Patents

Literature

98results about How to "Will not generate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid

The invention provides a preparation method and an electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid, which relates to electroplating liquid and electroplating technology. The invention solves the problems of poor stability of the traditional trivalent chromium electroplating liquid, low precipitating and depositing rate of harmful gas in an electroplating process, more components of the electroplating liquid, sensitivity for impurities, poor corrosion resistance of an electroplating layer, and the like. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid mainly comprises the following components of main salt, a complexation stabilizing agent, a combined additive, a buffering agent and a conducting salt. The electroplating liquid can work at normal temperature, thereby saving energy resources and having simple technology and high deposition rate, wherein the deposition rate can reach above 0.22micron.min<-1> under 6A / dm<2>. An anode of the invention is a Ti-based rare-metal tantalum-iridium-titanium anode, the anode oxygen-evolution overpotential is low, and harmful hexavalent chrome can not be generated. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid has good corrosion resistance and high stability.

Owner:HARBIN INST OF TECH

Road dust inhibitor and preparation method thereof

InactiveCN104449579AWith moisturizing functionWith bonding functionOther chemical processesCarrying capacityAnti freezing

The invention discloses a road dust inhibitor and a preparation method thereof. The road dust inhibitor is characterized in that the raw materials of the road dust inhibitor comprises surface active agents, stabilizers, hydrophilic agents, thickeners, anti-freezing auxiliaries, antibacterial agents and water. The preparation method comprises, firstly, adding an appropriate amount of water into a reactor; secondly, adding the surface active agents and the stabilizers in; thirdly, after the surface active agents and the stabilizers are fully dissolved, slowly adding the hydrophilic agents and the thickeners in and stirring to achieve dissolution; fourthly, adding the anti-freezing auxiliaries and the antibacterial agents in; lastly, adding the residue water in until reaching a designated concentration. By means of the surface active agent, the road dust inhibitor can form a layer of isolating film on the contact surface between dust and air, and the isolating film has high water carry capacities and adhesive performance; by adding a small amount of salt, the road dust inhibitor obtain certain anti-freezing and antibacterial effects.

Owner:HEFEI UNIV OF TECH

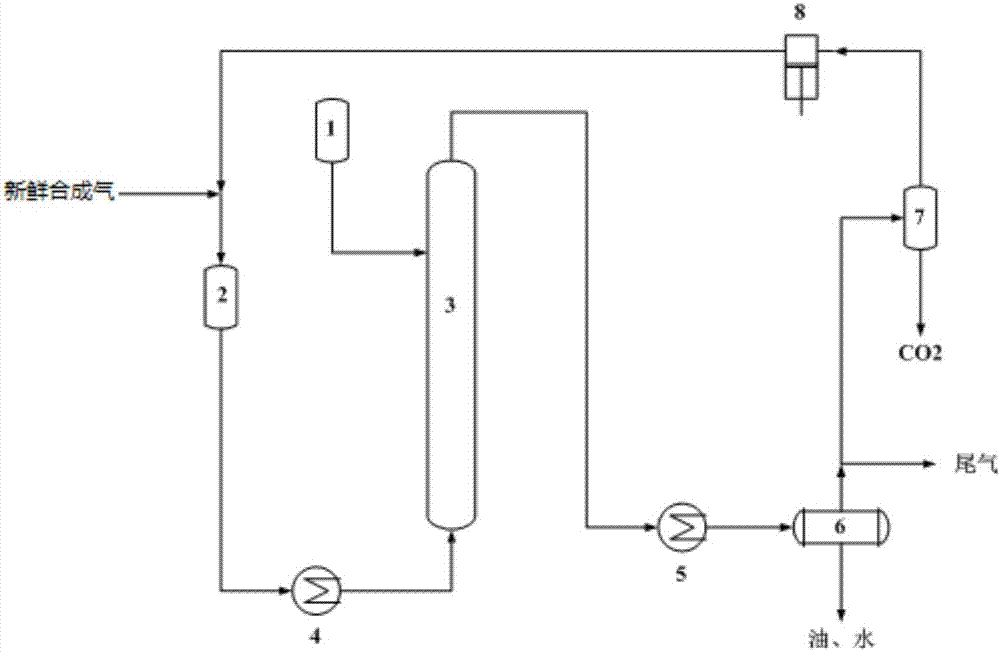

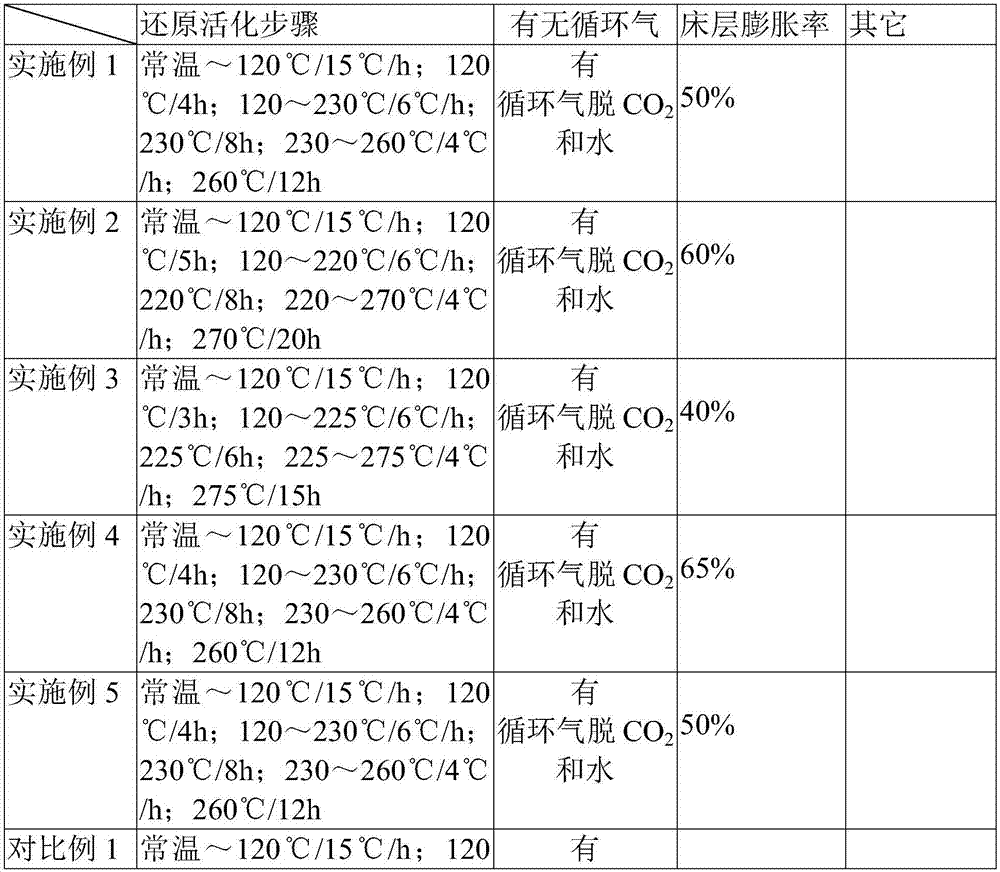

Reduction method for a Fischer-Tropsch synthesis iron-based catalyst

ActiveCN107149948AHigh activityLow selectivityCatalyst activation/preparationLiquid hydrocarbon mixture productionFluidized bedRoom temperature

The present invention relates to the field of Fischer-Tropsch synthesis iron-based catalyst reduction, and discloses a reduction method for a Fischer-Tropsch synthesis iron-based catalyst. The reduction method comprises: in the presence of a reducing gas, carrying out programmed heating reduction on Fischer-Tropsch synthesis iron-based catalyst particles in a fixed fluidized bed reactor, wherein the programmed heating reduction comprises that the heating rate is 10-20 DEG C / h and constant temperature treatment is performed for 2-8 h at a temperature of 120 DEG C when the temperature is from room temperature to 120 DEG C, the heating rate is 5-10 DEG C / h and constant temperature treatment is performed for 3-10 h at a temperature of 220-230 DEG C when the temperature is from 120 DEG C to (220-230) DEG C, and the heating rate is 3-5 DEG C / h and constant temperature treatment is performed for 10-30 h at a temperature of 260-280 DEG C when the temperature is from (220-230) DEG C to (260-280) DEG C. With the reduction method of the present invention, the Fischer-Tropsch synthesis iron-based catalyst can be smoothly subjected to the reduction reaction so as to reduce the influence on the water and the catalyst strength, and with the application of the reduced catalyst in the Fischer-Tropsch synthesis, the advantages of no breaking, high catalyst activity, low CO2 selectivity and low low-carbon hydrocarbon selectivity can be provided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

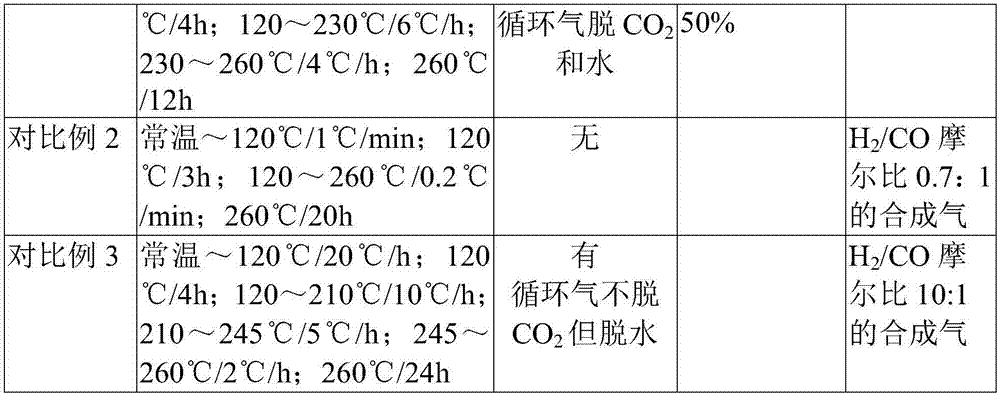

Method and device for producing milk foam or warm milk drinks

InactiveCN1682586AEasy to cleanWill not generateMilk preparationMilk treatmentMechanical engineeringFood science

A device comprises a pump (2) for suctioning milk from a container (1) via a suction line (3); an air supply line (5) connected to an air quantity controller (6); a continuous flow heater (4) located in the suction line; and a throttle valve (9) associated with outlet line (7). The air quantity controller opens into suction line or outlet line. The continuous flow heater takes a labyrinth form and is equipped with a heater element whose temperature is controllable, so that the temperature of the milk or the milk / air mixture can be adjusted. An independent claim is included for the continuous flow heater.

Owner:STEINER WEGGIS AG

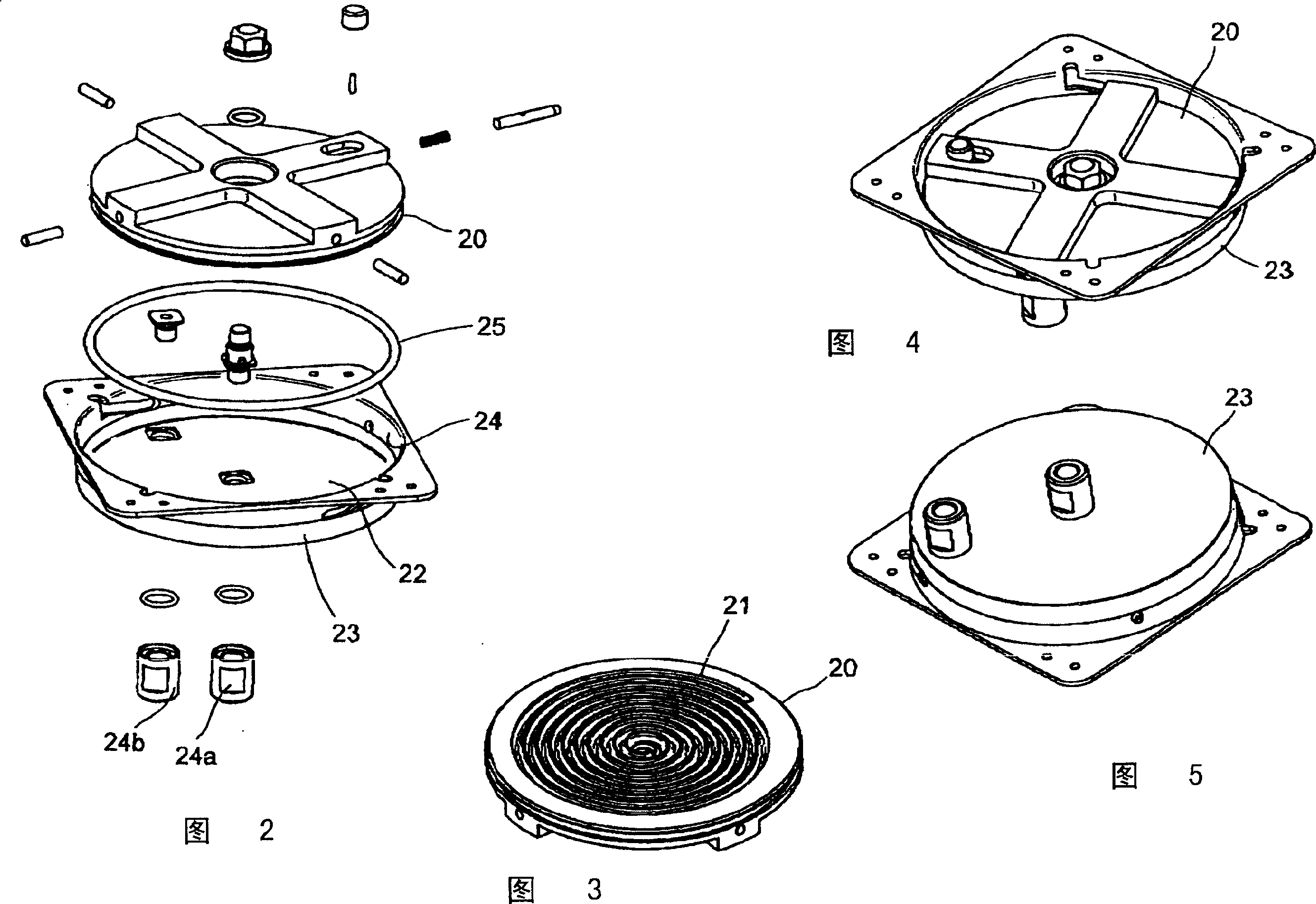

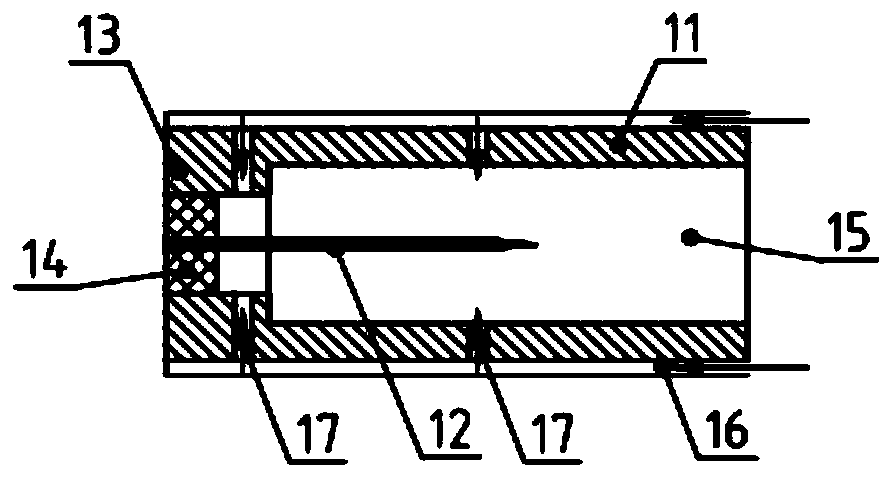

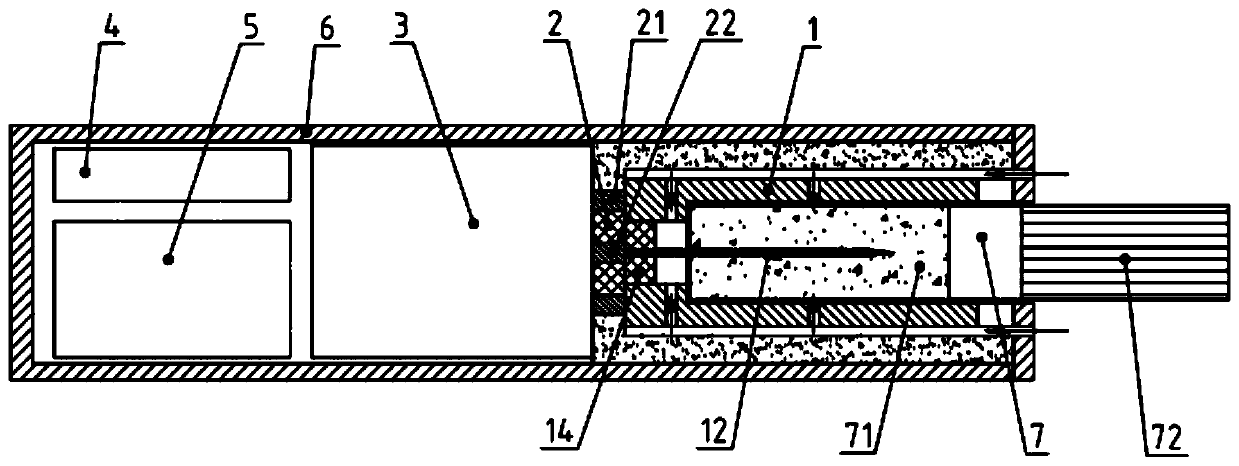

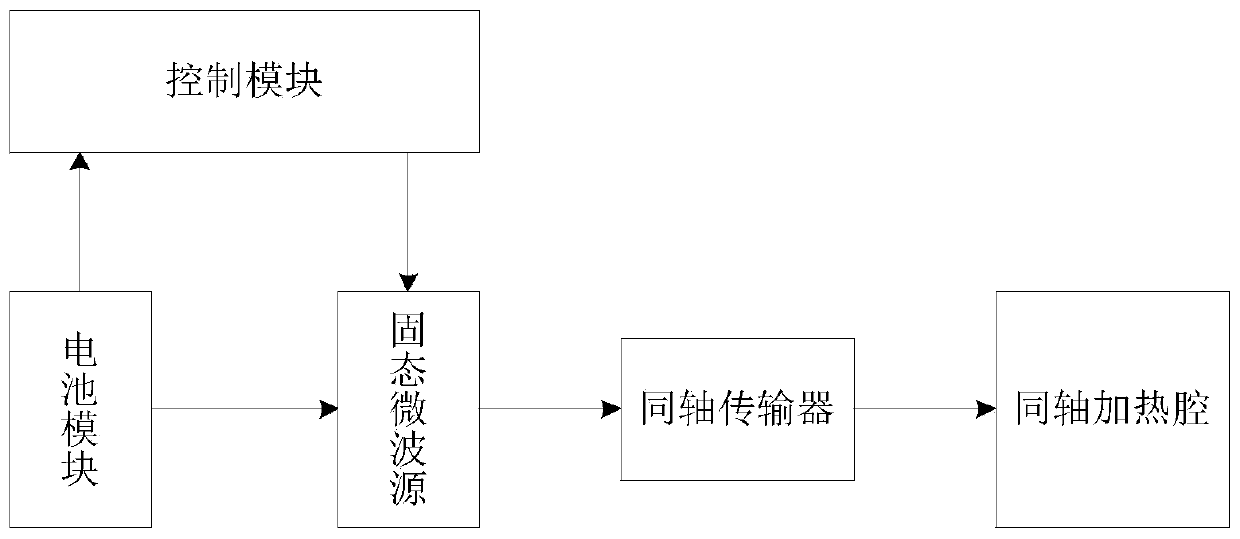

Coaxial heating chamber and electronic cigarette device with coaxial heating chamber

PendingCN110141002AHeating evenlyThere will be no local high temperatureTobacco devicesElectrical conductorElectronic cigarette

