Cyanide-free bright silver plating solution and electroplating method

A solution and silver electroplating technology, applied in electrolytic components, electrolytic processes, cells, etc., can solve the problems of polluted environment, poor stability, poor dispersion ability, etc., and achieve the effect of simple plating solution, good stability, and reduced harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Configuring a cyanide brightening silver plated solution: silver nitrate 20g / L, 2,4-imidazolinothenone 20g / L, 5,5-dimethylcyl urea 60 g / L, potassium carbonate 60g / L, PE Alcohol (400) 1 g / l.

[0027] Cleaning the copper base: The pressure of the potassium hydroxide solution of 10% is provided, and the substrate is placed in a solution of 5 min, water washing, and the volume fraction is 20% sulfuric acid solution, and the substrate is placed in a solution for 10 min, and the water was washed dried.

[0028] Put the processed substrate into the electroplated solution, the constant temperature water bath 40 ° C, the cathode current density is 0.3A / DM 2 The pulse width of the single pulse power supply is 30s, the duty cycle is 25%, and the electroplating is stopped 5 times in the pulse cycle (the plating layer reaches a suitable thickness).

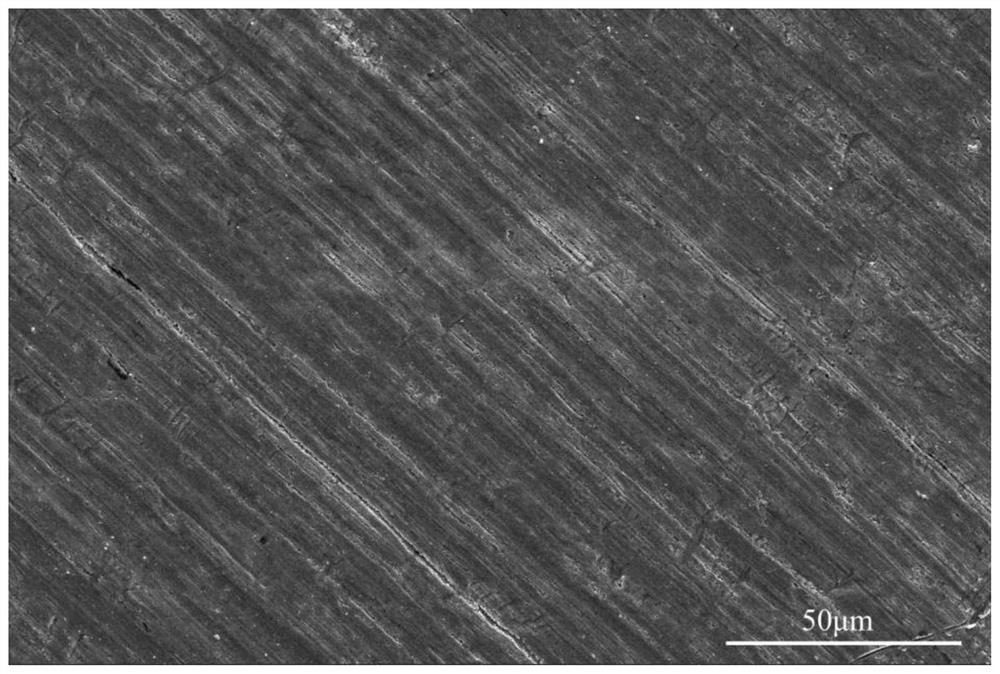

[0029] The surface of the silver plating surface of the present embodiment has a micro-morphology SEM map figure 1 As shown, t...

Embodiment 2

[0032] Configuring a cyanopide brightening silver plated solution, silver nitrate 20g / L, 2,4-imidazolinonidone 50 g / l, 5,5-dimethylcyl urea 60 g / L, potassium carbonate 60g / L, PE 2 Alcohol (400) 1 g / l.

[0033] Cleaning the copper base: The pressure of the potassium hydroxide solution of 10% is provided, and the substrate is placed in a solution of 5 min, water washing, and the volume fraction is 20% sulfuric acid solution, and the substrate is placed in a solution for 10 min, and the water was washed dried.

[0034] Put the processed substrate into an electroplated solution, a constant temperature water bath 40 ° C, the control cathode current density is 0.3A / DM 2 The pulse width of the single pulse power supply is 30s, the duty ratio is 25%, and the electroplating is stopped after the pulse cycle is 5 times.

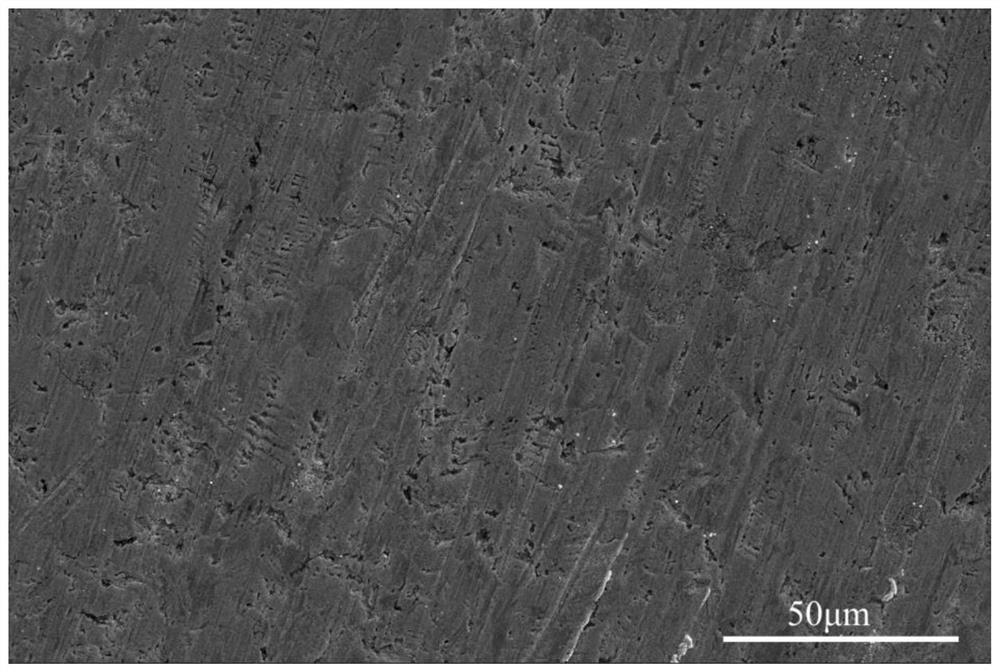

[0035] Silver plating surface micro morphology SEM map figure 2 As shown, the surface is equally confirmed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com