Method of manufacturing float glass

A float glass, melting glass technology, applied in the field of manufacturing float glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

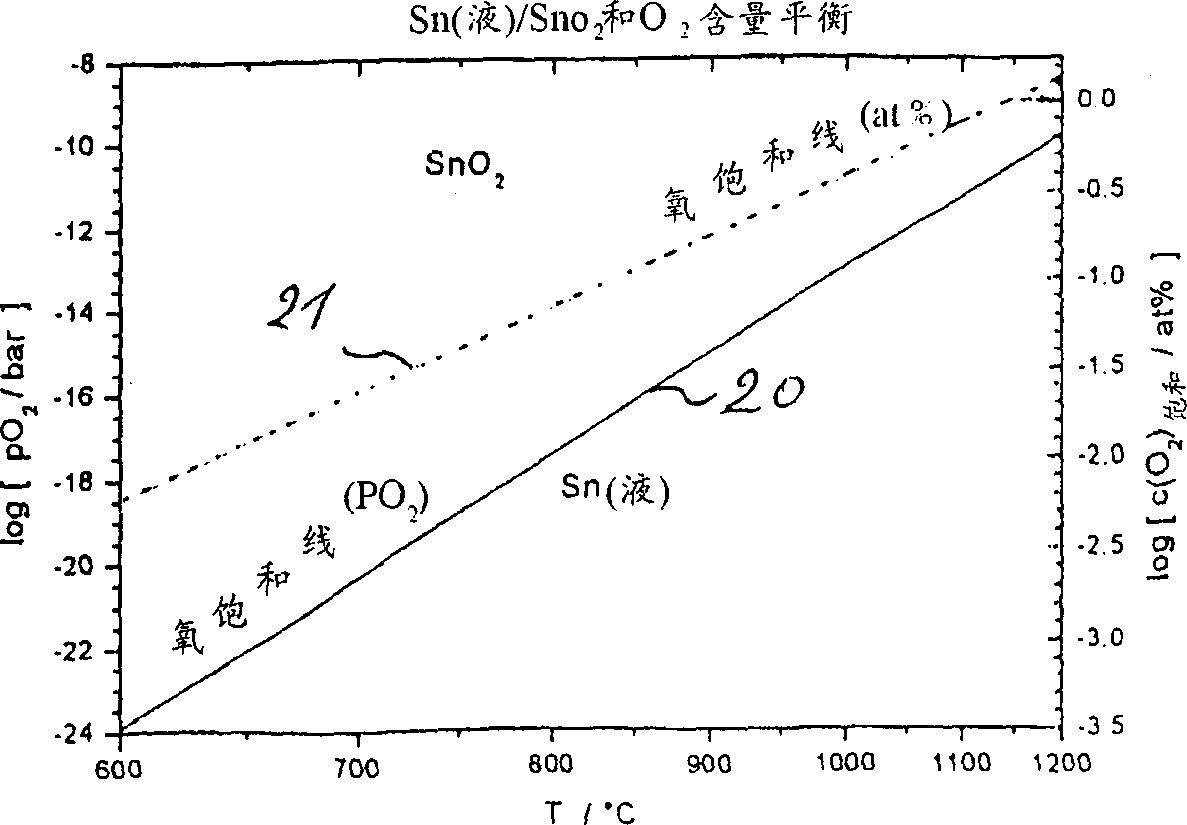

[0027] Liquid tin has a particularly high affinity for oxygen, so that even tiny amounts of oxygen lead to the formation of tin oxide. Oxygen remains homogeneously dissolved in the tin as long as the corresponding limit amount is not exceeded. The solubility of oxygen is strongly dependent on temperature, and clearly in a relationship with image 3 The corresponding phase diagram follows log[pO 2 ]=f(T) to represent.

[0028] From image 3 (curve 20), it can be seen that at typical metal bath temperatures above 600 °C, the presence of oxygen-containing liquid tin ranges from less than 10 -24 bar(600℃) and less than 10 -11 The partial pressure of oxygen in bar (1200°C) is defined. oxygen partial pressure pO 2 Indicates the binding force of liquid tin to dissolved oxygen. The binding force can vary over several orders of magnitude. Reference can be made to the formula in the book "Metallurgische Elektrochemmie (Metallurgy Electrochemistry)" published in Duesseldorf in 1975...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com