The invention discloses a coaxial heating chamber and an electronic cigarette device with the coaxial heating chamber. The electronic cigarette device with the coaxial heating chamber includes a coaxial heating chamber which is formed by the fact that an outer conductor chamber is regarded as a chamber, and an inner conductor column which is regarded as a column and inserts from one end of the outer conductor chamber into the outer conductor chamber; and a microwave source from one end of the inner conductor column inserted into the outer conductor chamber into the coaxial heating chamber to conduct microwave transmission to achieve the heating of microwave to a tobacco. A coaxial transmitter and the coaxial heating chamber are used, microwaves with the frequency of 915MHz and 2.45GHz canbe transmitted in the coaxial transmitter and the coaxial heating chamber, and therefore, a relatively mature solid-state microwave device can be used, especially 915MHz electrical conversion efficiency is higher; the size of the device can be effectively controlled; and due to the fact that the microwave has no temperature, through high frequency alternating electric field, polar molecules in thetobacco is made directly to move and heat, tobacco overall temperature is controlled in 200~300 DEG C, local high temperature does not exist, higher temperature does not exist in the overall coaxialheating chamber and the tobacco, cracking does not occur, and aldehyde or other harmful substances cannot be produced.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

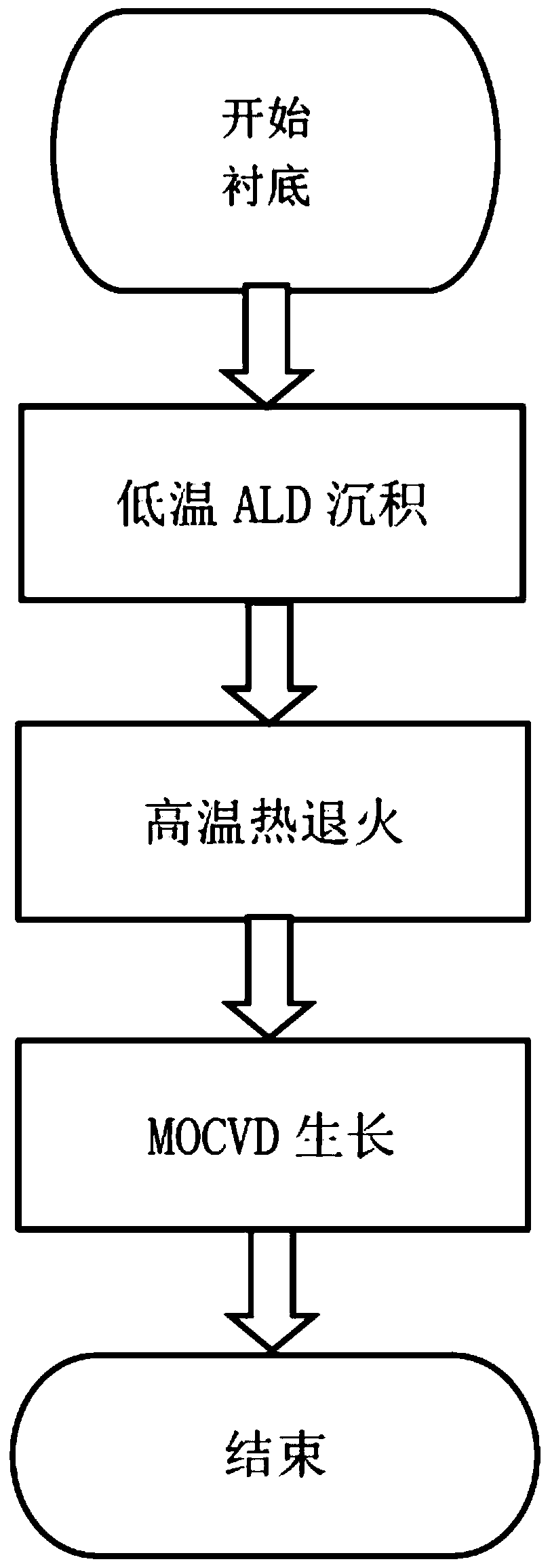

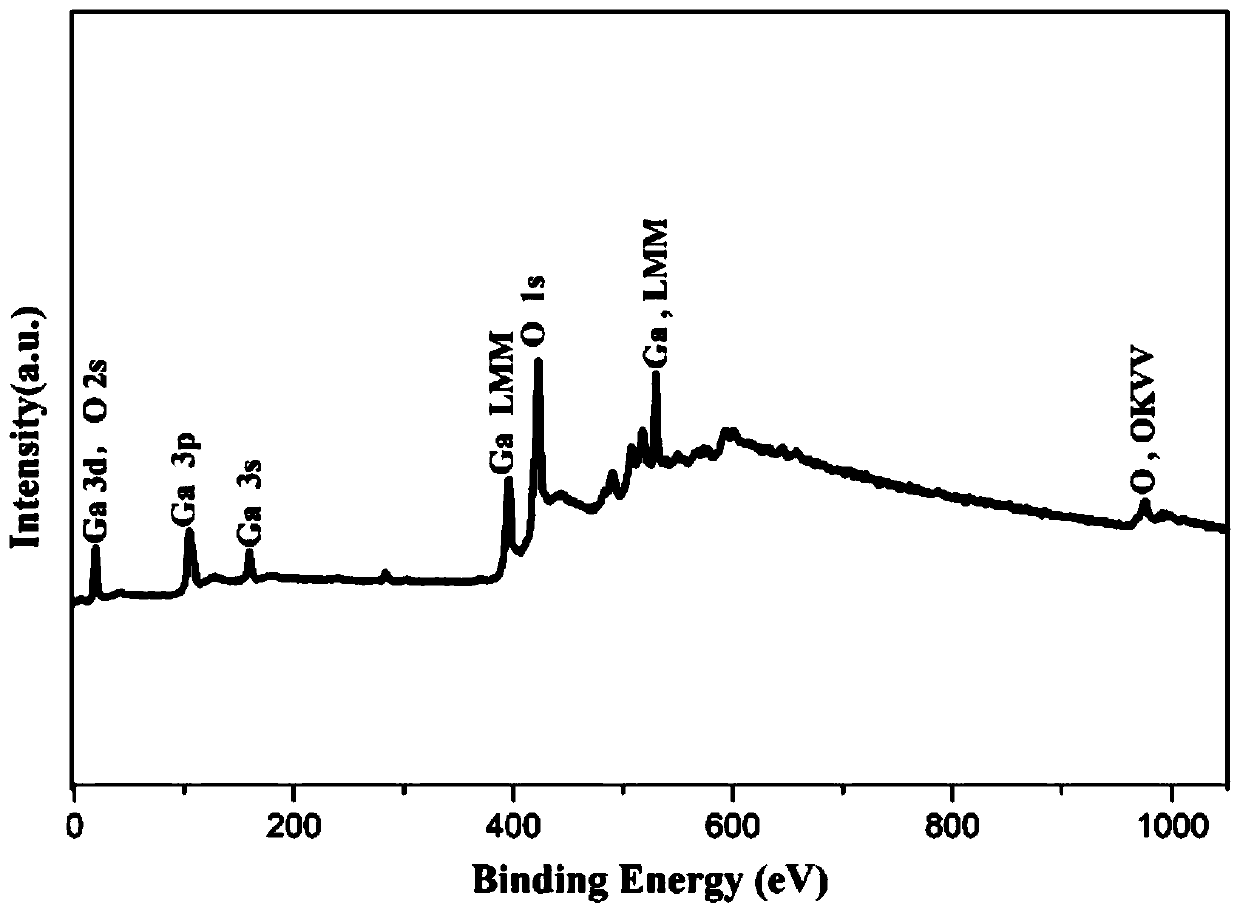

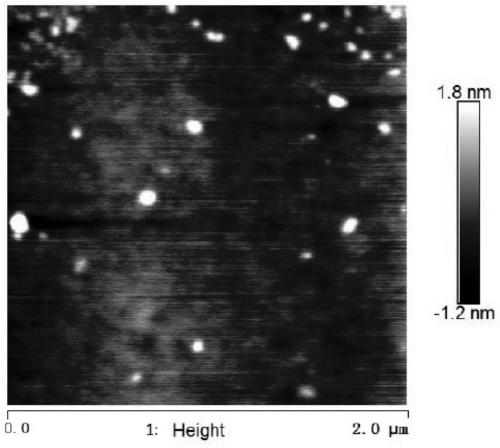

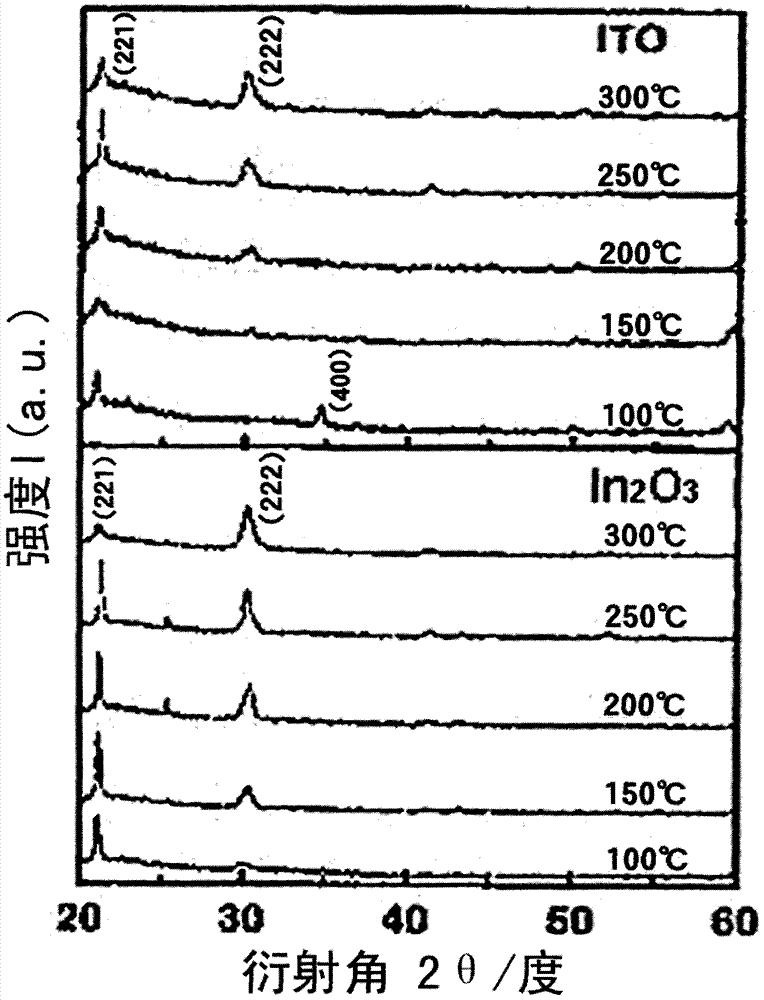

Method for preparing beta-Ga2O3 film

ActiveCN110195217AHigh activityImprove crystal qualityChemical vapor deposition coatingPhase mixingGas phase

The invention provides a method for preparing beta-Ga2O3 film and belongs to the technical field of micro-electronics. The problems of phase mixing and poor crystalline quality during preparation of the beta-Ga2O3 film are solved. The method comprises the steps that atomic layer deposition is reinforced through plasma, Ga2O3 film is grown on sapphire substrate, then high-temperature annealing recrystallization is conducted, metastable Ga2O3 is converted into stable Ga2O3, and finally the beta-Ga2O3 film is grown through metal organic chemical vapor deposition technology. The method for preparing the single-phase beta-Ga2O3 film can lay the foundation for preparing thick beta-Ga2O3 materials and devices.

Owner:BEIJING UNIV OF TECH

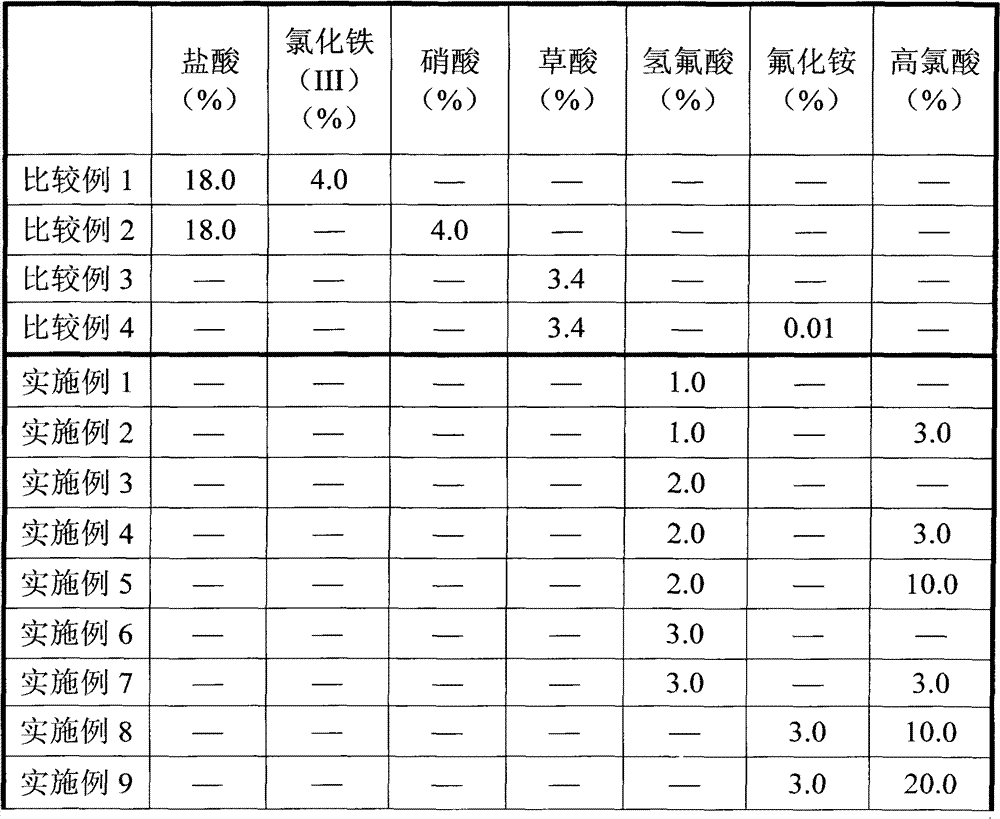

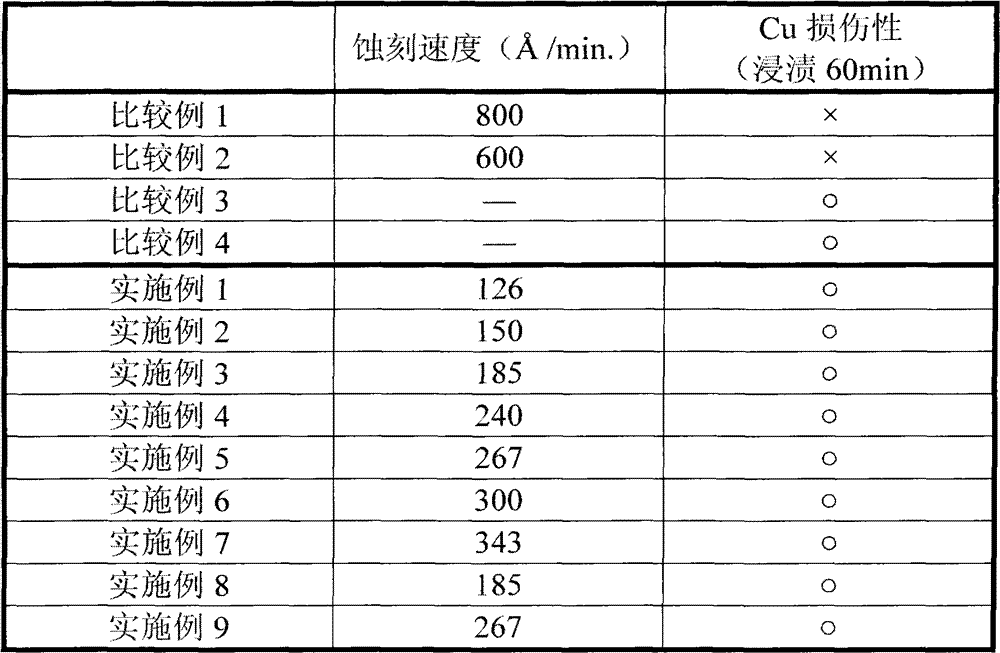

Etching solution composition for transparent conductive film

InactiveCN102732254AWill not generateCable/conductor manufactureSurface treatment compositionsTransparent conducting filmAqueous solution

The present invention provides an etching solution composition for etching crystalline transparent conductive films which enables etching of a crystalline ITO film without damaging copper and / or copper alloy used in electrode materials. Etching solution compositions for etching crystalline transparent conductive films described herein is consist of an aqueous solution that comprises 1-10 wt % of a fluorine compound.

Owner:KANTO CHEM CO INC

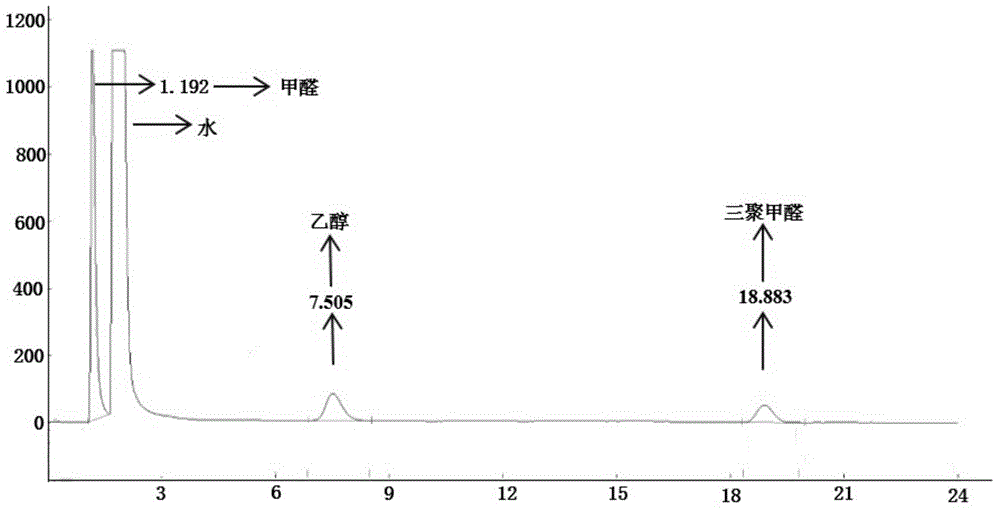

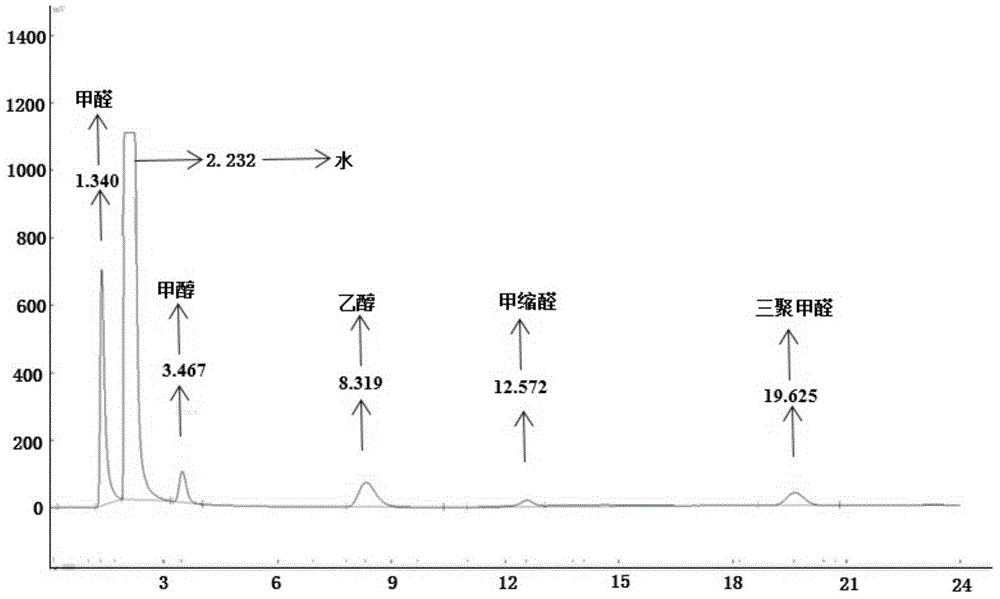

Method for synthesizing trioxymethylene

InactiveCN105218513AAvoid consumptionHigh latent heat of vaporizationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventDimethoxymethane

