Multilayer positive plate with lithium/sodium supplementing function, battery and preparation method

A positive electrode sheet and lithium supplement technology, which is applied in the field of lithium/sodium ion energy storage appliances, can solve the problems of reducing battery energy density, poor stability, and affecting the performance of battery positive electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

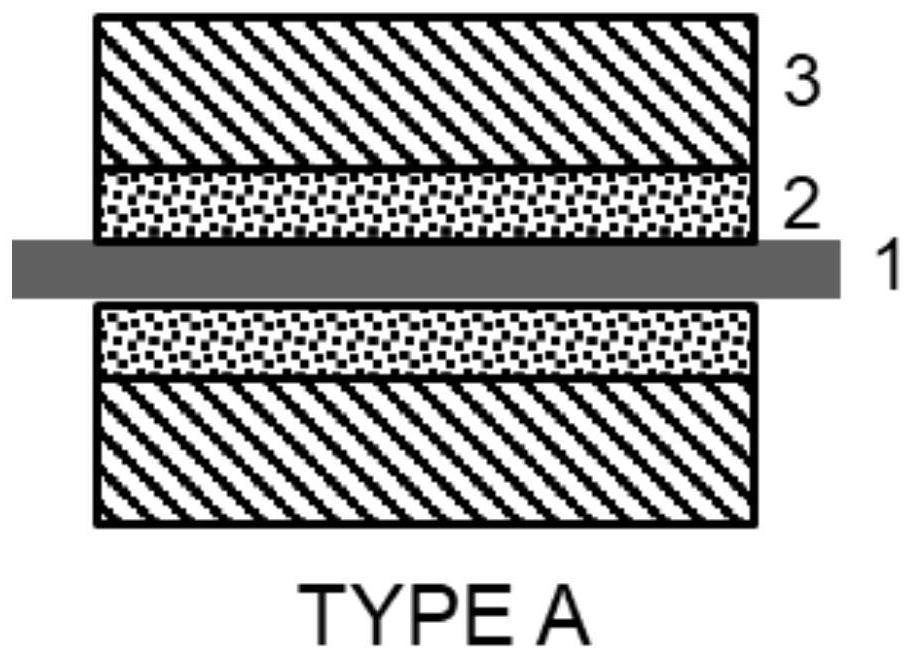

[0063] 1g of complex prelithiation reagent (containing 0.9g Li 2 C 2 o 4 Lithium supplementation reagent and 0.1g MnO 2 Catalyst) and 0.4g conductive agent C45 were uniformly mixed, and the uniformly mixed powder was mixed with 0.1g PVDF and 25ml NMP to form a slurry for later use. 9gLiFePO 4 Mix the positive electrode material with 0.5g conductive agent C45 evenly, and mix the uniformly mixed powder with 0.5g PVDF and 200ml NMP to form a slurry for later use. Coating the lithium-replenishing layer and the positive electrode material layer in a TYPE A-type coating method with a certain thickness (to ensure that the area mass ratio of the positive electrode active material to the lithium-replenishing reagent is 10:1), and then drying and rolling, Then the positive electrode and the hard carbon negative electrode were assembled into a full battery, and the sample was designated as A1.

