Patents

Literature

43results about How to "The composition of the plating solution is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid

The invention provides a preparation method and an electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid, which relates to electroplating liquid and electroplating technology. The invention solves the problems of poor stability of the traditional trivalent chromium electroplating liquid, low precipitating and depositing rate of harmful gas in an electroplating process, more components of the electroplating liquid, sensitivity for impurities, poor corrosion resistance of an electroplating layer, and the like. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid mainly comprises the following components of main salt, a complexation stabilizing agent, a combined additive, a buffering agent and a conducting salt. The electroplating liquid can work at normal temperature, thereby saving energy resources and having simple technology and high deposition rate, wherein the deposition rate can reach above 0.22micron.min<-1> under 6A / dm<2>. An anode of the invention is a Ti-based rare-metal tantalum-iridium-titanium anode, the anode oxygen-evolution overpotential is low, and harmful hexavalent chrome can not be generated. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid has good corrosion resistance and high stability.

Owner:HARBIN INST OF TECH

Light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition and preparation method thereof

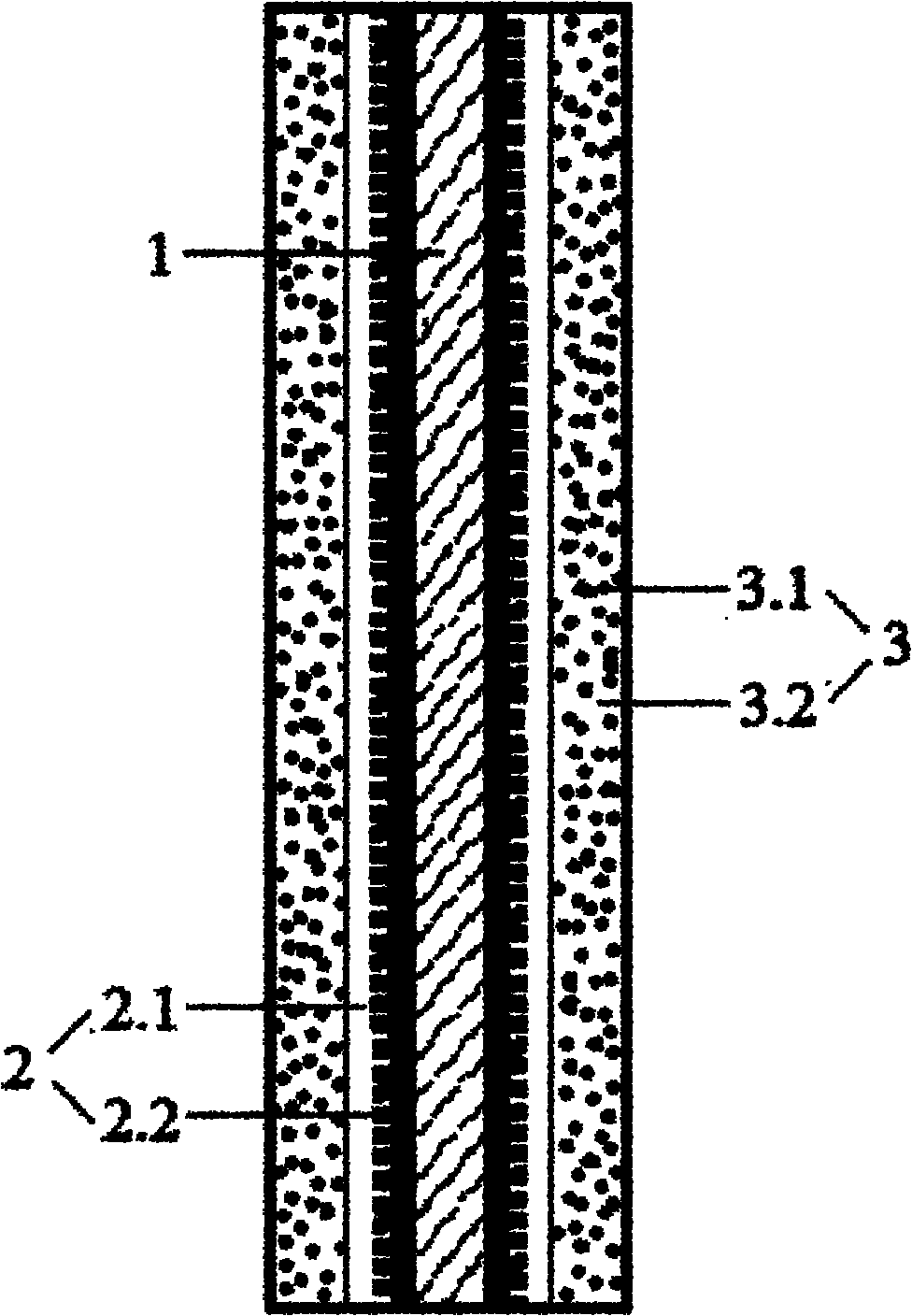

The invention relates to a light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition, which is composed of a metal substrate, an interlayer and a composite electro-catalysis superficial layer in sequence from inside to outside, wherein the metal substrate is Al or Al base alloy (Al-M1), the interlayer is a composite layer Al2O3-(Pb-M2) composed of Al2O3 or Pb base alloy, and the composite electro-catalysis superficial layer is a composite deposite (Pb-M2)-M3Ox composed of Pb or Pb base alloy and oxide catalyst or a composite deposite PbO2-M3Ox composed of PbO2 and oxide catalyst. The preparation method of the anode comprises the following steps: preparation of the metal substrate: carrying out anodic oxidation on the metal substrate surface and prefabricating a multihole Al2O3 layer; then performing an electro-deposition Pb or Pb base alloy layer on the multihole Al2O3 layer; and plating a (Pb-M2)-M3Ox or PbO2-M3Ox composite superficial layer on the surface of the Pb or Pb base alloy layer. The anode prepared by the invention can effectively reduce production energy consumption, improve cathode product quality, lower labor intensity, is suitable for industrialized production and can replace the Pb base alloy anode applied in the existing industry.

