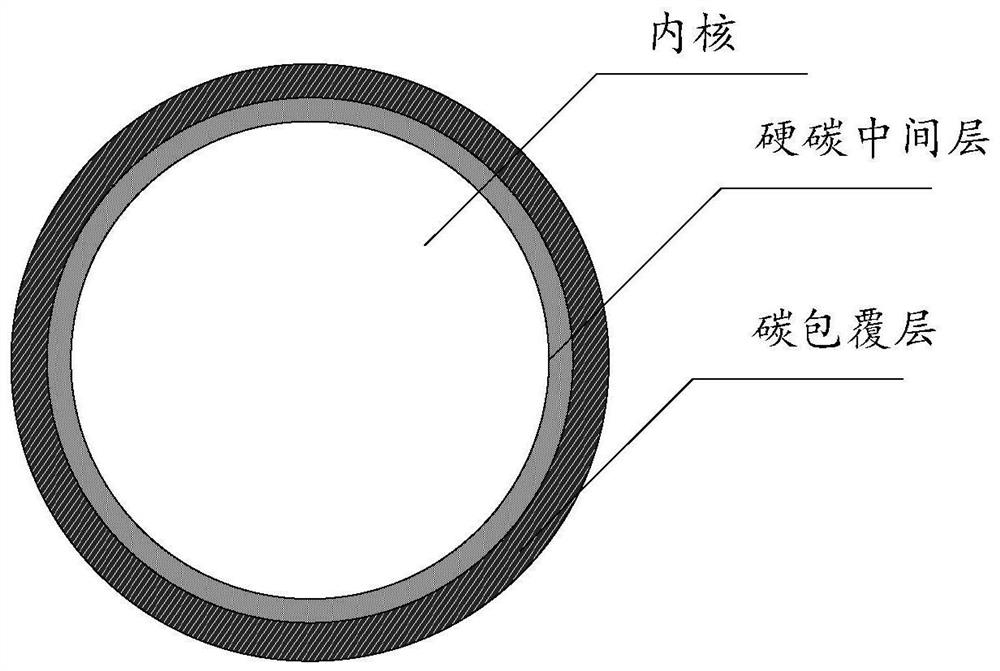

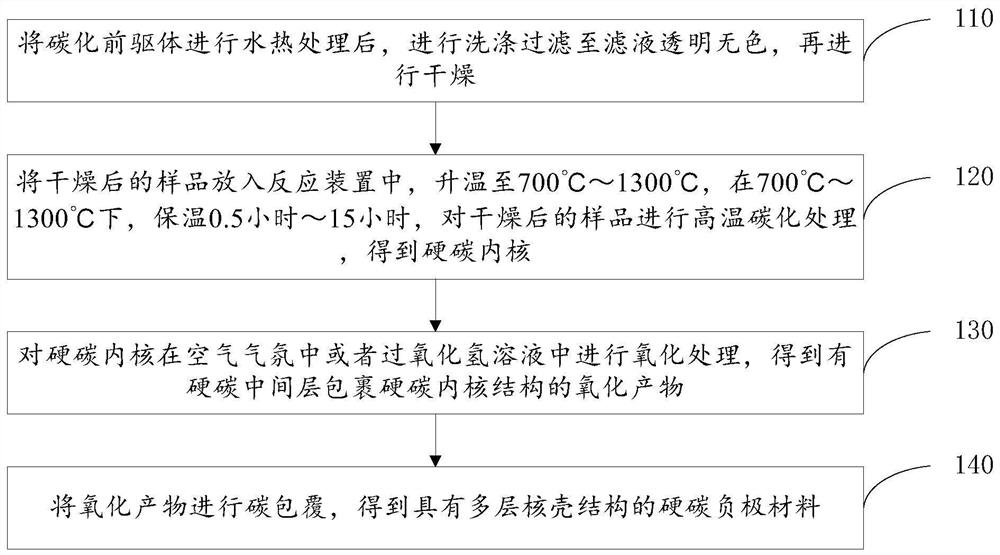

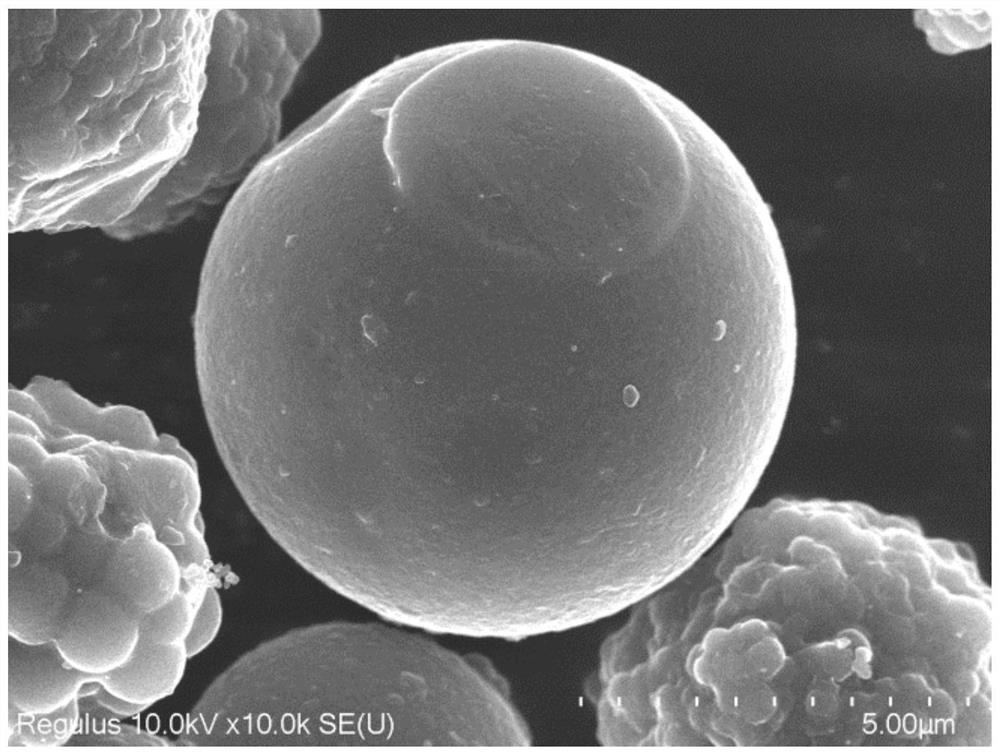

Hard carbon negative electrode material with multilayer core-shell structure and preparation method and application thereof

InactiveCN113328067AImprove first-week efficiencyImprove lithium intercalation capacityNegative electrodesSecondary cellsEpoxyCarbon coating

The embodiment of the invention relates to a hard carbon negative electrode material with a multilayer core-shell structure and a preparation method and application thereof. The size range of the hard carbon negative electrode material is 1-50 mum, and the hard carbon negative electrode material is composed of a hard carbon inner core, a hard carbon middle layer and a carbon coating layer; the hard carbon inner core is a hard carbon material prepared by taking one or more of glucose, cane sugar, polyvinylpyrrolidone, starch polyvinylidene fluoride, novolac epoxy resin or polyvinyl chloride as a carbonization precursor; the size range is 1-40 mum, and the Raman spectrum Id / Ig range is 0.7-0.9; the hard carbon middle layer is a hard carbon porous oxide layer, the porosity is 1%-80%, the pore size is 0.005-2 um, and the Raman spectrum Id / Ig range is 0.8-1.5; the carbon coating layer is prepared by a gas phase method, a liquid phase method or a solid phase method, and the Raman spectrum Id / Ig range is 0.7-1.3; in the hard carbon negative electrode material, the mass fraction of the hard carbon inner core to the hard carbon middle layer to the carbon coating layer is equal to (0, 100%) to (0, 50%) to (0, 30%).

