Method and device for waste asphalt mixture thermal regenerative heating

一种旧沥青混合料、加热方法的技术,应用在焦油沥青/石油沥青/天然沥青的加工、道路、建筑等方向,能够解决劣化沥青路用性能、环境污染等问题,达到提高路用性能、减少沥青老化量与挥发量、节约能源的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

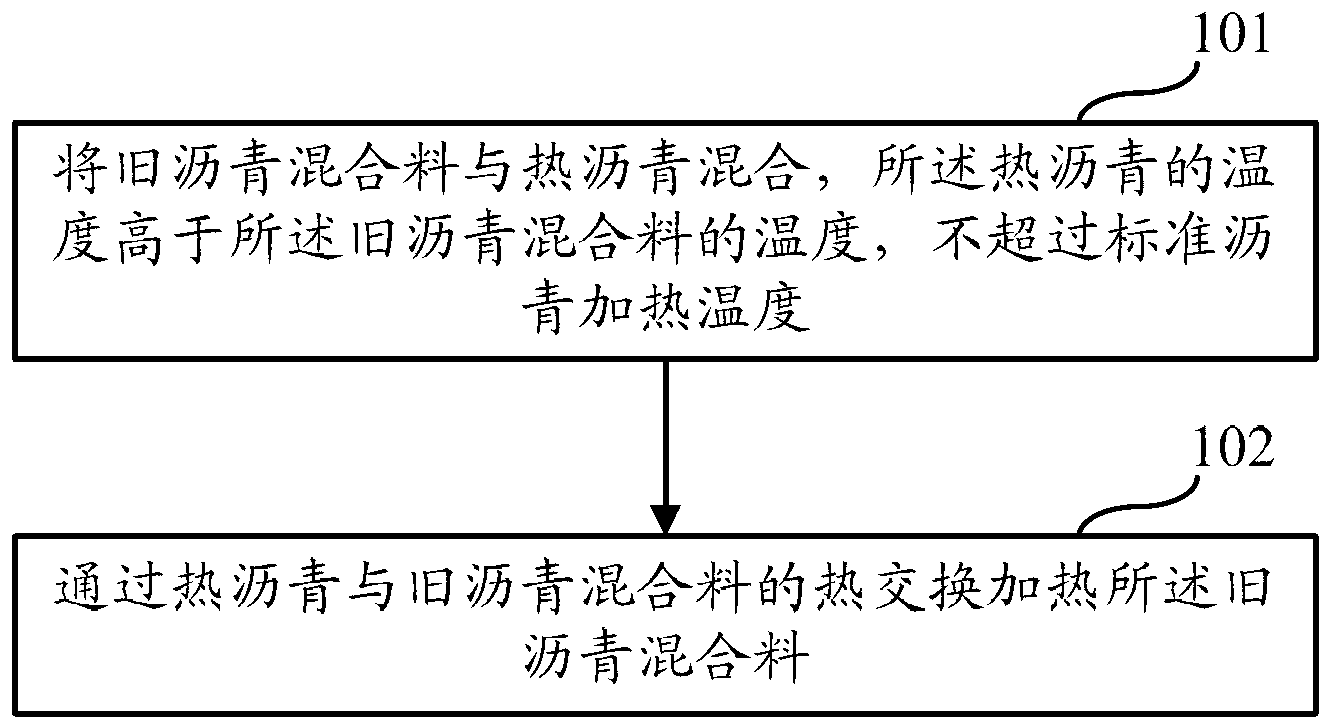

[0030] Such as figure 1 As shown, the old asphalt mixture thermal regeneration heating method of the embodiment of the present invention comprises the following steps:

[0031] Step 101, mixing the old asphalt mixture with hot asphalt; wherein the temperature of the hot asphalt is higher than the temperature of the old asphalt mixture, but not higher than the standard asphalt heating temperature.

[0032] Among them, the standard asphalt heating temperature refers to industry standards such as "People's Republic of China Industry Standard JTG F41-2008 [Technical Specifications for Highway Asphalt Pavement Recycling]" and "People's Republic of China Industry Standard JTG F40-2004 [Technical Specification for Highway Asphalt Pavement Construction]" The asphalt heating temperature determined in the specification, the asphalt heating temperature determined in the above standard is: No. 50 asphalt 160~170°C, No. 70 asphalt 155~165°C, No. 90 asphalt 150~160°C, No. 110 asphalt 145~15...

Embodiment 2

[0046] Mix the old asphalt mixture with hot asphalt at 150-160℃ of equal weight and heat and stir the mixture at the same time. When the temperature of the mixture of old asphalt mixture and asphalt reaches 150-160℃, the old asphalt mixture can be The mixture with asphalt is used as a binder in batch asphalt mixing equipment for the production of recycled asphalt mixture, or in asphalt pavement construction. When the above mixture is used in asphalt pavement construction (adhesive course, permeable course, synchronous gravel seal, etc.), the part with less mineral material and smaller particle size can be used to meet the construction process requirements.

Embodiment 3

[0048]Mix 10 parts by weight of old asphalt mixture with 1 part by weight of 150-160°C hot asphalt and heat and stir the mixture at the same time to keep the temperature of the mixture of old asphalt mixture and asphalt at 150-160°C. The performance index of asphalt does not meet the relevant requirements, and the performance of asphalt in the mixture can be improved by adding asphalt regenerant. At this time, the mixture of old asphalt mixture and hot asphalt can be used as a binder in the process of producing recycled asphalt mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com