Patents

Literature

126results about How to "To achieve the purpose of antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denitrification dephosphorization antibacterial composite water treatment material used for water reclamation

InactiveCN101716489ASmall steric hindranceIncreased internal diffusionAluminium silicatesWater/sewage treatment using germicide/oligodynamic-processIon exchangeRespiratory chain

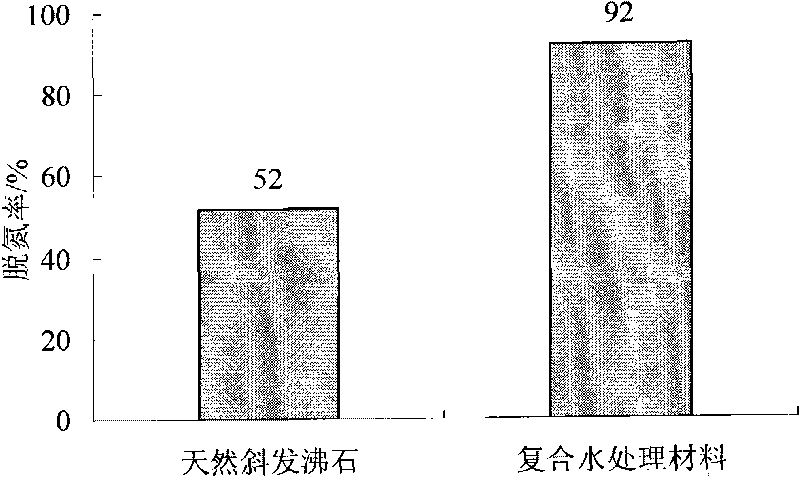

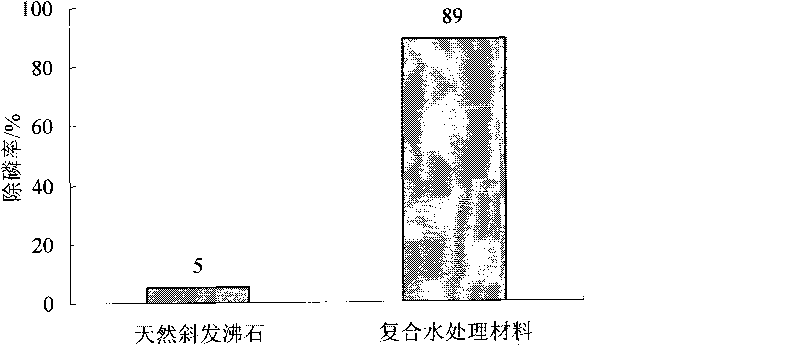

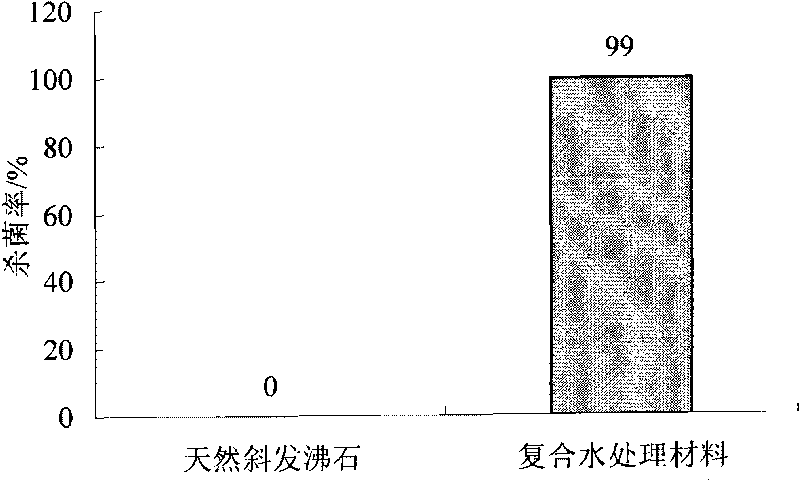

The invention discloses a denitrification dephosphorization antibacterial composite water treatment material used for water reclamation, belonging to the field of environmental protection. In the invention, zeolite is modified by a method combining high temperature activation and chemical treatment; natural clinoptilolite is treated by a NaCl solution for the first time to improve ammonia nitrogen removal capacity and reaction speed of the zeolite; then the zeolite is treated by lanthanum chloride used as a loading agent, wherein lanthanum is attached to the surface of the zeolite in a form of lanthanum oxide and is electrically absorbed to phosphate radical ions to generate lanthanum phosphate complex for dephosphorization; and finally, by utilizing ion-exchanging property of zeolite particles and loading inorganic antibacterial ion Ag+ inside pore canals of the zeolite by adopting a liquid phase ion-exchange method, silver ions and oxygen molecules generate ROS during bacteriostasis, and enzyme in a respiratory chain is inhibited by generated super-oxidation activators, thereby achieving the purpose of bacteriostasis. The invention takes the natural clinoptilolite as an absorbent, has the advantages of rich raw materials, low price, convenient reclamation, low cost on water treatment, and obvious denitrification dephosphorization antibacterial effect in the water reclamation.

Owner:UNIV OF SCI & TECH BEIJING

Nano-antibacterial deodorant PET (polyethylene glycol terephthalate) fiber and preparation method thereof

InactiveCN103484972AImprove mechanical propertiesMetabolic Reproductive InhibitionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterPolyethylene terephthalate

The invention relates to a nano-antibacterial deodorant PET (polyethylene glycol terephthalate) fiber which comprises 1 to 10% of antibacterial special master batch particles and 90 to 99% of PET sections. The invention also relates to a preparation method of the nano-antibacterial deodorant PET fiber. The preparation method comprises the following steps: (1), drying the antibacterial master batch particles by a drying machine, mixing with the PET polyester sections, to obtain antibacterial special master batch particles; and (2), mixing the antibacterial special master batch particles with the PET sections, carrying out melt spinning on spinning equipment, so as to obtain the nano-antibacterial deodorant PET fiber. The nano-antibacterial deodorant PET and the preparation method have the following beneficial effects that through adding the nano-silver antibacterial master batch particles as an effective antibacterial component in the melt spinning process of the nano-antibacterial deodorant PET, the antibacterial and deodorant purposes are realized, the fiber has a significant inhibiting function to escherichia coli and staphylococcus aureus, and the antibacterial rate is higher than 90%. In addition, the fiber further has excellent mechanical property.

Owner:KUNSHAN WANFENG GARMENT

Antibiotic composite plastic packing film

InactiveCN101092196AImprove barrier propertiesHigh mechanical strengthFlexible coversWrappersPlastic packagingHeat resistance

The invention provides an antibacterial composite plastic packing membrane and the making process thereof. And it comprises heat sealing layer, middle layer, and outer layer, where the composition of the heat sealing layer contains: LLDPE 5-40 parts, LDPE 10-35parts, MPE 15-35parts, and antibacterial agent 0.5-5 parts,the composition of the middle layer contains MPE 3-5parts, LDPE 15-25parts, LLDPE 55-70parts, antibacterial agent 0.2-3parts,the composition of the outer layer contains MPE 3-13parts, LDPE 15-35parts and LLDPE 45-65parts. And it carefully chooses antibacterial agent which has high-efficiency broad-spectrum property, is safe and nontoxic to human body, and has good heat resistance and succeeds in combining the antibacterial agent with PE membrane which has common physical and mechanical properties and makes the antibacterial agent uniformly distributed on the surface of the PE membrane, thus improving antibacterial function of the membrane and the surface polarity and hydrophily of the membrane, so as to make the membrane have good antistatic property.

Owner:哈尔滨上洋包装制品有限公司

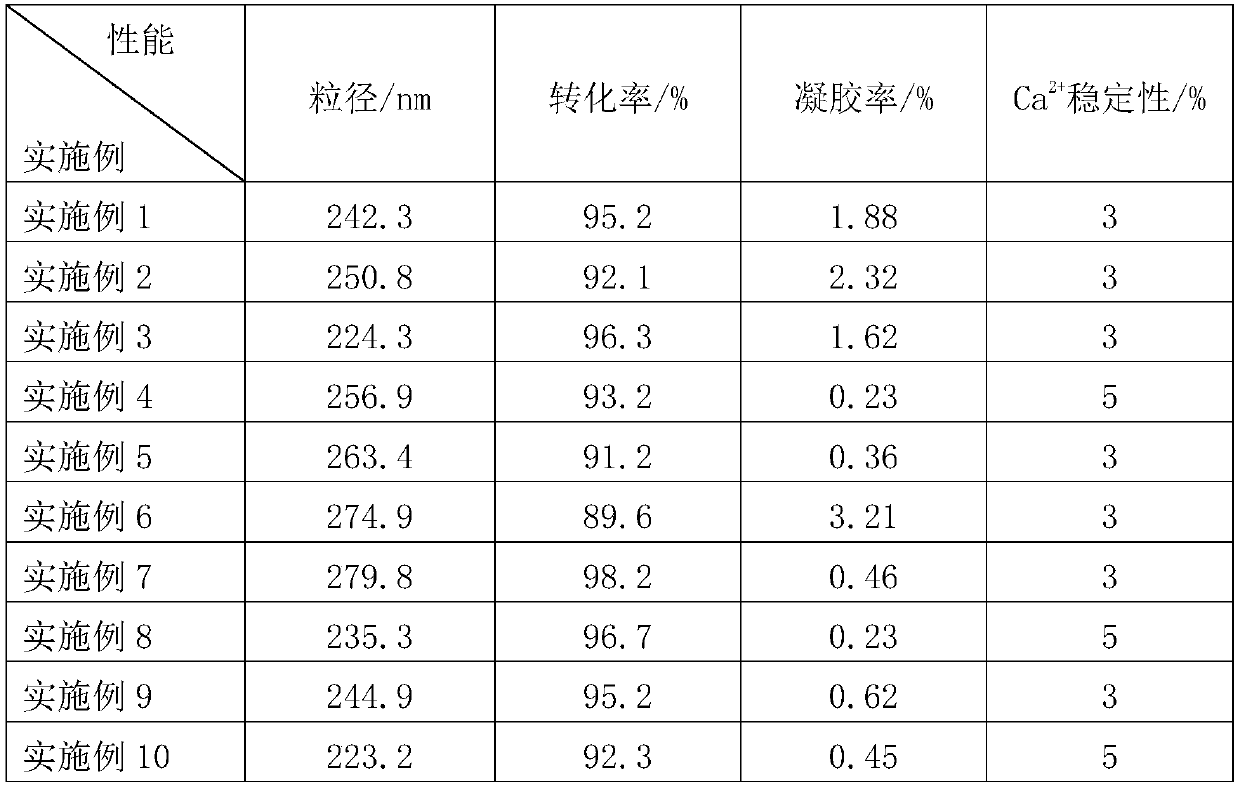

Water-based self-crosslinking cation copolymer emulsion as well as preparation method and application thereof

ActiveCN108676117AInhibition of growth and reproductionImprove water resistanceAntifouling/underwater paintsPaints with biocidesWater basedFunctional monomer