Owner:KUNMING HENDERA SCI & TECH

Preparing technology of Ni-Fe-P alloy-based compound coating

The invention provides a preparing technology of a Ni-Fe-P alloy-based compound coating. The matrix material of the compound coating is amorphous / nanocrystalline Ni-Fe-P alloy, the Ni content is 80-90wt% of the compound coating, the Fe content is 5-20wt% of the compound coating, and the P content is 5-15wt% of the compound coating. A second phase in the compound coating is a grain growth inhibitor, such as VC<1-x> and TiC, and the content of the second phase is 0-5wt% of the compound coating. The preparing technology of the compound coating comprises: 1, pretreating a metal plated surface; 2, activating second phase particles; 3, carrying out electric brushing plating on a Ni-Fe-P amorphous compound coating; and 4, carrying out partial crystallization transformation on the compound coating.

Owner:刘志红

Electroplating solution and method for electroplating bright nickel-titanium alloy

ActiveCN103397353AThe composition of the plating solution is simpleNon-toxicTrisodium citrateSubmarine

The invention provides an electroplating solution and method for electroplating a bright nickel-titanium alloy. The electroplating solution is composed of the following components: 1) 50-60 g / L nickel sulfate hexahydrate, 2) 0-15 g / L nickelous chloride hexahydrate, 3) 3.5-10.5 g / L titanyl sulfate, 4) 30-40 g / L boric acid, 5) 50-60 g / L trisodium citrate, 6) 8-10 g / L imine succinate, 7) 2-4 ml / L brightener and 8) 8-10 ml / L assistant. The electroplating parameters are as follows: the pH value is 3-5, the temperature is 40-60 DEG C, the cathode current density is 1.0-5.0 A / dm<2>, the anode material is a nickel plate or stainless steel board or ruthenium titanium alloy anode, and the electroplating time is 10-60 minutes. The electroplating solution is simple in components, non-toxic and pollution-free, and free of Cr<6+>; and when being used for electroplating the bright nickel-titanium alloy, the electroplating solution can substitute the electroplating technique, save the nickel, and substitute the electroplating of toxic and contaminative hexavalent chrome. The invention proves that the wear resistance, corrosion resistance and toughness of the coating are greatly enhanced. The invention has very important actions in common industry and in the fields of military affairs, national defense, aerospace and submarine ships.

Owner:湖北广志科技服务有限公司

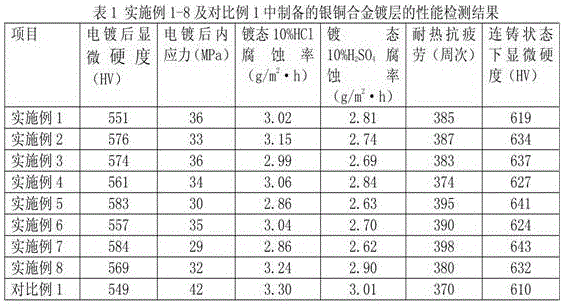

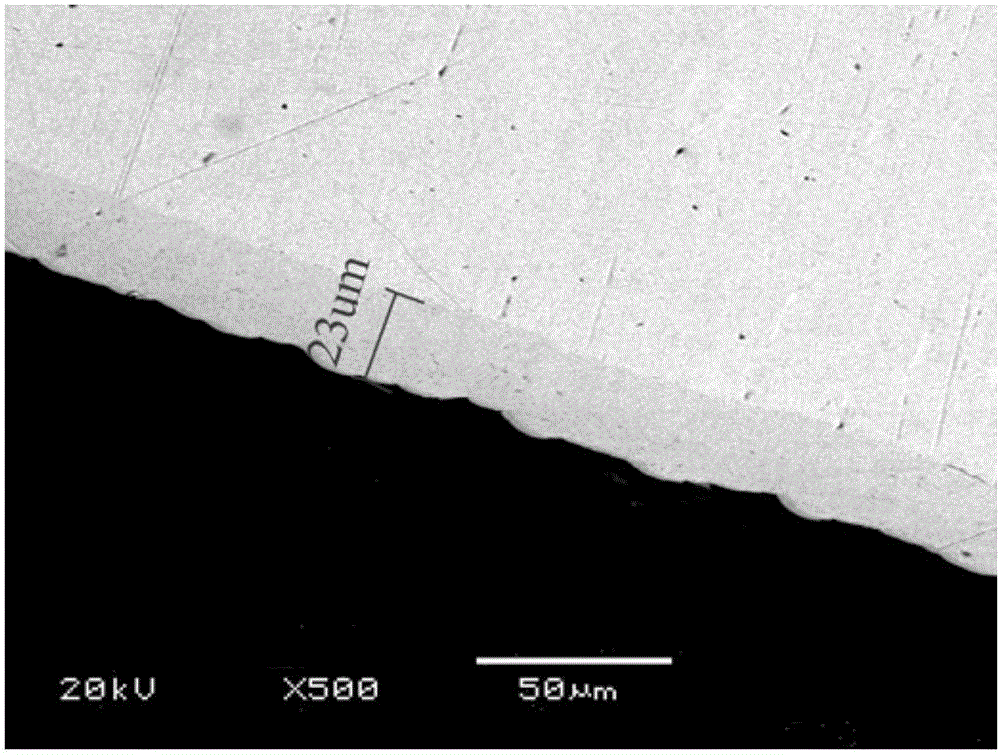

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

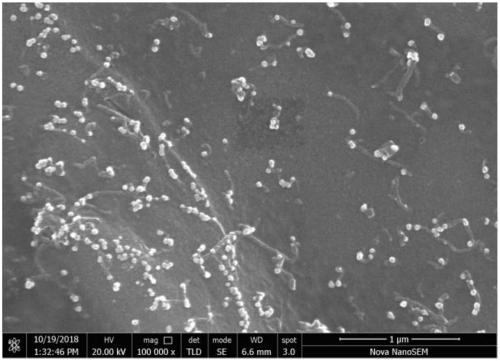

Method for preparing Pt-based catalyst by pulse electrodeposition under ultrasonic conditions

InactiveCN109331820AEvenly dispersedUniform and firm loadCell electrodesCatalyst activation/preparationPulse power supplyControllability

The invention discloses a method for preparing a Pt-based catalyst by pulse electrodeposition under ultrasonic conditions, and belongs to the technical field of electrodeposition. The method combinesadvantages of both pulse electrodeposition and ultrasonic conditions, and electrodeposits to prepare the Pt-based catalyst by separately preparing a desired salt solution as an electroplating solutionin an aqueous solution, an organic solvent or an ionic liquid, and using a carbon material as a carrier, and using a pulse power supply to set different pulse electrodeposition current densities, current on-off time ratios (ton / toff), temperatures and other process parameters. According to the invention, the method for preparing the Pt-based catalyst by combining the pulse electrodeposition withthe ultrasonic conditions is simple in process operation, environmentally-friendly and strong in condition controllability; and the prepared Pt-based catalyst is small in average particle size, largein specific surface area and firm to bond with the carrier.