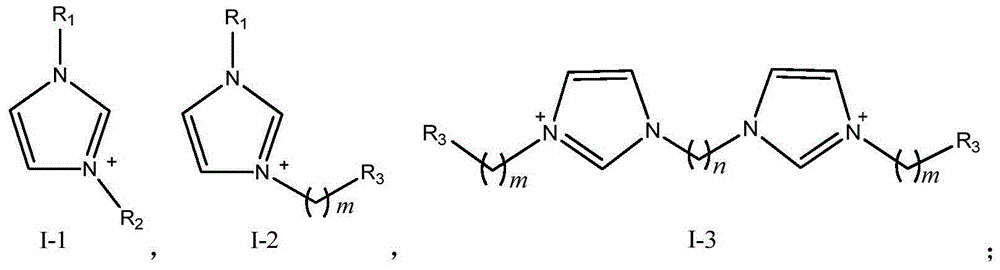

The invention provides a method for synthesizing trioxymethylene. The method comprises the step of carrying out a reaction at 30-150 DEG C for 0.1-5 hours to synthesize trioxymethylene by using an ionic liquid as a solvent and a catalyst and solid paraformaldehyde as a raw material, wherein the use amount of the solid paraformaldehyde is not more than 80% of total mass of the ionic liquid and the solid paraformaldehyde. By using the solid paraformaldehyde as the raw material and the ionic liquid as the solvent and the catalyst, the method provided by the invention is free of byproducts such as methyl formate, methanol, methylal and the like, and can remarkably improve the balanced yield of trioxymethylene and reduce the energy consumption, and the ionic liquid can be repeatedly used, so that the production cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

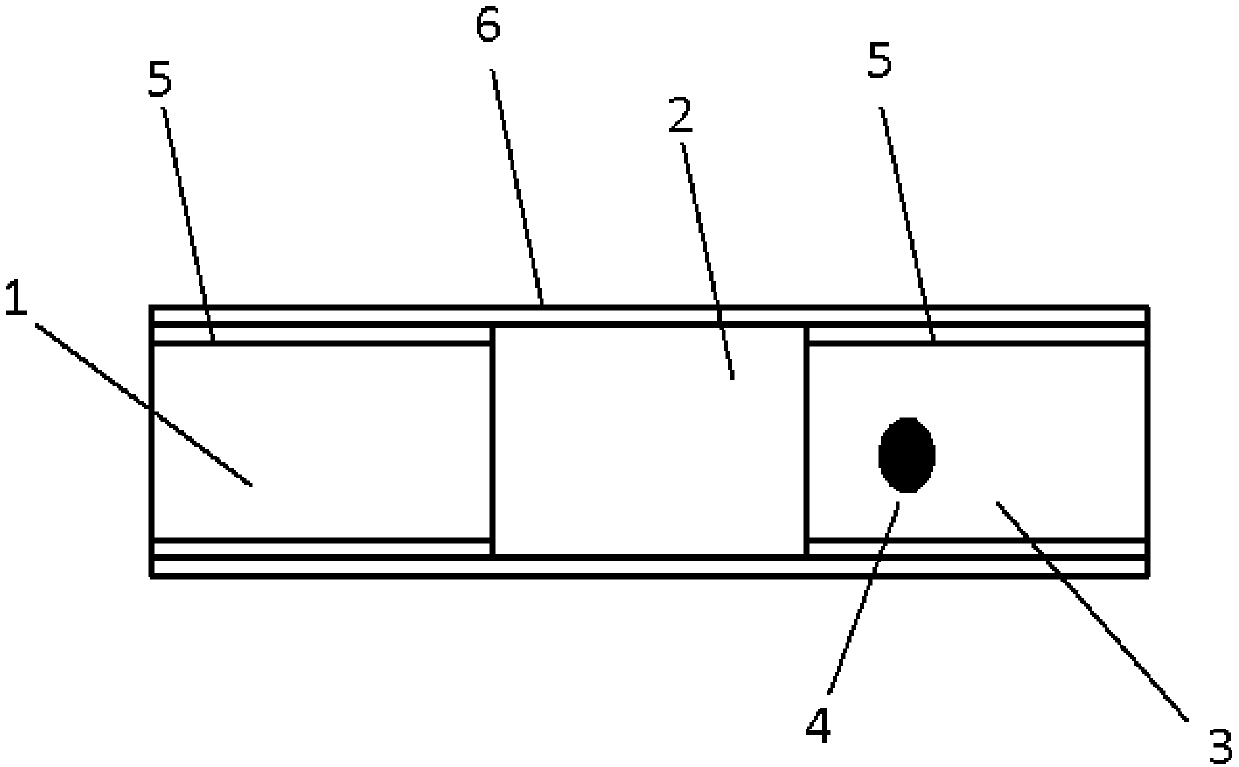

Color-changeable temperature developing ternary composite filter rod

ActiveCN107772528AIncrease temperatureNovel and unique pumping experienceTobacco smoke filtersCellulose diacetateComposite filter

The invention provides a color-changeable temperature developing ternary composite filter rod. The filter rod comprises a first cellulose diacetate filter rod section (1), a hollow section (2) and a second cellulose diacetate filter rod section (3) which are sequentially connected in an end-to-end manner, wherein the hollow section contains a cigarette blast bead, and the cigarette blast bead (4)comprises a fragile casing containing flavors and fragrances. The filter rod is characterized in that a thermochromic substance is added in each one of the sections, and the thermochromic temperatureof the thermochromic substance is equal to or higher than the heat volatilization temperature of the flavors and fragrances. The smoke temperature can be directly displayed through color change of thethermochromic substance, and a user can accurately master the opportunity of crumbing the cigarette blast ball to obtain the best flavor release effect.

Owner:CHINA TOBACCO YUNNAN IND

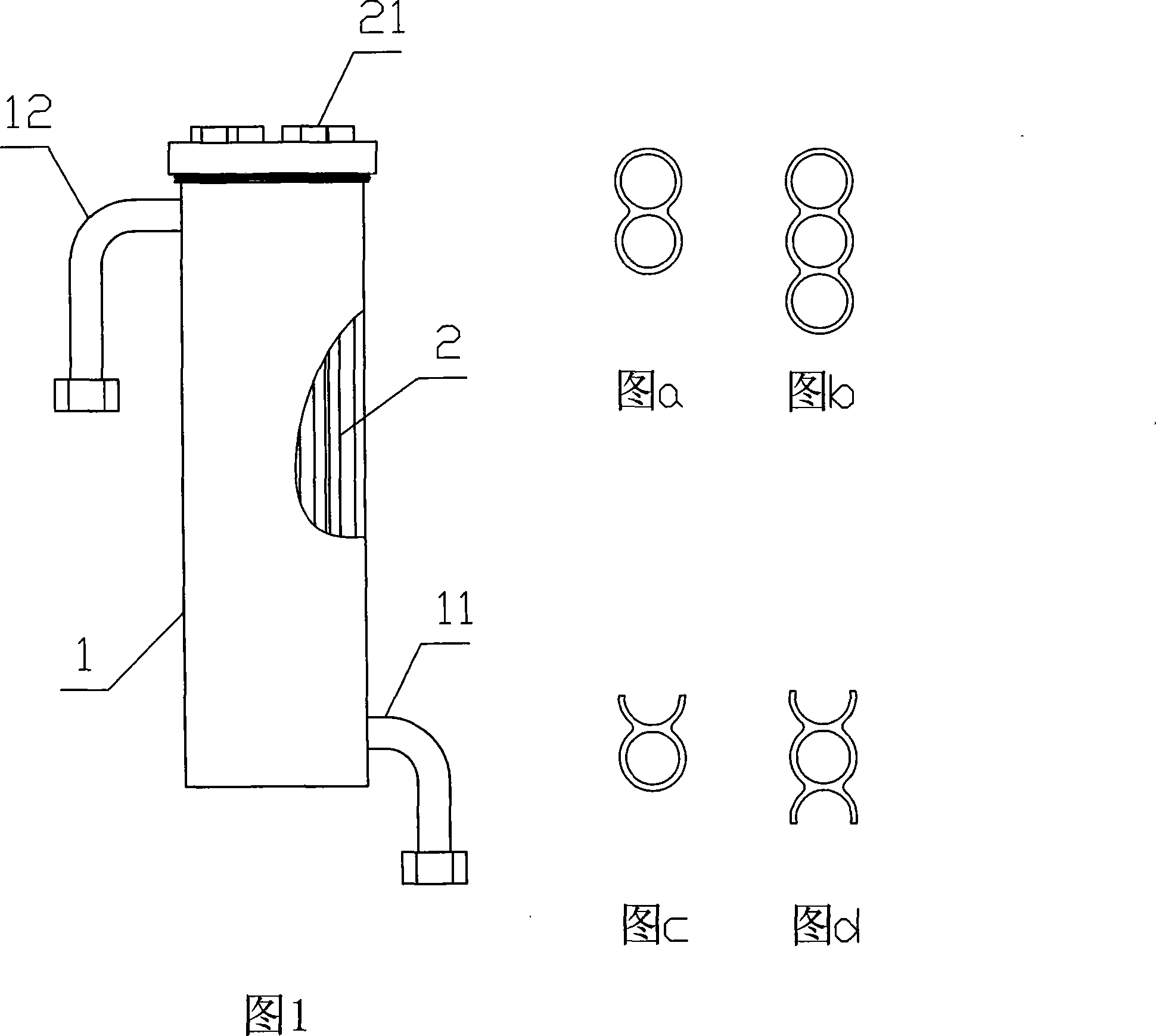

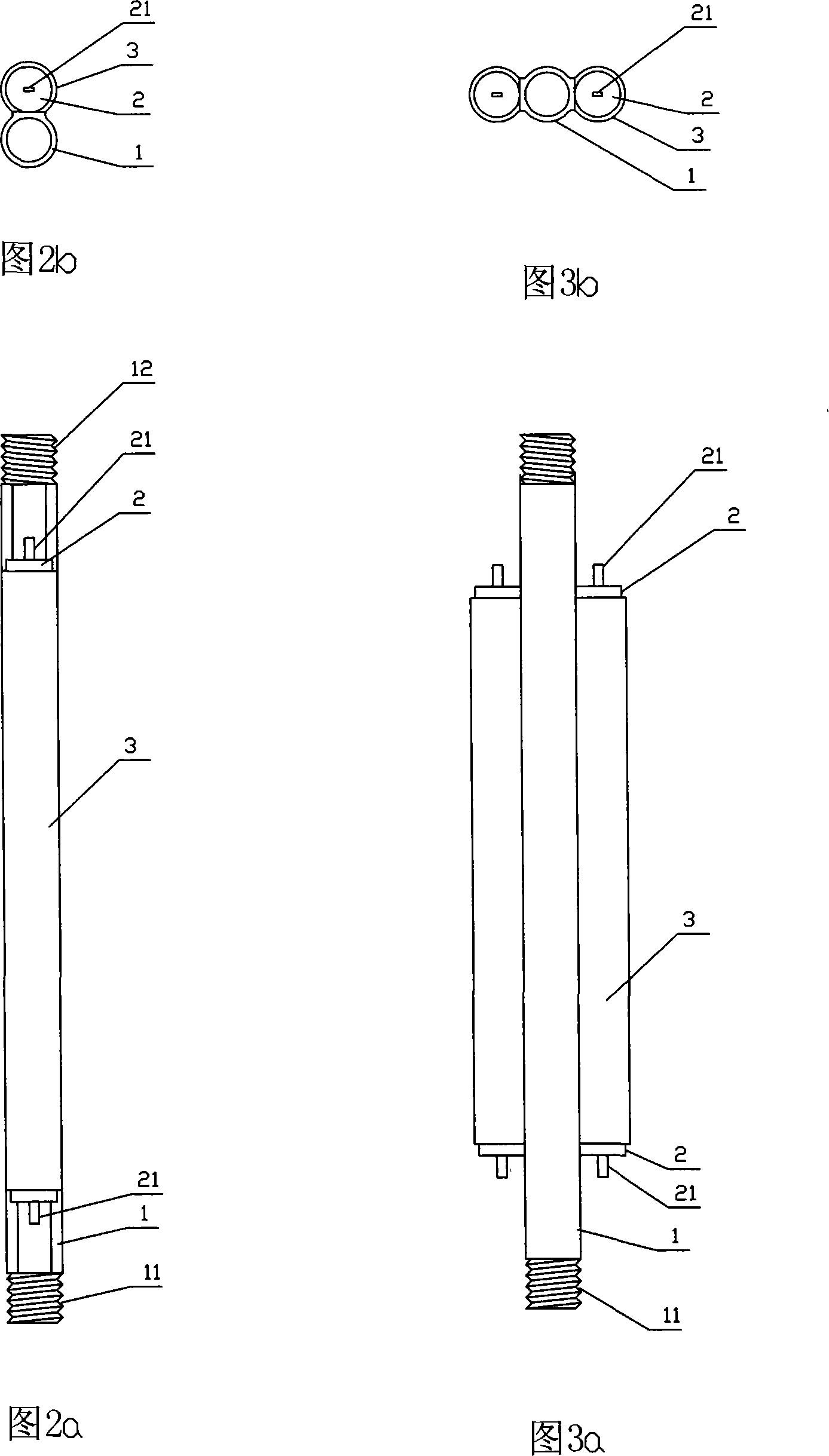

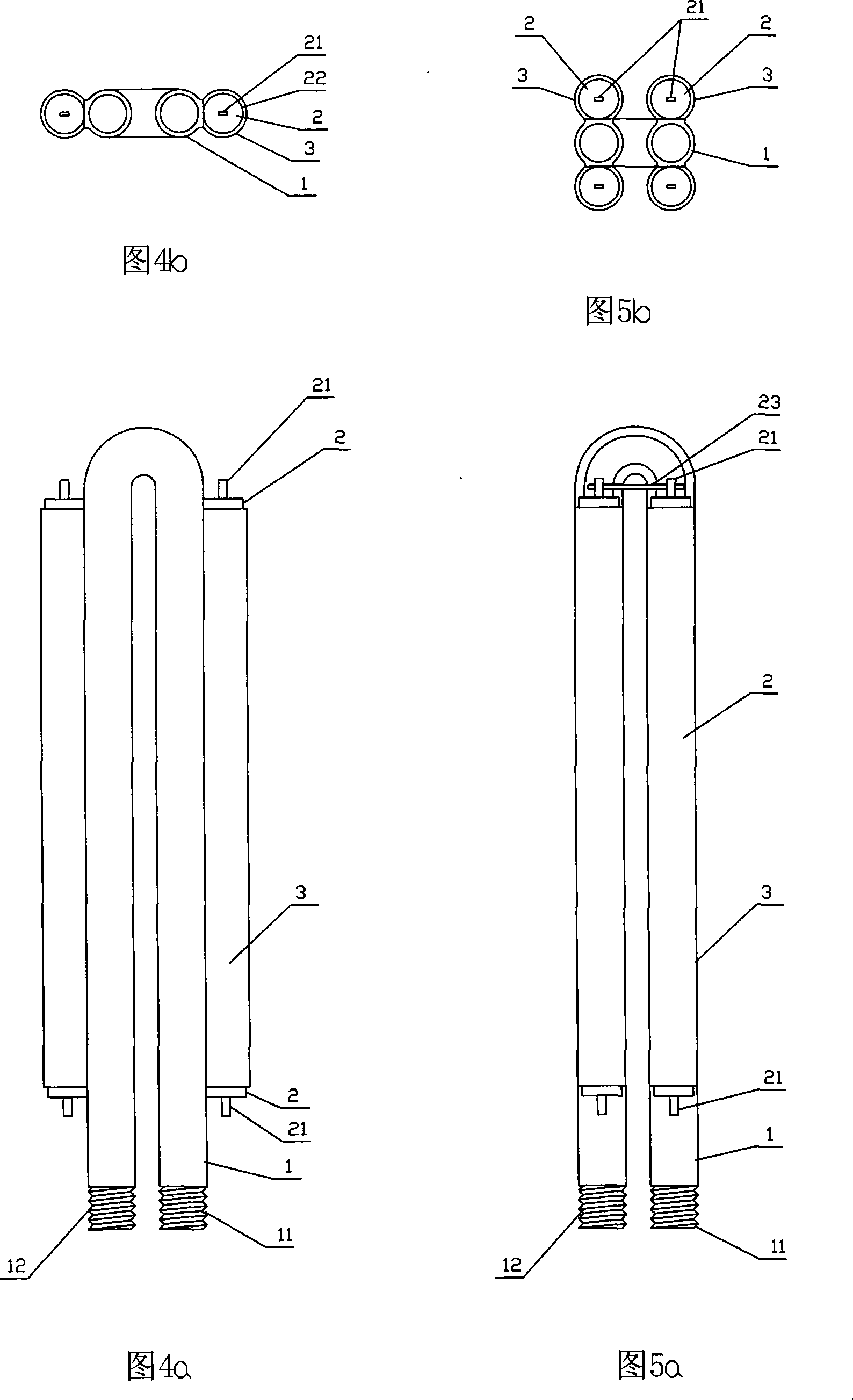

A tube type heater for electric water heater

InactiveCN101166380ASimple structureEasy to manufactureFluid heatersHeating element shapesStraight tubeEngineering

The disclosed tubular heater in use for electric water heater (EWH) includes heat exchange unit (HEU) and heating unit (HU). HEU is in metal multiple tube structure, in which at least one piece of tube is heating tube for the heating unit to be placed, and at least one piece of tube is as liquid passage tube (LPT). Tube connectors are setup at two ends of LPT. The heating tube can be in multiple tube structure for more than one HU to be installed in. HU can be bent to U shape, square shape, snake shape etc. Advantages are: (1) producing smaller EWH; (2) simple structure of HU, easy producing and low cost; (3) LPT is continuous tube without soldered dot so as to not produce leaking phenomena; (4) reasonable heat exchanging structure, and high thermal efficiency; (5) being not contacted to liquid, electric heating tube (EHT) is not be eroded, generates scale, and has long service life; (6) being in U shape or straight tube shape, EHT possesses low factory cost and steady quality.

