Method for improving yellowing resistance of antibacterial ultraviolet-proof composite curtain fabric

An anti-ultraviolet and anti-yellowing technology, which is applied to window decorations, chemical instruments and methods, curtains, etc., can solve the problems of high processing cost, easy yellowing of composite curtain fabrics, and darkening of color, and achieve antibacterial Wide range, excellent anti-ultraviolet performance, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

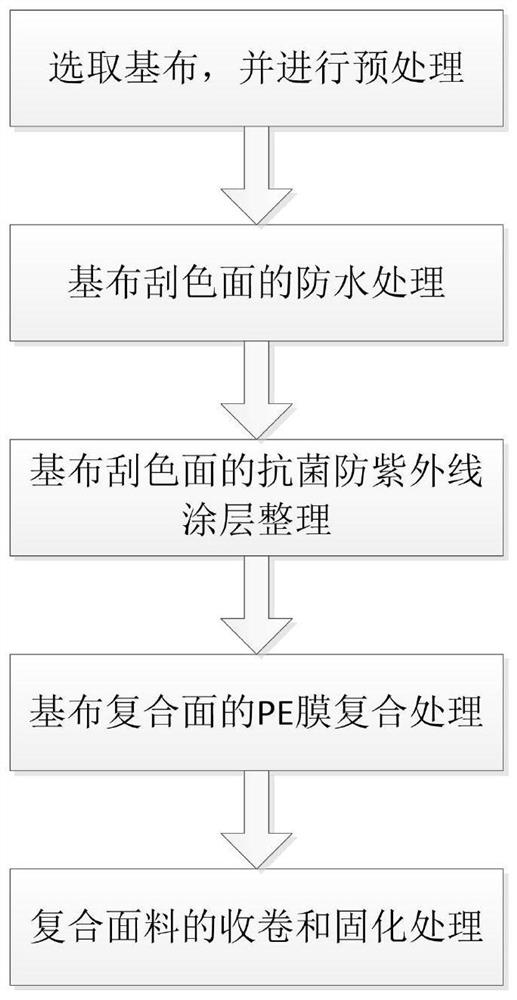

[0042] The following combination figure 1 , the specific implementation process of the present invention is explained in detail.

[0043] 1. Selection and pretreatment of base cloth

[0044] The base fabric is made of warp and weft yarns interwoven to form a woven fabric; the warp yarn is 32S recycled polyester yarn, the weft yarn is 16S and 21S polyester recycled yarn, and the spinning method of the recycled yarn is compact spinning.

[0045] The base fabric is woven with imported Tsudakoma dobby leading air-jet looms. The loom is equipped with two systems of weft insertion systems. The first system introduces one 16S weft yarn, and the second system simultaneously introduces three 21S weft yarns. The first system weft insertion and the second system The weft insertion of the two systems is carried out alternately.

[0046] Pretreatment of the base fabric: first, wash the base fabric with water; then carry out setting treatment on the base fabric through a setting machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com