Owner:DALIAN UNIV OF TECH

Technology for electroplating tungsten-cobalt-nickel alloy on surface of structural steel

The invention discloses a technology for electroplating a tungsten-cobalt-nickel alloy on a surface of structural steel. A plating solution adopted in the technology is composed of 12-18 g / L of cobalt sulfate, 80-84 g / L of sodium tungstate, 14-18 g / L of nickel sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, and the balance being water. The technology comprises the steps of washing and activating the structural steel; then putting the structural steel in the above plating solution; taking stainless steel as an anode; adjusting a pH value to 7.5-8.5 with ammonia water; heating to a temperature of 50-60 DEG C; controlling a current density at 12-16 A / dm<2> and electroplating for 20-30 minutes.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Cyanide-free electroplating bath for copper plating of iron and steel parts

InactiveCN102021617AThe composition of the plating solution is simplePlating solution is stableCopper platingPotassium thiocyanate

The invention discloses a cyanide-free electroplating bath for the copper plating of iron and steel parts. The electroplating bath provided by the invention comprises copper sulphate, potassium carbonate, one or more than two of organic phosphate and phytic acid, and one or more than two of sodium citrate, seignette salt and potassium thiocyanate. The electroplating bath provided by the invention is applied to the copper plating of the iron and steel parts, and has the advantages of fine and compact coating crystals, dispersing power and covering power both superior to those of cyaniding copper-plating solution, simple components, stability, no decomposition products, no need of heating, reduction in energy consumption and a strong binding force between a coating and a substrate.

Owner:GUANGZHOU JINHUI CHEM SCI TECH

Preparation method of plating solution for electroplating tungsten-molybdenum-nickel alloy coating on surface of petroleum-pumping component

InactiveCN104233389AGood corrosion and friction resistanceWell combinedAmmonium sulfateMetallic Nickel

The invention discloses a preparation method of a plating solution for electroplating a tungsten-molybdenum-nickel alloy coating on a surface of a petroleum-pumping component. The preparation method comprises the steps of measuring half of water; heating the water to a temperature of 55-65 DEG C; adding 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate and 20-24 g / L of ammonium sulfate; stirring to dissolve the above materials; adding 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate and 10-14 g / L of ascorbic acid; stirring for 3-5 minutes; adding 80-84 g / L of sodium tungstate, 6-10 g / L of sodium molybdate and 14-18 g / L of nickel sulfate; stirring for 10-20 minutes; and finally adding 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol and the residual water; stirring uniformly; and regulating a pH value to 8.0-9.0 with ammonia water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Solution for chemically plating nickel on surface of non-catalytic active material and plating process for solution

ActiveCN105695962AQuality improvementThe composition of the plating solution is simpleLiquid/solution decomposition chemical coatingNickel saltWater soluble

The invention relates to a solution for chemically plating nickel on the surface of a non-catalytic active material and a plating process for the solution, and belongs to the technical field of chemical nickel-plating. The solution comprises liquor A, liquor B, liquor C and / or liquor D, wherein the liquor A comprises a water-soluble nickel salt and a buffer agent; the liquor B comprises a reducing agent, a complexing agent, a buffer agent, a stabilizer and a surface wetting agent; the liquor C comprises the water-soluble nickel salt and the complexing agent; and the liquor D comprises the reducing agent and the stabilizer. The plating process for the solution comprises the following steps: preparing the liquor A, the liquor B and a diluent; uniformly mixing the liquor A, the liquor B and the diluent to obtain a mixture, regulating the pH value of the mixture to 7.0-8.0, heating the mixture to a temperature of 82-88 DEG C, and carrying out primary plating by using an iron material as an initiator; filtering plating liquor after carrying out primary plating; recycling filtrate for next-time plating, feeding plating liquor obtained by the next-time plating into the liquor C and the liquor D, and recycling the plating liquor. According to the solution and the plating process thereof, the combination and the process design are reasonable, generation and emission of waste liquor can be greatly reduced, and the utilization rate of the plating liquor can be increased.