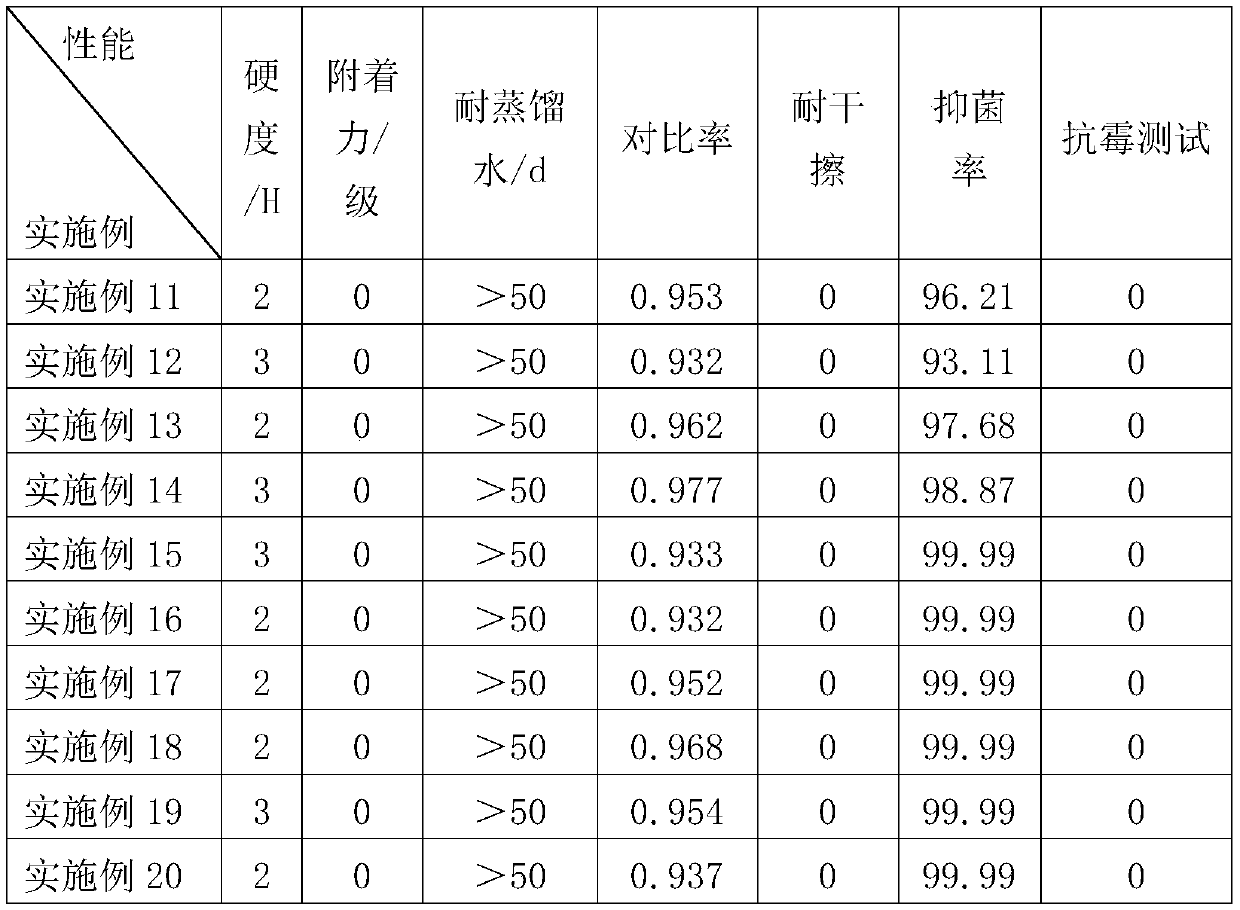

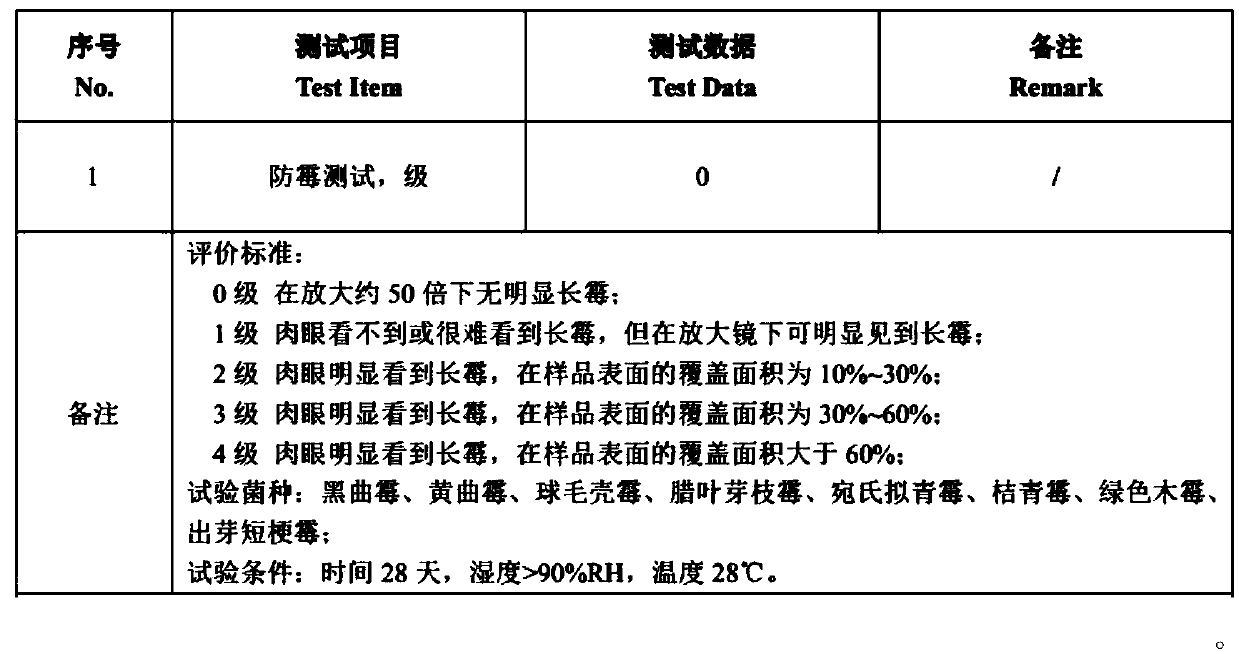

The invention discloses a water-based self-crosslinking cation copolymer emulsion as well as a preparation method and application thereof, and belongs to the field of paint. Cations can polymerize functional monomers, acrylate-type monomers are comonomers, and self-crosslinking monomers are added to obtain the water-based self-crosslinking cation copolymer emulsion. The functional monomers and theself-crosslinking monomers both with positive charges are introduced through copolymerization, and accordingly, the copolymer emulsion has high stability, long-lasting mildew resistance performance and high base material adhesion. A composited high-glass-transition-temperature self-crosslinking cation copolymer emulsion and a composited low-glass-transition-temperature self-crosslinking cation copolymer emulsion are mixed proportionally to serve as a film forming substance to prepare water-based antibacterial paint, addition of film forming aids is not needed, and films can be formed at the room temperature; adhesion force of coatings is excellent, water resistance of the films lasts more than 50 days, the films can resist more than twenty thousand times of scrubbing, mildew resistance reaches the zero level according to tests, and the bacteriostasis rate is higher than 99.99%.

Owner:BEIJING UNIV OF CHEM TECH

Curcumin loaded antibacterial fibrous membrane and preparation method thereof

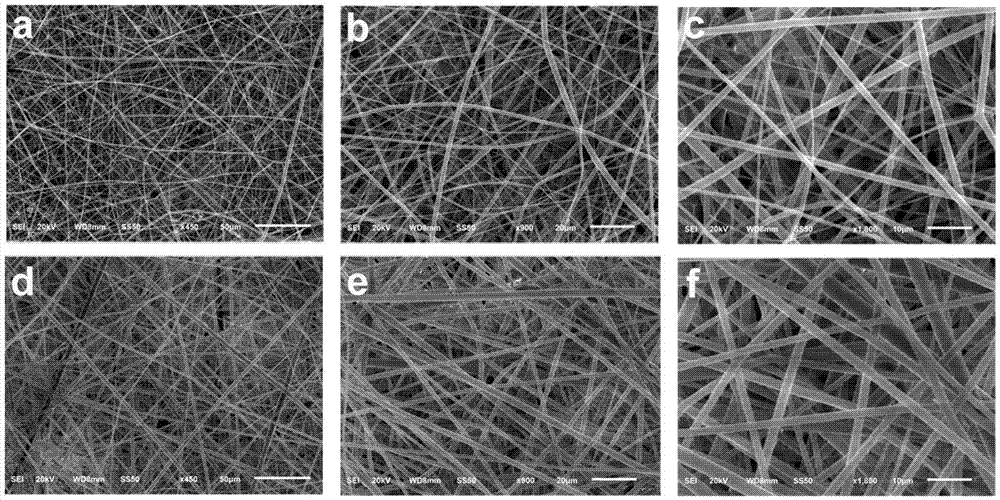

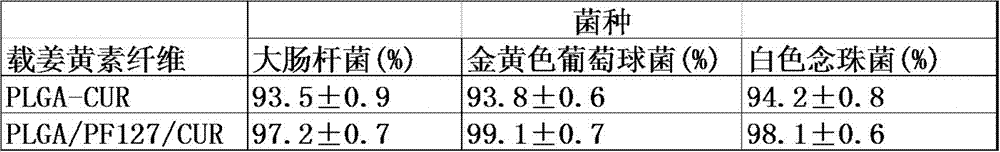

InactiveCN107308137AGood biocompatibilityPromote degradationAntibacterial agentsAntimycoticsEscherichia coliFiber

The invention discloses a curcumin loaded antibacterial fibrous membrane and a preparation method thereof. The antibacterial effect of the prepared fibrous membrane on candida albicans, escherichia coli and staphylococcus aureus reaches 93% or higher. The fibrous membrane is composed of an antibacterial agent and a carrier material, wherein curcumin is used as the antibacterial agent, a biodegradable polymer material is used as carrier material, and the two parts are modified by an amphiphilic substance simultaneously. The preparation method has the following specific steps: adding the curcumin, the amphiphilic substance and the biodegradable polymer material into an organic solvent to obtain a spinning solution; spinning the spinning solution with an electrostatic spinning apparatus, and volatilizing the organic solvent to prepare the curcumin loaded antibacterial fibrous membrane. The invention has the advantages that the curcumin loaded antibacterial fibrous membrane is environmentally friendly, the preparation method is simple, the cost is low, and the antibacterial effect reaches 93% or higher.

