Magnesium alloy oxidation coloring method and product thereof

A magnesium alloy and product technology, applied in the field of magnesium alloy oxidation color development method and its products, can solve the problem of single color tone of magnesium alloy surface treatment, and achieve the effect of making up for the single color vacancy, simple operation process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

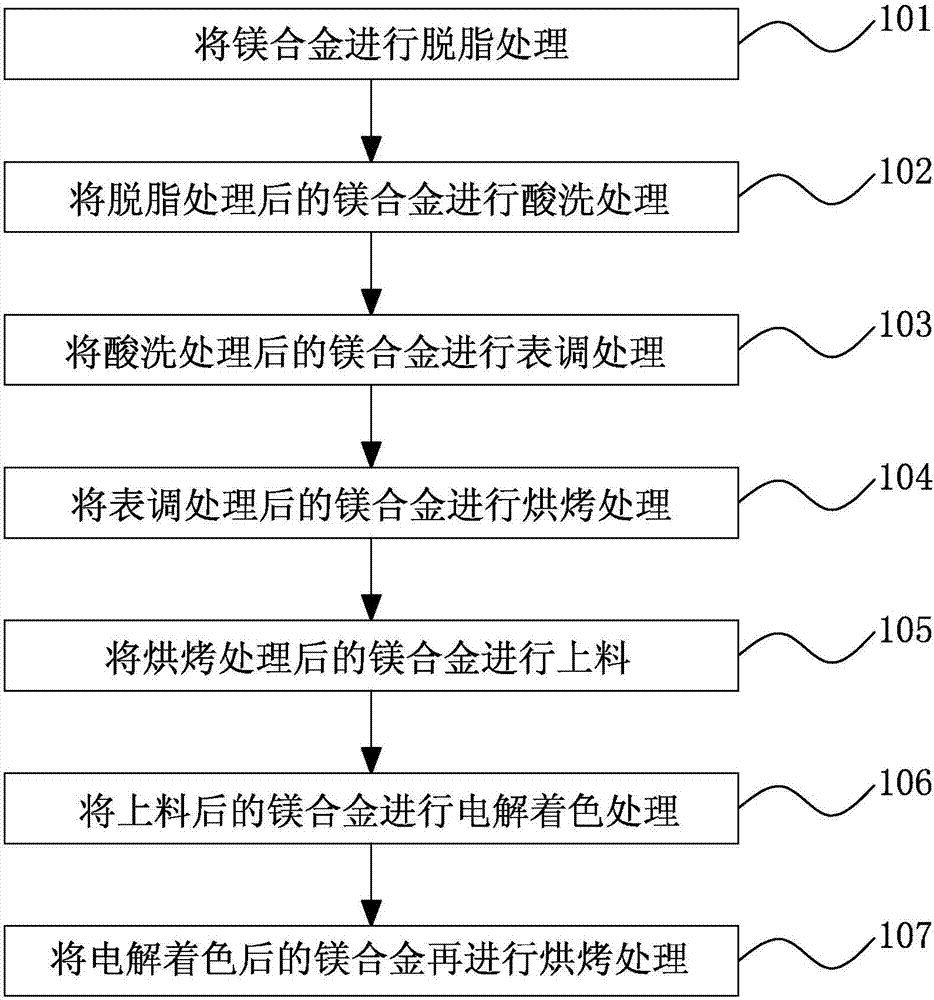

[0029] see figure 1 , figure 1 A flow chart of the magnesium alloy oxidation and color development method of the present invention is shown.

[0030] For a further understanding of the purpose of the present invention, method steps and functions, please refer to figure 1 , and detailed as follows:

[0031] In order to achieve the above object, the present invention provides a method for oxidation and color development of magnesium alloys, which comprises the following steps:

[0032] Step 101: degreasing the magnesium alloy;

[0033] Step 102: pickling the degreased magnesium alloy;

[0034] Step 103: performing surface conditioning treatment on the pickled magnesium alloy;

[0035] Step 104: Baking the surface-conditioned magnesium alloy;

[0036] Step 105: Loading the baked magnesium alloy;

[0037] Step 106: performing electrolytic coloring treatment on the loaded magnesium alloy;

[0038] Step 107: Baking the electrolytically colored magnesium alloy.

[0039] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com