Owner:CENT SOUTH UNIV

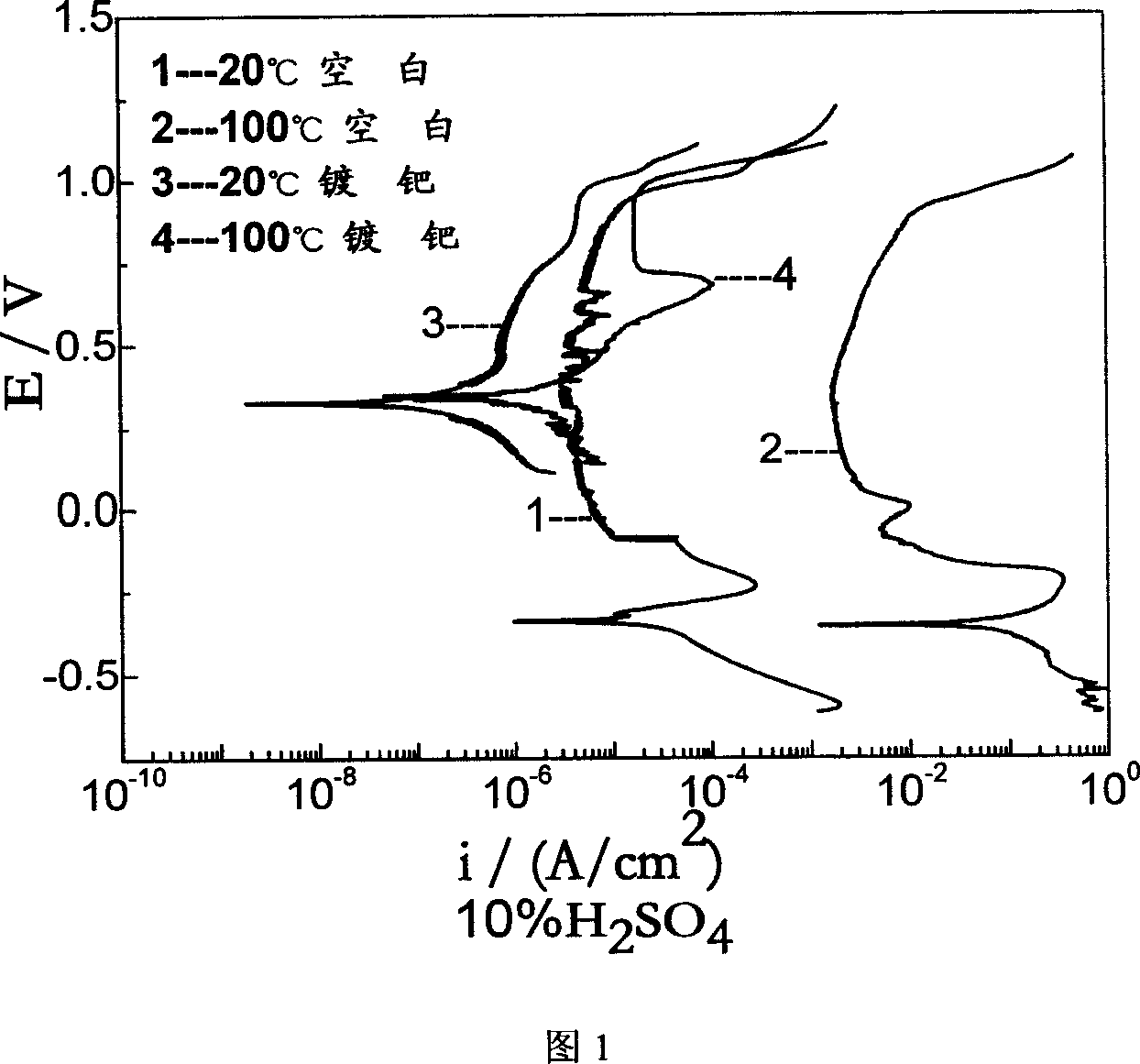

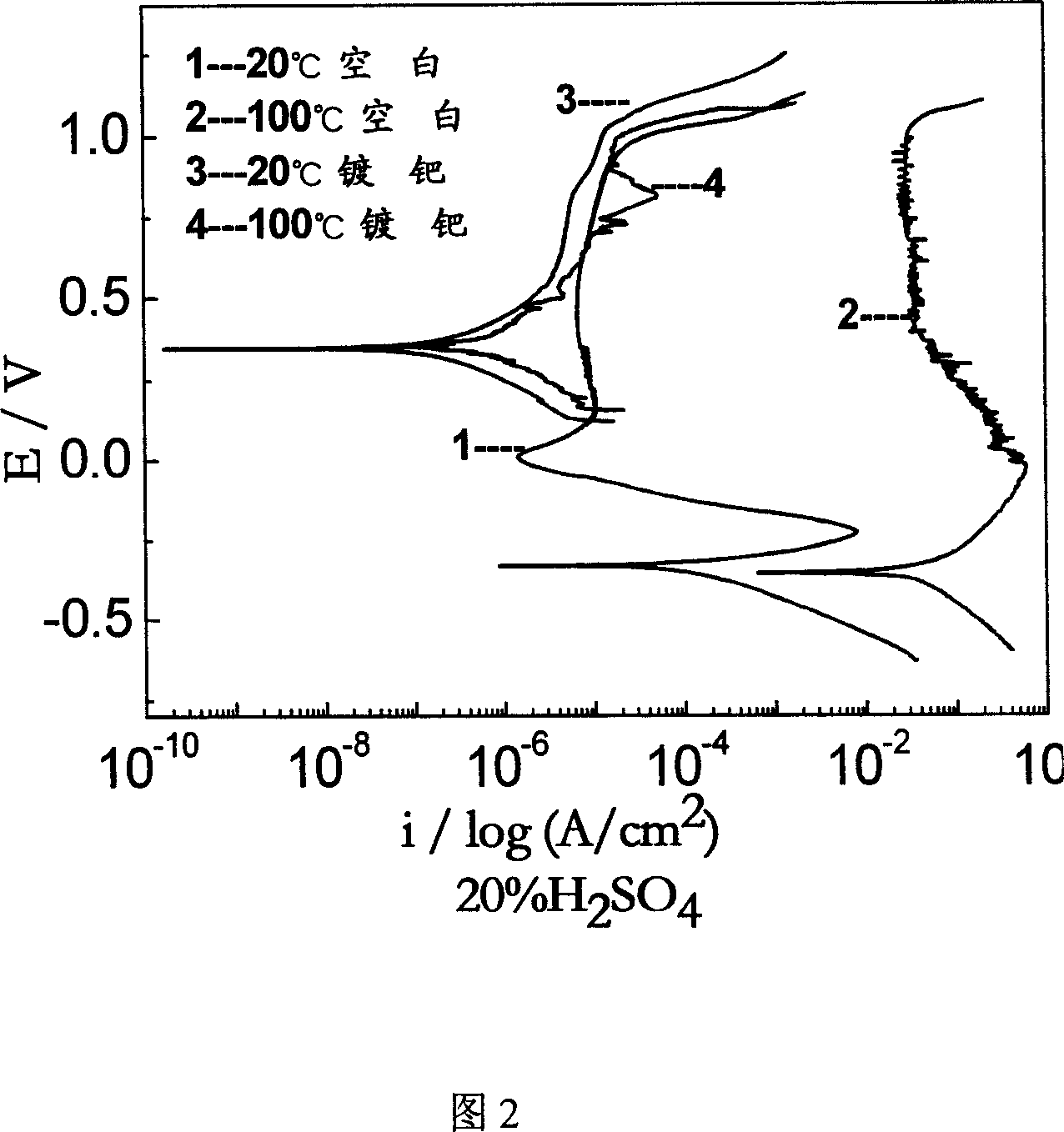

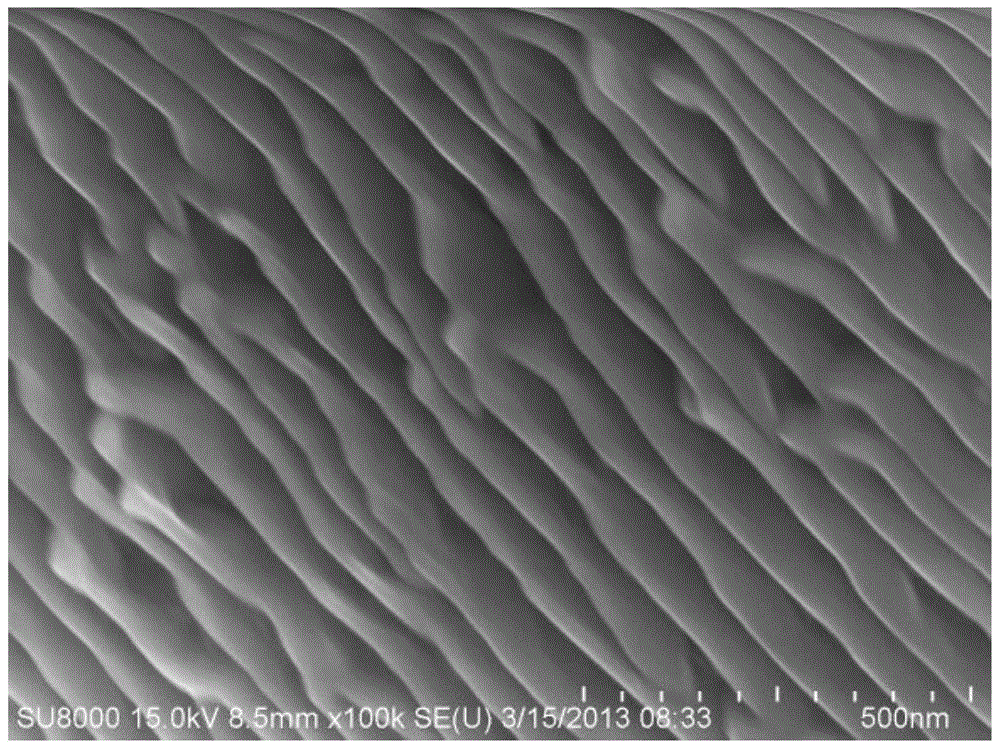

Chemical pd-plating process for stainless steel surface with excellent anticossive performance in non-oxidant medium

InactiveCN1932078AImprove passivation effectIncreased durabilityLiquid/solution decomposition chemical coatingChemical platingCompound (substance)

The present invention belongs to the field of surface treatment technology, and is especially chemical Pd-plating process for stainless steel surface with excellent anticorrosive performance in non-oxidant medium. The Pd-plated stainless steel is suitable for use in high temperature non-oxidant acidic medium environment. The chemical Pd-plating process includes surface pre-treatment and chemical plating, the surface pre-treatment includes deoiling and acid pickling, and chemical plating uses the plating solution comprising Pd salt Pd(NH3)4Cl2 in 1.5-5g / L accounting in PdCl2, stabilizer NH4Cl in 20-30 g / L, auxiliary complexing agent EDTA in 0-20g / L, surfactant Tween-20 in 0-0.002 ml / L, NH3 .H2O in 80-160 ml / L, reductant NaH2PO2 .H2O in 10-20g / L and water for the rest, of pH 9-10, for 30-60 min at 30-50 deg.c. The chemical Pd-plating process is simple.

Owner:BEIJING UNIV OF CHEM TECH

Plating solution for electroplating tungsten-molybdenum-nickel alloy coating on surface of petroleum-pumping component