Owner:SOUTHWEST UNIV

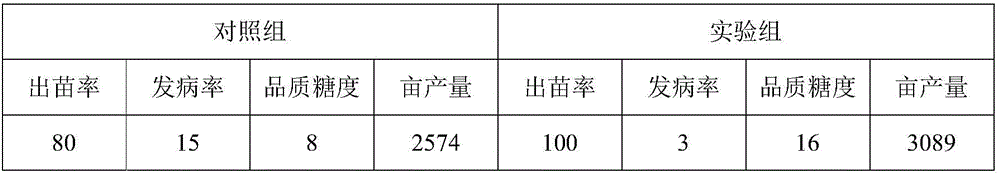

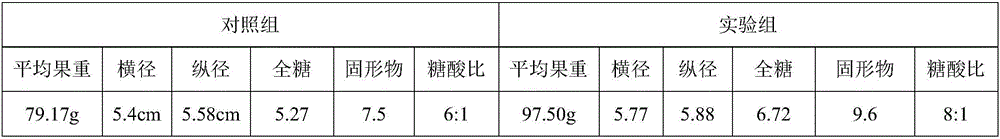

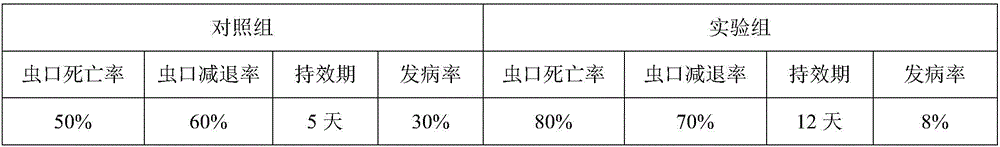

Preparation method for plant growth stimulant and application of plant growth stimulant

InactiveCN106472569AGrowth Stimulation EfficientEfficient disease prevention and stress resistanceBiocidePlant growth regulatorsPhosphateMonopotassium phosphate

The invention relates to the field of biostimulants and particularly relates to a preparation method for a plant growth stimulant and an application of the plant growth stimulant. The plant growth stimulant is prepared through preparing a seed solution from yellow-ocher streptomyces, inoculating the seed solution to a fermentation tank containing a mixed culture medium of maize meal, soybean meal, glutamic acid, potassium dihydrogen phosphate, sodium chloride, seaweed powder and cerealose which are in a certain ratio, carrying out fermentation, and uniformly mixing fermentation broth of the yellow-ocher streptomyces with multivitamins, multiple amino acids and algal polysaccharides which are in a certain ratio. The plant growth stimulant disclosed by the invention can be added into organic fertilizers, water-soluble fertilizers and microbicides according to a certain ratio so as to carry out synergizing, increase yield, prolong drug effect duration and enhance immunity. The plant growth stimulant disclosed by the invention has the effect of playing a role in stimulating natural courses of plants, including being beneficial to the enhancement of nutrient absorption, nutritional effects, abiotic stress resistance and crop quality, promoting the growth of roots, stems and leaves of crops, and improving the resistance of the crops, can be used for stimulating cell division of plants, promoting formation of chlorophyll and enhancing photosynthesis of the plants and has the aims of promoting growth, advancing ripeness, keeping enough flowers and young fruits, increasing yield, improving crop quality and achieving the yield increase and high yield of the crops.

Owner:海南博士威生物科技有限公司

Antibiotic finishing method of silk fabric

InactiveCN104264449AImprove antibacterial propertiesLong validity periodAnimal fibresSodium sulfateTitanium oxide

The invention discloses an antibiotic finishing method of a silk fabric. The method comprises the following steps: (1) preparing antibiotic finish liquor: uniformly mixing and stirring nanometer titanium oxide powder and deionized water, adding dispersing agent lauryl sodium sulfate and silane coupling agent kH560 in above mixed liquor, ultrasonically stirring for 30min; (2) warming the antibiotic finish liquor to 50-80 DEG.C, placing the silk fabric, dipping twice and rolling twice in the bath ratio of 1: 30 to 1: 60, wherein the pick-up rate is 80-90%; and (3) taking out the silk fabric, drying for 10min at 80 DEG.C, baking for 2-5min at 120-150 DEG.C to obtain the finished silk fabric. The silk fabric finished by using the method disclosed by the invention has good antibiotic performance, is long in validity, non-toxic, and in favor of environmental protection.

Owner:SUZHOU INSILK CO LTD

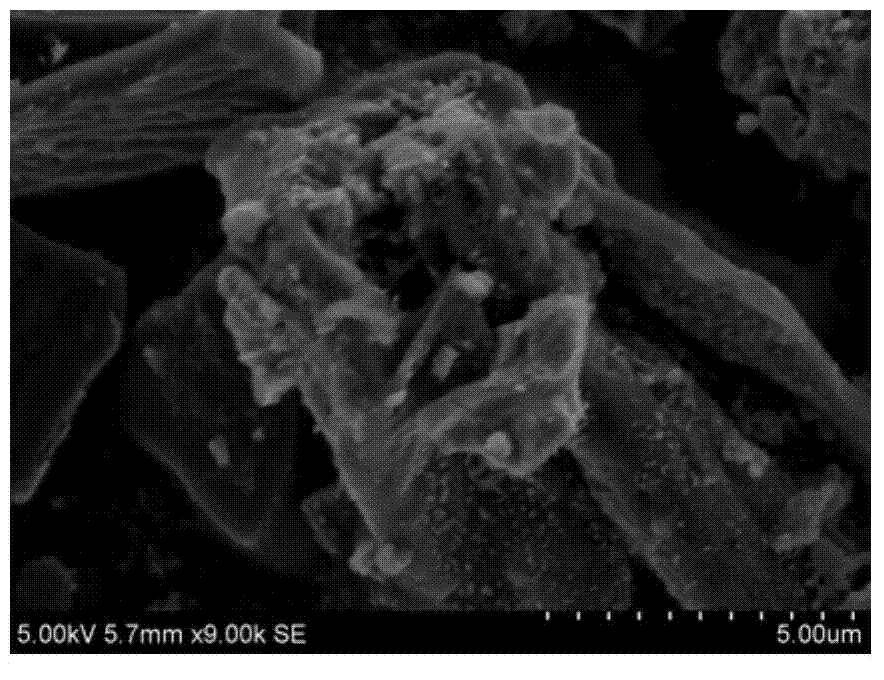

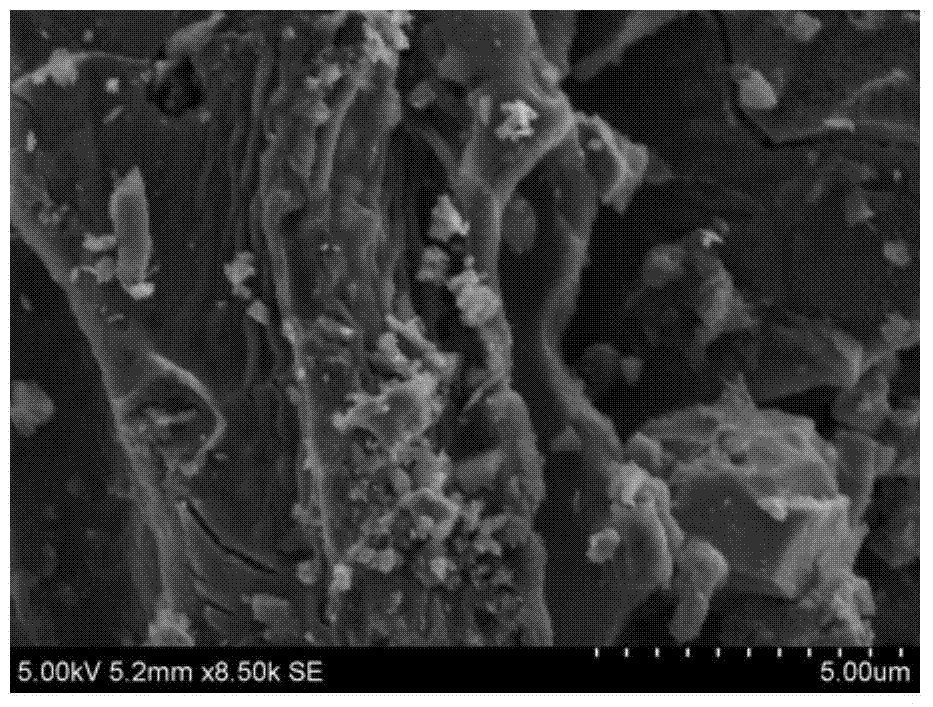

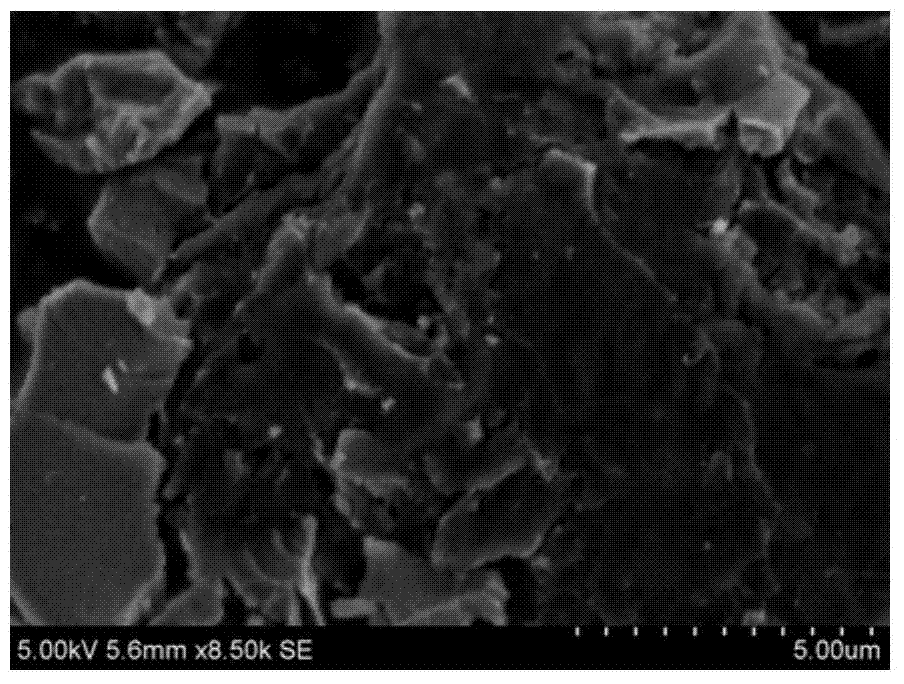

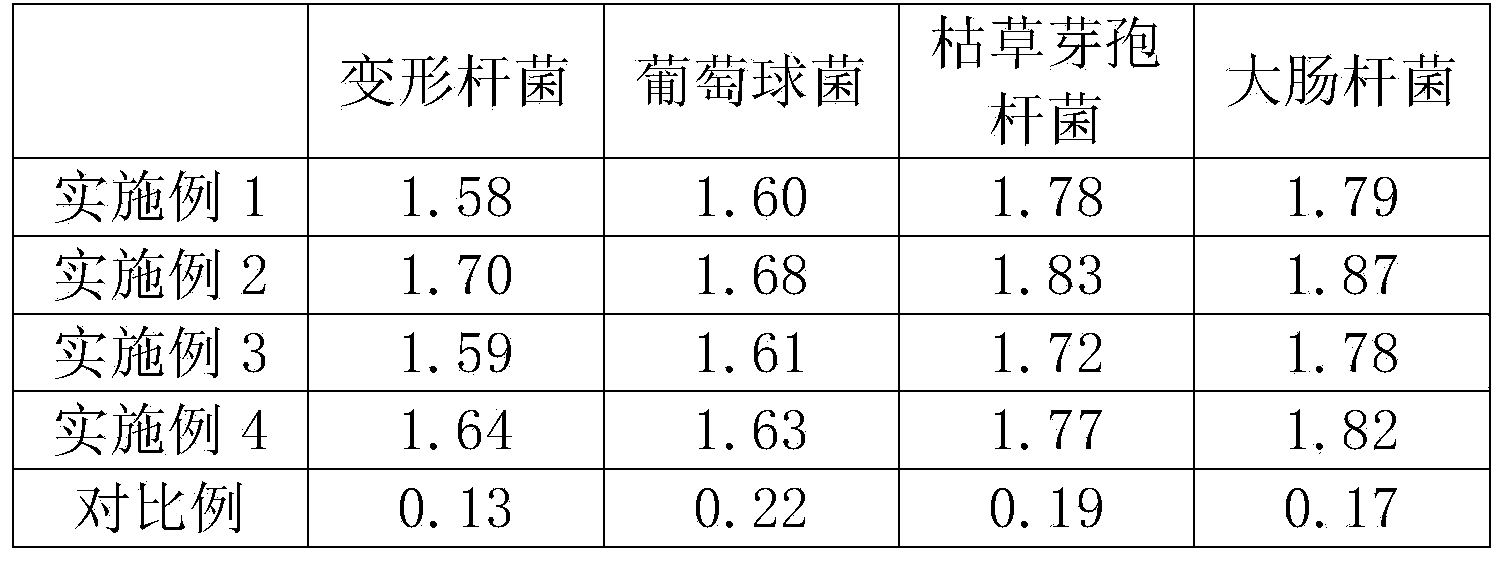

Antibacterial active carbon nano composite material and preparation method thereof

InactiveCN103783080AStrong oxidation abilityTo achieve the purpose of antibacterialBiocideCarbon compoundsFiberActivated carbon

The invention provides an antibacterial active carbon nano composite material. The preparation method comprises the following steps: by taking waste fiber plates as a raw material, charring for 1-1.5 hours at 550-600 DEG C; activating the obtained carbide crushed by introducing vapor at 700-800 DEG C; sieving the activated carbon and dehydrating at constant temperature; then, carrying out TiO2 load on the activated carbon by a sol-gel method; and microwave heating the dried gel under a condition of 500-800w to obtain the antibacterial active carbon nano composite material. The active carbon nano composite material product prepared by the method provided by the invention is high in density, good in thermal stability, high in content of loaded TiO2 and uniform in dispersion of the loaded TiO2, has broad-spectrum antibacterial property, and also has high antibacterial rate, good antibacterial property and durability of antibacterial property.

