Method and device for producing milk foam or warm milk drinks

A technology for heating milk and milk, applied in beverage preparation devices, milk processing equipment, milk preparations, etc., can solve problems such as complex cleaning procedures, and achieve the effect of simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

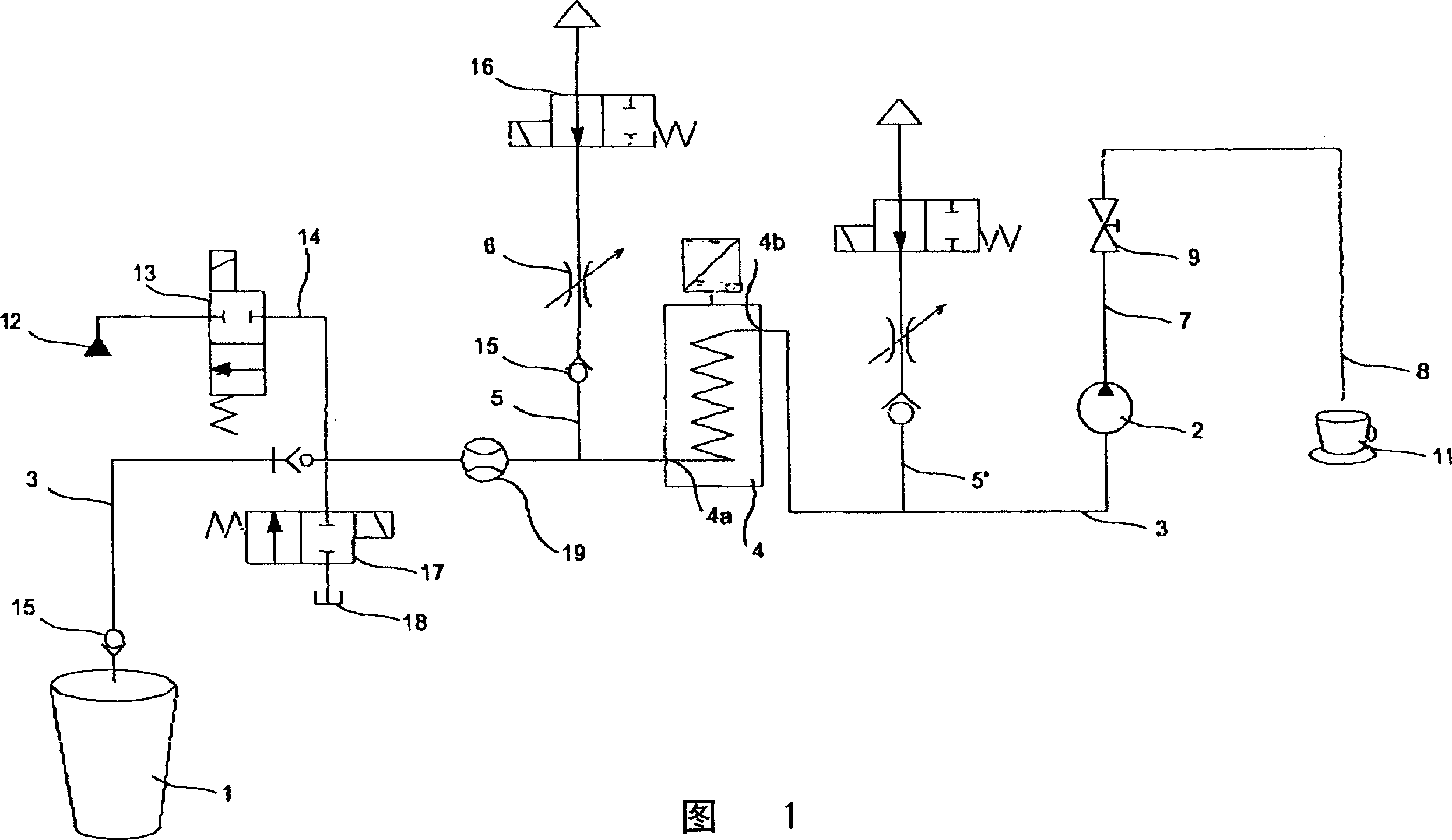

[0015] Fig. 1 shows a container 1 for adorning milk, and various additives, such as chocolate, vanilla, etc., can be added to the milk as required. Cold milk is drawn from the container 1 by means of a pump 2 through a suction pipe 3 and then heated by a continuous flow heater 4 . Reference numeral 4a in FIG. 1 denotes an inlet of the continuous flow heater 4, and reference numeral 4b is an outlet. Before entering the inlet 4a of the continuous flow heater 4, the air supply duct 5 leads to the suction duct 3 to which an adjustable air flow controller 6 is assigned. However, it is also possible to use a fixed nozzle instead of the controller 6 . Through the air supply pipe 5, a certain amount of air can be added to the milk, so that the milk / air mixture (or just milk) can be sucked by the pump 2 and heated in the continuous flow heater 4. In principle, gas mixtures can also be used instead of air.

[0016] On the air supply pipe 5, an active valve 16 can be further designed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com