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

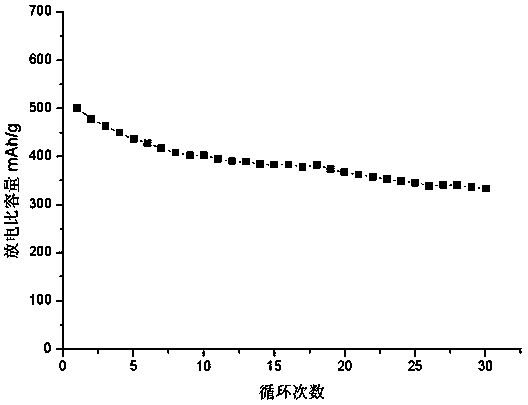

Composite cathode material for lithium ion battery and preparation method thereof

InactiveCN102005569AImprove lithium intercalation capacityImprove the first Coulombic efficiencyElectrode manufacturing processesNano siliconComposite cathode

The invention provides a composite cathode material for a lithium ion battery and a preparation method thereof. The composite cathode material of the invention comprises nano Si and graphitized needle coke; the average grain diameter is 5-15 microns; and the mass content of the nano Si in the composite cathode material is 5-30 percent. The composite cathode material of the invention not only improves the lithium embedding capacity of needle coke by 2.5-5 times but also overcomes the defects of low conductivity and easy volume expansion of silicon with high lithium embedding capacity. The preparation method of the invention comprises the following steps of: grinding the needle coke; carrying out graphitization treatment at argon atmosphere; mixing with nano silicon; depositing carbon on the particle surface of Si / needle coke; and then carrying out surface treatment on the composite cathode material. On one hand, the preparation method of the composite cathode material solves the problem of lower lithium embedding capacity of a single needle coke cathode material, on the other hand, the preparation method of the composite cathode material overcomes the defects existing in the nano Si used as the cathode material.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD +1

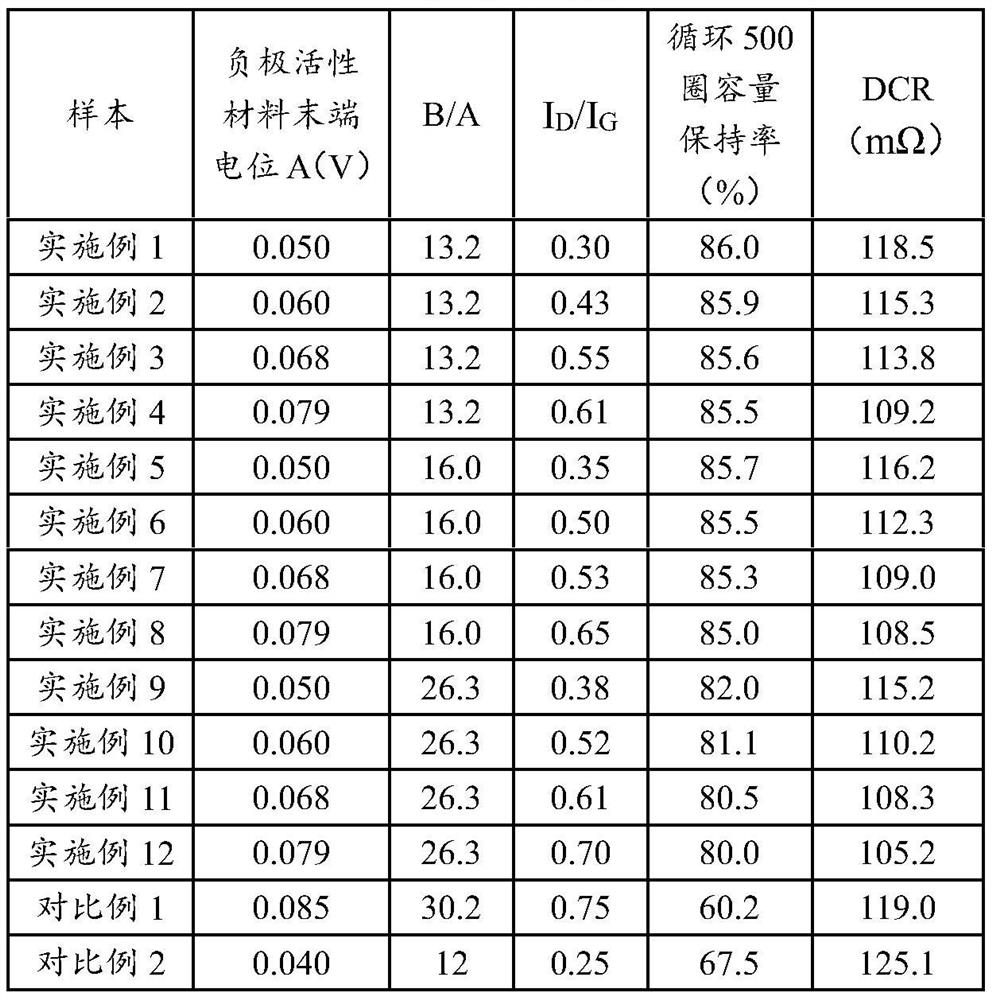

Electrochemical device and electronic equipment

ActiveCN113097429AImprove lithium intercalation capacityImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolytic agentElectrical battery

The invention relates to the technical field of secondary batteries, in particular to an electrochemical device and electronic equipment. The electrochemical device comprises a positive electrode, a negative electrode and an electrolyte, wherein the positive electrode comprises a positive current collector and a positive active material layer arranged on the positive current collector, and the positive active material layer comprises a positive active material; the negative electrode comprises a negative current collector and a negative active material layer arranged on the negative current collector, and the negative active material layer comprises a negative active material; and when the electrochemical device is in a fully charged state, the terminal potential of the negative active material is AV, the excess coefficient of the electrochemical device is B, and a ratio of B / A is in a range of 13.2 to 26.3. According to the electrochemical device and the electronic equipment provided by the invention, the rate capability of a battery can be improved without influencing the energy density of the battery.

