Polyurethane material, and preparation method and application thereof

A technology of polyurethane material and degree of polymerization, applied in the field of polyurethane material and its preparation, can solve the problems of restricting the sustainable development of polyurethane, harm to operators and the environment, and cytotoxicity affecting the application, etc., so as to achieve biodegradability and reduce production costs. , the effect of avoiding cytotoxicity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

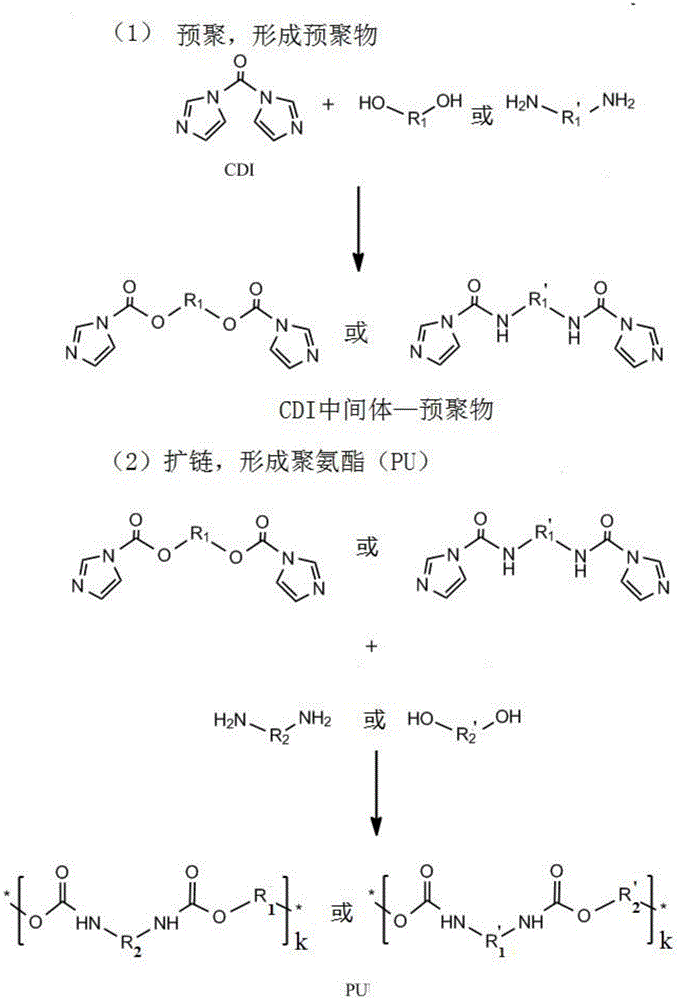

Method used

Image

Examples

Embodiment 1

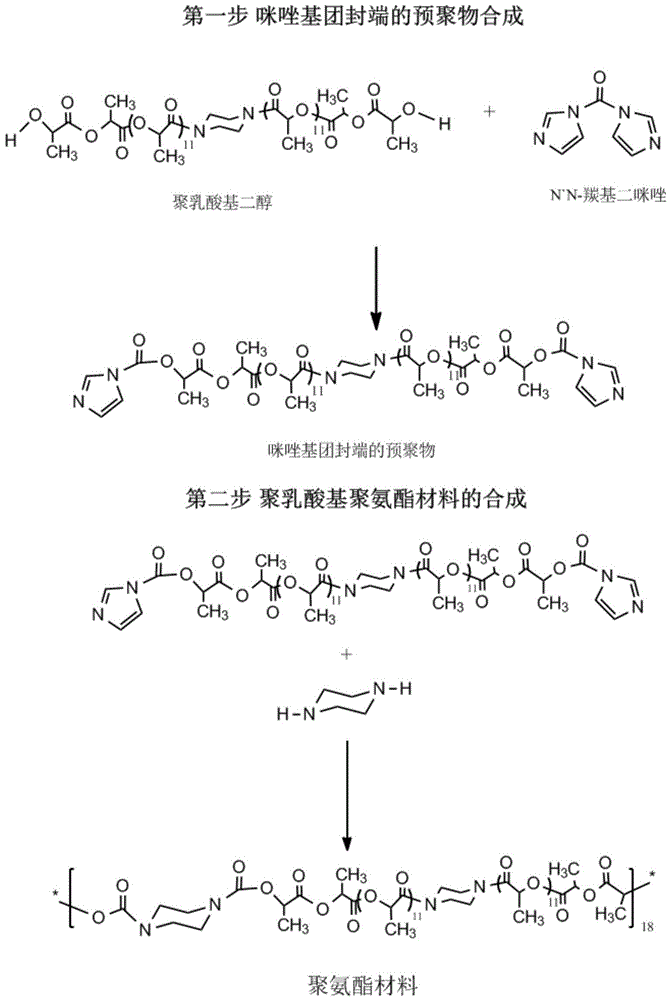

[0075] A preparation method of polyurethane material, comprising the following steps:

[0076] (1) Prepolymerization: Dissolve polylactic acid-based diol (molecular weight 1957g / mol, abbreviated as PDLLA diol) and CDI in anhydrous toluene at a molar ratio of 1:1.1, add stannous octoate, of which stannous octoate The mass ratio to PDLLA diol is 1:100, and the prepolymerization reaction is carried out at a reaction temperature of 75°C for 3.5 hours to obtain a prepolymer, which is an ester imidazole;