Owner:奥特朗电器(广州)有限公司

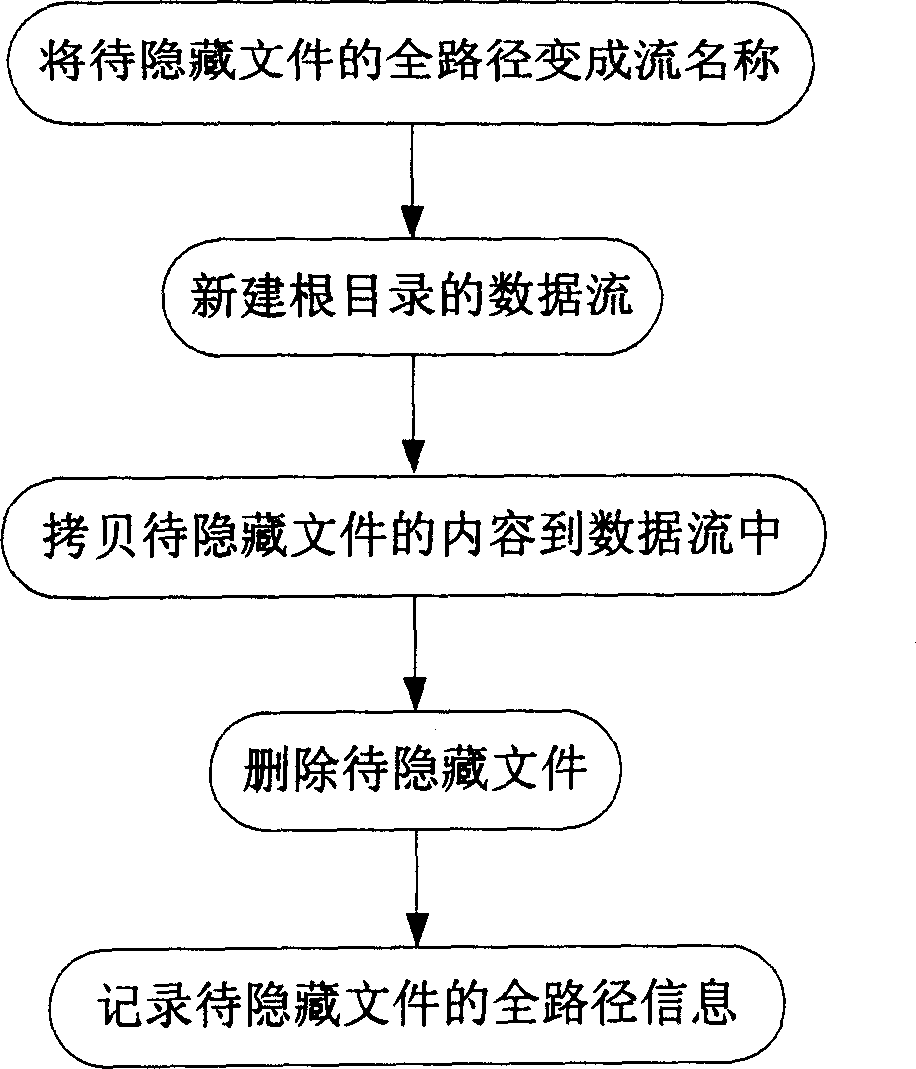

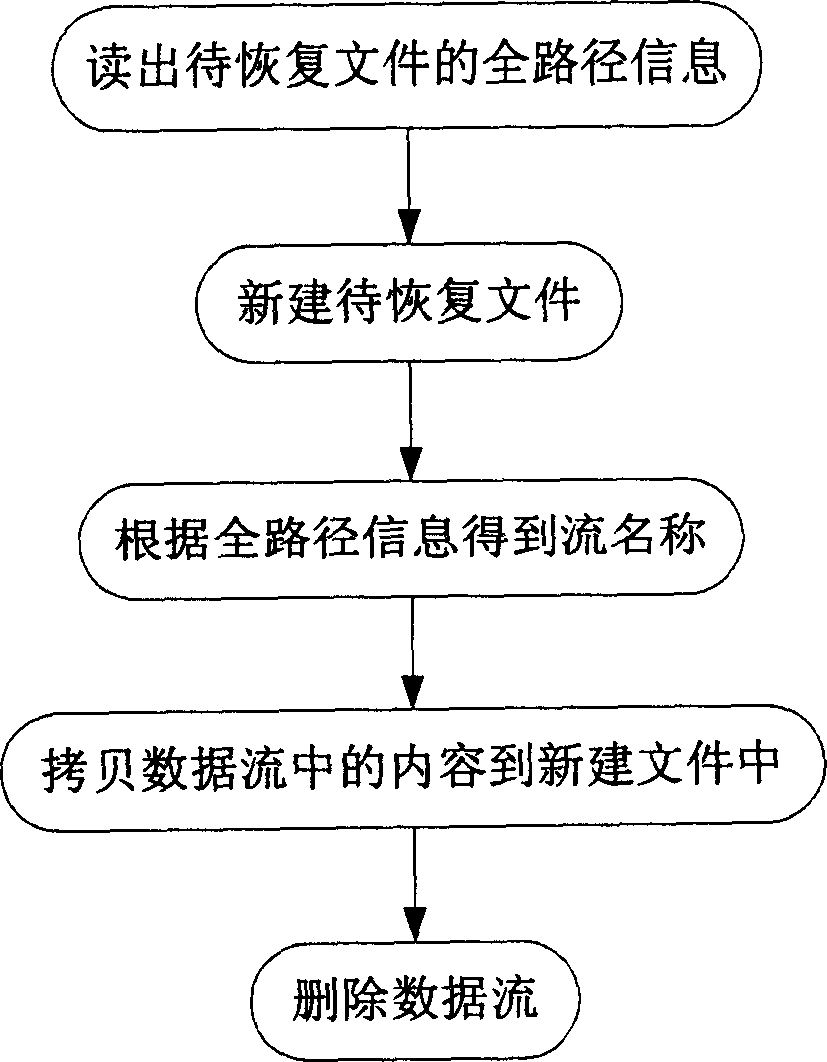

Files hiding method based on NTFS disk files system structure

InactiveCN1434451APermanentWill not generateUsing non-detectable carrier informationUnauthorized memory use protectionSystem structureRoot directory

The invention discloses a file hiding method based on NTFS disk file system structure, it includes following steps: (1) eliminates the illegal characters in the whole route name of the pending hidingfiles and gets a unique flow name; (2) founds a data flow of the root directory and its name is the flow name in steps (1); (3) copies the content sof files into the flow; (4) deletes the pending hiding files; (5) records the whole route information of the files.

Owner:HUAZHONG UNIV OF SCI & TECH

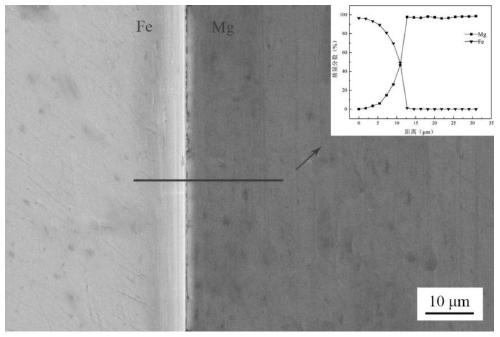

Magnesium/steel layered composite material and preparation method thereof

ActiveCN109849455AReduce manufacturing costEasy to operateLamination ancillary operationsLaminationOperating temperature rangeSolid solution

The invention relates to a magnesium / steel layered composite material and a preparation method thereof, belonging to the field of metal layered composite materials. The magnesium / steel layered composite material of the present invention is formed by interfacial metallurgical bonding of magnesium material and steel material, without an intermediate layer between the magnesium material and the steelmaterial, and is prepared by the steps of mechanical grinding surface treatment, alternating lamination and combination to form composite blanks, wrapping the composite blanks with metal sleeve and performing vacuum treatment, heating, hot rolling, diffusion heat treatment after removing the metal sleeve, and the like. The invention has the advantages that the magnesium / steel layered composite material has both excellent mechanical properties and vibration damping properties, can be used at the working temperature of 200-600 DEG C for a long time without solid solution or intermetallic compound at that interface between magnesium and steel, the interfacial bonding strength is stable or even gradually increased in the working temperature range, and the magnesium / steel layered composite billet need not be heated in vacuum or inert gas atmosphere, so the operation is convenient, the requirement for equipment is low, the price of required equipment is cheap, and the production cost is low, so the composite billet has universal popularization and application value.

Owner:UNIV OF SCI & TECH BEIJING

Novel three-dimensional gel dosimetric material and preparation method thereof

The invention discloses a novel three-dimensional gel dosimetric material and a preparation method thereof. The novel three-dimensional gel dosimetric material realizes calculation of dosing information according to luminescent intensity of quantum dots uniformly dispersed in hydrogel and prevents ion concentration diffusion problems of a Fricke gel dosemeter. The novel three-dimensional gel dosimetric material is prepared from simple raw materials, is free of isolation from oxygen in the environment, is free of a high temperature and can be synthesized easily. In synthesis, harmful gas is not produced and environmental harm is small. The novel three-dimensional gel dosimetric material has good physical and chemical stability, is not oxidized easily, can be stored easily and is convenient for repeated use. The preparation method of the novel three-dimensional gel dosimetric material utilizes a radiation crosslinking method, can be operated simply and easily and has a short preparation period. The novel three-dimensional gel dosimetric material is pure and does not contain impurities.

Owner:美中嘉和医学技术发展集团股份有限公司

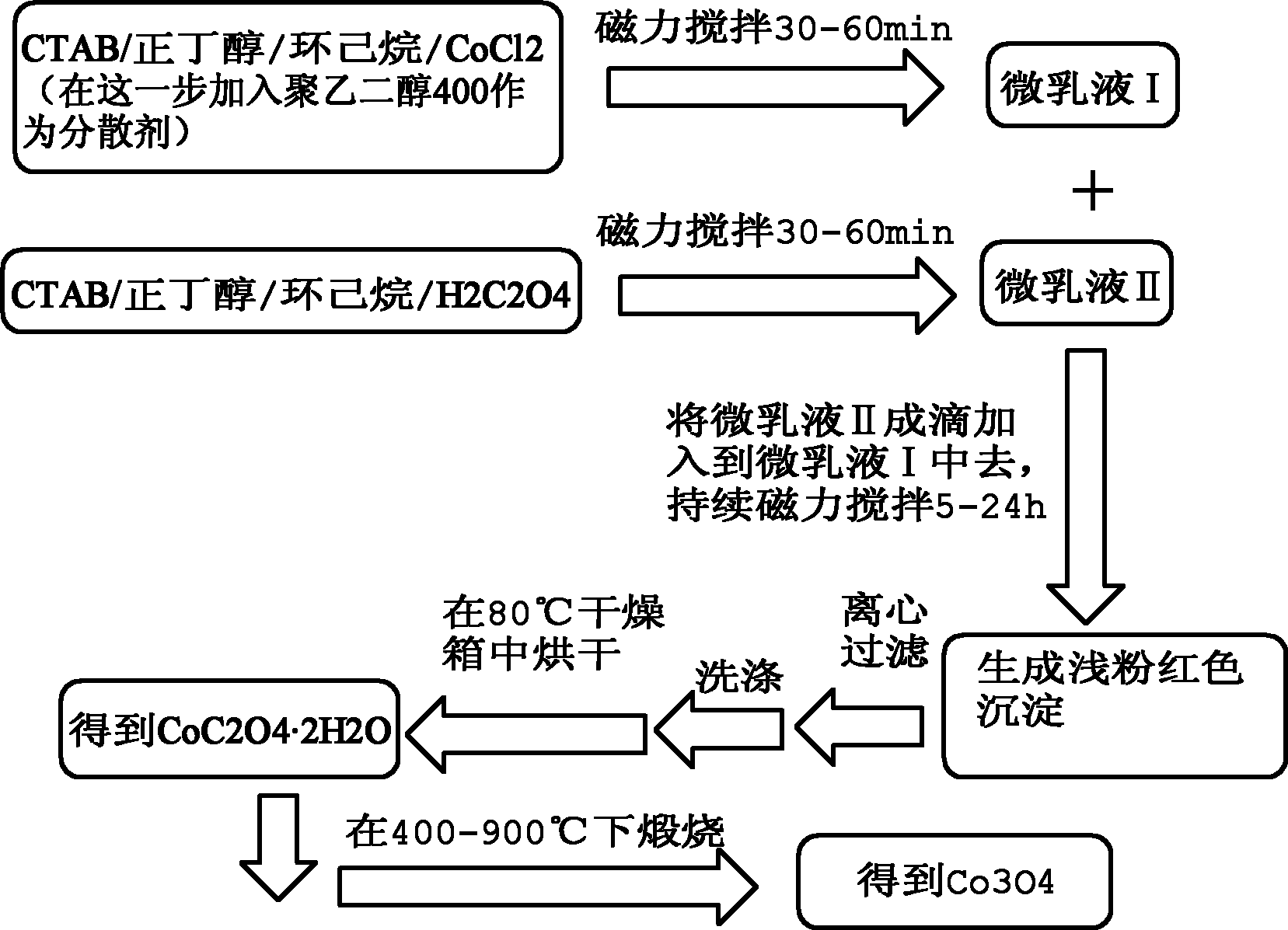

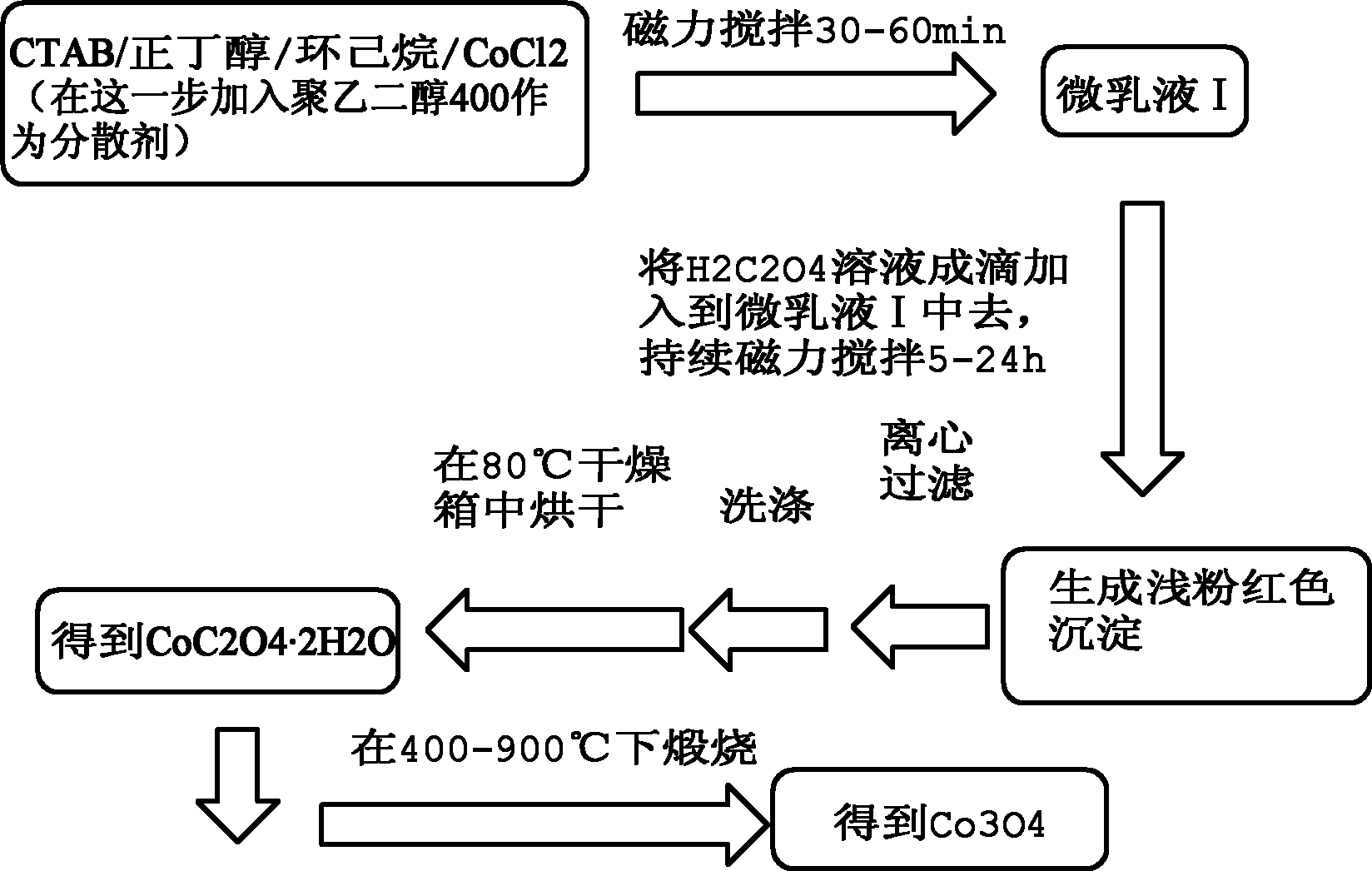

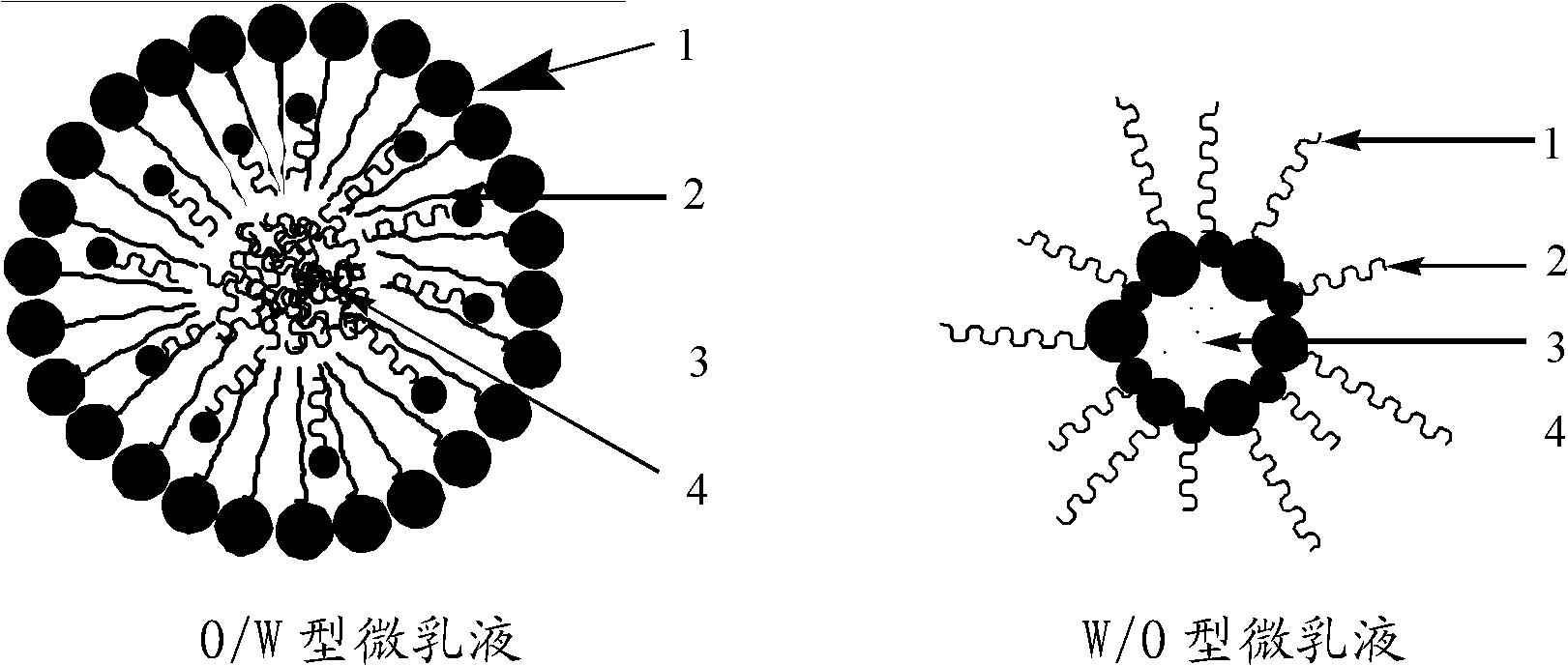

Method for preparing cobaltosic oxide nanorod by using microemulsion

InactiveCN102115213AExperimental raw materials are cheapAvoid pollutionCatalyst carriersNanotechnologyChemistrySolution composition

The invention discloses a method for preparing a cobaltosic oxide nanorod by using microemulsion. A double microemulsion system and a single emulsion system are provided, wherein the double microemulsion system consists of a microemulsion I and a microemulsion II; each of the microemulsion I and the microemulsion II consists of CTAB (Cetyltrimethyl Ammonium Bromide) serving as a surfactant, normal butanol serving as a cosurfactant, oil phase cyclohexane and a water phase; the mass ratio of the oil phase to the water phase is 1:20-20:1; and in the microemulsion I, the water phase is a CoCl2 aqueous solution; in the microemulsion II, the water phase is an H2C2O4 solution. Polyethylene glycol serving as a dispersant is added into the system, wherein the polyethylene glycol accounts for 10-80 percent by mass of the entire microemulsion system (the double microemulsions comprise the microemulsion I and the microemulsion II, the single microemulsion comprises the microemulsion I, and the double microemulsions and the single microemulsion do not comprise the polyethylene glycol). The single microemulsion system consists of the microemulsion I and the H2C2O4 aqueous solution, and the composition of the microemulsion I is the same as that of the microemulsion I in the double microemulsions. By adopting the method, the diameter of the obtained nanorod is between 70 nanometers and 150 nanometers, and the length is between 1 mu m and 3 mu m.

