Harmless treatment method and system of lithium metal waste residue

A technology of harmless treatment and metal lithium, applied in the direction of improving process efficiency, can solve the problems of high equipment requirements, polychloride, long process, etc., and achieve the effect of good safety performance, less time-consuming processing, and rapid process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

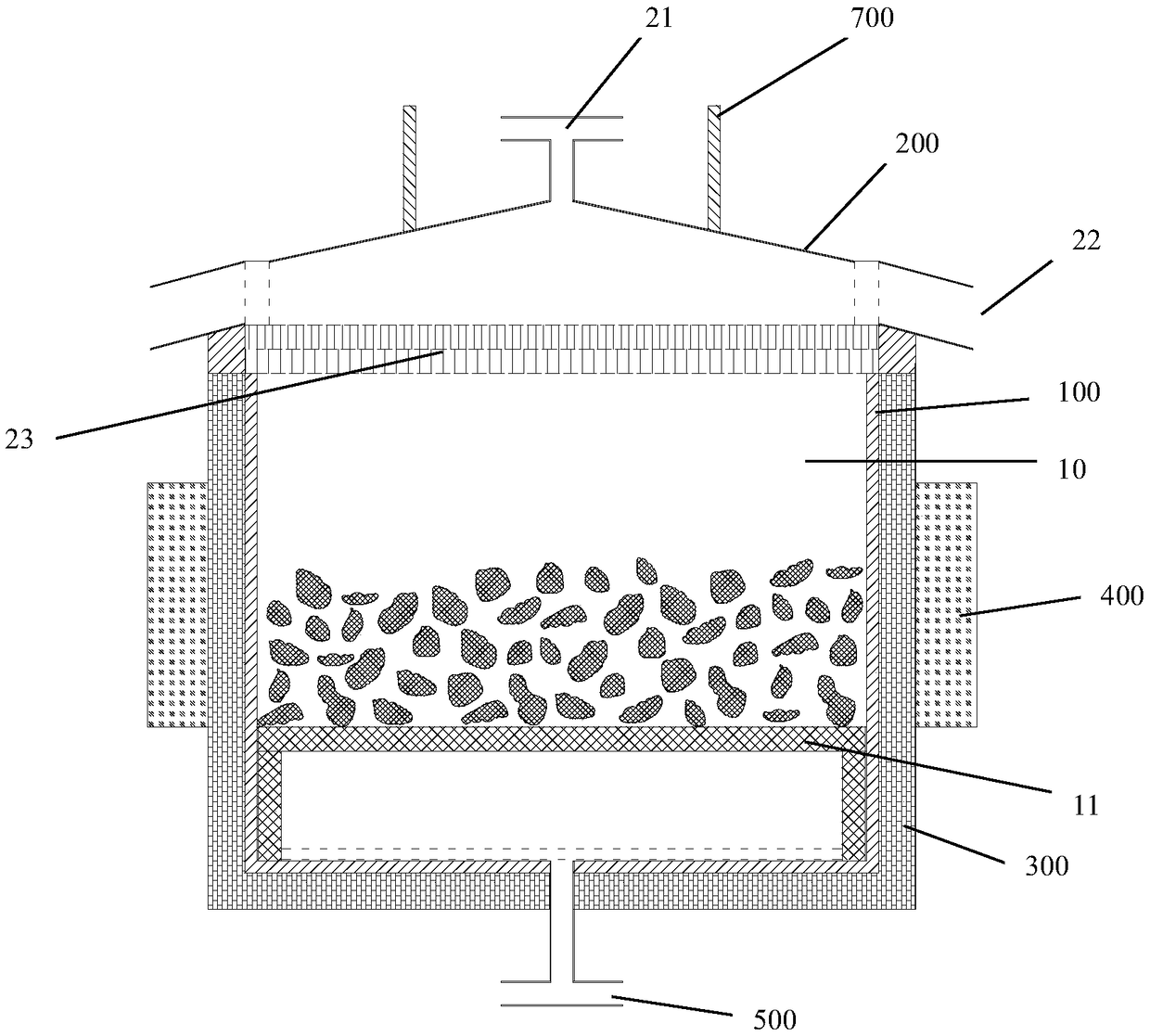

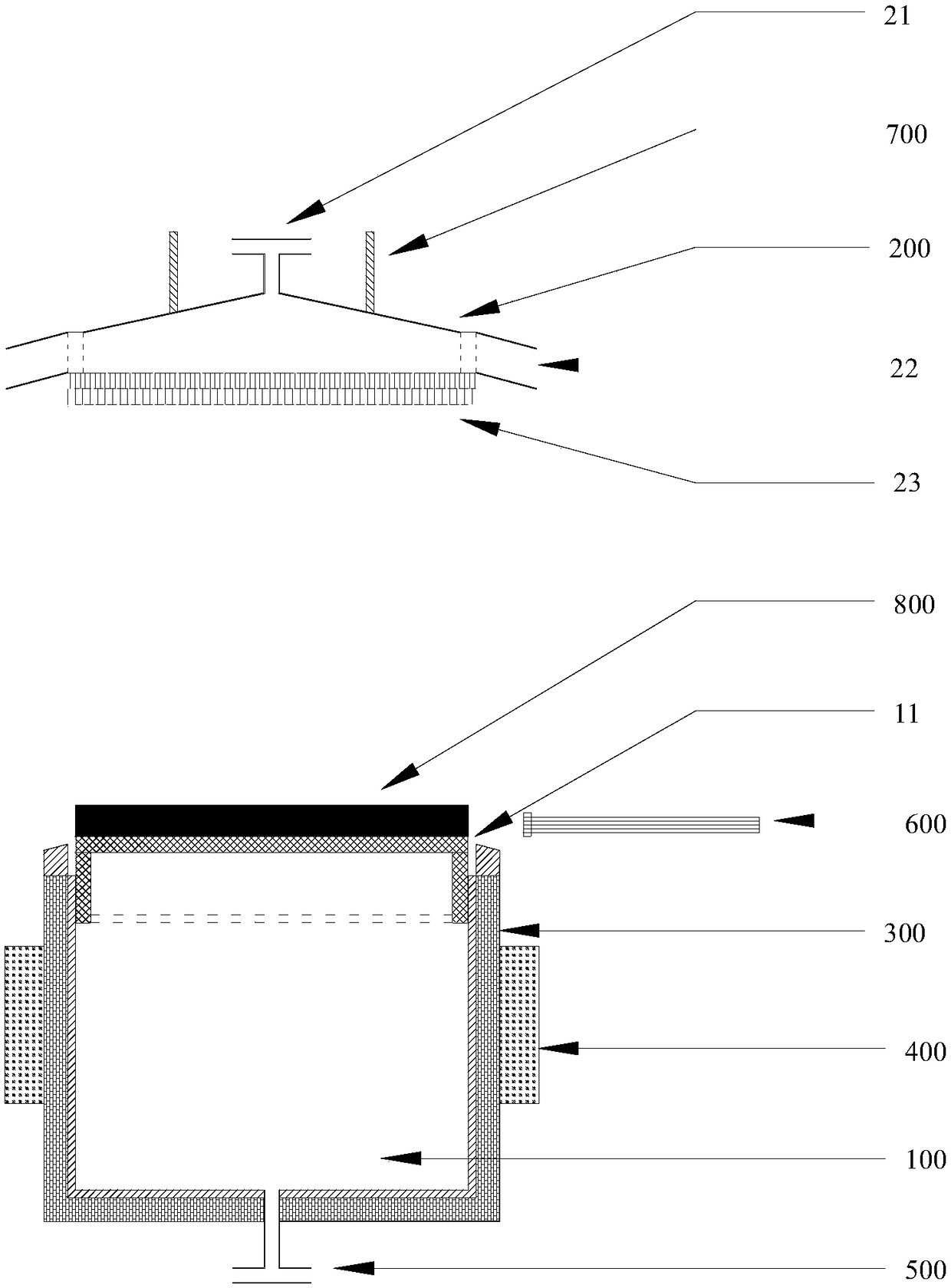

Image

Examples

Embodiment 1

[0102] The harmless treatment method of metal lithium waste residue in the present embodiment specifically comprises the following steps:

[0103] 1. Take 1000g lithium metal waste residue in a high-purity argon protective atmosphere, and put it into a waste residue heating container;

[0104] 2. Install a filter screen with a pore size of 50 μm on the upper cover with a protective gas pipeline and a lithium outlet pipeline, and lower the upper cover through a hydraulic lifting rod to seal the waste residue heating container;

[0105] 3. Turn on the gas control unit, discharge the waste residue through the protective gas pipeline on the upper cover, heat the inner atmosphere of the container to a vacuum of 0.09MPa and fill it with high-purity argon to normal pressure, stop after 3 cycles;

[0106] 4. Turn off the gas control unit, turn on the temperature control system, and heat the waste slag heating container, working gas heating container, working gas pipeline and lithium o...

Embodiment 2

[0114] The harmless treatment method of metal lithium waste residue in the present embodiment specifically comprises the following steps:

[0115] 1. Take 1000g lithium metal waste residue in a high-purity argon protective atmosphere, and put it into a waste residue heating container;