Owner:NINGDE AMPEREX TECH

Preparation method for hollow carbon-coated nano-silicon composite graphite material

PendingCN108336320APromote circulationIncrease energy densityMaterial nanotechnologyCell electrodesNano siliconMicrosphere

The invention discloses a preparation method for a hollow carbon-coated nano-silicon composite graphite material. The preparation method comprises the following steps: wrapping a lithium intercalationmaterial, i.e., nano-silicon, with hollow carbon spheres; and then carrying out compounding with highly-graphitized synthetic graphite so as to prepare the hollow carbon sphere-coated nano-silicon composite material. The prepared composite material is applied as an active material for a negative electrode of a lithium battery, has high lithium intercalation capacity, allows the lithium battery tohave good cycle performance and can realize stable reversible lithium intercalation and deintercalation, which enables the energy density of the lithium battery to be improved.

Owner:OPTIMUM BATTERY CO LTD

Lithium ion battery anode material and preparation method thereof, lithium ion battery anode piece and lithium ion battery

InactiveCN104425807AIncrease capacityImprove lithium intercalation capacityCell electrodesSecondary cellsHigh energyMaterials science

An embodiment of the present invention provides a negative electrode material of a lithium-ion battery. The negative electrode material of a lithium-ion battery comprises a negative electrode active material, a conductive agent, a bonding agent, and an organic solvent. The negative electrode active material, the conductive agent and the bonding agent account for 70% to 90%, 5% to 20% and 5% to 10% of the total mass of the negative electrode active material, the conductive agent and the bonding agent respectively. The negative electrode active material comprises Li4Ti5O12 particles and transition metal particles. The Li4Ti5O12 particles account for 50% to 95% of the total mass of the negative electrode active material. The transition metal particles comprise one or more kinds of following particles: nickel oxide particles, ferric oxide particles, ferroferric oxide particles, titanium dioxide particles, and cobaltosic oxide particles. The present invention solves the problem that the Li4Ti5O12 negative electrode material is low in specific capacity and cannot meet requirements for preparing a high-energy high-density lithium-ion battery.

Owner:HUAWEI TECH CO LTD

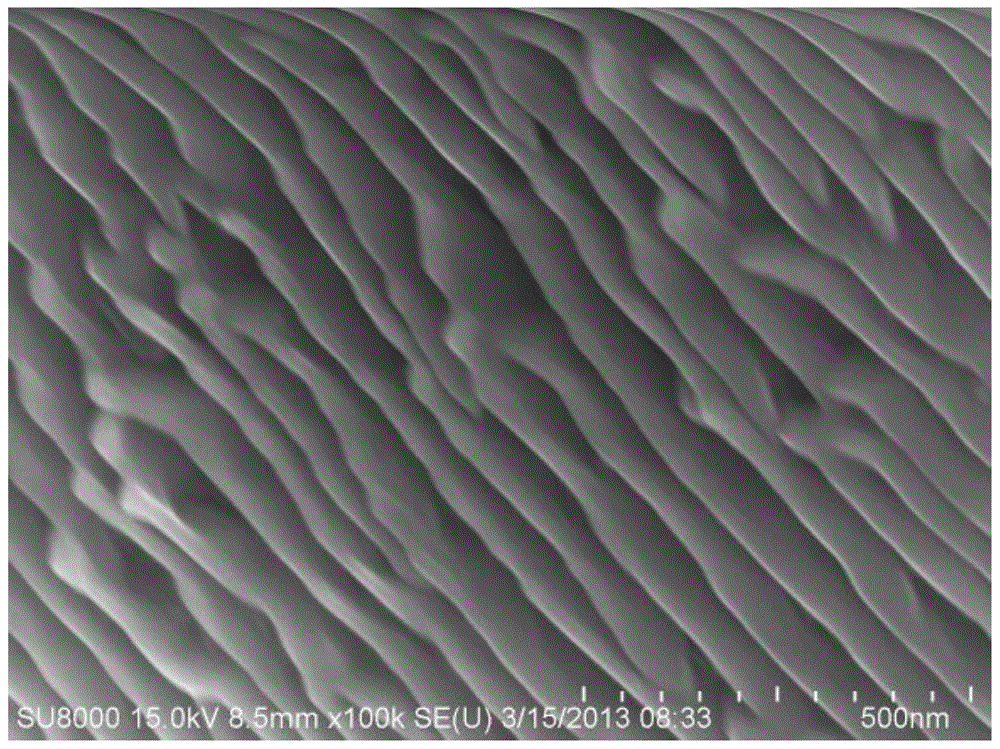

A kind of method for preparing layered tin coating by electrodeposition

ActiveCN105088290BInhibition of volume expansionThe composition of the plating solution is simpleTinningPower flow

The invention relates to a method for preparing layered tin coatings in an electrolytic deposition manner. According to the method, the problem that an existing tinning method can only prepare bright compact coatings is solved. The method comprises the steps of removing oil on a coated part in an alkaline manner, rinsing the coated part, and pickling the coated part; then rinsing the coated part again, and drying the coated part to obtain an electroplating negative pole and using elementary substance tin as an electroplating positive pole; and setting the electroplating current density as 2-5A / dm<2>, the electroplating temperature as 10-35 DEG C and the electroplating time as 3-9min to obtain the layered tin coatings. Plating solution comprises stannous mono sulphate, concentrated sulfuric acid, gelatin, additive and ascorbic acid. The method can be used for preparing tin coatings of a layered structure in the electrolytic deposition manner, the plating solution is simple in composition, and the electroplating process is easy to control. The method is applied to the field of material preparing.