The invention discloses a plating solution for electroplating a tungsten-molybdenum-nickel alloy coating on a surface of a petroleum-pumping component. The plating solution comprises, 80-84 g / L of sodium tungstate, 6-10 g / L of sodium molybdate, 14-18 g / L of nickel sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, and the balance being water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Method for preparing layered tin coatings in electrolytic deposition manner

ActiveCN105088290AThe composition of the plating solution is simplePlating process is easy to controlLayered structureTinning

The invention relates to a method for preparing layered tin coatings in an electrolytic deposition manner. According to the method, the problem that an existing tinning method can only prepare bright compact coatings is solved. The method comprises the steps of removing oil on a coated part in an alkaline manner, rinsing the coated part, and pickling the coated part; then rinsing the coated part again, and drying the coated part to obtain an electroplating negative pole and using elementary substance tin as an electroplating positive pole; and setting the electroplating current density as 2-5A / dm<2>, the electroplating temperature as 10-35 DEG C and the electroplating time as 3-9min to obtain the layered tin coatings. Plating solution comprises stannous mono sulphate, concentrated sulfuric acid, gelatin, additive and ascorbic acid. The method can be used for preparing tin coatings of a layered structure in the electrolytic deposition manner, the plating solution is simple in composition, and the electroplating process is easy to control. The method is applied to the field of material preparing.

