Color-changeable temperature developing ternary composite filter rod

A ternary composite and color-changing technology, which is applied in e-liquid filter elements, applications, tobacco, etc., can solve the problems of affecting the effect of flavor enhancement, affecting the use efficiency of flavors and fragrances, and failing to reach the volatilization temperature of flavors and fragrances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

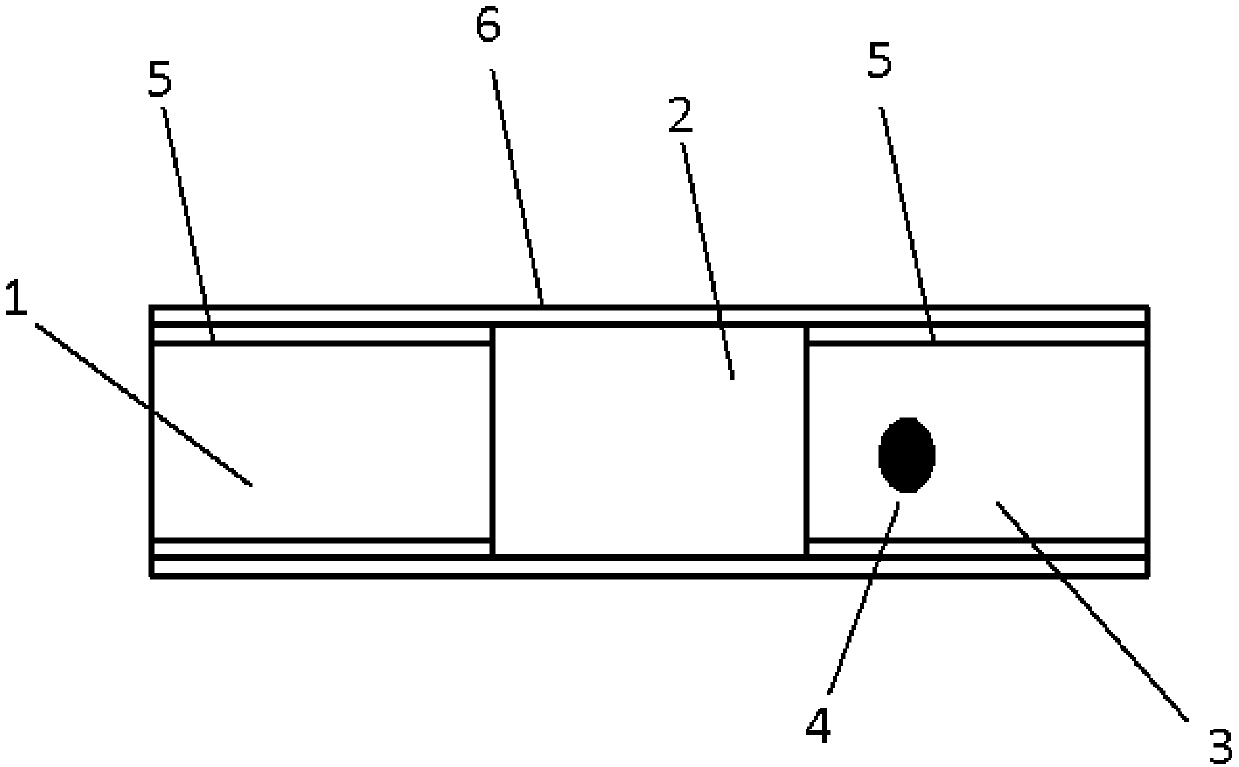

[0027] The ternary composite filter rod is divided into a first acetate fiber filter rod section 1, a hollow section 2, and a second acetate fiber filter rod section 3, wherein the hollow section contains explosive beads 4 for cigarettes. Each section has its own molding paper 5, and the three sections are wrapped with tipping paper 6 as a whole to form a ternary composite filter rod. The ternary compound filter rod can be compounded in the way of 5mm+15mm+10mm.

[0028] In this example, the flavor and fragrance substance in the popcorn for cigarettes is Yunnan olive, a characteristic plant extract of Yunnan, and its heat volatilization temperature is 65°C. , when the temperature rises to 50-60°C, the particles change from green to colorless. The particles made of the thermochromic substance are placed in the hollow solid part of the filter rod.

[0029] When the cigarette is smoked, the smoke enters the hollow area of the firmware, and the temperature of the firmware sect...

Embodiment 2

[0031] The structure of the ternary composite filter stick is the same as that in Example 1, and the flavor and fragrance substances are prepared from the extract of mint lobular mint, a characteristic plant in Yunnan. Correspondingly, the thermochromic substances are selected from electron transfer organic compounds The reversible color-reversing substance prepared by the system is an organic color-emitting system with a special chemical structure. At a specific temperature, the molecular structure of the organic substance changes due to electron transfer, thereby achieving color transformation. The color-changing substance is not only bright in color, but also can realize the color change from the states of "colored===colorless" and "colorless===colored". Use this substance to prepare reversible discoloration particles, and use transparent materials such as polypropylene materials for injection molding, extrusion molding, and compression molding. According to the degree of c...

Embodiment 3

[0036] The structure of the ternary composite filter rod is the same as that in Example 1, and the flavor and fragrance substances are prepared from the extract of Yunnan characteristic plant cool taste mint. agent and a sensitizer, and sprayed on the forming paper wrapping the second cellulose acetate filter rod section 3, a transparent window is opened here on the external tipping paper to facilitate the user to observe the temperature-induced discoloration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com