[0116] 2. Install a filter screen with a pore size of 1000 μm on the upper cover with a protective gas pipeline and a lithium outlet pipeline, and lower the upper cover through a hydraulic lifting rod to seal the waste residue heating container;

[0117] 3. Turn on the gas control unit, discharge the waste residue through the protective gas pipeline on the upper cover, heat the inner atmosphere of the container to a vacuum of 0.09MPa and fill it with high-purity argon to normal pressure, stop after 3 cycles;

[0118] 4. Turn off the gas control unit, turn on the temperature control system, and heat the waste slag heating container, working gas heating container, working gas pipeline and lithium...

Embodiment 3

[0126] The harmless treatment method of metal lithium waste residue in the present embodiment specifically comprises the following steps:

[0127] 1. Take 1000g lithium metal waste residue in a high-purity argon protective atmosphere, and put it into a waste residue heating container;

[0128] 2. Install a filter screen with a pore size of 5 μm on the upper cover with a protective gas pipeline and a lithium outlet pipeline, and lower the upper cover through a hydraulic lifting rod to seal the waste slag heating container;

[0129] 3. Turn on the gas control unit, discharge the waste residue through the protective gas pipeline on the upper cover, heat the inner atmosphere of the container to a vacuum of 0.09MPa and fill it with high-purity argon to normal pressure, stop after 3 cycles;

[0130] 4. Turn off the gas control unit, turn on the temperature control system, and heat the waste slag heating container, working gas heating container, working gas pipeline and lithium outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com