Owner:BEIJING FORESTRY UNIVERSITY

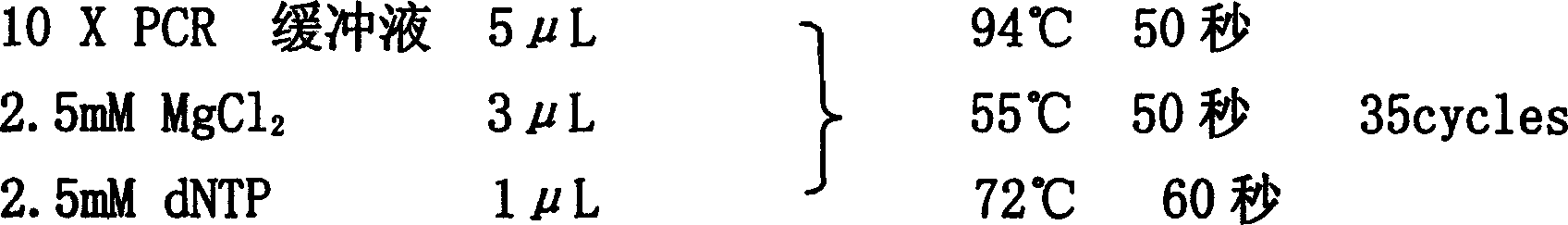

Expressions of recombined swine lactoferrin and its peptide by pichia

InactiveCN1584035AUnique mechanism of actionTo achieve the purpose of antibacterialFungiFermentationYeastFeed additive

A bichia methanol saccharomyces expressing recombinant swine lactoferrin and its peptide are disclosed. It includes: amplifying LF gene, constructing and identifying recombinant saccharomyces expressing carrier, sieving and detecting PMAD11 or PMAD16 and Ade+Muts phenotypic conversion, inducing expressing Ade+Muts strain, purifying and identifying objective protein, transferring into fermenter to grow after identifying. It achieves simple process and high purity for feed additives.

Owner:ZHEJIANG UNIV

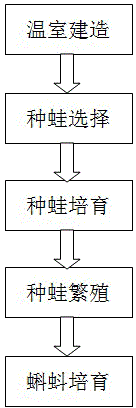

Method for managing parent frogs in greenhouses

ActiveCN104920298AImprove survival rateGood economic benefitsFood processingClimate change adaptationIrrigationTrace element

Owner:蒙有恳

Antibacterial float glass

The invention discloses an antibiotic float glass, which comprises the following compositions (by weight percent): SiO2 68-75%, Na2O 10-18%, CaO 5-15, MgO 0-5%, Al2O3 0-5%, K2O 0-5%, Sb2O3 0.1-0.6%, TiO2 0.8-1.6%, Ag2O 0-2%, ZnO 0-6%, Ca4(CaF)(PO4)3 0.1-0.8%, Ca4(CaCl)(PO4)3 0.1-0.6%. The float glass has the functions of bacteria repellency and air purification.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Production method of heat-sealing self-adhesive medical dialyzing paper

ActiveCN110939009AImprove surface bond strengthHigh bonding strengthWater-repelling agents additionPulp beating methodsProcess engineeringSizing

The invention discloses a production method of heat-sealing self-adhesive medical dialyzing paper. The production method comprises the following steps: pulping a pulp; pulping; preparing materials; forming on a net; squeezing and dehydrating; drying and surface sizing; drying, transferring and coating; calendaring and coiling; rewinding and packaging to obtain a finished product. According to themedical dialyzing paper prepared by the method, the indexes of air permeability and bonding strength can meet the use requirements of the medical industry, the production of base paper and an adhesivelayer is completed in a papermaking machine in one time, the medical dialyzing paper is directly used for manufacturing medical packaging paper plastic bags, the equipment, labor and transportation cost can be saved, and the efficiency is greatly improved.

Owner:安徽华邦古楼新材料有限公司

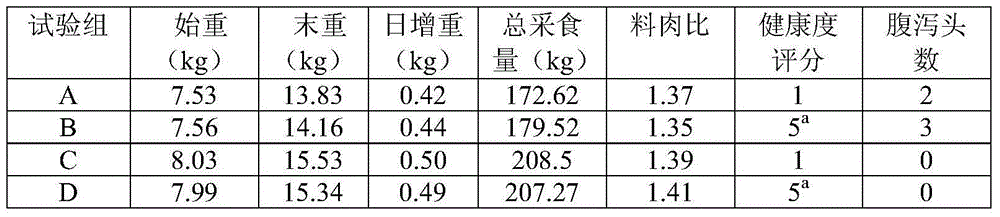

Preweaning feed free of zinc oxide

The invention discloses a preweaning feed free of zinc oxide. The preweaning feed is prepared from the following raw materials in parts by weight: 8-10 parts of common maize, 15-20 parts of expended maize, 20-25 parts of broken rice, 1-3 parts of hulled soybean meal, 2-5 parts of dietary fiber, 5-10 parts of low-protein whey powder, 10-15 parts of expanded full-fat soybean, 5-10 parts of fish meal, 2-5 parts of potato protein powder, 3-5 parts of emulsified grease, 0.5-1 part of organic calcium, 1-3 parts of monocalcium phosphate, 3-5 parts of glucose, 1-3 parts of white sugar, 0.1-0.2 part of choline chloride, 1-3 parts of dried porcine soluble, 3-5 parts of plasma and 2-5 parts of core material. The invention provides the preweaning feed for controlling the diarrhea of piglets independent of zinc oxide. In the preweaning feed, easily digested raw materials with low stress and low antigen and multiple intestinal tract health-care technologies are preferably selected to prevent the diarrhea of the piglets, and the effect is obvious.

Owner:青岛大信饲料有限公司

Method for preparing activated carbon prepn. used for anti-bacterial, deodoring and antimildew

InactiveCN1559221AImprove adsorption capacityRedoxBiocideAnimal repellantsActivated carbonNano zinc oxide

An antibacterial, antimildew and deodoring activated carbon product for fabrics and shoe is prepared from activated carbon, nano-zinc oxide, nano-titanium oxide, lamina Ag-ion antibacterial agent, nano-class antimildew deodoring agent, filming adhesiveand inorganic assistant through proportional mixing.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

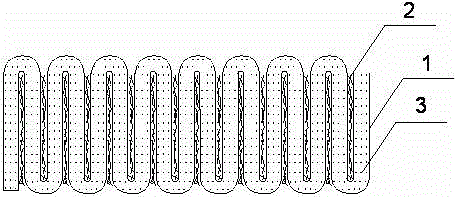

High-elastic antibacterial vertical cotton with fiber-bonded honeycomb structure and preparation method of vertical cotton

High-elastic antibacterial vertical cotton with a fiber-bonded honeycomb structure comprises back-and-forth Z-shaped sequentially stacked fiber meshes. Antibacterial agents are sprayed into the fiber meshes, the fiber meshes are sequentially connected end to end, and hot-melting fibers are clamped between the adjacent fiber meshes. During manufacture, the fiber meshes are prepared by mesh forming pre-preparation and mechanical combing mesh forming procedures and are mixtures of low-melting-point polyester staple fibers and elastic polyester staple fibers, the weight percent of the low-melting-point polyester staple fibers is 15%-35%, and the weight percent of the elastic polyester staple fibers is 65%-85%. After the antibacterial agents are sprayed into the fiber meshes, the fiber meshes are vertically laid by a vertical mesh laying procedure, the hot-melting fibers are spread among the fiber meshes, and the high-elastic antibacterial vertical cotton with the fiber-bonded honeycomb structure is prepared by drying, trimming and winding procedures. The high-elastic antibacterial vertical cotton is high in elasticity, fine in antibacterial property, simple in structure, low in cost and environmentally friendly.

Owner:WUHAN TEXTILE UNIV

Agaric cultivation medium with jasmine flower residue

ActiveCN104030842ATo achieve the purpose of antibacterialImprove antioxidant capacityFertilizer mixturesMusa aurantiacaSugar

The invention discloses an agaric cultivation medium with jasmine flower residue, the agaric cultivation medium comprises, by weight, 60-65 percent of sawdust, 25-30 percent of auxiliary material, 7-13 percent of jasmine flower residue, 0.8-1.5 percent of sugar, and 0.8-1.2 percent of gypsum. By means of the agaric cultivation medium with the jasmine flower residue, the growth of infectious microbe can be restrained very well in the cultivating process of agaric, the yield and quality of the agaric are improved, and the anti-oxidization effect of the agaric can be improved. In addition, the cost of the jasmine flower residue which is processed as waste materials and added into the agaric cultivation medium is low, the resources are fully utilized, and more than 20 percent of cost of the cultivation medium is reduced.

Owner:重庆市荣昌区小雨伞蘑菇种植有限责任公司

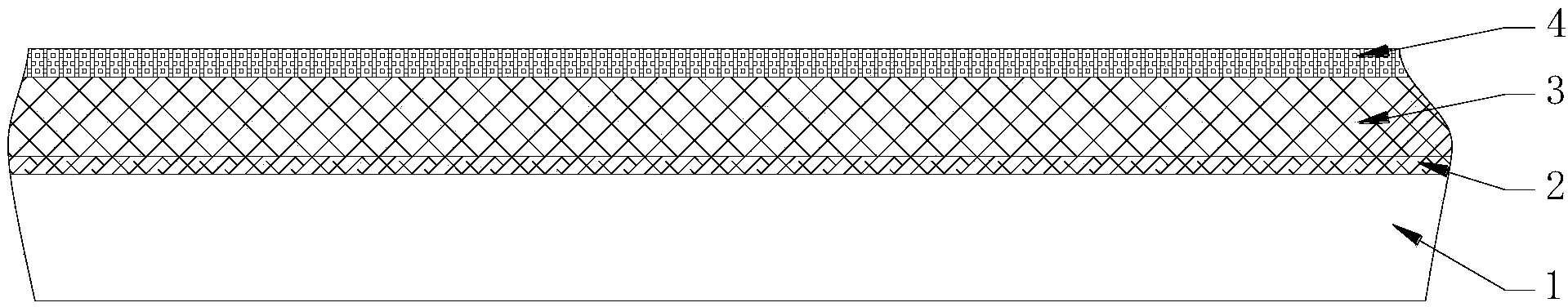

Antibacterial-layer panel of electronic product

InactiveCN104230181AImprove overall light transmittanceInhibit bacterial growthGlass/slag layered productsChemistryAnti bacterial

The invention discloses an antibacterial-layer panel of an electronic product. The antibacterial-layer panel comprises a transparent substrate, wherein the transparent substrate is provided with a first surface and a second surface which is arranged opposite to the first surface, the first surface of the transparent substrate is outwardly and sequentially plated with a SiO2 bottom layer, an antireflection plated film layer and an antibacterial layer, the antireflection plated film layer is formed by sequentially and alternately laminating a plurality of high-refractive-index material layers and low-refractive-index material layers, the antibacterial layer is a composite silver material layer, and both the antireflection plated film layer and the antibacterial layer are formed through film plating in a magnetron sputtering film plating manner. The antibacterial-layer panel has the advantages that the transmittance of light of the panel can be increased, and the reflectance of light of the surface of the panel can be decreased, so that human eyes can clearly see content on a screen; meanwhile, the antibacterial layer of the surface has a relatively good antibacterial effect, so that the growth of bacteria can be effectively inhibited for a long term.