Owner:BEIJING UNIV OF CHEM TECH +1

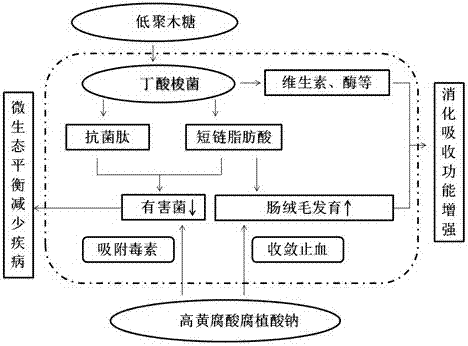

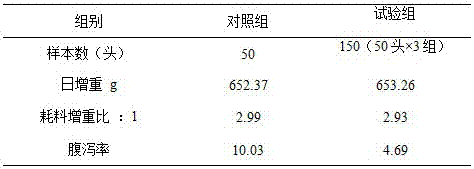

Additive for synergetically promoting multiplication and colonization of intestinal probiotics and use method of additive

PendingCN106858066AShorten the lag periodMild responseAnimal feeding stuffAccessory food factorsNutrientOrganic acid

The invention relates to an additive for synergetically promoting multiplication and colonization of intestinal probiotics and a use method of the additive. The additive contains xylooligosaccharide, clostridium butyricum and high fulvic acid sodium humate, wherein the xylooligosaccharide is capable of supplying nutrients to the clostridium butyricum and promoting the multiplication of the multiplication in intestinal tracts; the clostridium butyricum is capable of secreting vitamins, growth factors and the like so as to promote the multiplication of the probiotics and simultaneously secreting organic acid, antibacterial peptide and the like so as to inhibit the growth of harmful bacteria; and the high fulvic acid sodium humate is capable of repairing the injury of intestinal mucosa, increasing the level of an probiotics adhesin receptor on the surface of intestinal mucosa and promoting the colonization of the probiotics in the intestinal tracts. By virtue of process coupling and function synergy of the xylooligosaccharide, the clostridium butyricum and high fulvic acid sodium humate, the intestinal microecological balance of beasts and birds is finally realized, the shielding and absorbing functions of the intestinal tracts are enhanced, the diarrhea rate is decreased, the feed utilization rate is increased, and furthermore, the dependence on antibiotics in a cultivation process is reduced.

Owner:QILU UNIV OF TECH +3

Slow-release glass fertilizer and preparation method thereof

The invention relates to a slow-release glass fertilizer and a preparation method thereof, wherein the slow-release glass fertilizer comprises the following raw materials in molar percentage: 30 to 50 percent of P2O5, 15 to 45 percent of Na2O, 5 to 30 percent of K2O, 1 to 20 percent of CaO, 1 to 20 percent of MgO, 1 to 10 percent of Al2O3, 1 to 10 percent of CuO and 1 to 10 percent of Fe2O3; the preparation method comprises the following steps: weighing, mixing, melting, casting, ball milling and packaging; and the invention has the advantages of less dosage, high fertilizer effect, long fertilizer effect, difficult loss, convenient fertilizer application, preservation and transportation, difficult agglomeration and difficult deterioration and can achieve the required release amount by controlling the dissolution rate and the granularity of the glass fertilizer.

Owner:郑庆云

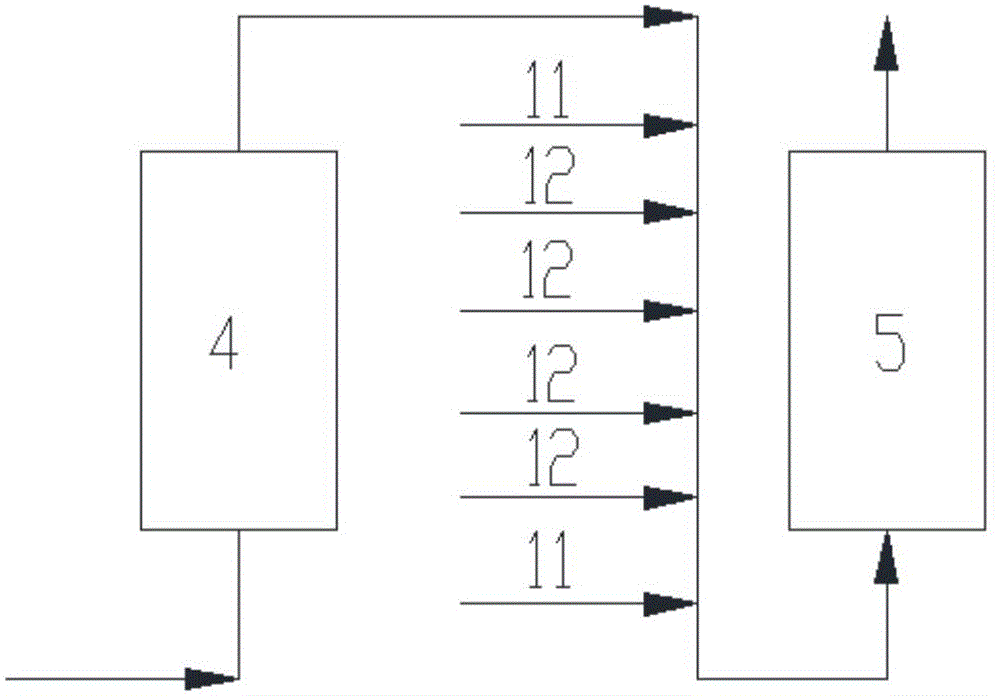

Temperature control method for slurry bed reactor, design method and application thereof

InactiveCN104888666AImprove running stabilityStable temperatureTemperature control using electric meansChemical/physical processesAutomatic controlHydrodesulfurization

The invention provides a temperature control method for a slurry bed reactor, a design method and the application thereof. The method comprises the step of injecting a coolant in pipes in front of the inlets of a reactors at all levels. The pipes are connected with at least one coolant pipeline to realize the temperature control. The coolant is composed of cold hydrogen and cold oil. According to the method, the method can be applied to reactors during the heavy oil hydrodesulfurization process, the direct coal liquefaction process and the oil-coal mixing process. Through adjusting the number of coolant pipelines and the flow of the coolant, the reaction temperature of the reactor can be controlled. The method is easy to realize during the project implementation process, and facilitates the automatic control. Meanwhile, the operation stability of the reactor is improved. Cold hydrogen and cold oil are necessary raw materials for the reaction, and the forestage reaction heat of the reactor is fully utilized. Therefore, the efficient utilization of heat is realized. The method is especially suitable for second-stage reactors and third-stage reactors. For first-stage reactors, the temperature control effect can still be realized through respectively heating two ways of hydrogen and then mixing up the two ways of hydrogen.

Owner:CATECH TECH

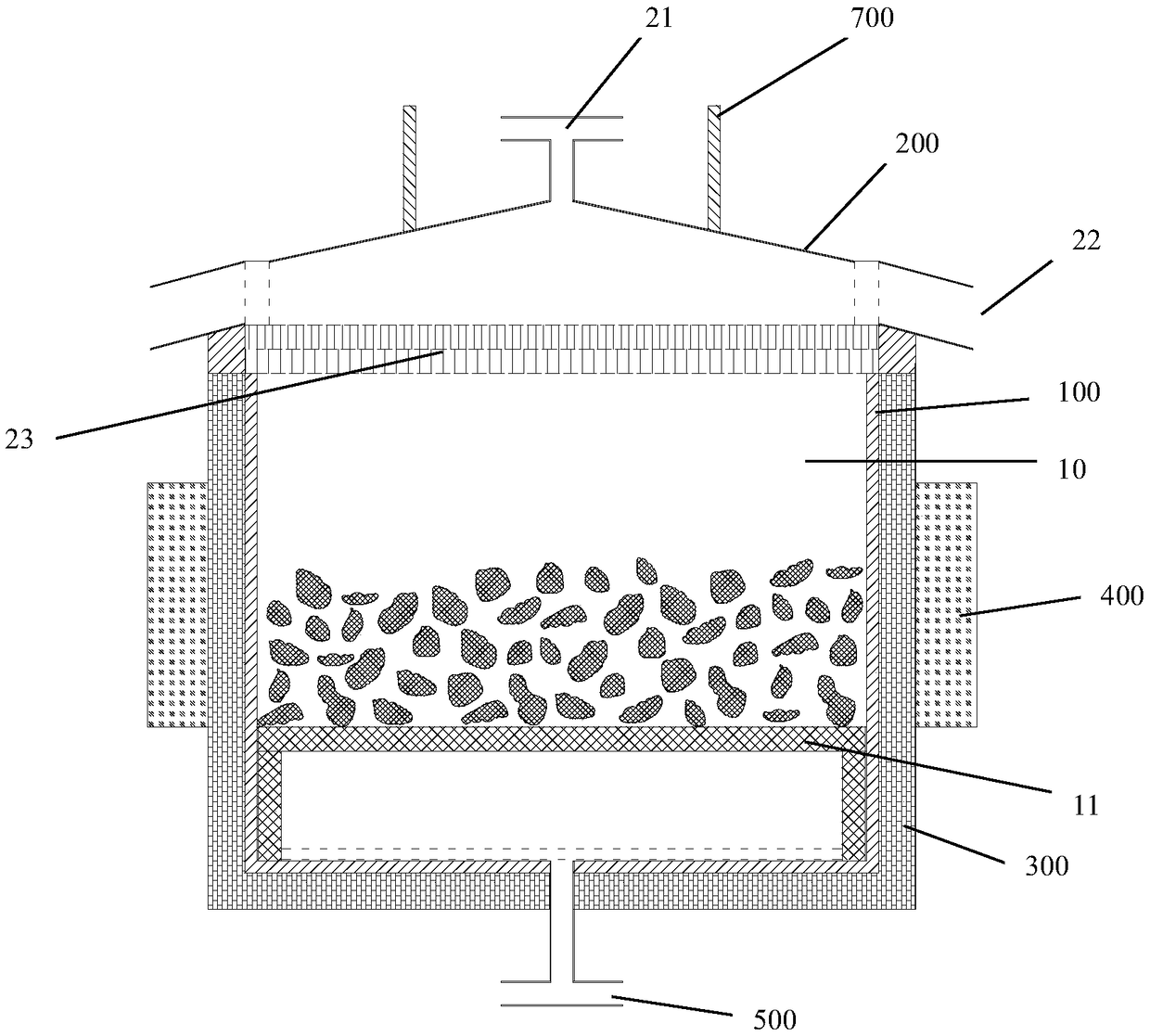

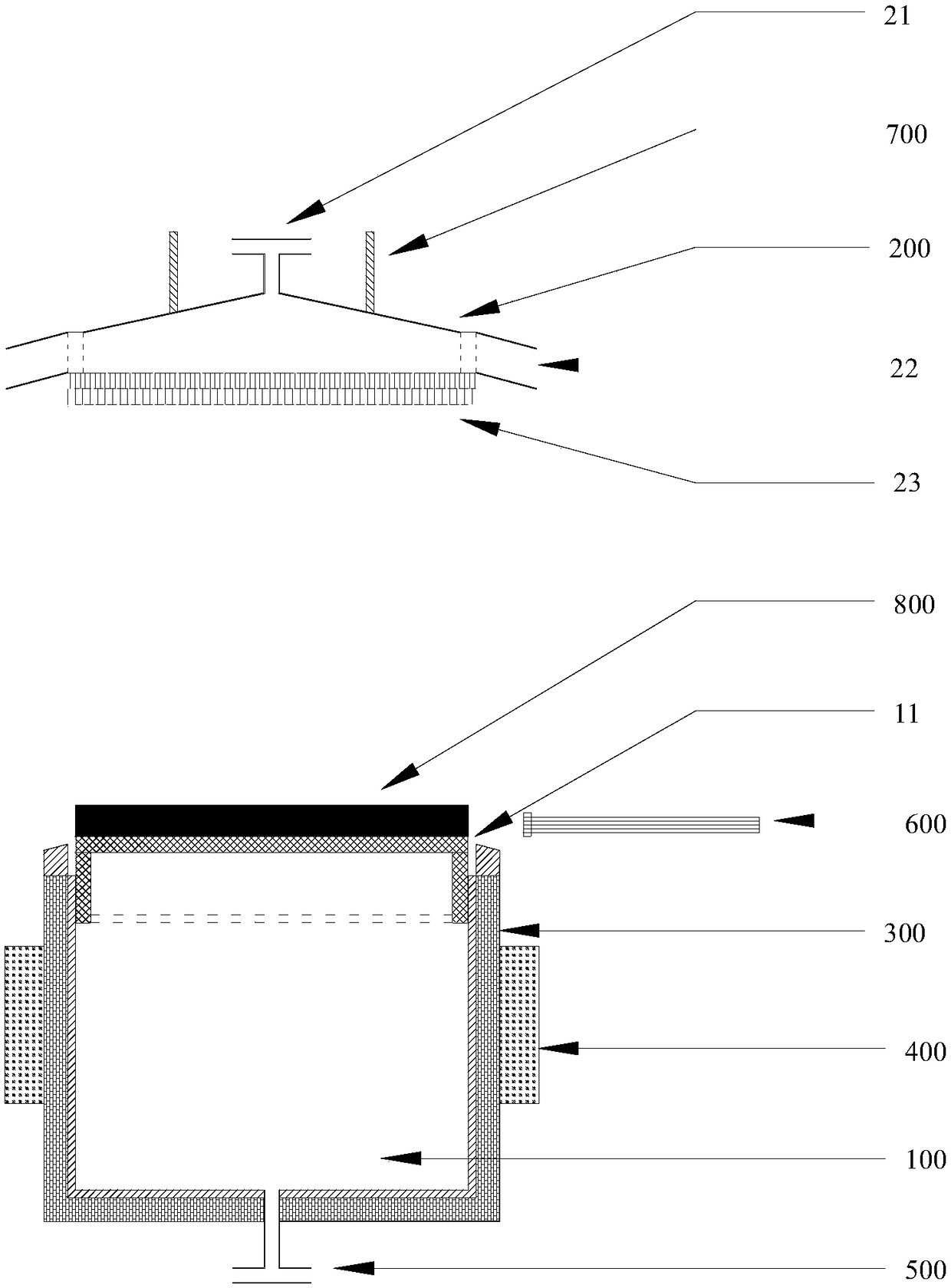

Harmless treatment method and system of lithium metal waste residue

ActiveCN109355506AAvoid safety hazardsSimple processProcess efficiency improvementChemical reactionLithium metal

The invention discloses a harmless treatment method and system of lithium metal waste residue. The harmless treatment method of the lithium metal waste residue comprises the following steps: putting the lithium metal waste residue in a sealed heating chamber and completely replacing gas in the heating chamber with protective gas which does not react with lithium; heating the lithium metal waste residue to a first temperature, disturbing the lithium metal waste residue, and vacuumizing the heating chamber in order to achieve oil removal treatment; after finishing the oil removal treatment, heating the lithium metal waste residue to a second temperature and disturbing the lithium metal waste residue in order to cause the lithium metal to melt and aggregate into lithium metal liquid and layerthe lithium metal liquid with solid impurities; and enabling the lithium metal liquid to flow out from the heating chamber after passing through a filter net placed in the heating chamber in order tointercept the solid impurities by the filter net. The harmless treatment method has no chemical reaction and no contact with air during treating the lithium metal waste residue, eliminates potentialsafety hazards, can directly, rapidly and effectively recover the lithium metal from the lithium metal waste residue, and has simple process and high economic benefit.

Owner:天齐锂业(江苏)有限公司

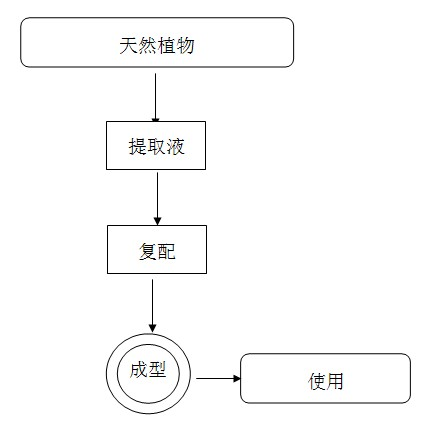

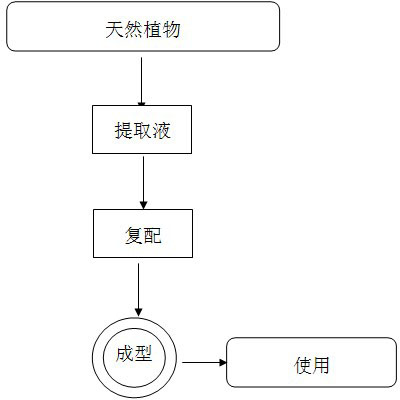

N-containing compound peculiar smell removing liquid

The invention discloses N-containing compound peculiar smell removing liquid. The peculiar smell removing liquid is prepared from one to four kinds of ginger, peppermint, garlic and pepper extracting solutions or oil. A natural plant extracting solution has stable chemical and physical properties, and does not have toxicity, explosibility, flammability, or irritation to skin; after the N-containing compound peculiar smell removing liquid is reacted with peculiar smell modules, products with toxic or sides are not produced, secondary pollution is avoided, and the efficiency of purifying N-containing compounds in odor is high; through detection of an authority institution, know engineering meets the requirements of relative national standards and specifications. The defects existing when N-containing compound peculiar smell is treated by using common chemical medicines are avoided.

