Method for preparing Pt-based catalyst by pulse electrodeposition under ultrasonic conditions

A pulse electrodeposition and catalyst technology, applied in the field of electrodeposition, can solve the problems of Pt-based catalyst falling off, affecting the catalytic effect, particle aggregation, etc., and achieving the effects of improving wetting conditions, enhancing bonding strength, and bonding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

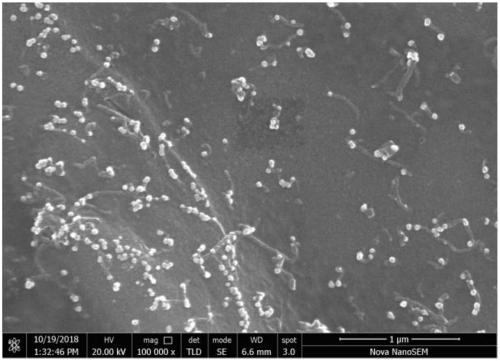

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of PtRu / C catalyst by pulse electrodeposition under ultrasonic conditions:

[0033] The first step, the surface pretreatment of the base material

[0034] Carry out pretreatment (degreasing, activation, water washing, drying, etc.) on the foamed nickel base material in sequence.

[0035] The second step is to prepare the carbon material suspension

[0036] Preparation of carbon slurry: According to the ratio of adding 2 mg of activated carbon black per milliliter of absolute ethanol, add activated carbon black to absolute ethanol to prepare an ethanol suspension containing activated carbon black. Then add Nafion solution according to the ratio of the volume percentage of activated carbon black ethanol suspension to Nafion solution of 1:100, and ultrasonically disperse for 20 minutes to form carbon slurry.

[0037] The third step, the preparation of the working electrode

[0038] Pipette 160 μL of the above carbon slurry per square centimeter an...

Embodiment 2

[0043] Example 2: Preparation of PtPd / C catalyst by pulse electrodeposition under ultrasonic conditions:

[0044] The first step, the surface pretreatment of the base material

[0045] Carry out pretreatment (degreasing, activation, water washing, drying, etc.) on the copper base material in sequence.

[0046] The second step is to prepare the carbon material suspension

[0047] Preparation of carbon slurry: According to the ratio of adding 4 mg of activated carbon black per milliliter of absolute ethanol, add activated carbon to absolute ethanol to prepare an ethanol suspension containing activated carbon black. Then add the Nafion solution according to the ratio of the volume percentage of the ethanol suspension of activated carbon black to the Nafion solution of 2:100, and ultrasonically disperse for 40 minutes to form a carbon slurry.

[0048] The third step, the preparation of the working electrode

[0049] Pipette 105 μL of the above-mentioned active carbon slurry per...

Embodiment 3

[0054] Example 3: Preparation of PtAg / C catalyst by pulse electrodeposition under ultrasonic conditions:

[0055] The first step, the surface pretreatment of the base material

[0056] Carry out pretreatment (degreasing, activation, water washing, drying, etc.) on the iron matrix material in sequence.

[0057] The second step is to prepare the carbon material suspension

[0058] Preparation of carbon slurry: According to the ratio of adding 8 mg of activated carbon black per milliliter of absolute ethanol, add activated carbon to absolute ethanol to prepare an ethanol suspension containing activated carbon black. Then, according to the ratio of the volume percentage of the ethanol suspension of activated carbon black to the Nafion solution of 4:100, add the Nafion solution and ultrasonically disperse for 80 minutes to form a carbon slurry.

[0059] The third step, the preparation of the working electrode

[0060] Pipette 300 μL of the above carbon slurry per square centimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com