Owner:苏州胜利光学玻璃有限公司

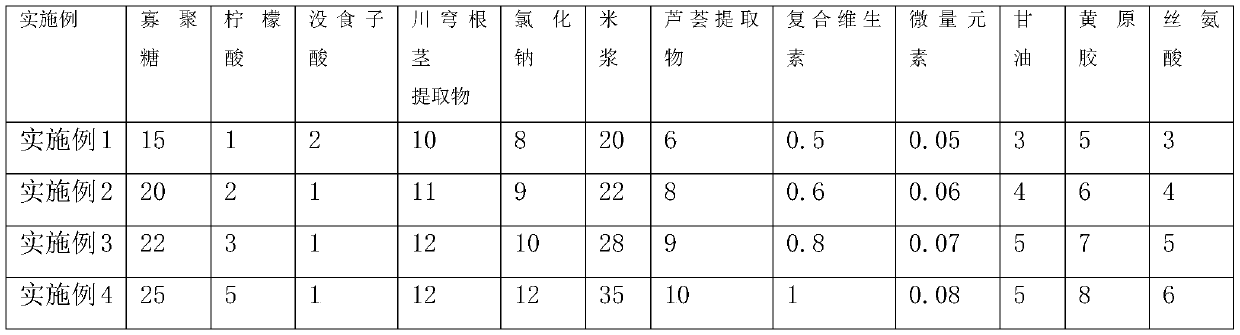

Fresh bamboo shoot fresh keeping agent and preparation method and application

ActiveCN110235935AAnti agingControl the freshness degree and freshness timeFruit and vegetables preservationNutrientChemistry

The invention discloses a fresh bamboo shoot fresh keeping agent and a preparation method and application, and belongs to the field of fresh keeping of bamboo shoots. The raw materials of the fresh bamboo shoot fresh keeping agent comprise oligosaccharide, citric acid, gallic acid, a sichuan lovage rhizome extract, sodium chloride, rice pulp, an aloe extract, complex vitamins, trace elements, glycerine, modified xanthan gum and serine, wherein the modified xanthan gum is prepared by modifying the xanthan gum with peanut tetraenoic acid, and after being diluted for 10-25 times, the fresh bamboo shoot fresh keeping agent is uniformly sprayed to the surfaces of fresh bamboo shoots. Then the fresh bamboo shoots are preserved under the condition that the temperature is 0-10 DEG C and the relative humidity is 80-90%. The prepared fresh bamboo shoot fresh keeping agent can realize fresh keeping on the fresh bamboo shoots, can prevent the nutrients of the bamboo shoots in the fresh keeping process from running off, and cannot cause mouth feel of the bamboo shoots to be reduced.

Owner:CHONGQING ACADEMY OF FORESTRY SCI

Anticorrosive antibacterial wood production method

InactiveCN104858956AImprove permeabilityImprove wettabilityBiocideWood treatment detailsEnvironmental resistanceHigh resistance

The invention discloses an anticorrosive antibacterial wood production method including the steps of pretreatment of wood, preparation of a wood treatment agent, preparation of a wood treatment liquid, dipping treatment, curing treatment, drying treatment and lighting treatment, and the wood treatment agent includes following components by mass: 20-30 parts of n-butyl titanate, 50-80 parts of polyethylene glycol, 0.1-1 part of glacial acetic acid, 320-400 parts of water, 20-30 parts of silica sol, 10-15 parts of trimethyl borate, 8-12 parts of dodecyl dimethyl benzyl ammonium chloride, 2-8 parts of carbendazim, 1-3 parts of isooctanol phosphate, and 1-2 parts of lauryl sodium sulfate. The beneficial effect is that the anticorrosive antibacterial wood production method has the advantages of simple process, high efficiency, low energy consumption, environmental friendliness and the like, the treated wood has good size stability, good resistance to corrosion, anti-bacterial function, high resistance to erosion, high strength, heat resistance, good resistance to wear and the like.