Owner:SHANGHAI YEMA ENVIRONMENTAL PROTECTION EQUIP ENG

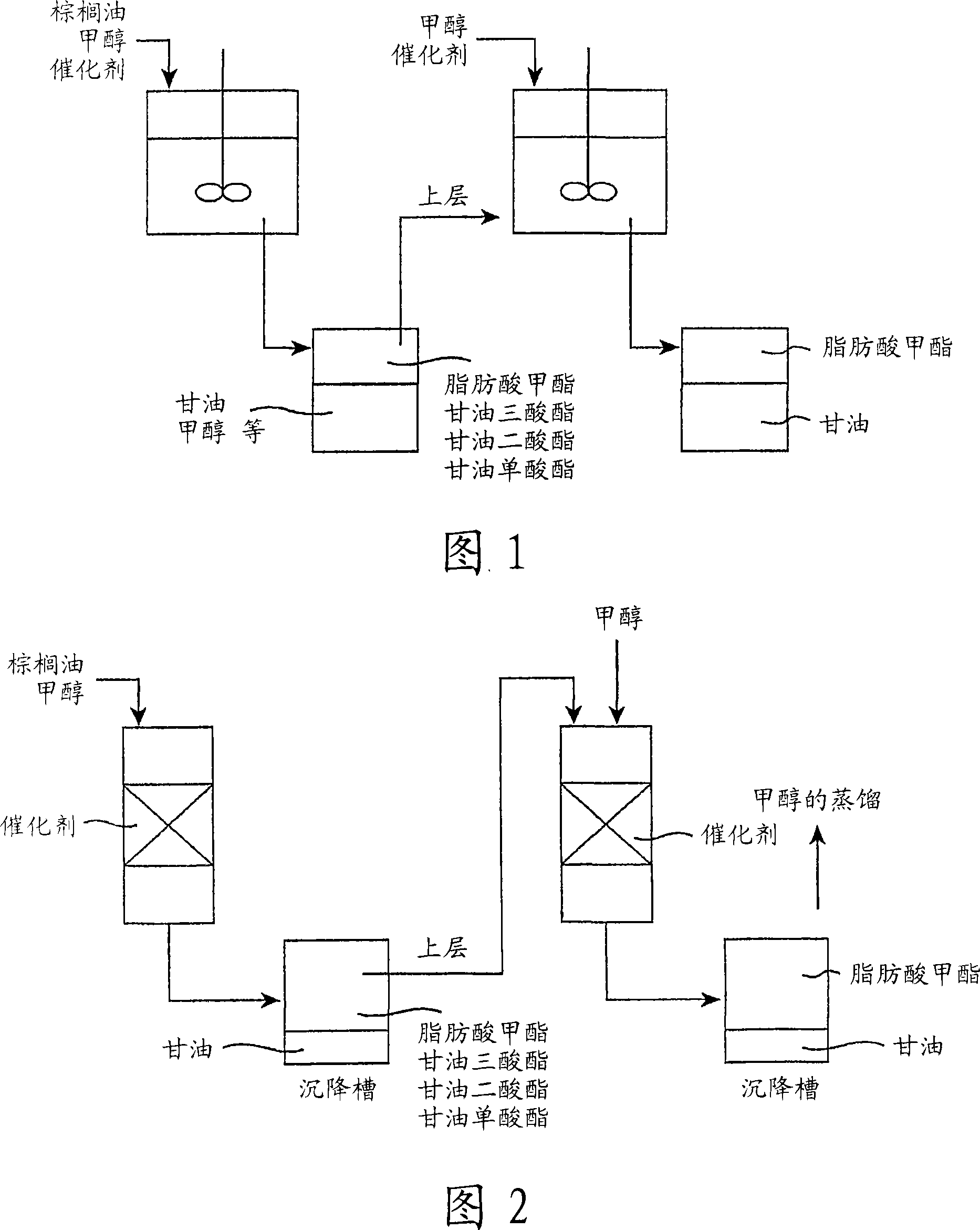

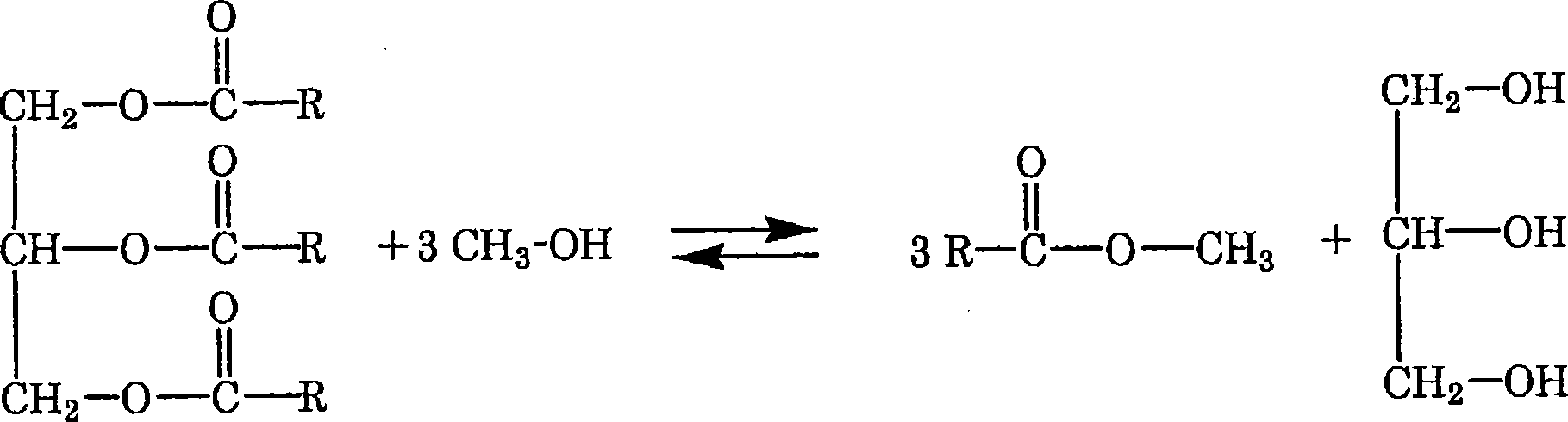

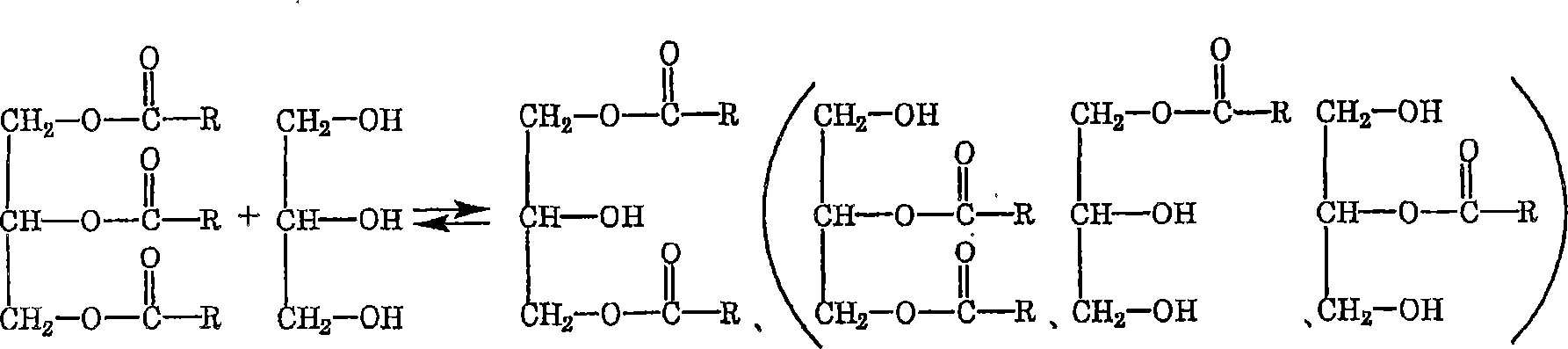

Method for producing fatty acid alkyl esters and/or glycerin

InactiveCN101128572AImprove overall lifespanSimplify or omit separation and removal stepsFatty acid esterificationPreparation by ester-hydroxy reactionGlycerolHigh activity

To provide: a production method using a catalyst which can substantially suppress leaching of active metal components and exhibit high activity for both reactions of transesterification of glycerides and esterification of free fatty acids each contained in a fat or oil; and the catalyst. A method for producing fatty acid alkyl esters and / or glycerin comprising a step of bringing a fat or oil into contact with an alcohol in the presence of a catalyst, wherein the catalyst is at least one catalyst selected from the group consisting of the following (I) to (V): (I) a metal oxide having an ilmenite structure and / or a slyrankite structure; (II) an oxide containing a metallic element belonging to the Group 12 and a metallic element belonging to the Group 4; (III) a mixed oxide containing a metallic element belonging to the Group 12 and a tetravalent transition metallic element; (IV) a metal oxide containing zirconium and at least one metallic element selected from the group consisting of metallic elements belonging to the Groups 4, 5 and 8; and (V) a metal oxide containing anatase type titanium oxide and / or rutile type titanium oxide, and the metal oxide containing a sulfur component of 700 ppm or less.

Owner:NIPPON SHOKUBAI CO LTD +1

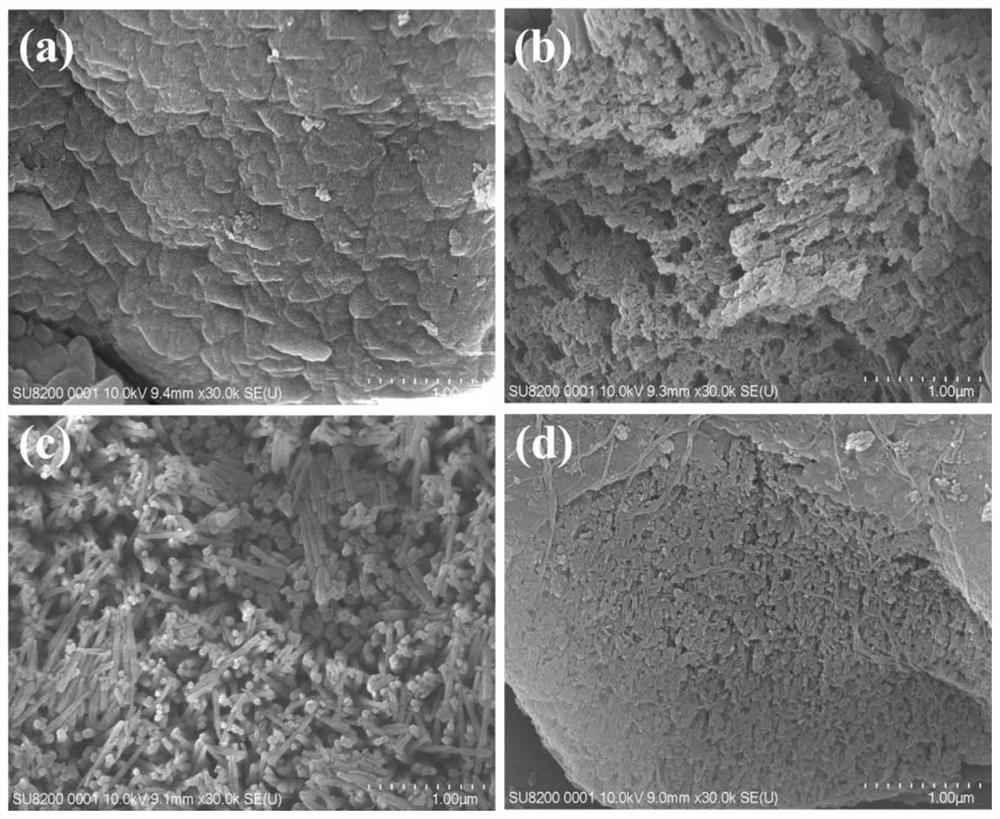

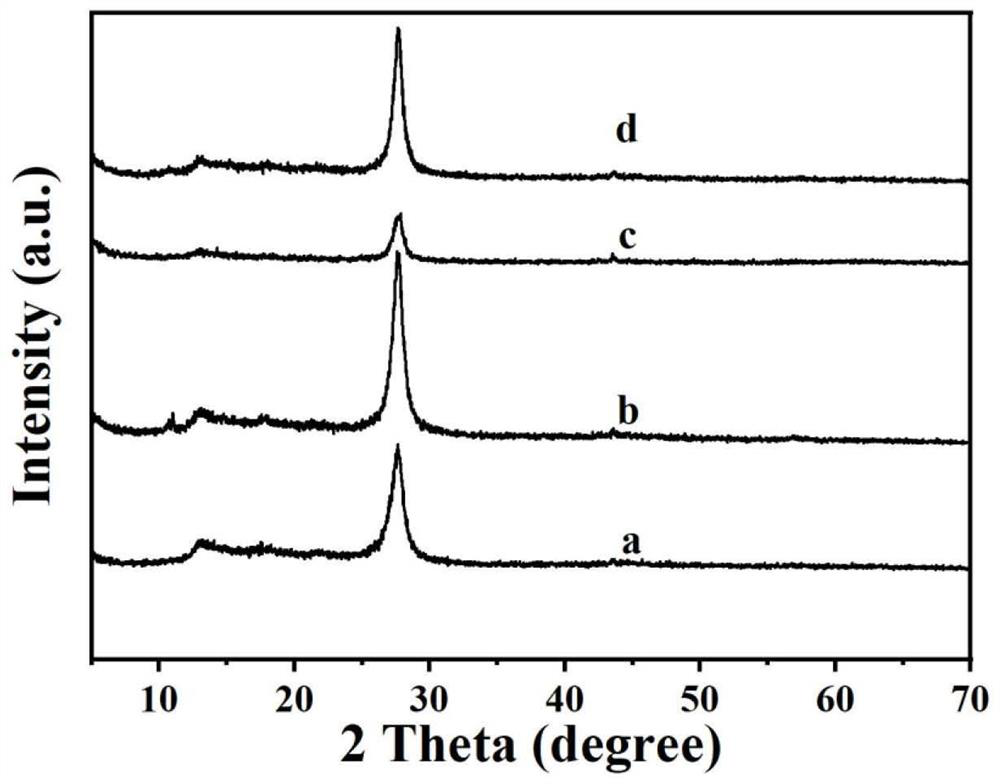

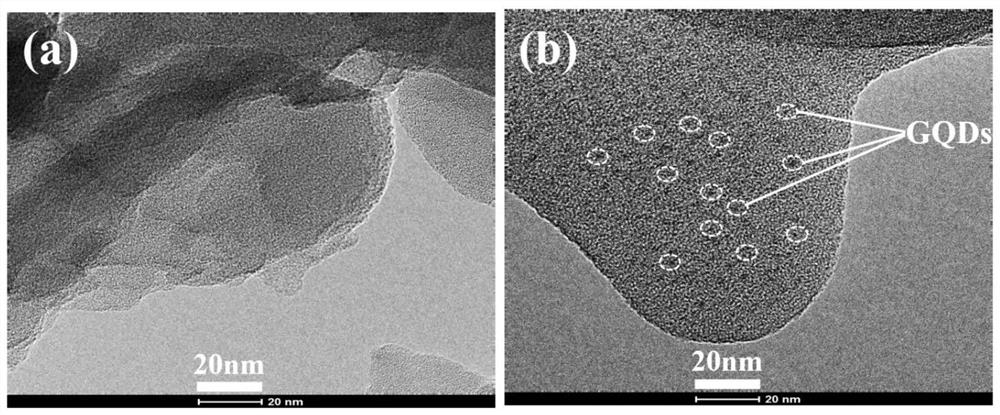

Preparation method of composite visible light catalyst graphene quantum dot/graphite-phase nitrogen carbide

InactiveCN113210003APromote degradationImprove efficiencyBiocideDispersed particle separationPtru catalystMaterials science

The invention discloses a preparation method of a composite visible light catalyst graphene quantum dot / graphite phase nitrogen carbide, and solves the problem that the efficiency of degrading NO by g-C3N4 under visible light is relatively low. The method comprises the following steps: by taking citric acid monohydrate CA as a raw material, pyrolyzing to prepare GQDs; then taking melamine as a raw material, and calcining to prepare CN (Carbon Nitride); and then preparing the g-C3N4 composite photocatalyst GQDs / CN containing the graphene quantum dots GQDs by using a one-step hydrothermal method. Compared with a pure g-C3N4 photocatalyst, the GQDs / CN has the advantages that the NO degradation capability is improved, and the selectivity for generating NO3 <-> is enhanced. A new thought is provided for application of the graphene quantum dot doped semiconductor catalyst in the field of environmental purification.

Owner:南京奇安威尔环境科技有限公司

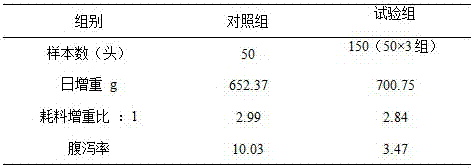

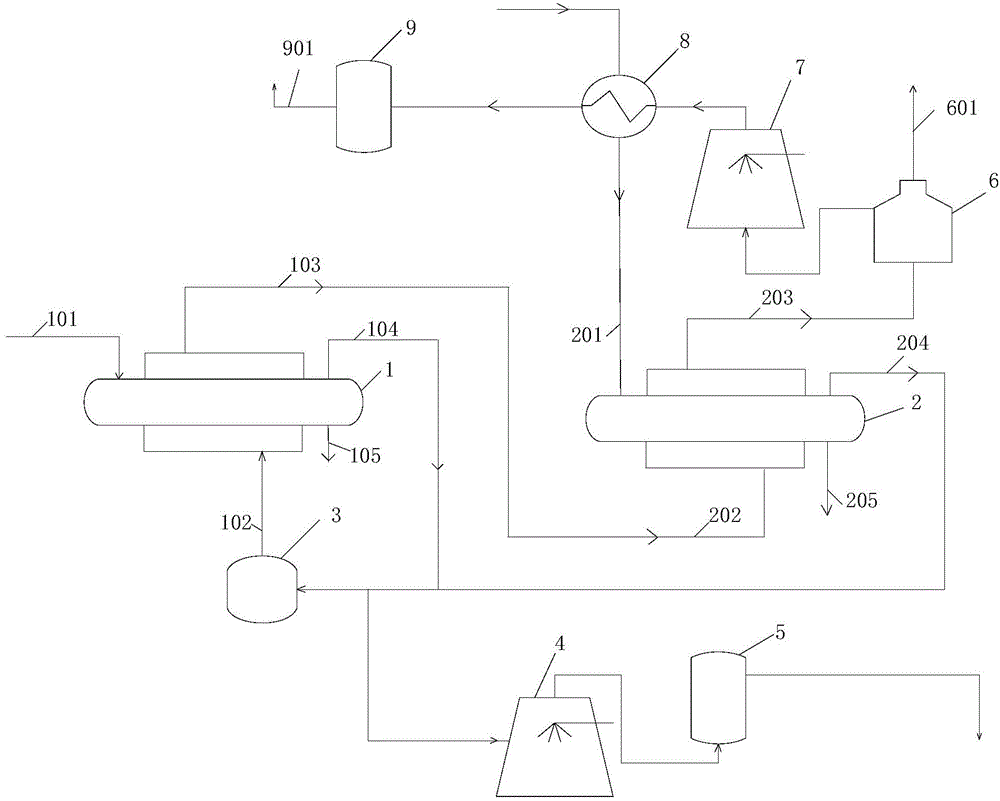

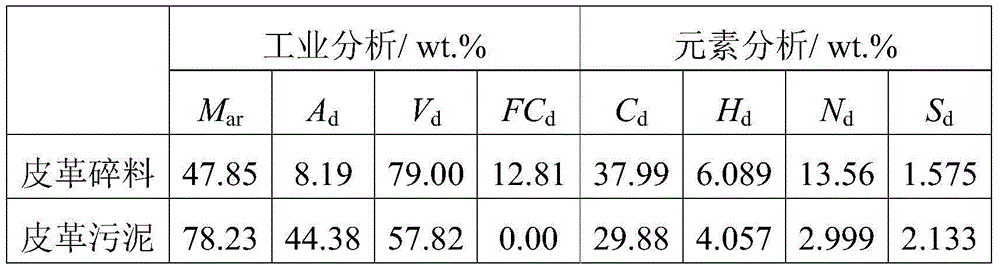

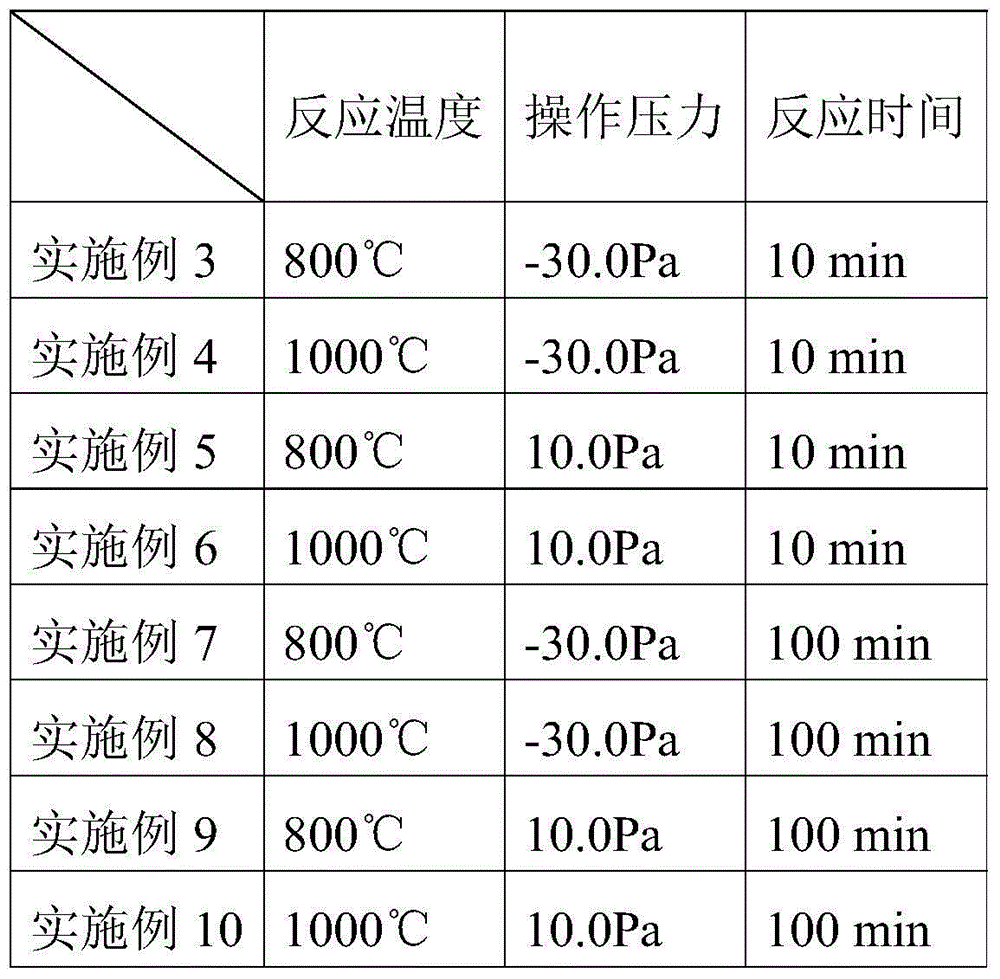

Graded pyrolysis gasifying system and application thereof, and treatment method of leather-producing wastes

ActiveCN104694166AWill not generateAvoid blendingSolid waste disposalCombustible gas productionCombustion chamberSlag

The invention discloses a graded pyrolysis gasifying system and application thereof, and a treatment method of leather-producing wastes. The system comprises a first rotary kiln and a second rotary kiln, wherein the first rotary kiln comprises a leather crushing feeding opening, a high-temperature smoke inlet, a medium-temperature smoke outlet, a first rough gas outlet and a second byproduct discharging opening; the second rotary kiln comprises a leather sludge feeding opening, a medium-temperature smoke outlet, a first rough gas outlet and a sludge slag discharging opening; the medium-temperature smoke outlet of the first rotary kiln is communicated with the medium-temperature smoke inlet of the second rotary kiln; the high-temperature smoke inlet is communicated with a secondary combustion chamber; the first rough gas outlet and / or the second rough gas outlet is communicated with the secondary combustion chamber. The treatment method of the leather-producing wastes is clean and efficient; the leather-producing wastes can be reduced by 90% or more.