[0077] (2) Chain extension: After the reaction temperature in step (1) drops to room temperature, piperazine is added to the ester imidazole prepolymer in step (1) as a chain extender, and the chain extension is carried out at a reaction temperature of 35°C. The chain reaction was stopped for 5 hours to obtain a polyurethane material (PU), wherein the molar ratio of piperazine to polylactic acid-based diol was 0.1:1.

[0078] (3) The polyurethane material obtained in step (2) was...

Embodiment 2

[0086] A kind of preparation method of polyurethane material, operation step is the same as embodiment 1, and difference is: in step (1), the mol ratio of polylactic acid base diol used and CDI is 1:1.3, and in step (2), piperazine The molar ratio to polylactic acid-based diol is 0.3:1.

Embodiment example 2

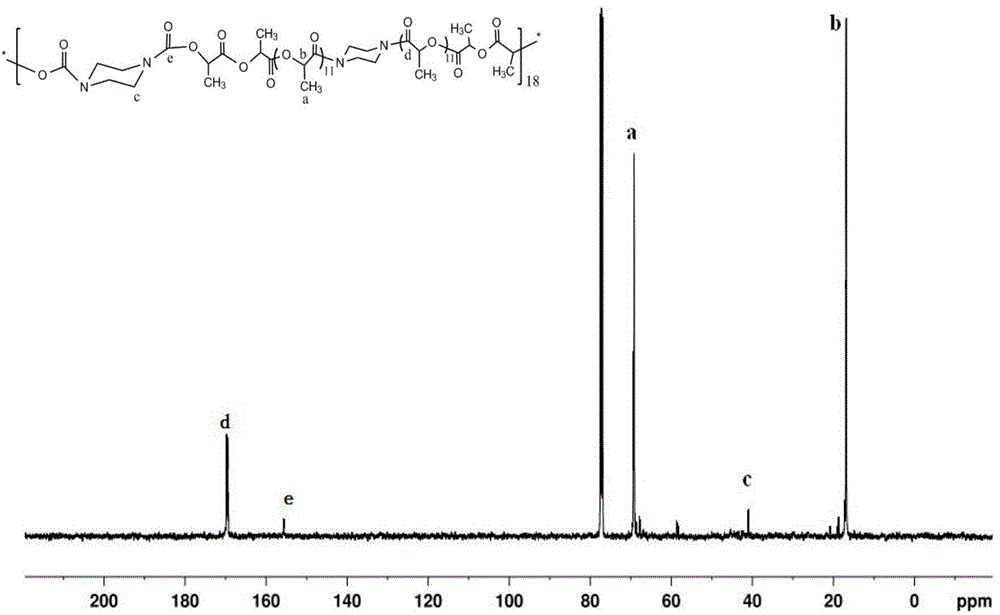

[0087] The yield of the polyurethane material (PU) prepared in Example 2 is 70%, and its structure is linear, as shown in the structural formula (I), where the degree of polymerization k=25. The molecular weight of PU measured and calculated by a viscometer is 48538, and the molecular weight of PU is somewhat higher than that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com