Owner:HARBIN INST OF TECH

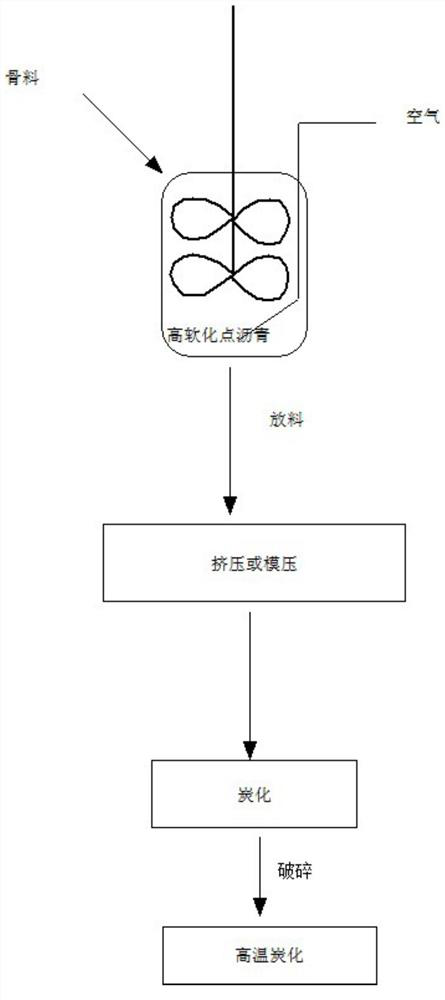

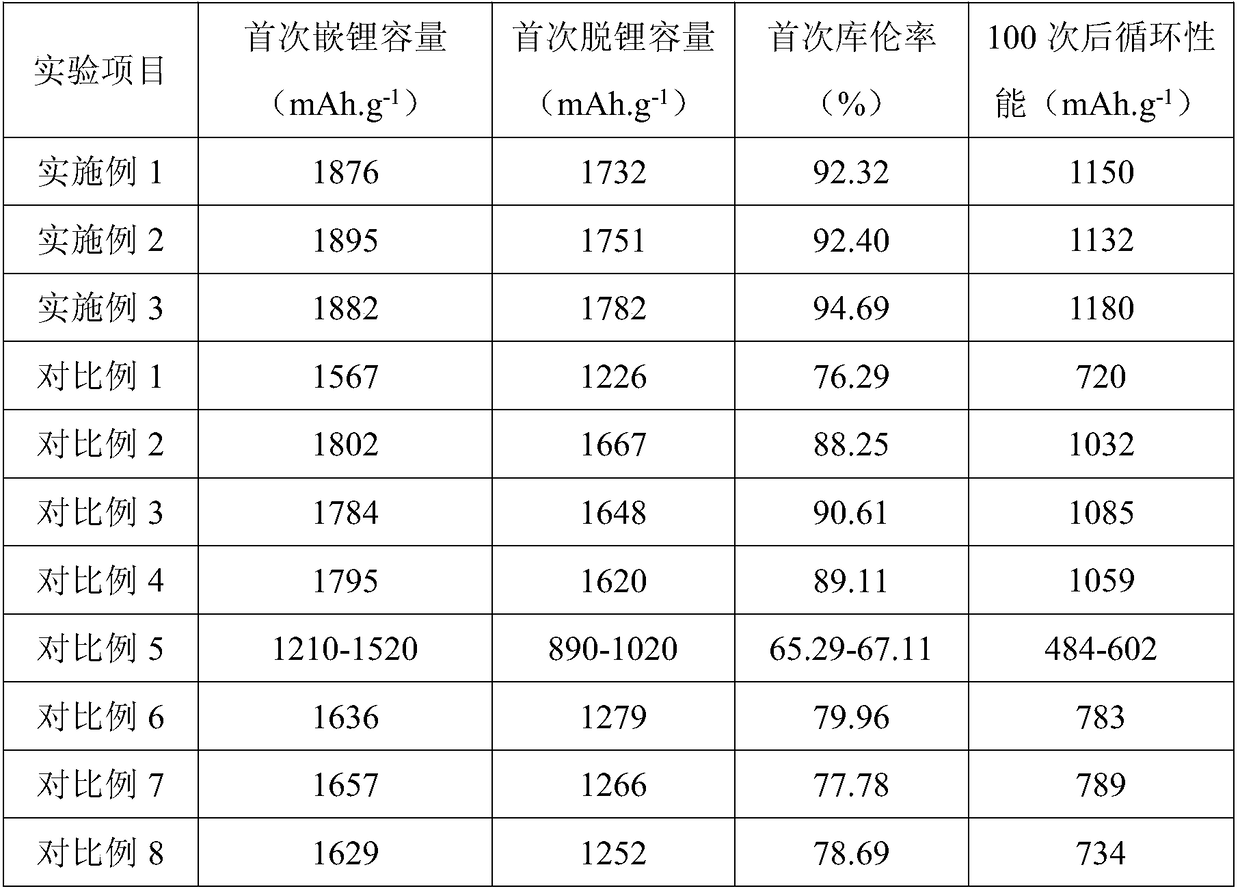

A kind of preparation method of hard carbon negative electrode material

ActiveCN107986254BWell mixedIncreased oxygen-containing functional groupsCell electrodesSecondary cellsMixed materialsAsphalt

The invention provides a preparation method of a hard carbon negative electrode material. The preparation method comprises steps as follows: aggregates and asphalt with a softening point being 200-280DEG C are mixed and kneaded at 300-380 DEG C, and a mixed material is obtained; the mixed material is subjected to molding and then is carbonized at 400-500 DEG C, and a precursor is obtained; the precursor is crushed and carbonized at 900-1400 DEG C, and the hard carbon negative electrode material is obtained. Compared with the prior art, the preparation method has the beneficial effects as follows: air and asphalt can be sufficiently and uniformly mixed in a mixing and kneading pot, a uniform cross-linking reaction is performed, oxygen-containing functional groups on the surface of asphaltare increased through oxidizing modification, and superior conditions are created for production of a large quantity of uniform lithium storage holes based on carbonization.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

A cathode material -- SiC for a lithium ion battery and a lithium ion secondary battery using such material

InactiveCN104300146AFriendly pollutionImprove lithium intercalation capacityCell electrodesSecondary cellsElectrical batteryEngineering

The invention relates to a new-type cathode material -- SiC used in a lithium ion secondary battery. The lithium ion secondary battery, which is manufactured from a material containing such active substance SiC and a lithium plate, is characterized in that the lithium ion secondary battery has a charging voltage platform of 0.6V and a discharging voltage platform of 0.4V respectively, and a theoretical specific capacity of up to 2680 mAh / g, and has a good charge-discharge cycle performance and environmentally-friendly and pollution-free characterizations. The SiC is a new-type, high capacity and high safety lithium ion battery cathode material with promising applications.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST +1

Alumina-modified graphene lithium ion battery anode material and preparation method thereof

ActiveCN108365209AThe first lithium intercalation capacity is highHigh delithiation capacity for the first timeNegative electrodesSecondary cellsFiberCarbon fibers

The invention discloses an alumina-modified graphene lithium ion battery anode material and a preparation method thereof, which belong to the technical field of lithium ion battery anode materials. The alumina-modified graphene lithium ion battery anode material consists of the following raw materials: nano-silicon powder, carbon fibers, graphene, carbon nanotubes, ethylene carbonate, alumina andpolyacrylic acid; and the lithium ion battery anode material is prepared by steps such as ultrasonic treatment, magnetic stirring, microwave treatment and high-temperature calcination. According to the invention, by means of a reinforcing system composed of ethylene carbonate, alumina and polyacrylic acid, the lithium intercalation capacity, lithium deintercalation capacity, initial coulombic efficiency and cycle performance of the alumina-modified graphene lithium ion battery anode material are increased.