Owner:EAST CHINA UNIV OF SCI & TECH +2

Preparation method for toothpaste capable of repairing dental enamel

ActiveCN111135104AWill not generateIncrease the rate of remineralizationCosmetic preparationsTransportation and packagingOil in waterCalcium biphosphate

The invention relates to a preparation method for toothpaste capable of repairing dental enamel. According to the preparation method, soluble calcium salt and soluble phosphate are each wrapped with an inner water phase of a water-in-oil-in-water emulsion, and thus, after being added into the toothpaste, the soluble calcium salt and soluble phosphate can stably exist at the same time for a long time without reacting to produce calcium phosphate precipitates. When teeth are brushed with the toothpaste, the water-in-oil-in-water emulsion breaks up under the action of friction and extrusion to release the soluble calcium salt and / or the soluble phosphate wrapped in the inner water phases, so that liquid in an oral cavity contains calcium ions and phosphate anions of relatively high concentration, and the remineralization rate of the dental enamel and dentin in the oral cavity can be increased.

Owner:YUNNAN BAIYAO GRP HEALTH PROD CO LTD +1

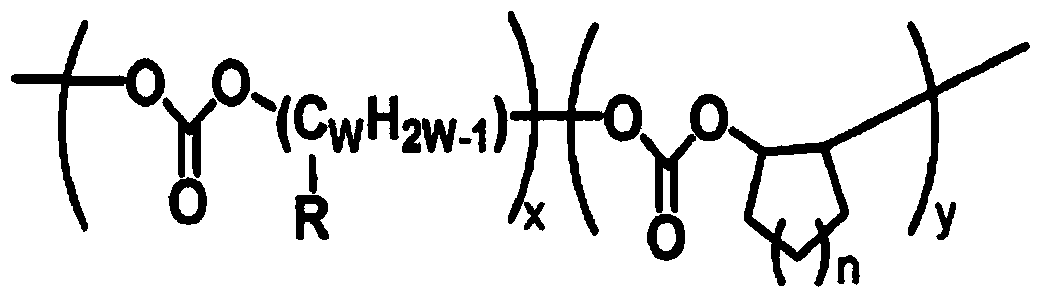

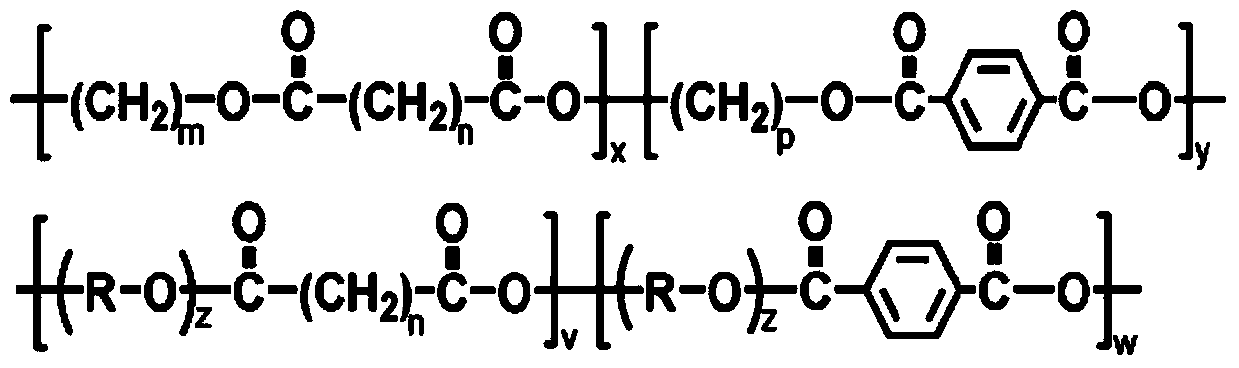

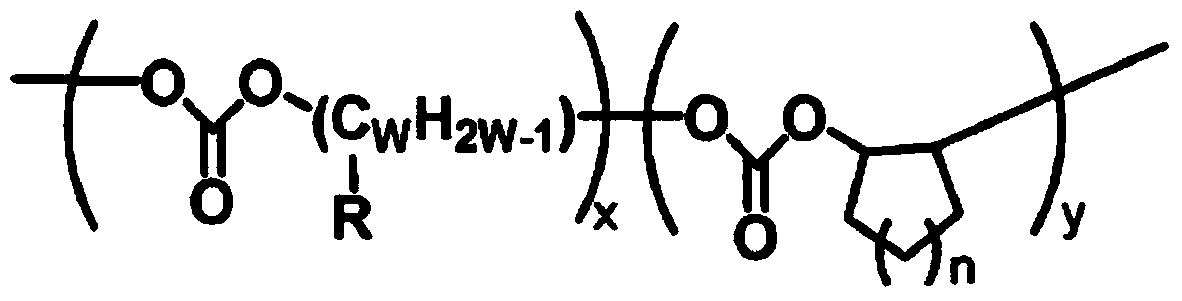

Eco-friendly poly(alkylene carbonate) resin composition for high-transparency and high-gloss sheet

ActiveCN104011107AWon't happenWill not generateThin material handlingThermoplasticPolyvinyl chloride

Provided is an eco-friendly poly(propylene carbonate) resin composition for a sheet, which is characterized by using a poly(alkylene carbonate) resin developed by efficiently utilizing carbon dioxide, which is a major contributor to global warming, as a main material, and including appropriate additives, such as, a strength modifier, and a flexibilizer, thereby completely solving environmental hazards controversy of the existing polyvinyl chloride resin products; exhibiting excellent mechanical and thermal properties, processability, post processability (printability, embossing and surface treatment, laminating characteristics) and superior anti-flaming property (low smoke density) and elongation characteristics as compared with the existing polyvinyl chloride resin products; and overcoming an extruding production method which is a small-sized production manner, corresponding to a big defect in thermoplastic plastics emerged as substitutes for polyvinyl chloride resin products and thus applying a calendering process method which is a mass production manner.

Owner:SK INNOVATION CO LTD +1

Agent for removing heavy metal ions from water and preparation method of agent

ActiveCN104355382AWill not generateLow priceWater contaminantsWater/sewage treatment by flocculation/precipitationNitrogenSewage treatment

The invention relates to sewage treatment agents, in particular to a preparation method and use of an agent for removing heavy metal ions from water. According to the technical scheme, the agent comprises the following raw materials in part by weight: 2 parts of natural weathered coal and 1 part of 30-50% of a sodium hydroxide solution. The preparation method comprises the following steps: (1) grinding the natural weathered coal; (2) carrying out a reaction between the ground weathered coal and the sodium hydroxide solution at the temperature of 60-80 DEG C for 5-10 h; (3) clarifying the reaction solution, sucking supernatant, and filtrating the supernatant for later use; (4) heating the filtrated supernatant which is protected by nitrogen to 50-60 DEG C in a reaction vessel to realize a polymerization reaction for 2-3 h; (5) taking out the polymer for drying. The preparation method has the advantages as follows: (1) adjusting the pH value in water is avoided when the agent is in use, and the agent can be directly put in water containing the heavy metal ions; (2) no toxic and harmful gas is generated after a coagulation reaction; (3) the weathered coal taken as a raw material is cheap, so that the preparation method provided by the invention is suitable for popularization and application.

Owner:中关村科技租赁股份有限公司

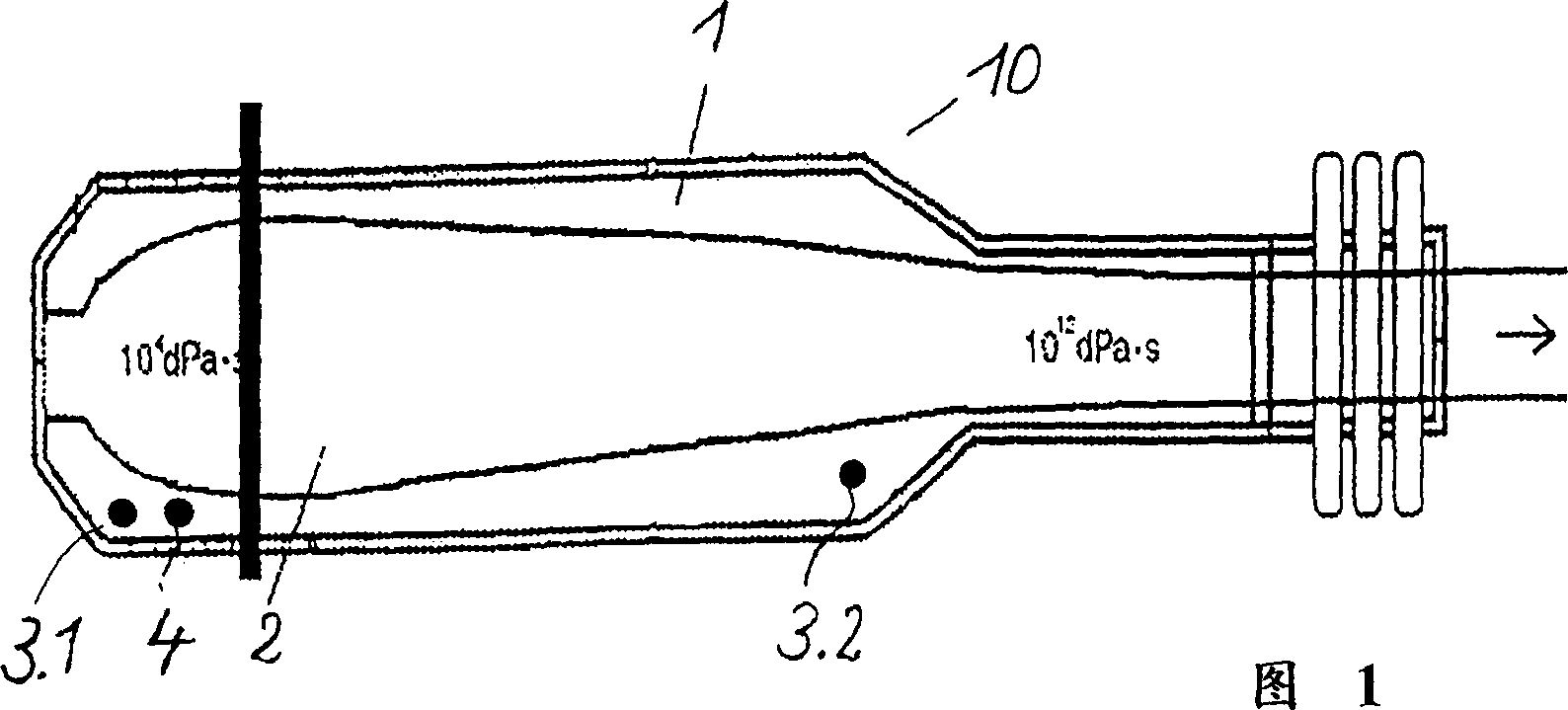

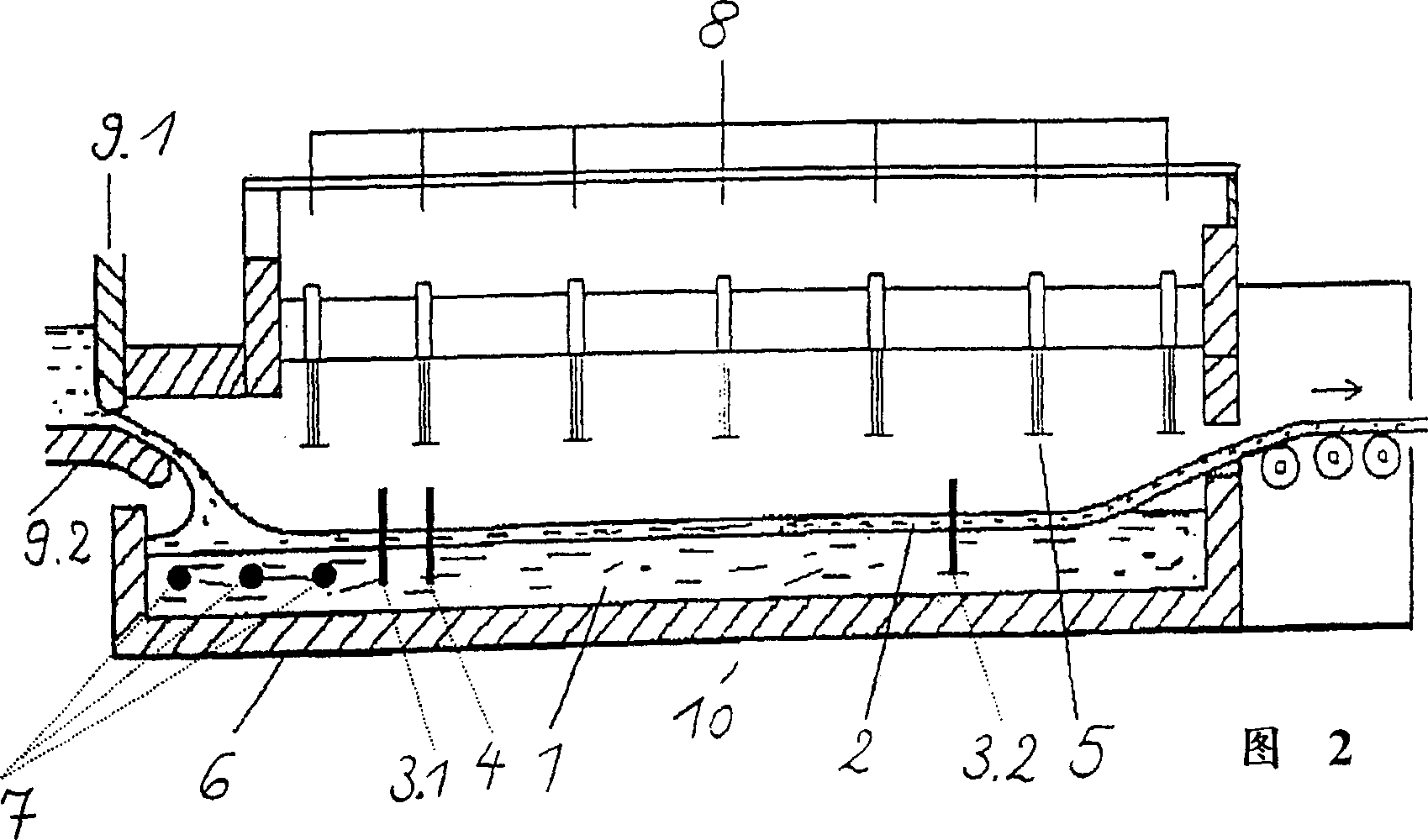

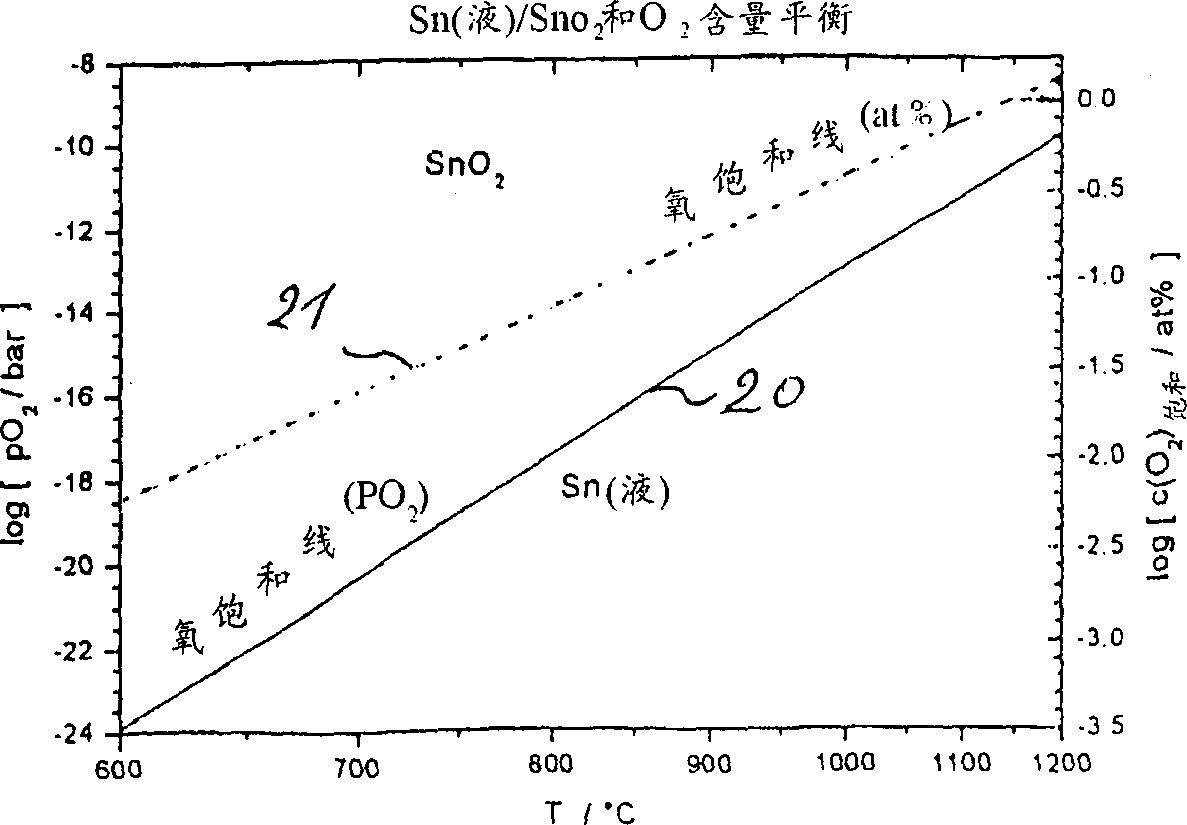

Method of manufacturing float glass

The invention discloses a method of manufacturing float glass in which molten glass (2) floating on molten metal (1) between the hot and cold ends of a molten metal bath (10) is formed into a flat glass , and affect the oxygen concentration of the molten metal. In order to achieve a high glass quality, the oxygen concentration of the molten metal ( 1 ) is influenced during glass production in such a way that it does not exceed the saturation solubility of the cold end at any place.