Embodiment 2

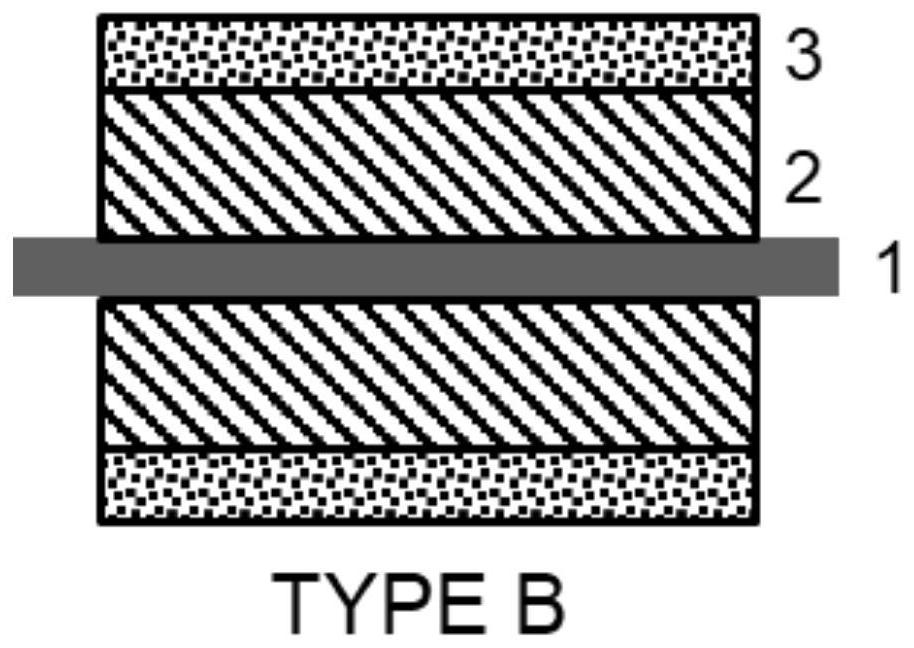

[0065] 1g of complex prelithiation reagent (containing 0.9g Li 2 C 2 o 4 Lithium supplementation reagent and 0.1g MnO 2 Catalyst) and 0.4g conductive agent C45 were uniformly mixed, and the uniformly mixed powder was mixed with 0.1g PVDF and 25ml NMP to form a slurry for later use. 9gLiFePO 4 Mix the positive electrode material with 0.5g conductive agent C45 evenly, and mix the uniformly mixed powder with 0.5g PVDF and 200ml NMP to form a slurry for later use. Coating the lithium-replenishing layer and the positive electrode material layer in a TYPE B-type coating method with a certain thickness (to ensure that the area mass ratio of the positive electrode active material to the lithium-replenishing reagent is 10:1), and then drying and rolling, Then the positive electrode and the hard carbon negative electrode were assembled into a full battery, and the sample was designated as A2.

Embodiment 3

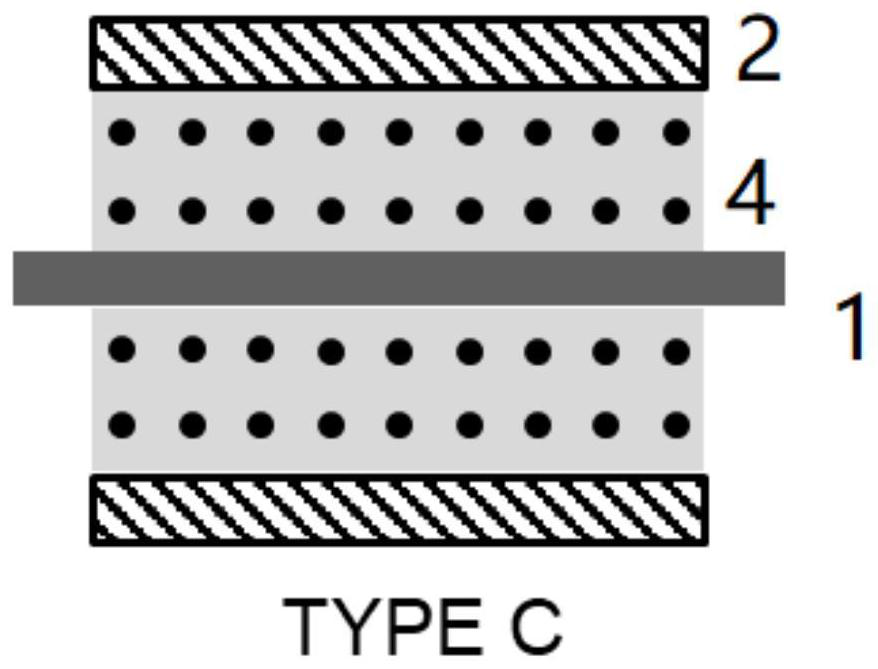

[0067] 1g of complex prelithiation reagent (containing 0.9g Li 2 C 2 o 4 Lithium supplementation reagent and 0.1g MnO 2 Catalyst) and 0.4g conductive agent C45 were uniformly mixed, and the uniformly mixed powder was mixed with 0.1g PVDF and 25ml NMP to form a slurry for later use. 9gLiFePO 4 Mix the positive electrode material with 0.5g conductive agent C45 evenly, and mix the uniformly mixed powder with 0.5g PVDF and 200ml NMP to form a slurry for later use. Coating the lithium-replenishing layer and the positive electrode material layer in a TYPE C-type coating method with a certain thickness (to ensure that the area mass ratio of the positive electrode active material to the lithium-replenishing reagent is 10:1), and then drying and rolling, Then the positive electrode and the hard carbon negative electrode were assembled into a full battery, and the sample was designated as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com