Owner:王玉燕

Preparation method of antibacterial and deodorizing absorption product

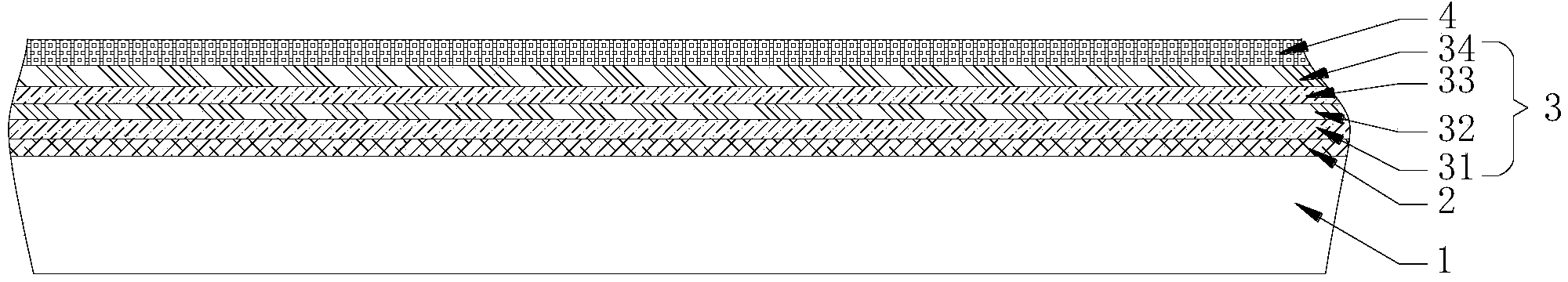

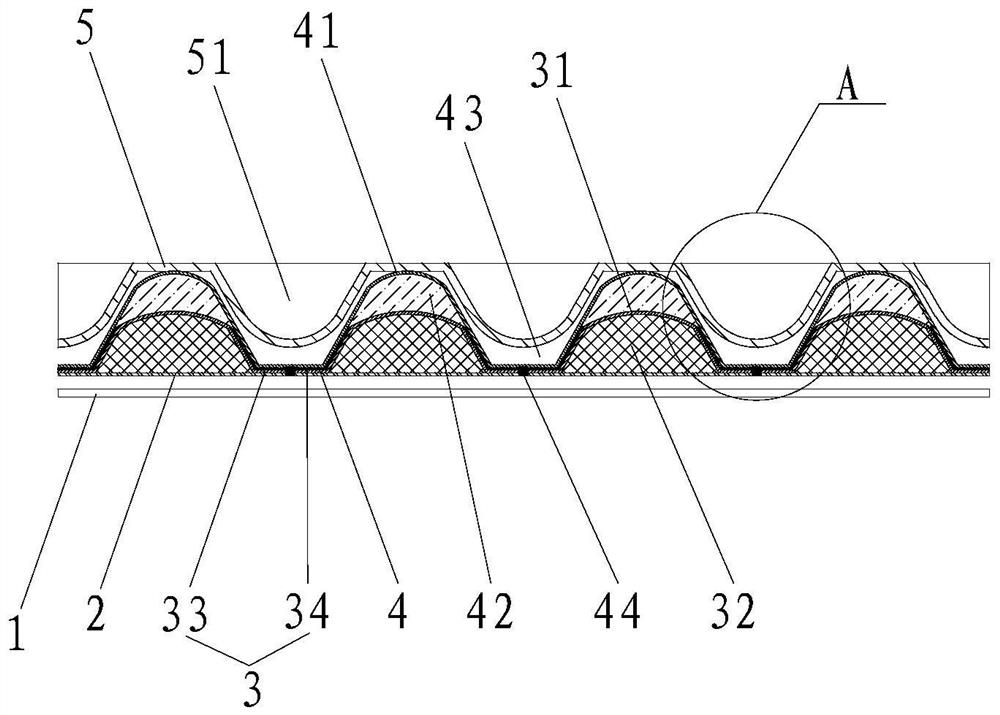

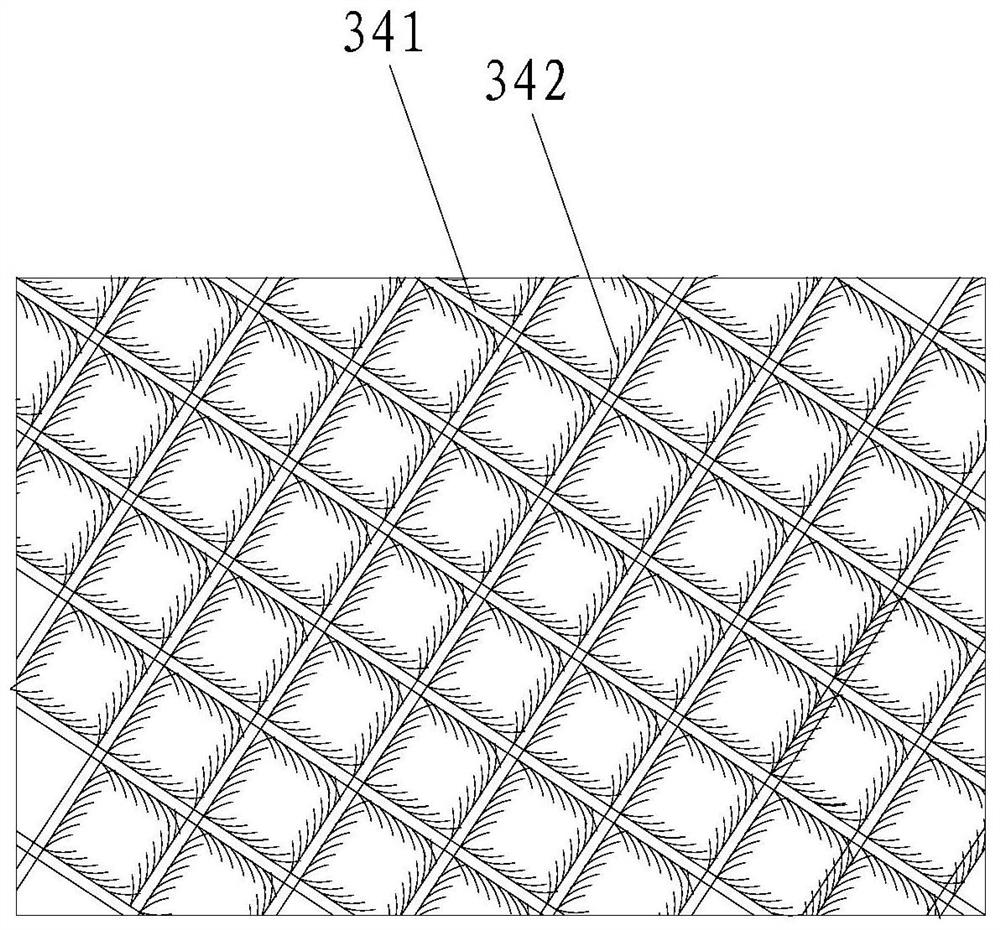

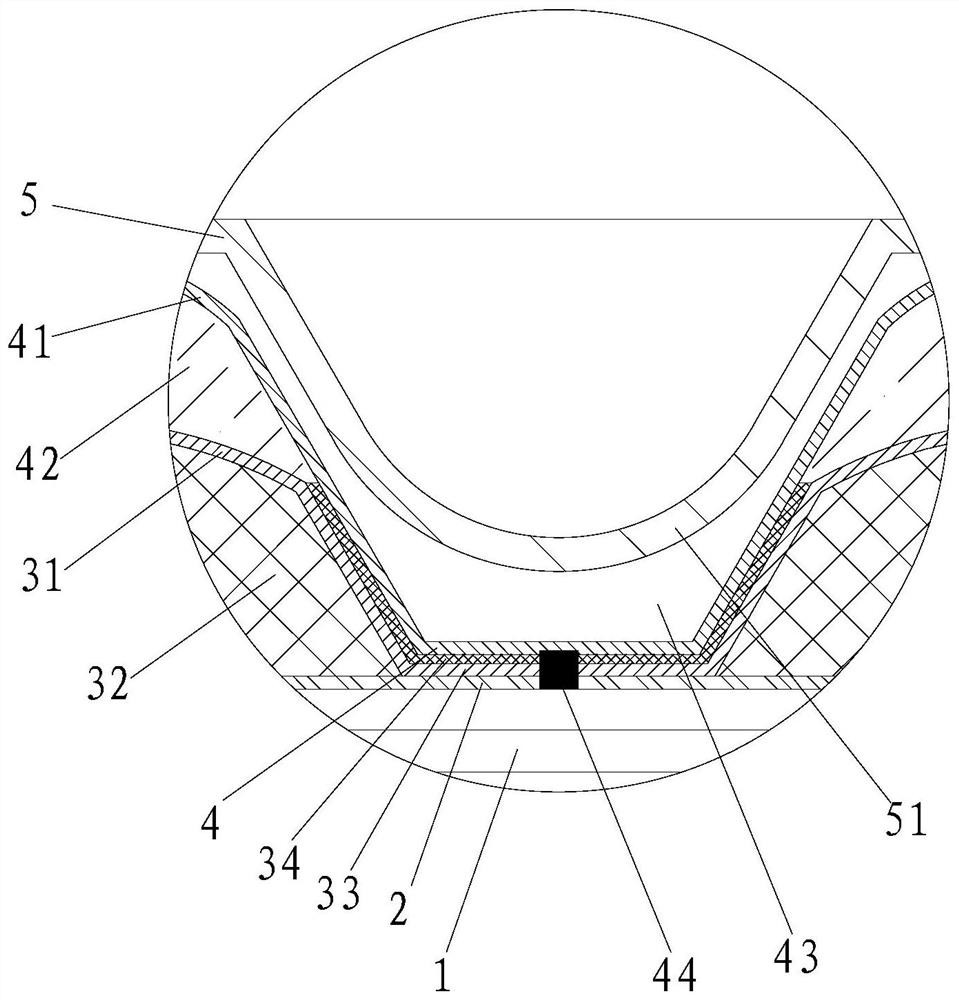

InactiveCN112618778AAchieve penetrationGuaranteed softnessAdhesive articlesAbsorbent padsPolymer scienceUltrasonic welding

The invention relates to the field of disposable hygienic products, in particular to a preparation method of an antibacterial and deodorizing absorption product. The method comprises the following steps of 1, rolling a hydrophilic non-woven fabric, forming a bottom layer with a plurality of hydrophilic recesses, laying wood pulp cotton, compounding an antibacterial non-woven fabric material, carrying out secondary rolling to form antibacterial recesses, laying an SAP material, then compounding a bottom-layer non-woven fabric material on the peripheral sides of the hydrophilic recesses in a hot rolling or ultrasonic welding manner, forming dotted joint parts, and forming an absorption core; 2, forming a plurality of liquid-permeable recesses in a liquid-permeable surface layer, and forming through holes in the bottoms of the liquid-permeable recesses; 3, compounding the liquid-permeable surface layer and the absorption core, and enabling the liquid-permeable recesses and the hydrophilic recesses to be distributed in a staggered manner; and 4, compounding a bottom-layer water-repellent material to form a basic absorption product. The method solves the technical problems that an existing antibacterial and deodorizing absorption product is relatively thick and relatively poor in absorption performance.

Owner:CHIAUS FUJIAN IND DEV

Anthocyanin-contained composition and application thereof

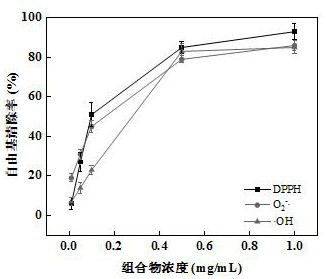

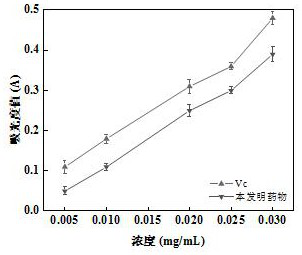

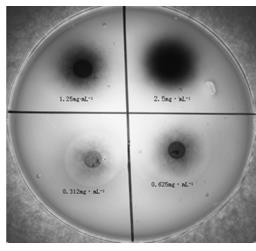

InactiveCN113143908AStrong reductionEnhanced Antioxidant MechanismOrganic active ingredientsPowder deliveryEscherichia coliSuperoxide

The invention relates to the field of medicinal use of anthocyanin and discloses an anthocyanin-contained composition and application thereof. If anthocyanin is extracted from grape skin, the composition is applied to antioxidation drugs, plays a role in clearing away DPPH free radicals, superoxide anion free radicals (O2<->.) and hydroxyl free radicals (.OH) and has a relatively high reducing property; if the anthocyanin is extracted from mulberries, the composition is applied to bacteriostatic drugs and plays a role in inhibiting staphylococcus aureus, Escherichia coli and bacillus subtilis; and the composition can also be applied to blood sugar reducing, blood fat reducing and atherosclerosis inhibiting and plays a role in inhibiting intestinal alpha-glucosidase, the blood sugar reducing activity of acarbose is enhanced obviously, the synthesis of fats is inhibited, the decomposition of the fats is stimulated, and the composition has blood sugar reducing and blood fat reducing actions and can be used for inhibiting expression of adhesion molecules and inhibiting formation of atherosclerosis.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Wear-resistant anti-cracking environment-friendly plasterboard and preparation method thereof

The invention discloses a wear-resistant anti-cracking environment-friendly plasterboard which is prepared from the following raw materials in parts by weight: polyvinyl alcohol 8-14 parts, pulverized fuel ash 7-9 parts, old plasterboard powder 35-45 parts, gypsum powder 25-35 parts, anti-cracking fiber 10-14 parts, an initiator 1-3 parts, an antifoamer 1-1.4 parts, a dispersant 2-4 parts, crystalline flake graphite 10-14 parts, starch 5-10 parts, and deionized water 50-70 parts. The plasterboard of the invention has the advantages of high and compression strength, static bending strength, large screw holding capability and breaking resistant elasticity modulus, low heat conductivity coefficient, and has the characteristics of good antibacterial property, mechanical property, anti-electromagnetic radiation property and anti-friction property. Meanwhile, the raw materials of the wear-resistant anti-cracking environment-friendly plasterboard are safe and reliable, environment-friendly and easily-accessible, the cost is low, the process is simple and is easy to operate and realize industrial production, and the process has high practical value and good application prospects.

Owner:合肥市淑芹美装饰工程有限公司

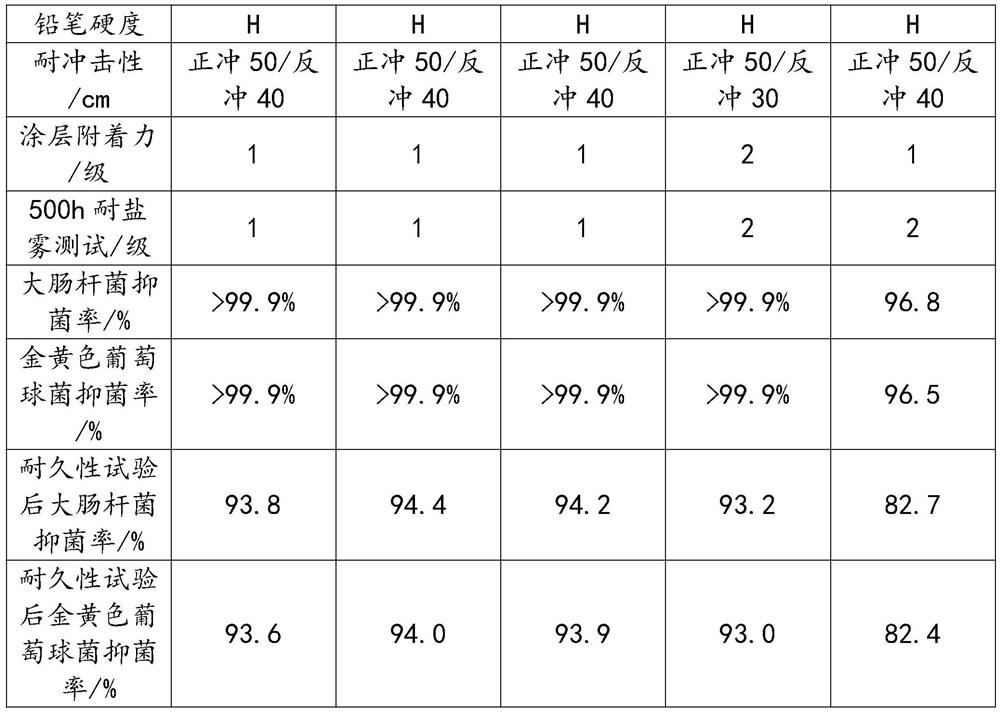

Antibacterial and antivirus powder coating and preparation process thereof

InactiveCN111978772AImprove water resistanceGood antibacterial propertiesAntifouling/underwater paintsPaints with biocidesWeather resistanceAnti bacterial

The invention discloses an antibacterial and antivirus powder coating. The antibacterial and antivirus powder coating comprises the following components in parts by weight: 60-70 parts of polyester resin, 3-4 parts of an antibacterial agent, 4-5 parts of graphene, 1.6-2 parts of a coupling agent, 5-6 parts of a curing agent and 1-1.2 parts of a leveling agent. The invention further discloses a preparation process of the powder coating. Polyester resin synthesized by using different polyhydric alcohols and polyatomic acids as raw material is used as a film-forming matrix of the coating, so thatthe water resistance, the weather resistance and the mechanical property of the coating can be effectively improved; a self-made antibacterial agent is added into the coating, and the antibacterial agent is a macromolecular quaternary phosphonium salt antibacterial agent, has efficient antibacterial performance, has good compatibility with a coating matrix, has relatively high dissolution resistance, and endows the coating with a good antibacterial effect and antibacterial durability; and through the auxiliary matching of other auxiliary agents, the prepared coating has antibacterial and antivirus effects on the basis of weather resistance, water resistance and high mechanical properties.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Environment-friendly paint and preparation method thereof

InactiveCN107236397ANo pollution in the processTo achieve the purpose of antibacterialAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceActivated carbon

The invention discloses environment-friendly paint. The environment-friendly paint is prepared from raw materials in parts by weight as follows: 8-15 parts of waterborne alkyd resin, 15-23 parts of attapulgite clay, 10-20 parts of polyethyleneimine, 12-15 parts of an acrylate emulsion, 10-30 parts of diatom ooze, 3-5 parts of activated carbon, 13-17 parts of negative ion powder, 1.8-2.5 parts of a coalescing agent, 3-6 parts of plant pigments, 2-3 parts of a dispersing agent, 0.5-1.5 parts of a propellant, 0.4-0.7 parts of a defoaming agent and an appropriate amount of deionized water. The environment-friendly paint has the decorative function of common environment-friendly paint, can also be effectively antibacterial, is long in antibacterialpropertylasting time and stable in effect, has the function of adsorbing harmful substances and is energy-saving and environment-friendly.