Owner:HARBIN INST OF TECH

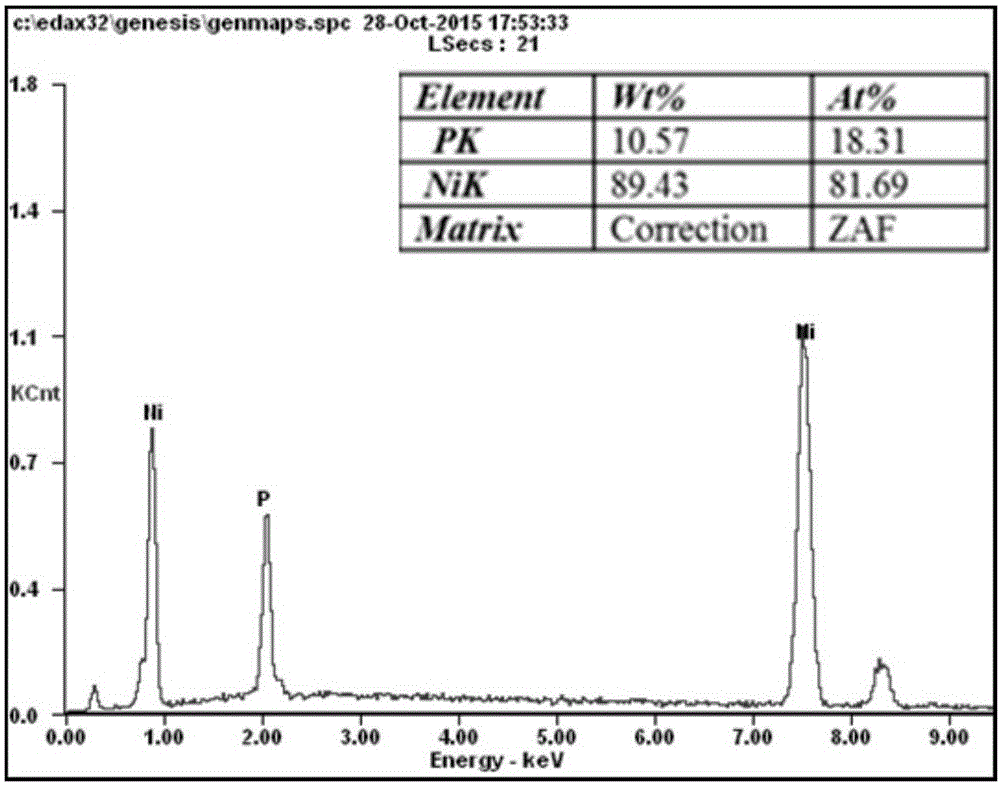

Nickel-phosphorus/nano V8C7 composite plating liquid

The invention discloses a nickel-phosphorus / nano V8C7 composite plating liquid. The plating liquid comprises the following components: 120-180 g / L of nickel sulfate, 10-30 g / L of nickel chloride, 30-50 g / L of sodium hypophosphite, 10-25 g / L of boric acid, 0.2-2 g / L of a complexing agent, 0.1-0.5 g / L of a brightening agent and 5-20 g / L of nano V8C7. Compared with the prior art, by adopting the composite plating liquid disclosed by the invention, a composite plate taking nickel-phosphorus amorphous alloy as a basal body and the nano V8C7 as a second phase can be prepared, and the surface is free of microcracks. The nickel-phosphorus / nano V8C7 composite plating liquid is high in abrasion resistance and corrosion resistance. The composite plating liquid is simple in composition, little in damage of reagents to the environment, stable in technology, simple in operation and high in current efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for improving binding force of plating by adopting magnetron sputtering

InactiveCN103805994AThe composition of the plating solution is simplePlating solution is stableVacuum evaporation coatingSputtering coatingCopper nickel alloyBinding force

A method for improving the binding force of a plating by adopting magnetron sputtering comprises the processes of plasma cleaning, magnetron sputtering of a copper-nickel alloy interlayer, and non-cyanide copper plating. The adoption of the plasma cleaning in the method can fully remove oil stains and oxides on the surface of the substrate in order to improve the combination of a preplating, and the adoption of the magnetron sputtering of the copper-nickel alloy interlayer can simply and greatly improve the binding force of the plating and the substrate.

Owner:WUXI XINSANZHOU STEEL

Electroplating solution and electroplating method for electroplating bright nickel-titanium alloy on motorcycle accessories

InactiveCN104195598AThe composition of the plating solution is simplePlating solution is stableHexavalent chromiumCopper

The invention discloses an electroplating solution and an electroplating method for electroplating bright nickel-titanium alloy on motorcycle accessories. The electroplating solution comprises the following components in weight ratios: 1) 220g / L nickel sulfate, 2) 80g / L nickel chloride, 3) 8g / L titanium oxysulfate, 4) 42g / L boric acid, 5) 10ml / L brightener, 6) 10ml / L softener, 7) 0.8ml / L wetting agents and the balance of distilled water or deionized water. By adopting the electroplating solution and the electroplating method for electroplating the bright nickel-titanium alloy on the motorcycle accessories, no cyanide, no chromium and no pollution can be achieved and the performance of the electroplating solution and the performance of a coating can both reach the coating effect of 'electroplating nickel + electroplating chrome and 'electroplating bright copper + electroplating bright nickel + electroplating chrome (with hexavalent chromium salts)'.

Owner:CHONGQING HENGKE MACHINERY MFG

Technique for producing alkaline zincate galvanizing additive

InactiveCN101191239AThe composition of the plating solution is simpleEasy to adjust the plating solutionBenzimidazoleChemistry

The invention provides a production technique for alkalinity zincate zinc-plating additive, wherein the hexamethylenetetramine is dissolved in the distilled water, in which the 2-thiol group benzimidazole is added, the chloroepoxy propane is added while stirring, the mixed liquid is heated up and refluxed for half an hour after the complete reaction. The invention has the advantages of simplifying ingredients of the bath, conveniently adjusting and controlling the bath for lowering cost and being applicable to the passivation of the low chromium, along with the environmental protection.

Owner:TIANJIN HANLONG ZINC PLATING

Electroplating liquid for electroplating bright nickel-titanium alloy on accessory of motorcycle and electroplating method

InactiveCN106435669AThe composition of the plating solution is simpleNon-toxicChromium freeCopper plating

The invention discloses electroplating liquid for electroplating bright nickel-titanium alloy on an accessory of a motorcycle. The electroplating liquid comprises the following components in specific weight ratio: 220 g / L of nickel sulfate, 80 g / L of nickel chloride, 8 g / L of titanyl sulfate, 42 g / L of boracic acid, 10 ml / L of a brightener, 10 ml / L of a softener, 0.8 ml / L of a wetting agent and the rest of distilled water or deionized water. The electroplating liquid for electroplating the bright nickel-titanium alloy on the accessory of the motorcycle and the electroplating method can be cyanide-free, chromium-free and pollution-free; and the performance of the electroplating liquid and the performance of an electroplated layer can achieve the effects of a plating layer of 'nickel plating+ chromium plating' and a plating layer of 'bright copper plating+ bright nickel plating+ chromium plating (with hexavalent chromium salt)'.

