Antibacterial reverse osmosis composite membrane as well as preparation method and application thereof

A reverse osmosis composite membrane, antibacterial coating technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the complex preparation method of nanoparticles, biological pollution of reverse osmosis composite membrane, salt rejection and water In order to avoid the decline of antibacterial performance, facilitate large-scale production and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the reverse osmosis membrane: step a, add m-phenylenediamine, triethylamine and camphorsulfonic acid into water in proportion, stir magnetically for 10 minutes until dissolved, and obtain m-phenylenediamine aqueous solution, wherein the mass of m-phenylenediamine Concentration is 6%, the mass concentration of triethylamine is 3%, and the mass concentration of camphorsulfonic acid is 6%;

[0025] Step b, adding trimesoyl chloride into n-hexane in proportion, stirring until dissolved to obtain a n-hexane solution of trimesoyl chloride, wherein the mass concentration of trimesoyl chloride is 0.3%;

[0026] Step c, immerse the polysulfone support membrane in the m-phenylenediamine aqueous solution prepared in step a, the immersion time is 25s, remove the solvent after taking it out, and then immerse it in the n-hexane solution of trimesoyl chloride prepared in step 2 to carry out interfacial polymerization reaction, the interfacial polymerization r...

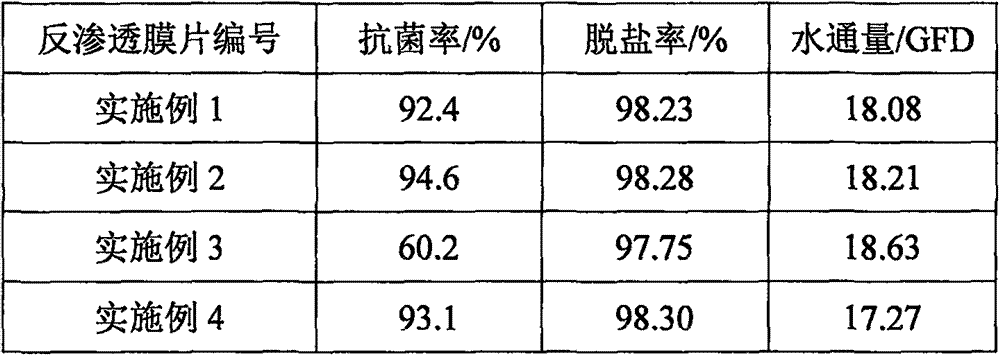

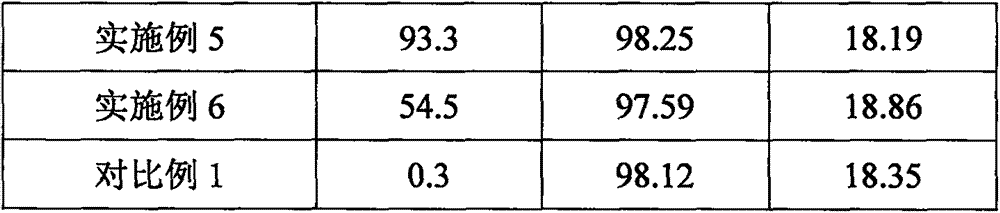

Embodiment 1

[0029] Step 1. Dissolve PVA with a degree of polymerization of 1000 and a degree of alcoholysis of 99% in an aqueous solution at 80°C and stir evenly to obtain a PVA aqueous solution with a mass concentration of 5%; then add purified and activated PVA to the aqueous solution of PVA Diatomite with a particle size of 2 μm was magnetically stirred and ultrasonically dispersed for 15 minutes to obtain a diatomite PVA aqueous solution with a mass concentration of 0.01%;

[0030] Step 2. In the diatomite-containing PVA aqueous solution prepared in step 1, add glutaraldehyde and hydrochloric acid until the mass concentration of the glutaraldehyde is 0.6% and the mass concentration of the hydrochloric acid is 0.2%, then magnetically stir And ultrasonically dispersed for 20 minutes to obtain a coating solution containing diatomaceous earth;

[0031] Step 3: Coating the diatomite-containing coating solution prepared in Step 2 on the surface of the reverse osmosis membrane, and putting i...

Embodiment 2

[0033] Step 1. Dissolve PVA with a degree of polymerization of 1000 and a degree of alcoholysis of 99% in an aqueous solution at 80°C and stir evenly to obtain a PVA aqueous solution with a mass concentration of 5%; then add purified and activated PVA to the aqueous solution of PVA Diatomite with a particle size of 4 μm was magnetically stirred and ultrasonically dispersed for 15 minutes to obtain a diatomite PVA aqueous solution with a mass concentration of 0.01%;

[0034] Step 2. In the diatomite-containing PVA aqueous solution prepared in step 1, add glutaraldehyde and hydrochloric acid until the mass concentration of the glutaraldehyde is 0.6% and the mass concentration of the hydrochloric acid is 0.2%, then magnetically stir And ultrasonically dispersed for 20 minutes to obtain a coating solution containing diatomaceous earth;

[0035] Step 3: Coating the diatomite-containing coating solution prepared in Step 2 on the surface of the reverse osmosis membrane, and putting i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com