Owner:山东信开源科技创新发展有限责任公司

Spinel type lithium nickel manganese oxide battery

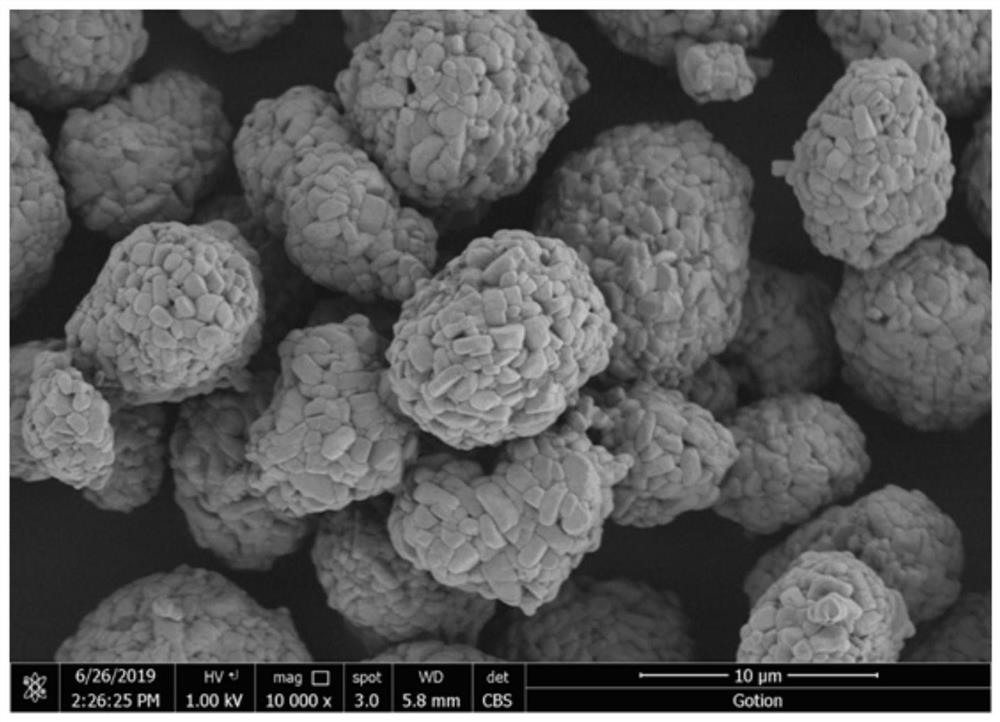

InactiveCN106784673AImprove securityImprove electrochemical performanceCell electrodesSecondary cellsMicrosphereNew energy

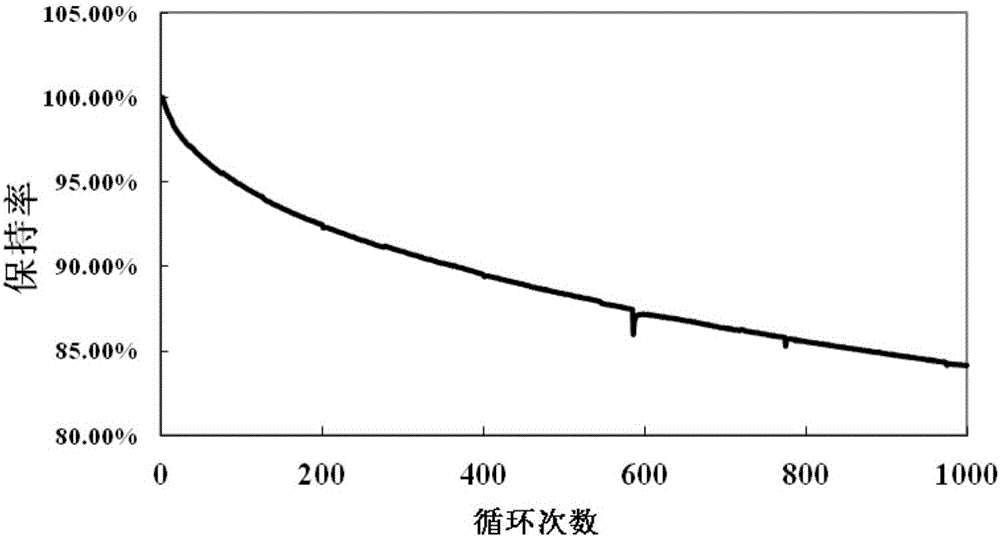

The invention discloses a spinel type lithium nickel manganese oxide battery, wherein the positive pole comprises 92.0-95.0% of lithium nickel manganese oxide LiNi0.5Mn1.5O4, 3.0-6.0% of polyvinylidene fluoride, 1.5-2.5% of oily carbon nano tubes and 0.5-1.0% of SP type conductive black; and the negative pole comprises 90.0-94.0% of nano-scale mesocarbon microbeads, 1.0-2.0% of sodium carboxymethylcellulose, 3.0-6.0% of an adhesive, 0.3-1.0% of SP type conductive black, 0.5-1.8% of C45 type conductive black and 1.2-2.4% of KS-6 type conductive graphite. The spinel type lithium nickel manganese oxide battery disclosed by the invention can reach a working voltage of 4.73V, can be continuously charged and discharged at a room temperature of 5 DEG C, has a capacity retention ratio of higher than 85% after 1000 times of cycle and meets the service requirements of small electric tools, aviation, spaceflight and new energy automobile.

Owner:湖南锂顺能源科技有限公司

High-volume V2O5 film anode material for lithium ion battery

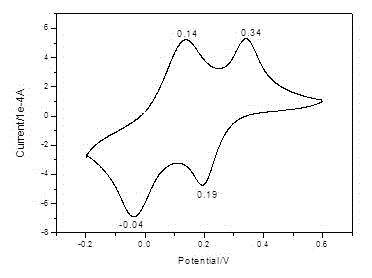

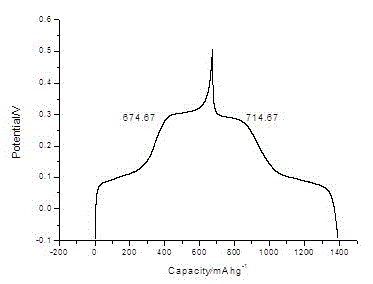

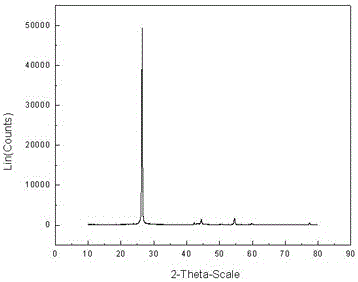

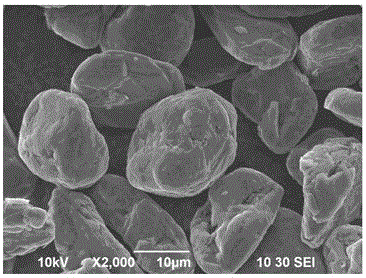

InactiveCN103078082BUnique shapeStable charging and discharging platformCell electrodesVanadium oxidesThin film electrodePhysical chemistry

The invention discloses a high-volume V2O5 film anode material for a lithium ion battery. A preparation method of the high-volume V2O5 film anode material for a lithium ion battery comprises the following steps of 1, preparing V2O5 sol by mixing V2O5 powder and H2O2 with stirring, 2, preparing sol having different concentrations by preparing the V2O5 sol into the sol respectively having concentrations of 0.002-0.016mol / L, 3, pre-treating a Pt substrate by immersing the Pt substrate in hydrogen peroxide for 10 min, flushing by deionized water and naturally drying in air, and 4, preparing a V2O5 film electrode by taking 10 microliters of the V2O5 sol having the required concentration, laying the V2O5 sol on the Pt substrate, naturally drying in air, putting the Pt substrate with the dried V2O5 sol into a muffle furnace having a temperature of 500 DEG C, carrying out calcination for 2 hours, and naturally cooling to a room temperature to obtain a V2O5 film electrode. The high-volume V2O5 film anode material for a lithium ion battery has a special microstructure and can improve a specific capacity of a lithium ion battery.