Owner:重庆帆玛机车制造有限公司

Technology for electroplating tungsten-cobalt-iron-cerium alloy on surface of structural steel

The invention discloses a technology for electroplating a tungsten-cobalt-iron-cerium alloy on a surface of structural steel. A plating solution adopted by the technology is composed of 32-36 g / L of cobalt sulfate, 80-84 g / L of sodium tungstate, 22-26 g / L of ferrous sulfate, 1.5-2.5 g / L of cerium sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, 4-6 mg / L of thiourea, and the balance being water. The technology comprises the steps of washing and activating the structural steel by removing oil; then putting the structural steel in the above plating solution to be used as a cathode; taking stainless steel as an anode; adjusting a pH value to 3.5-4.5 with acetic acid; heating to a temperature of 50-60 DEG C; controlling a current density at 12-16 A / dm<2> and electroplating for 20-30 minutes.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

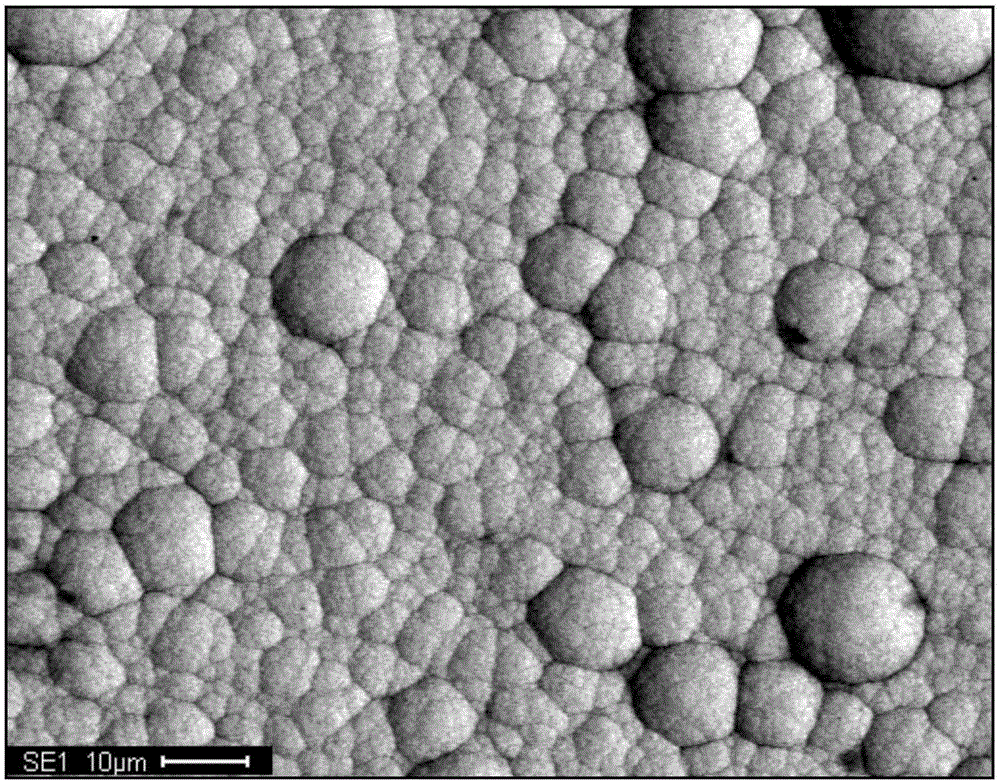

A kind of anti-ablation aluminum alloy cartridge and its preparation method

ActiveCN107255431BHigh melting pointCorrosion resistanceLiquid/solution decomposition chemical coatingCartridge ammunitionChemical platingAlloy substrate

The invention relates to an anti-ablation aluminum alloy cartridge and a preparation method thereof and belongs to the technical field of cartridge design and preparation. According to the anti-ablation aluminum alloy cartridge and the preparation method thereof, the situation that a Ni-P alloy layer is prepared on the surface of the aluminum alloy cartridge through chemical plating, and thus the anti-ablation capacity of the aluminum alloy cartridge is improved is firstly attempted. The designed and prepared aluminum alloy cartridge comprises an aluminum alloy substrate and the Ni-P alloy plated layer which is uniformly attached to the aluminum alloy substrate. The cartridge has the characteristics of being small in mass, excellent in conductive property and capable of resisting ablation and corrosion. The anti-ablation aluminum alloy cartridge and the preparation method thereof provide a complete idea for development of new generation ammunition.

Owner:CENT SOUTH UNIV

Cyanide-free bright silver plating solution and electroplating method

The invention discloses a cyanide-free bright silver plating solution and an electroplating method. The silver electroplating solution comprises 10-30 g / L of silver nitrate; 10 to 80 g / L of 2, 4-imidazolinedione; 5, 5-dimethyl hydantoin with a concentration of 40 to 100 g / L; 40-100 g / L of potassium carbonate; and 0.3-2 g / L of polyethylene glycol. According to the method, the specially designed cyanide-free silver plating solution is utilized, and the pulse current is adopted, so that the silver plating layer with excellent binding force and excellent plating layer surface performance is obtained on the copper substrate, especially the red copper substrate.

Owner:CHONGQING UNIV

A kind of method for preparing layered tin coating by electrodeposition

ActiveCN105088290BInhibition of volume expansionThe composition of the plating solution is simpleTinningPower flow

The invention relates to a method for preparing layered tin coatings in an electrolytic deposition manner. According to the method, the problem that an existing tinning method can only prepare bright compact coatings is solved. The method comprises the steps of removing oil on a coated part in an alkaline manner, rinsing the coated part, and pickling the coated part; then rinsing the coated part again, and drying the coated part to obtain an electroplating negative pole and using elementary substance tin as an electroplating positive pole; and setting the electroplating current density as 2-5A / dm<2>, the electroplating temperature as 10-35 DEG C and the electroplating time as 3-9min to obtain the layered tin coatings. Plating solution comprises stannous mono sulphate, concentrated sulfuric acid, gelatin, additive and ascorbic acid. The method can be used for preparing tin coatings of a layered structure in the electrolytic deposition manner, the plating solution is simple in composition, and the electroplating process is easy to control. The method is applied to the field of material preparing.