Owner:舱壁玻璃公司

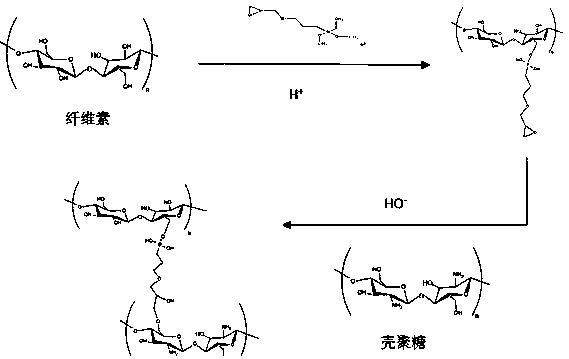

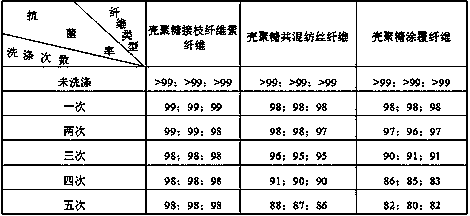

Preparation process for novel chitosan antibacterial fiber

InactiveCN108774888ATo achieve the purpose of antibacterialHigh grafting rateBiochemical fibre treatmentVegetal fibresAfter treatmentSilanes

The invention relates to a preparation process for novel chitosan antibacterial fiber, which comprises the following steps: A. preparation of raw materials, B. preparation of a silane coupling agent kh560 grafted fiber, C. preparation of the novel chitosan antibacterial fiber. The preparation process adopts grafting technique, chitosan and cellulose fiber are effectively connected, the grafted chitosan fiber has acid and base resistance, and can ensure that the fiber has good antibacterial performance after treatment including dyeing, washing, drying, etc. The grafting rate of chitosan and cellulose is high, waste of raw materials is less, and production cost is low.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

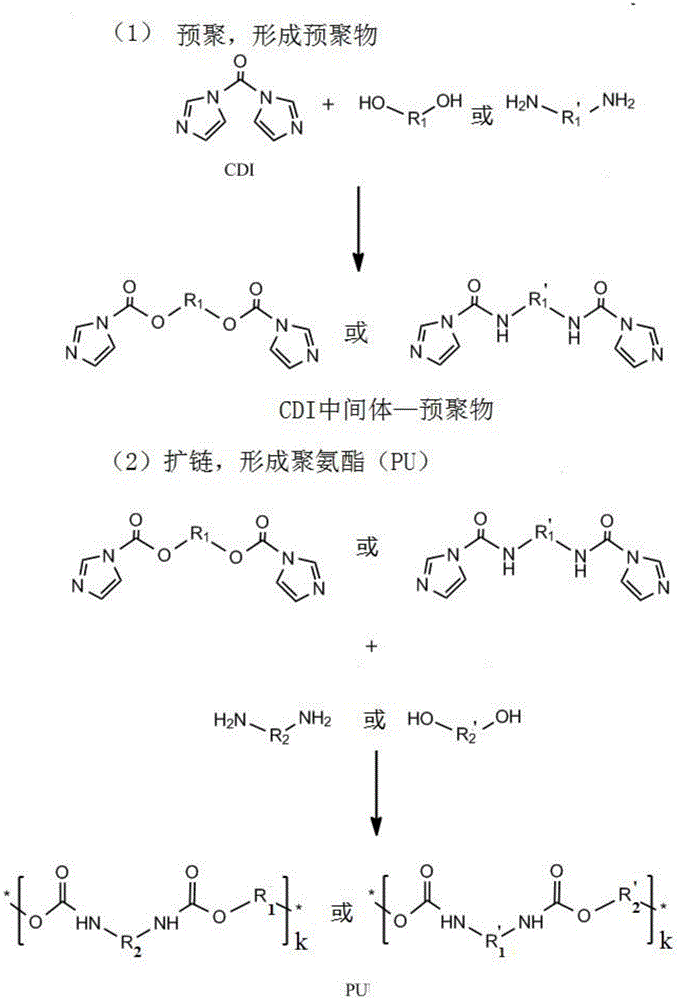

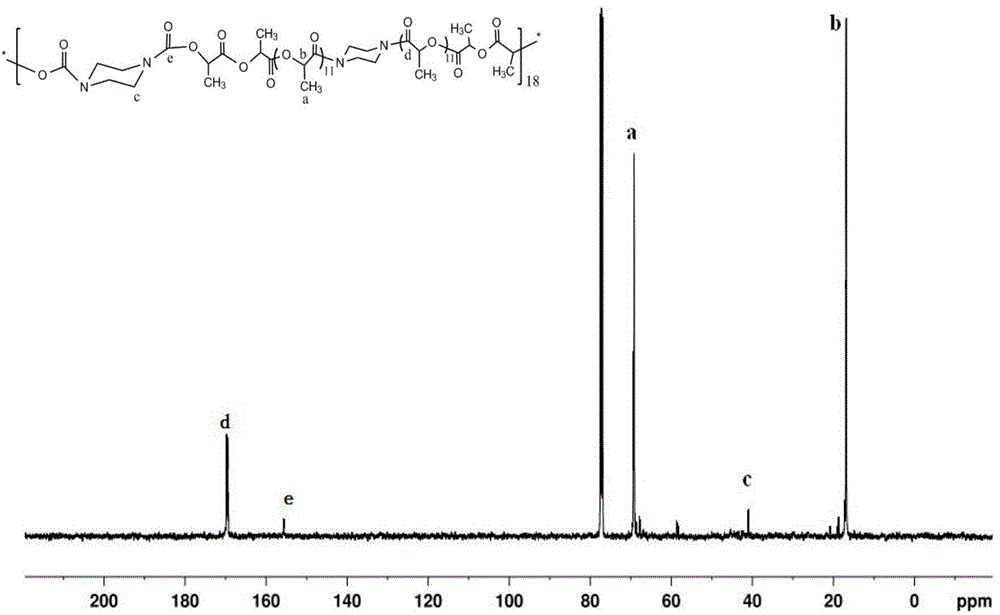

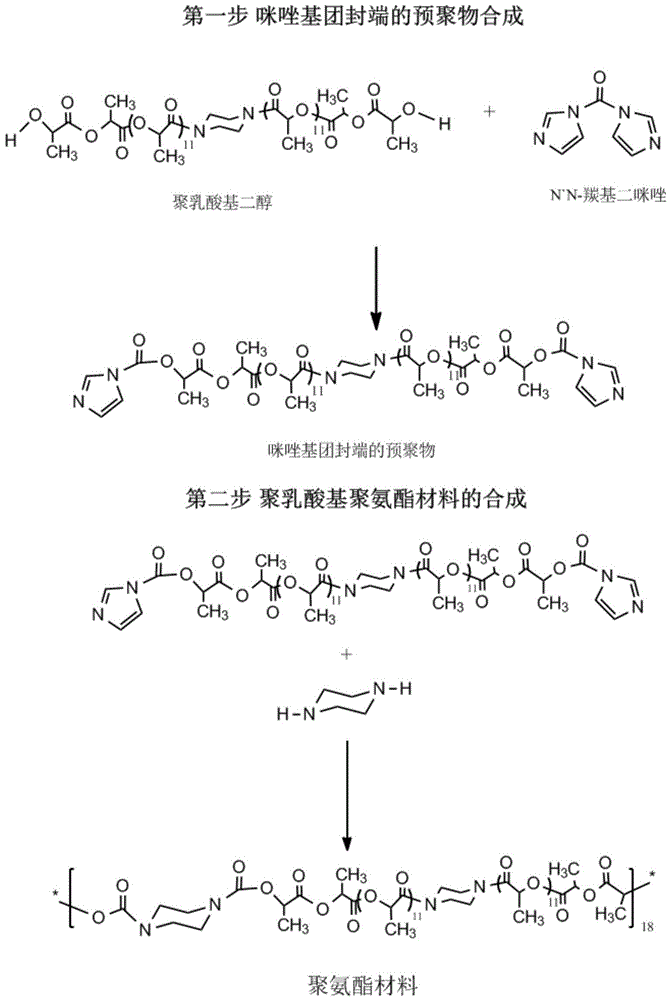

Polyurethane material, and preparation method and application thereof

The invention discloses a polyurethane material and a preparation method thereof. The preparation method comprises the following steps: carrying out prepolymerization reaction on polydibasic alcohol or polydiamine and excessive N'N-carbonyldiimidazole to obtain a prepolymer of which both ends are closed by imidazolyl groups, and carrying out chain extension reaction on the prepolymer and micromolecule diamine or micromolecule dibasic alcohol through the imidazolyl groups on the two ends of the prepolymer to obtain the target polyurethane material. The obtained polyurethane material has high purity, and the molecular weight is 30000-90000. The method improves the traditional polyurethane synthesis technique, and uses the N'N-carbonyldiimidazole instead of the high-toxicity isocyanate, thereby effectively avoiding the environmental pollution and injuries to the human body due to the adoption of the isocyanate in the polyurethane production process.

Owner:华南生物医用材料(深圳)有限公司

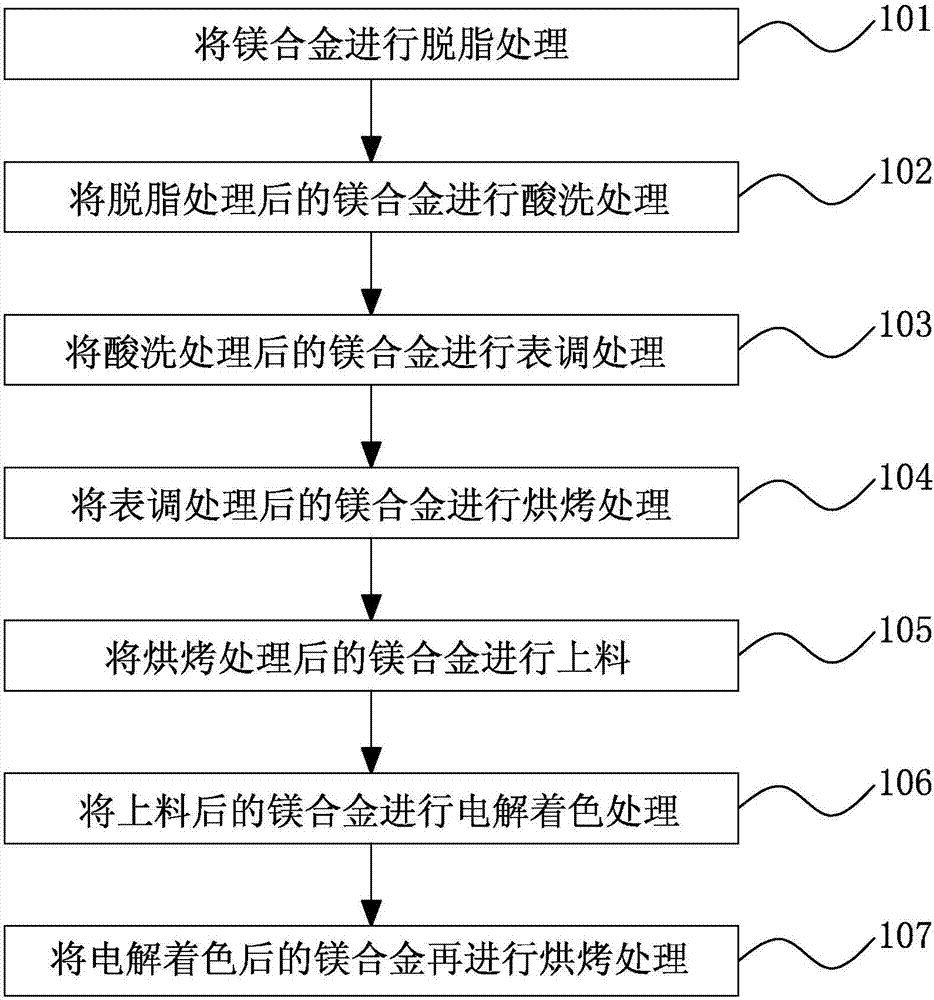

Magnesium alloy oxidation coloring method and product thereof

InactiveCN107313099AImprove corrosion resistanceImprove wear resistanceAnodisationElectrolysisHazardous substance

The invention discloses a magnesium alloy oxidation coloring method and a product thereof. The magnesium alloy oxidation coloring method comprises the steps: (1) degreasing magnesium alloy; (2) carrying out acid pickling on the degreased magnesium alloy; (3) carrying out surface conditioning on the magnesium alloy subjected to acid pickling; (4) baking the magnesium alloy subjected to surface conditioning; (5) feeding the baked magnesium alloy; (6) carrying out electrolytic coloring on the fed magnesium alloy; and (7) baking the magnesium alloy subjected to electrolytic coloring. The product is produced by using the magnesium alloy oxidation coloring method. The magnesium alloy oxidation coloring is combined with formation pretreatment and is simple and convenient in operation process and good in effect, the defect of single color for surface treatment on magnesium alloy is overcome, the range of a requirement for the quality of the surface of a material is relatively wide, the corrosion resistance and wear resistance of the magnesium alloy are greatly improved by the surface appearance of a coloring sample, the coloring process is relatively environment-friendly, a great number of harmful substances cannot be produced in an oxidation reaction process, and therefore, the magnesium alloy oxidation coloring method is suitable for factory quantified production.

Owner:KUNSHAN HANDING PRECISION METAL CO LTD

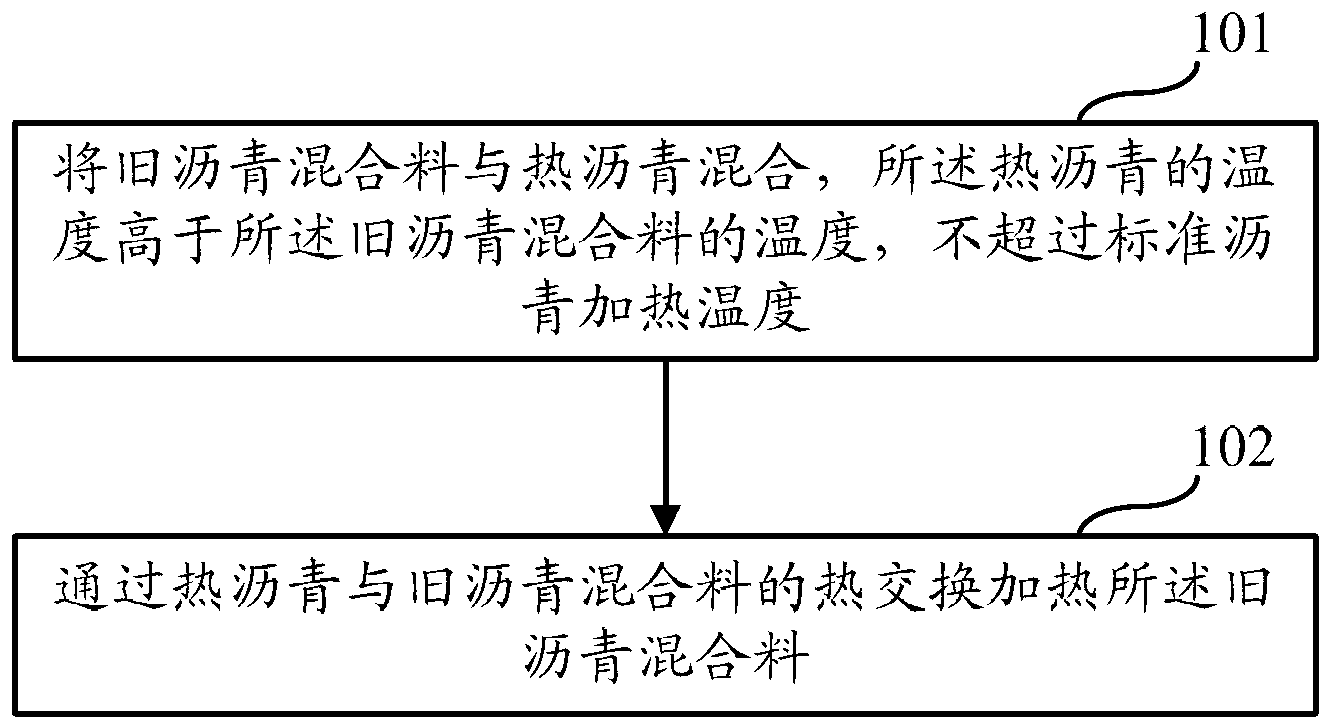

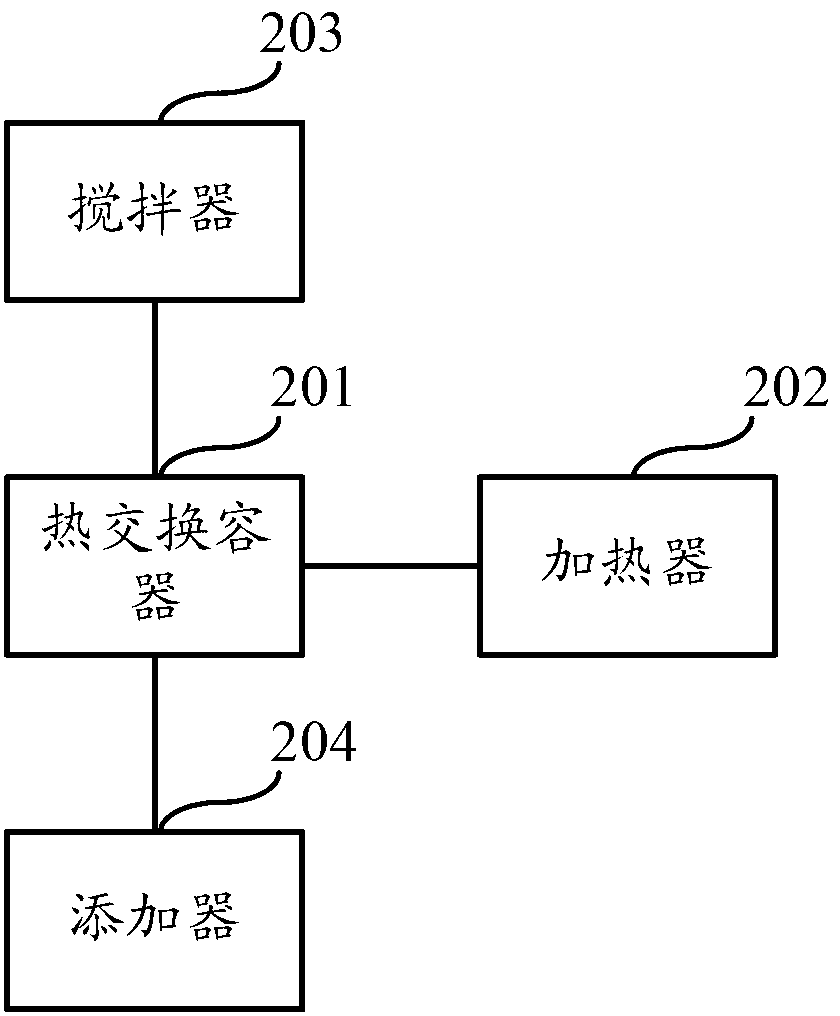

Method and device for waste asphalt mixture thermal regenerative heating

InactiveCN102704373AImprove road performanceReduce the degree of asphalt performance degradationClimate change adaptationWorking-up pitch/asphalt/bitumenAsphaltHeating temperature

The invention discloses a method for waste asphalt mixture thermal regenerative heating. The method includes that: waste asphalt mixtures and hot asphalt are mixed, wherein the temperature of the hot asphalt is higher than that of the waste asphalt mixtures and is not higher than the heating temperature of standard asphalt; and the waste asphalt mixtures are heated through heat exchange between the hot asphalt and the waste asphalt mixtures. The invention further discloses a device for waste asphalt mixture thermal regenerative heating. The device comprises a heat exchange container for containing mixtures of the waste asphalt mixtures and the hot asphalt, and the waste asphalt mixtures are heated through heat exchange between the hot asphalt and the waste asphalt mixtures, wherein the temperature of the hot asphalt is higher than that of the waste asphalt mixtures and is not higher than the heating temperature of the standard asphalt. The method and the device can reduce the asphalt performance degrading degree of the waste asphalt mixtures in the heating process and improve the pavement performance of the heated waste asphalt mixtures.

Owner:苏强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com