Owner:CHONGQING UNIV

Negative electrode material for power lithium-ion battery with core-shell structure and preparation method thereof

InactiveCN103811717BImprove lithium intercalation capacityAdaptableCell electrodesSecondary cellsCarbonizationCarbide

Owner:XINXIANG SAIRI NEW ENERGY SCI & TECH

Preparation method and application of a coal tar pitch-based lithium-ion battery negative electrode material

ActiveCN109422258BHigh yieldSimple processCell electrodesSecondary cellsCarbonizationPhysical chemistry

The invention discloses a preparation method of a coal pitch-based lithium ion battery negative electrode material. Pitch balls with a diameter of less than 100 μm and a softening point of 90° C. to 130° C. are added with a sulfonating agent to be sulfonated at room temperature, and then sulfonated at a temperature of 400 to 500° C. The sulfonating agent is decomposed at ℃, the asphalt balls from which the sulfonating agent has been removed are placed in the reaction vessel, and air-oxidized at 280-350 ℃. Hard carbon anode materials with different median diameters were obtained. The invention has the advantages of high yield, simple process, convenient operation and very low cost compared with mesophase carbon microspheres.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Preparation method of sodium-nitrogen in-situ doped ternary material

InactiveCN112279312AImprove capacity playImprove stabilityCell electrodesLi-accumulatorsLithiumPhysical chemistry

The invention discloses a preparation method of a sodium-nitrogen in-situ doped ternary material, which comprises the following steps: uniformly mixing a lithium source, a sodium source and a ternaryprecursor Ni,1-a-b>CoMn (OH)<2> weighed according to a molar ratio, sintering at 700-900 DEG C in an oxygen-enriched atmosphere containing a nitrogen source, and naturally cooling to obtain the sodium-nitrogen in-situ doped ternary material Li<1-y>Na<y> (Ni<1-a-b>CoMn) N<x>O<2-X>, wherein x is larger than 0 and smaller than 0.1, y is larger than 0 and smaller than 0.1, 1-a-b is larger than 0.5 and smaller than 1, a is larger than 0 and smaller than or equal to 0.2, and b is larger than 0 and smaller than or equal to 0.2. The sodium-nitrogen in-situ doped ternary material prepared by theinvention not only is simple in preparation process, but also can effectively improve the capacity, the cycle performance and the rate capability of the ternary material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of silicon-containing porous amorphous alloy lithium-ion battery negative electrode material and preparation method thereof

ActiveCN106159246BLower specific capacityImprove lithium intercalation capacityCell electrodesSecondary cellsFiltrationAlloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Graphene composite transition metal oxide nanofiber lithium ion battery electrode material and preparation method thereof

InactiveCN102931408BQuick releaseShorten migration distanceMaterial nanotechnologyCell electrodesLithium-ion batteryMaterials science

The invention discloses a graphene composite transition metal oxide nanofiber lithium ion battery electrode material and a preparation method thereof. The composite electrode material combines a function of a graphene laminated structure for embedding and binding transition metal oxide nanoparticles, a function of a micropore tunnel structure interconnected in graphene composite transition metal oxide nanofiber for quickly embedding and taking off lithium ions and a function of three-dimensional space structures wound with each other among nanofibers and used for effectively releasing greatly-changed stress when the volume in an electrode membrane is expanded or contracted. Due to the integration of the three functions, the volume effect of the transition metal oxide material in the process of embedding / taking off the lithium ions can be effectively restrained and buffered, the loss of the irreversible capacity can be reduced, and then, the capacity and the cycling stability performance of a lithium ion battery are further improved.

Owner:DALIAN OCEAN UNIV +1

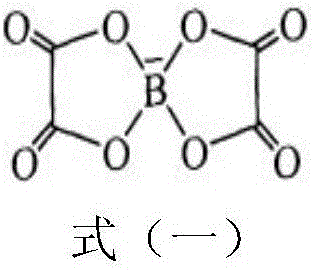

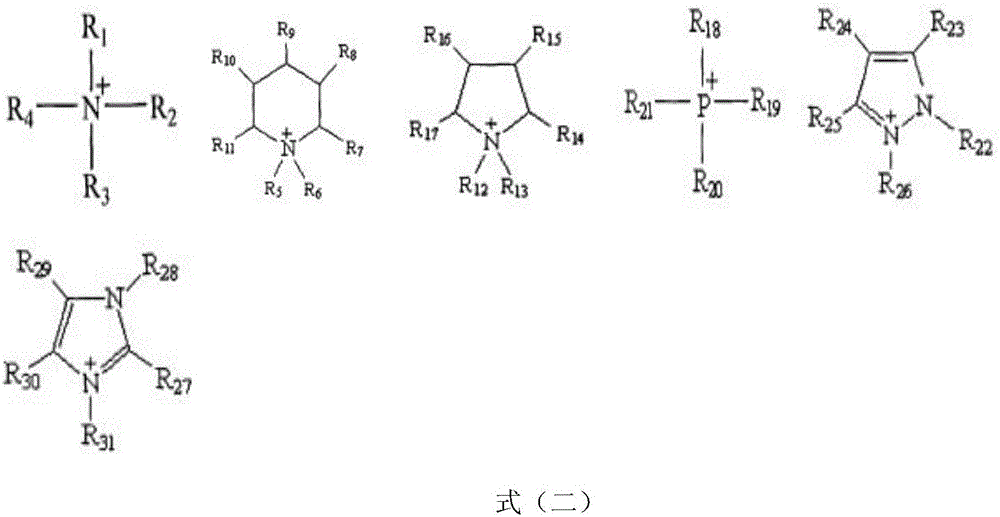

A lithium-ion carbon-based supercapacitor

InactiveCN104183390BImprove electrical performanceImprove lithium intercalation capacityHybrid capacitor separatorsHybrid capacitor electrodesActivated carbonOrganic solvent