Owner:HARBIN INST OF TECH

Method for electroplating cobalt tungsten molybdenum iron alloy coating on surface of oil pumping part

The invention discloses a method for electroplating a cobalt tungsten molybdenum iron alloy coating on surface of an oil pumping part. A liter of plating liquid comprises the following components: 56-60g ferrous sulphate, 14-18g sodium tungstate, 6-10g sodium molybdate, 8-12g cobaltous sulfate, 8-10g sodium hypophosphate, 13-17g boric acid, 20-24g ammonium sulfate, 30-34g tartrate, 11-15g potassium pyrophosphate, 10-14g ascorbic acid, 1-3ml formaldehyde, 2-4ml dimethyl alkynol, 2-4mg thiourea and the balance of water. The method comprises the following steps: cleaning the oil pumping part and activating, placing in the plating liquid as cathode, taking graphite as anode, adjusting the pH value to 7.5-8.5 by ammoniacal liquor, heating to 65-75 DEG C, and electroplating at the current density being 12-16A / dm<2> for 20-30 minutes.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Plating liquid for electroplating tungsten-molybdenum-cobalt-iron alloy plating on surface of oil-pumping part

A disclosed plating liquid for electroplating a tungsten-molybdenum-cobalt-iron alloy plating on the surface of an oil-pumping part comprises, 56-60 g / L of ferrous sulphate, 14-18 g / L of sodium tungstate, 6-10 g / L of sodium molybdate, 8-12 g / L of cobalt sulfate, 8-10 g / L of sodium hypophosphite, 13-17 g / L of boric acid, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of Potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimehtyl hexynol, 2-4 mg / L of thiourea, and the balance water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Boron-tungsten-iron-nickel alloy electroplating liquid

InactiveCN101928968BThe composition of the plating solution is simpleEasy to operateSulfateNickel alloy

Owner:合鸿新材科技有限公司

An amorphous iron-phosphorus alloy/v8c7 composite coating and its electroplating process

An amorphous iron-phosphorus alloy / V8C7 composite coating and its electroplating process, the matrix material of the composite coating is an amorphous Fe-P alloy, the Fe content is 60-89wt% of the composite coating, and the P content is 10% of the composite coating -30wt%, the composite coating contains solid particle V8C7, the content is 1-10wt% of the composite coating. The invention also includes the electroplating process of the amorphous iron-phosphorus alloy / V8C7 composite coating. The amorphous iron-phosphorus alloy / V8C7 composite coating of the invention has the properties of V8C7 and amorphous alloy, and has the advantages of high strength, high plasticity, high wear resistance, high transition temperature and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Plating solution for electroplating molybdenum-nickel-cerium alloy plating on surface of oil-pumping part

The invention discloses a plating solution for electroplating a molybdenum-nickel-cerium alloy plating on the surface of an oil-pumping part. The plating solution comprises, 36-40 g / L of nickel sulfate, 6-10 g / L of sodium molybdate, 1.5-2.5 g / L of cerium sulfate, 8-10 g / L of sodium hypophosphite, 13-17 g / L of boric acid, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 mL / L of formaldehyde, 2-4 mL / L of dimethyl hexynol, 2-4m g / L of thiourea, and the balance water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Cobalt-tungsten-nickel-phosphorus alloy electroplating liquid

InactiveCN101928967BHarm reductionGood corrosion resistance and friction resistancePhosphorous acidSodium tungstate dihydrate

The invention discloses cobalt-tungsten-nickel-phosphorus alloy electroplating liquid which is prepared from the following ingredients: 10-30g / L of sodium tungstate, 1-5g / L of cobalt sulfate, 120-180g / L of nickel sulfate, 5-20g / L of phosphorous acid, 60-100g / L of complexing agent and 2-12g / L of bright additive, making the solution up to 1000ml after deionized water added. Compared with the prior art, the electroplating liquid of the invention has the following advantages: the plating prepared from the electroplating liquid is amorphous, has no microcracks on the surface and has good corrosionresistance and abrasion resistance; the chemical reagents do little harm to the environment; the electroplating liquid has stable process and simple ingredients, is convenient to operate and can be stored for a long term after preparation; and the electroplating liquid does not exhaust acid mist during working and has high current efficiency.

Owner:合鸿新材科技有限公司

Cobalt-tungsten-iron-nickel alloy electroplating liquid

InactiveCN101532152BGood corrosion resistance and friction resistanceHarm reductionSimple componentIron–nickel alloy

The invention discloses cobalt-tungsten-iron-nickel alloy electroplating liquid and belongs to the field of material surface treatment. A formula of the electroplating liquid comprises: 1 to 5 grams / litre of cobalt sulfate, 20 to 60 grams / litre of sodium tungstate, 10 to 50 grams / litre of ferrous sulfate, 20 to 60 grams / litre of nickel sulfate, 10 milliliters / litre of 28 percent oxalic acid, 5 to15 grams / litre of ammonia sulfate, 20 to 40 grams / litre of a complexing agent, 1 to 8 grams / litre of a stabilizing agent, 2 to 5 milliliters / litre of a brightness additive and 1,000 milliliters of deionized water. The surface of an electroplating layer obtained by using the cobalt-tungsten-iron-nickel alloy electroplating liquid has no microcrack and has good corrosion and friction resistance; each chemical reagent of the electroplating liquid has small harm to the environment; the process is stable; the electroplating liquid has simple components, is convenient to operate and can be stored for a long time after being prepared; and in addition, the electroplating liquid emits no acid mist in the working process and has high current efficiency.

Owner:乔瀚文

Technique for producing alkaline zincate galvanizing additive

InactiveCN101191243AThe composition of the plating solution is simpleEasy to adjust the plating solutionWater bathsAlkalinity

The invention provides a production technique for alkalinity zincate zinc-plating additive, wherein the hexamethylenetetramine is dissolved in the distilled water, in which the 2-thiol group benzimidazole is added, after the complete reaction the chloroepoxy propane is added with stirring, the mixed liquid is refluxed in a water bath with the temperature of 80 DEG C for half an hour. The invention has the advantages of simplifying ingredients of the bath, conveniently adjusting and controlling the bath for lowering cost and being applicable to the passivation of the low chromium, along with the environmental protection.

Owner:TIANJIN HANLONG ZINC PLATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com