Owner:合肥永泰新型建材有限公司

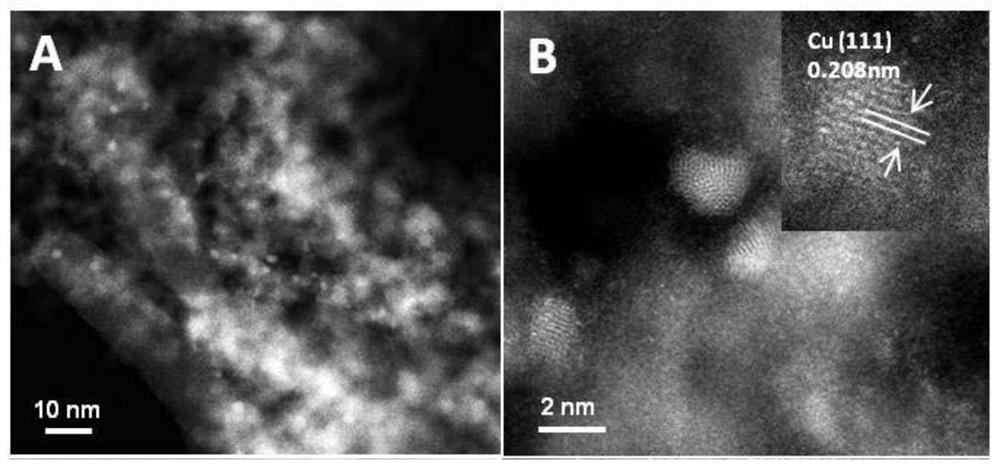

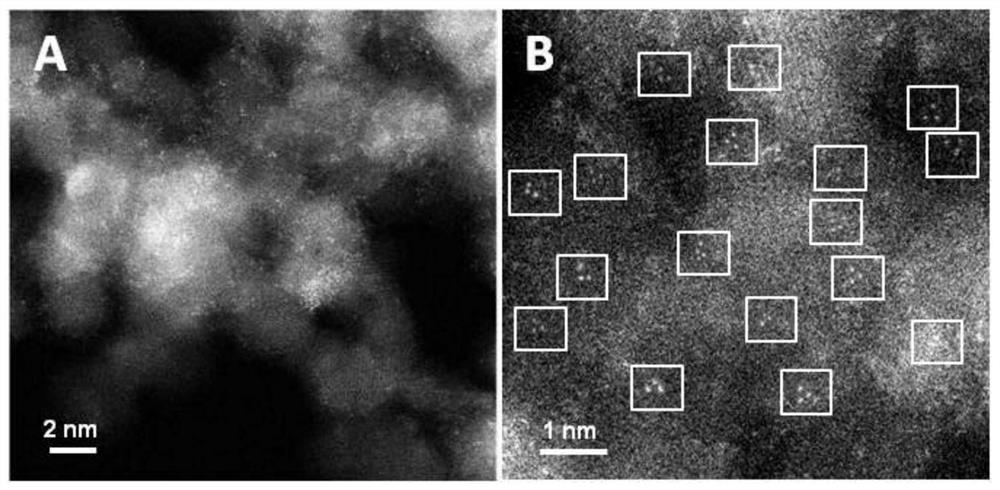

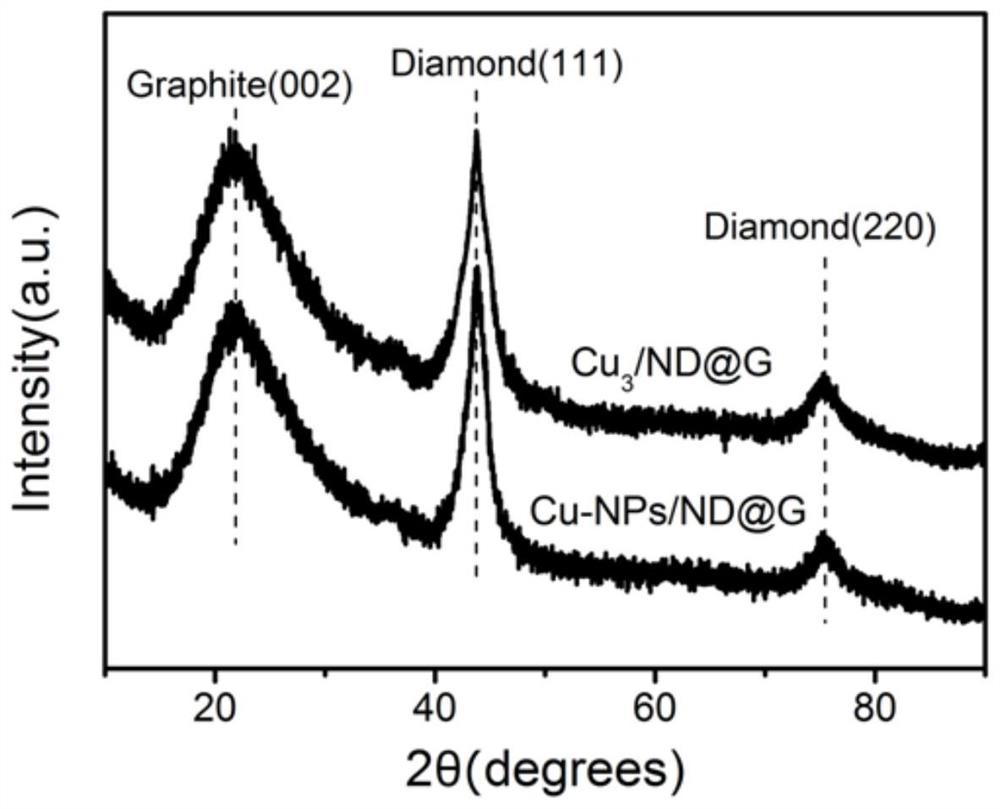

Nano-carbon loaded cluster-state copper nano-enzyme as well as preparation method and application thereof

PendingCN112337466AStrong sterilizing effectExcellent oxidase catalytic activityBiocideFungicidesCombinatorial chemistryNano carbon

The invention discloses a nano-carbon loaded cluster-state copper nano-enzyme as well as a preparation method and application thereof. The nano-carbon loaded copper in the cluster state is used as a nano-enzyme, oxygen in air can be catalyzed to be decomposed at room temperature to generate active oxygen substances, and the active oxygen substances act on bacteria to achieve the sterilization purpose. In the nano-enzyme, the copper exists in the form of atomic-scale dispersed clusters, so that the enzyme catalytic activity of copper is remarkably improved, and the antibacterial rate can reach100%. The synthesis process is simple and convenient, the reaction process is easy to control, and the prepared nanocarbon-loaded cluster-state copper nanoenzyme shows excellent catalytic antibacterial performance and has potential application in the field of biomedicine.

Owner:LIAONING UNIVERSITY

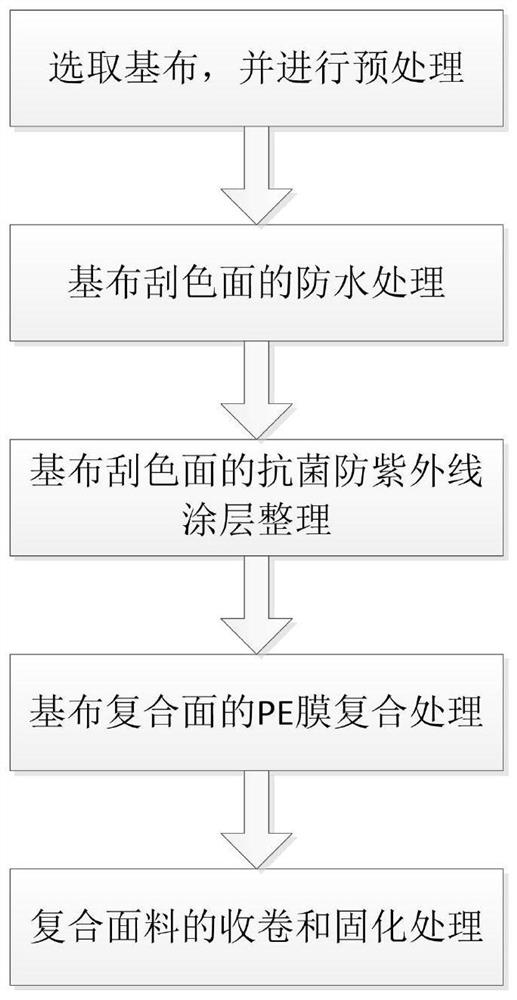

Method for improving yellowing resistance of antibacterial ultraviolet-proof composite curtain fabric

PendingCN114193866AAntibacterialFunctionalLamination ancillary operationsSynthetic resin layered productsPolymer scienceEngineering

The invention discloses a method for improving the yellowing resistance of an antibacterial and ultraviolet-proof composite curtain fabric. The method comprises the following steps: S1, selecting base cloth and performing pretreatment; s2, performing color scraping surface waterproof treatment on the color scraping surface of the base cloth; s3, preparing antibacterial and ultraviolet-proof color paste, blade-coating the color scraping surface of the base cloth with the antibacterial and ultraviolet-proof color paste, and then sequentially performing drying treatment and calendaring treatment on the color scraping surface; s4, bonding a PE film to the composite surface of the base cloth; s5, carrying out rolling and curing treatment on the compounded fabric to obtain a finished product of the antibacterial and ultraviolet-proof type composite curtain fabric. On the premise of ensuring that the composite curtain fabric has antibacterial and ultraviolet-proof properties, the yellowing resistance of the fabric is improved, the use requirement standard of customers is met, and the processing cost and the popularization difficulty of products are reduced.