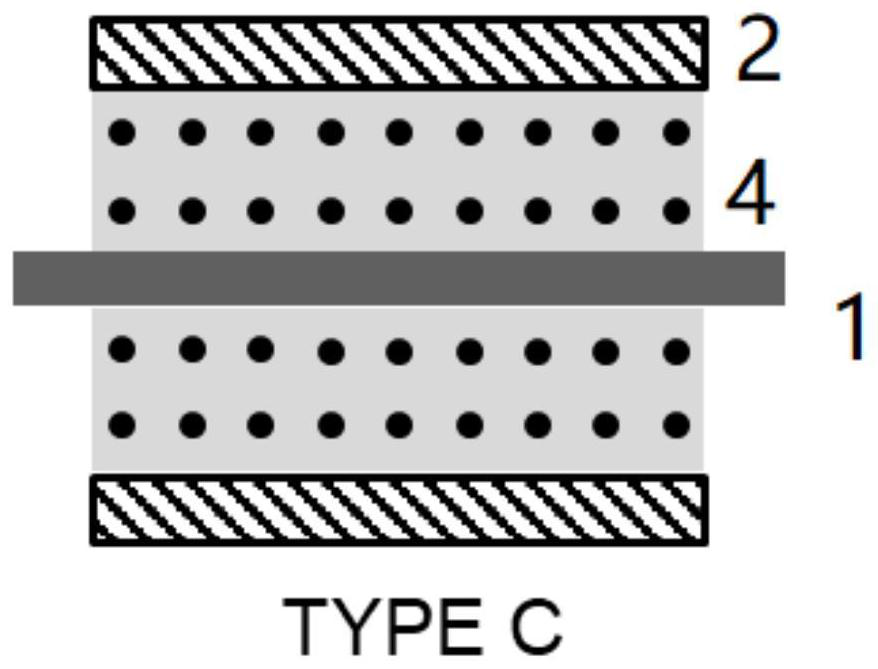

The invention relates to the field of electrochemical energy storage devices, in particular to a novel lithium ion carbon-based super capacitor. The lithium ion carbon-based super capacitor is composed of a shell, a positive electrode slice, a negative electrode slice, a diaphragm located between the positive electrode slice and the negative electrode slice and organic electrolyte. The lithium ion carbon-based super capacitor is characterized in that the positive electrode slice is mainly formed by pressing activated carbon and a single conductive agent and bonding agent mixing face on a current collector; the negative electrode slice is mainly formed by coating copper foil with graphite and a single conductive agent and bonding agent mixing face; the organic electrolyte is composed of electrolyte salt containing lithium ions and a mixed organic solvent, and a lithium slice and a diaphragm are further arranged between the shell and the negative electrode slice. The super capacitor has the advantages that compared with an existing lithium ion battery, the product is higher in power density, longer in service life and better is safety performance.

Owner:DONGGUAN MCNAIR NEW POWER

Lithium ion battery silicon substrate composite negative electrode materials and preparation method thereof

ActiveCN103151503BImprove electronic conductivityReduce contact resistanceCell electrodesCvd grapheneCarbon source

The invention provides lithium ion battery silicon substrate composite negative electrode materials and a preparation method of the lithium ion battery silicon substrate composite negative electrode materials, and belongs to the technical field of lithium ion batteries. The prepared lithium ion battery silicon substrate composite negative electrode materials comprise, 23-56 wt% of silicon, 12.1-75.4 wt% of magnesium oxide and 2-12 wt% of graphene. A magnesiothermic reduction method is adopted, and magnesium powder serves as a reducing agent for reducing oxide of silicon (SiOx, and x is larger than 0.5 and smaller than 2) to prepare silicon / magnesium oxide composite materials. Then, the magnesium oxide attached on a reaction product on the surface of the silicon serves as a catalyst. A carbon source is adopted to carry out catalytic chemical vapor deposition so as to generate the graphene. The silicon / magnesium / graphene composite negative electrode materials are prepared. According to a prepared silicon substrate lithium ion battery, after magnesiothermic reduction is carried out on the oxide of the silicon, the magnesium oxide is generated on the interior of the oxide of the silicon, a volume effect of the silicon is relieved, the magnesium oxide generated on the interior and the exterior of the oxide of the silicon has the function of the catalyst, the graphene is catalyzed and generated, the volume effect of the silicon can be further relieved, and electrical conductivity of the materials is remarkably strengthened.

Owner:云南前沿液态金属研究院有限公司

A kind of silicon carbon negative electrode material and preparation method thereof

ActiveCN109671941BImprove stabilityImprove structural stabilityMaterial nanotechnologyCell electrodesCarbon layerIn situ polymerization

The invention discloses a silicon-carbon negative electrode material and a preparation method thereof, which sequentially include: silicon / silicon oxide particles, N-3-(trimethoxysilyl) propyl vinyl diamine molecular layer, and carbon nanotubes from the inside to the outside. Conductive layer, polydopamine carbonized layer, the silicon / silicon oxygen particles are polyvalent oxides of silicon or silicon or a mixture thereof, the N-3-(trimethoxysilyl) propyl vinyl diamine molecular layer, The thickness is 1-10 μm; the polydopamine macromolecule in the polydopamine carbon layer uniformly forms a film on the outermost layer to cover silicon / silicon oxide particles and carbon nanotubes, and the film thickness is 0.01-3 μm. The synergistic effect of the three-layer structure and silicon / silicon oxide particles can significantly improve the structural stability and conductivity of silicon-based anode materials, and further improve the rate performance and cycle performance. The preparation method of the invention combines molecular self-assembly technology and in-situ polymerization technology and is applied to the field of negative electrode materials of lithium ion batteries, and has simple process, convenient operation and short preparation period.

Owner:余姚市海泰贸易有限公司

Preparation method of aluminum oxide modified graphene lithium ion battery negative electrode material

ActiveCN108365209BThe first lithium intercalation capacity is highHigh delithiation capacity for the first timeSecondary cellsNegative electrodesCarbon fibersCarbon nanotube

The invention discloses an alumina-modified graphene lithium ion battery anode material and a preparation method thereof, which belong to the technical field of lithium ion battery anode materials. The alumina-modified graphene lithium ion battery anode material consists of the following raw materials: nano-silicon powder, carbon fibers, graphene, carbon nanotubes, ethylene carbonate, alumina andpolyacrylic acid; and the lithium ion battery anode material is prepared by steps such as ultrasonic treatment, magnetic stirring, microwave treatment and high-temperature calcination. According to the invention, by means of a reinforcing system composed of ethylene carbonate, alumina and polyacrylic acid, the lithium intercalation capacity, lithium deintercalation capacity, initial coulombic efficiency and cycle performance of the alumina-modified graphene lithium ion battery anode material are increased.