Owner:CHANGZHOU TAILUN TEXTILE CO LTD

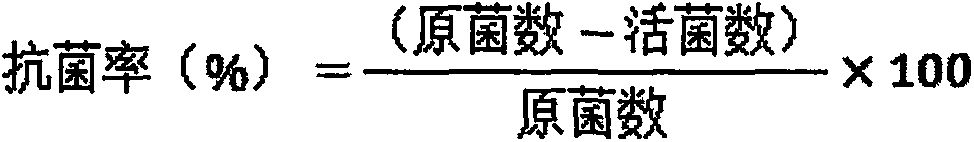

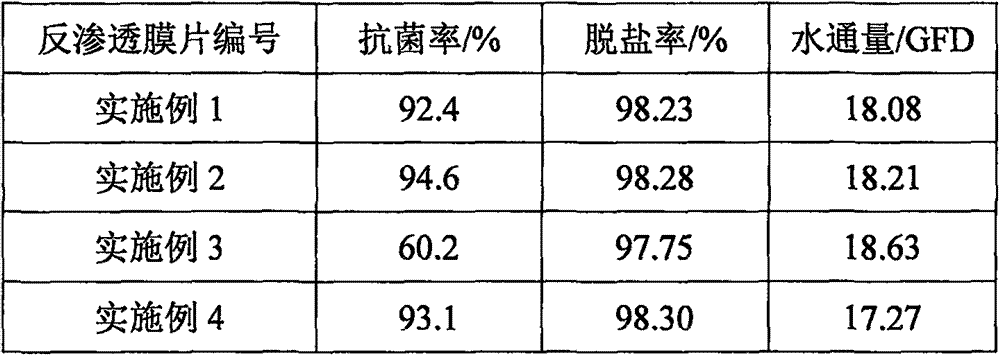

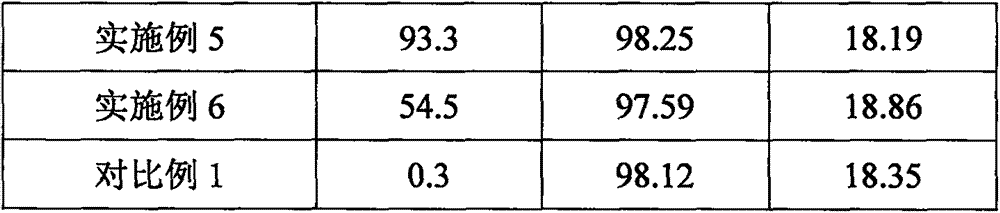

Antibacterial reverse osmosis composite membrane as well as preparation method and application thereof

InactiveCN107213804AGood antibacterial effectImprove adsorption capacityMembranesReverse osmosisCross-linkPolyvinyl alcohol

The invention relates to an antibacterial reverse osmosis composite membrane as well as a preparation method and application thereof. The preparation method of the antibacterial reverse osmosis composite membrane comprises the following steps: 1, purifying and activating kieselguhr to obtain the kieselguhr; 2, dissolving polyvinyl alcohol (PVA) into a water solution at the temperature of 50-90 DEG C, and evenly stirring to obtain a PVA water solution; then, adding the kieselguhr into the PVA water solution, carrying out magnetic stirring, and carrying out ultrasonic dispersion for 10-30min to obtain kieselguhr-containing PVA water solution; 3, adding a cross-linking agent and an acid catalyst into the kieselguhr-containing PVA water solution, carrying out magnetic stirring, and carrying out ultrasonic dispersion for 10-30min to obtain a kieselguhr-containing coating solution; 4, coating the surface of a reverse osmosis membrane with the kieselguhr-containing coating solution, putting the reverse osmosis membrane into a drying oven at the temperature of 60-120 DEG C, and carrying out a cross-linking reaction for 5-20min to obtain the antibacterial reverse osmosis composite membrane. The antibacterial reverse osmosis composite membrane prepared by the method is stable in antibacterial properties and low in manufacturing cost.

Owner:宁波日新恒力科技有限公司

Modified polypropylene duct for power cable and preparation method thereof

ActiveCN106633389AImprove antioxidant capacityImprove thermal stabilityPlastic/resin/waxes insulatorsAntioxidantEngineering

The invention relates to the field of cable ducts, and discloses a modified polypropylene duct for a power cable and a preparation method of the modified polypropylene duct for the power cable. The duct is prepared from the following components in parts by mass: 90 to 110 parts of polypropylene, 5 to 10 parts of styrene butadiene rubber, 5 to 10 parts of phenoxy resin, 5 to 10 parts of an ethylene-vinyl acetate copolymer, 10 to 20 parts of tetrabutyl titanate, 5 to 10 parts of a silane coupling agent, 2 to 6 parts of a functional additive, 0.1 to 0.5 part of an antioxidant, 1 to 3 parts of a stabilizer, 90 to 110 parts of xylene, 10 to 20 parts of ethanol, and 5 to 20 parts of water. The modified polypropylene duct for the power cable disclosed by the invention is good in dispersion of each component and compatibility in materials, and the modified polypropylene material is relatively good in toughness, impact resistance and antibacterial properties, and long in service life.

Owner:杭州欣隆实业有限公司

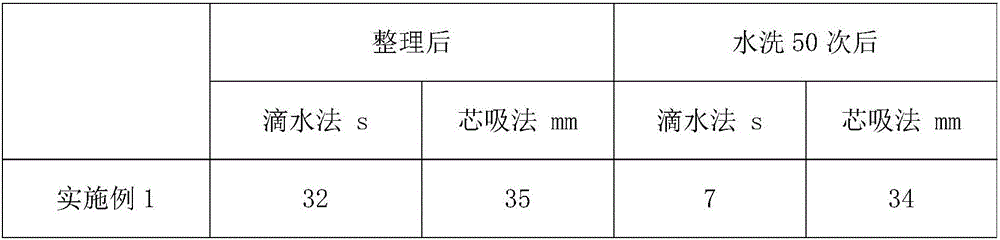

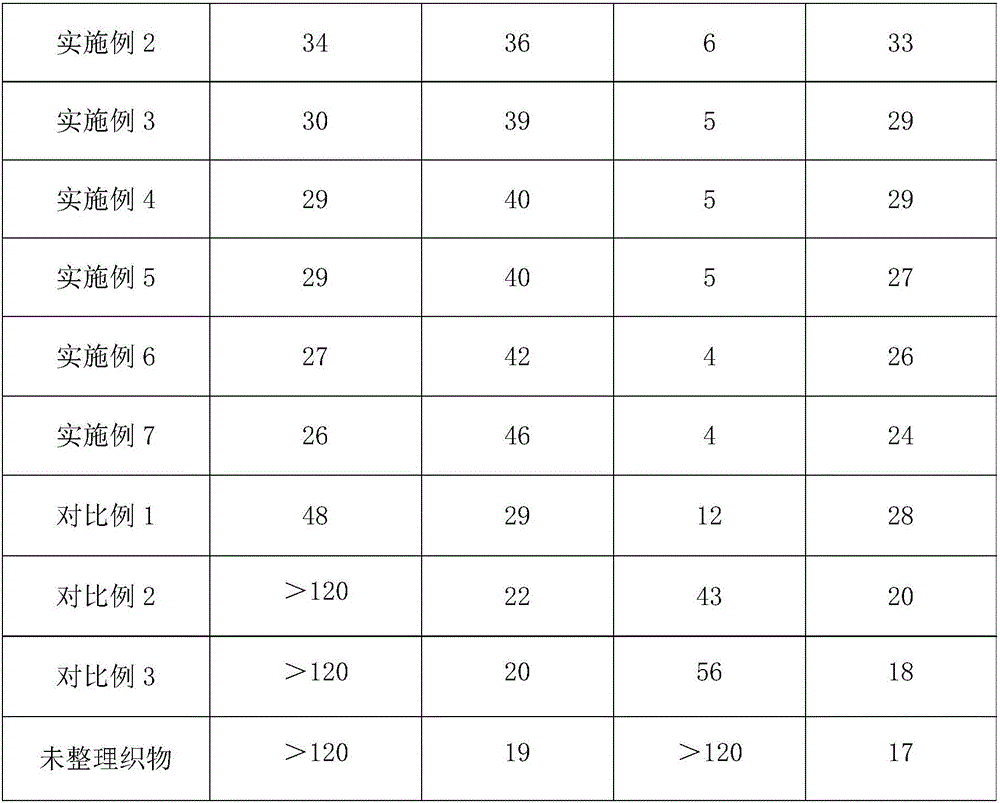

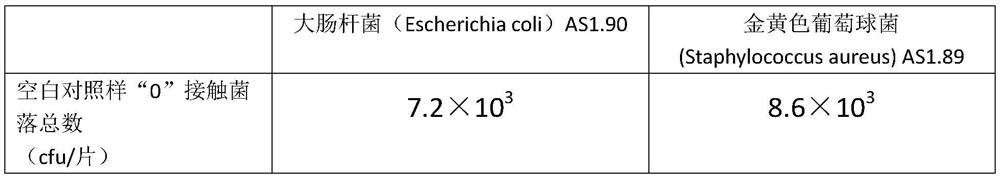

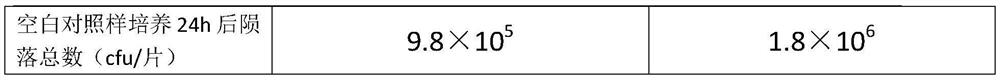

Water-soluble thermal-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent and application thereof

InactiveCN106498749AIncrease the degree of cross-linkingImprove hydrophilicityBiochemical fibre treatmentHeat resistant fibresAceglutamideGlycerol

The invention relates to the technical field of textile auxiliary agents, and discloses a water-soluble thermal-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent. The water-soluble thermal-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent comprises components by following weight part: 15-20 parts of water-soluble thermal-reactive polyurethane, 0.1-10 parts of aceglutamide and 2-12 parts of glycerol. The aceglutamide is added as an additive in the finishing agent, and the water-soluble thermal-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent can catalyze proceeding of reaction and significantly improve crosslinking rate of the polyurethane and synthetic fibers, the lower concentration polyurethane can endow the synthetic fibers and wool fibers with lasting hydrophilicity, and simultaneously significantly enhances reactivity and softness, and is high in durability, and a fabric after being tidied not only has good hydrophilicity, but also has fire resistance and antibacterial performance.

Owner:FOSHAN XUNTUOAO TECH CO LTD

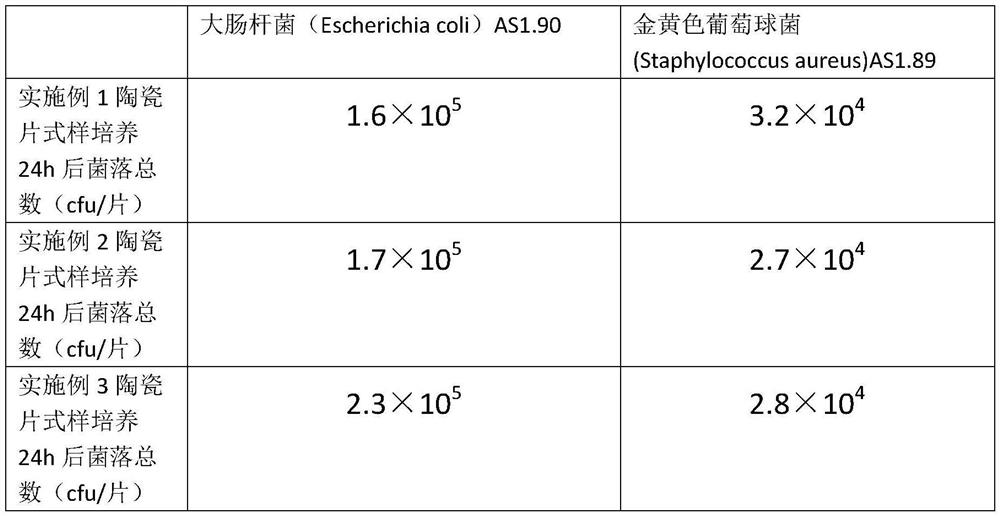

Antibacterial wear-resistant glaze and preparation method thereof

ActiveCN113429221AImprove adhesionTo achieve the purpose of antibacterialCeramic materials productionClaywaresPowder talcumPerovskite

The invention discloses antibacterial wear-resistant glaze and a preparation method thereof. The glaze comprises a first component and a second component, wherein the first component comprises the following substances in parts by mass: zircon, willemite, white mud, talcum powder, marble, feldspar, quartzite and monazite; and the second component is prepared from the following substances in parts by mass: zircon, spodumene, willemite, clay, feldspar, quartz stone, chalcanthite, perovskite, edible gum and cuprous oxide. The preparation method of the glaze comprises the steps of taking the metered first component, and grinding in a ball milling tank; taking the metered second component, and putting into the ball milling tank to be ground; adding water into the ground first component, and stirring to obtain slurry; soaking a ceramic blank in the slurry, and naturally drying; calcining the naturally dried ceramic blank; and adding the ground second component into water, stirring, dipping the calcined blank into the ground second component, and naturally drying and calcining to obtain the product. The glaze layer disclosed by the invention has compact and wear-resistant effects and antibacterial performance.

Owner:广东中印陶瓷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com