Owner:山东信开源科技创新发展有限责任公司

Titanium dioxide (B) negative electrode material with improved performance and preparation method thereof

PendingCN114039032ALoose structureIncrease layer spacingNegative electrodesDischarge efficiencyDopant

The invention discloses a titanium dioxide (B) negative electrode material with improved performance and a preparation method thereof. The titanium dioxide (B) negative electrode material is prepared from the following raw materials in parts by weight: 130-195 parts of titanium dioxide (B), 20-85 parts of tetraethoxysilane, 60-135 parts of graphite, 90-130 parts of a lithium source, 5-13 parts of a dopant, 25-35 parts of a carbon source and 35-45 parts of ionic liquid. The raw materials are prepared through the procedures of mixing, roasting, dispersing, grinding, drying, wrapping and sintering at a time. The negative electrode material prepared by the formula and the preparation method disclosed by the invention has excellent capacity performance, cycle performance, rate charge-discharge performance and first charge-discharge efficiency.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Carbon nanotube hard carbon composite negative electrode material with core-shell structure, preparation method and application

ActiveCN113328068BImprove first-week efficiencySmall specific surface areaCell electrodesSecondary cellsEpoxyCarbon composites

The embodiment of the present invention relates to a carbon nanotube hard carbon composite negative electrode material with a core-shell structure and its preparation method and application. The outer carbon coating is composed of; the inner core includes a first phase and a second phase; One or several combinations of these are hard carbon materials prepared from carbonized precursors, with a size range of 1um to 40um, and a Raman spectrum Id / Ig range of 0.7 to 0.9; the second phase is carbon nanotubes, with a size of 1nm to 50nm; the carbon coating layer is prepared by gas phase method, liquid phase method or solid phase method, and the range of Raman spectrum Id / Ig is 0.7~1.3; in the carbon nanotube hard carbon composite negative electrode material, according to the mass Score, first phase: second phase: carbon coating = (0, 100%]: (0, 60%]: (0, 40%].

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

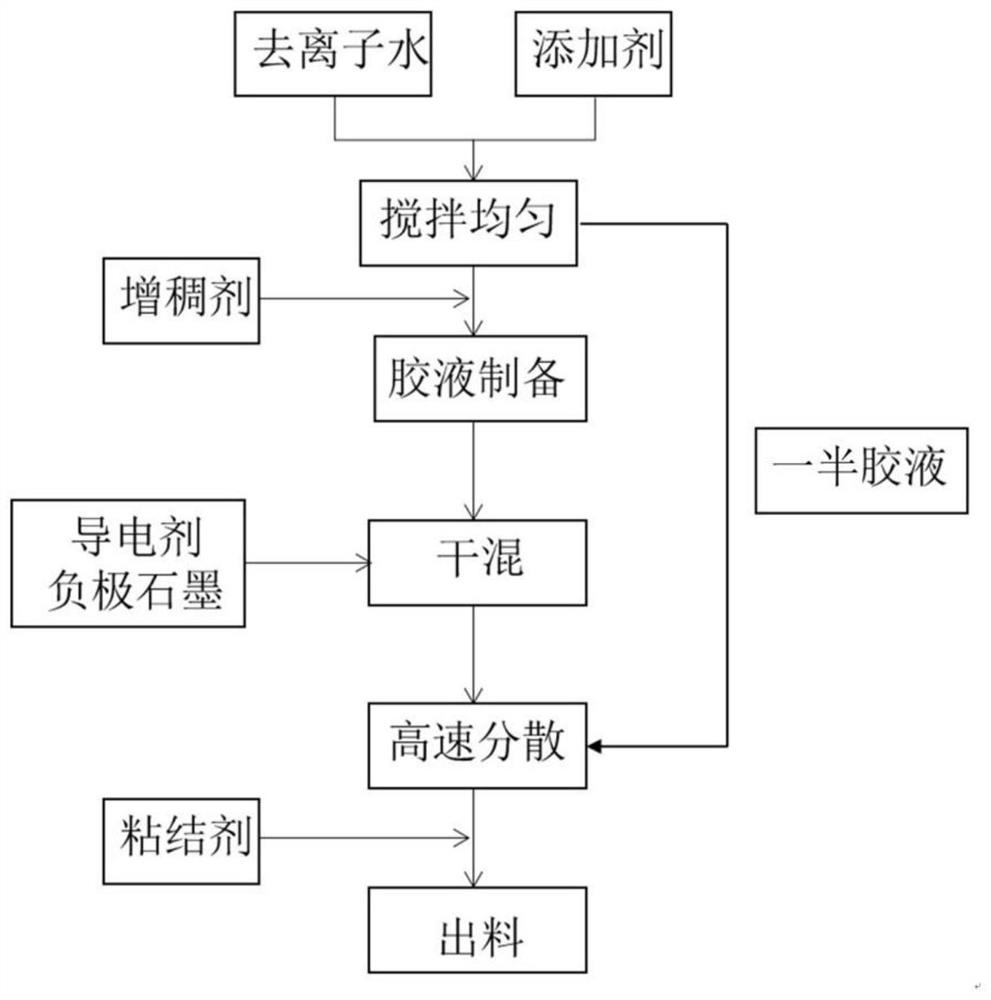

A slurry mixing process for lithium-ion battery composite graphite negative electrode

ActiveCN108899543BIncrease capacityIncrease capacity ratioCarbon compoundsCell electrodesElectrical batteryAdhesive

The invention discloses a slurry blending process of a composite graphite cathode of a lithium ion battery. The slurry blending process comprises the following steps: adding an additive into deionizedwater, stirring until dissolving, so as to obtain an additive solution; adding a thickening agent into the additive solution so as to prepare a glue solution, and equally dividing the glue solution into two parts for later use; adding a conducting agent and composite graphite into one half of the glue solution, and carrying out dry blending, so as to obtain slurry 1; adding the other half of theglue solution into the slurry 1, carrying out high-speed dispersion, so as to obtain slurry 2; and adding an adhesive into the slurry 2, uniformly dispersing so as to obtain slurry 3, adjusting the viscosity of the slurry 3 within a process range, and discharging. The primary efficiency of the lithium ion battery prepared by virtue of the slurry blending process of the cathode is improved, graphite does not settle in the slurry blending process, the performance of the battery is improved, and the service life of the battery is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of hard carbon-based negative electrode material

ActiveCN112551505ARich sourcesWide variety of sourcesNegative electrodesSecondary cellsElectric arc furnaceCarbonization

The invention discloses a preparation method of a hard carbon-based negative electrode material. The preparation method comprises the preparation steps of adding an alcohol solvent into bottom glycerol residues, stirring and heating to boil until the bottom glycerol residues are dissolved into liquid; adding dimethylamine into the glycerol residue solution; putting the aminated glycerol residue solution into a high-temperature heating furnace, and carrying out primary carbonization treatment; putting the glycerol residues subjected to primary carbonization into a plasma sintering furnace, vacuumizing, pressurizing, heating and sintering; putting the secondarily carbonized glycerol residues into an electric arc furnace, heating and sintering the secondarily carbonized glycerol residues under the protection of inert gas, and carrying out tertiary carbonization treatment; mixing the hard carbon-based material and a conductive agent, grinding, dispersing in absolute ethyl alcohol, adding an adhesive, uniformly stirring, drying and tabletting to obtain the hard carbon-based material negative electrode material. The bottom glycerol residues used in the method are rich in carbon resources, can be recycled, have very high social and environmental benefits, and has great significance for realizing green sustainable development.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com