A tube type heater for electric water heater

A technology for tubular heaters and electric water heaters, applied in the direction of fluid heaters, heating element shapes, lighting and heating equipment, etc., can solve the problems of reduced thermal efficiency, scrapped heaters, difficult production, etc., to achieve reasonable heat exchange structure, fluid Fast heat exchange and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

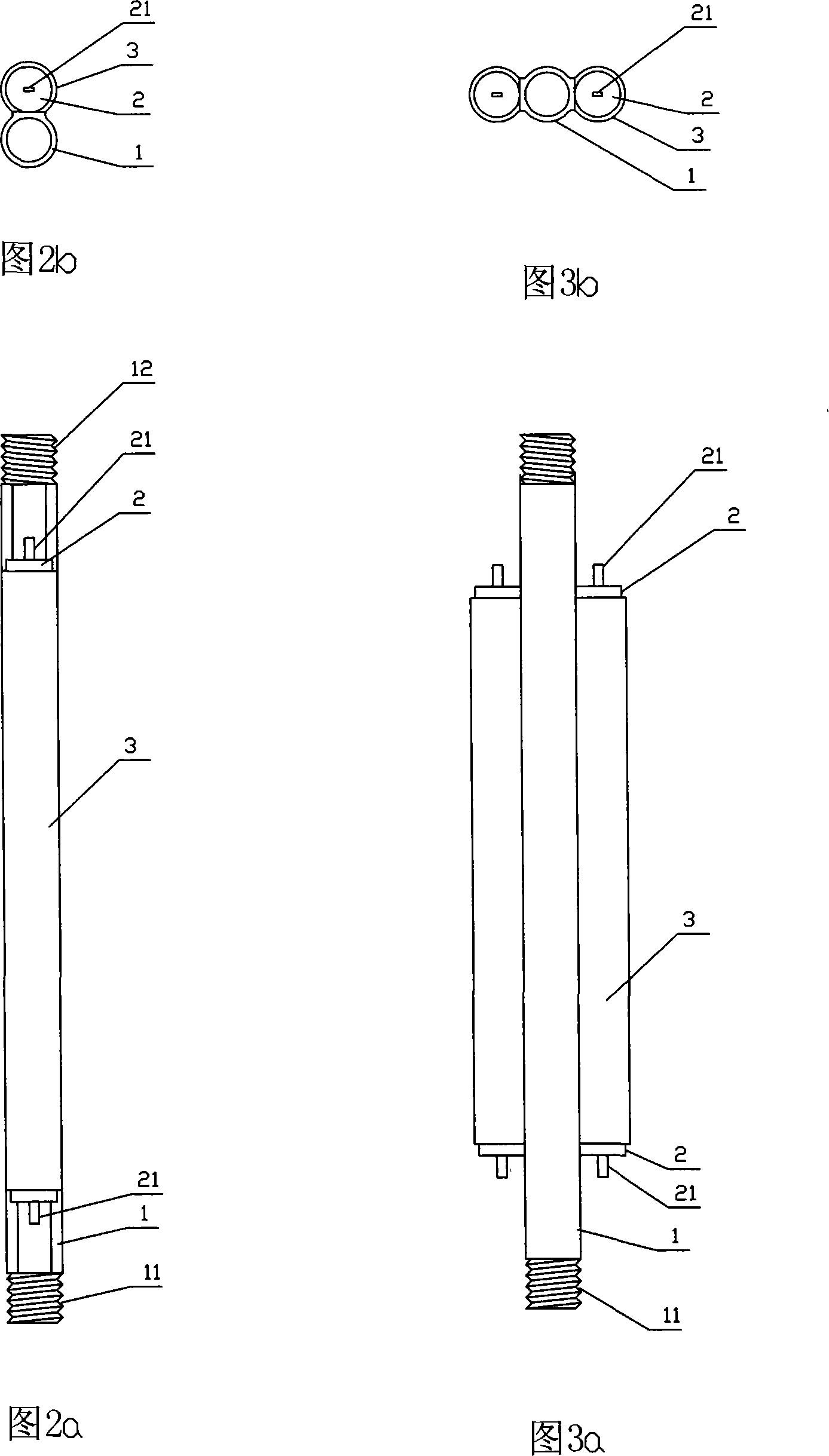

Embodiment 1

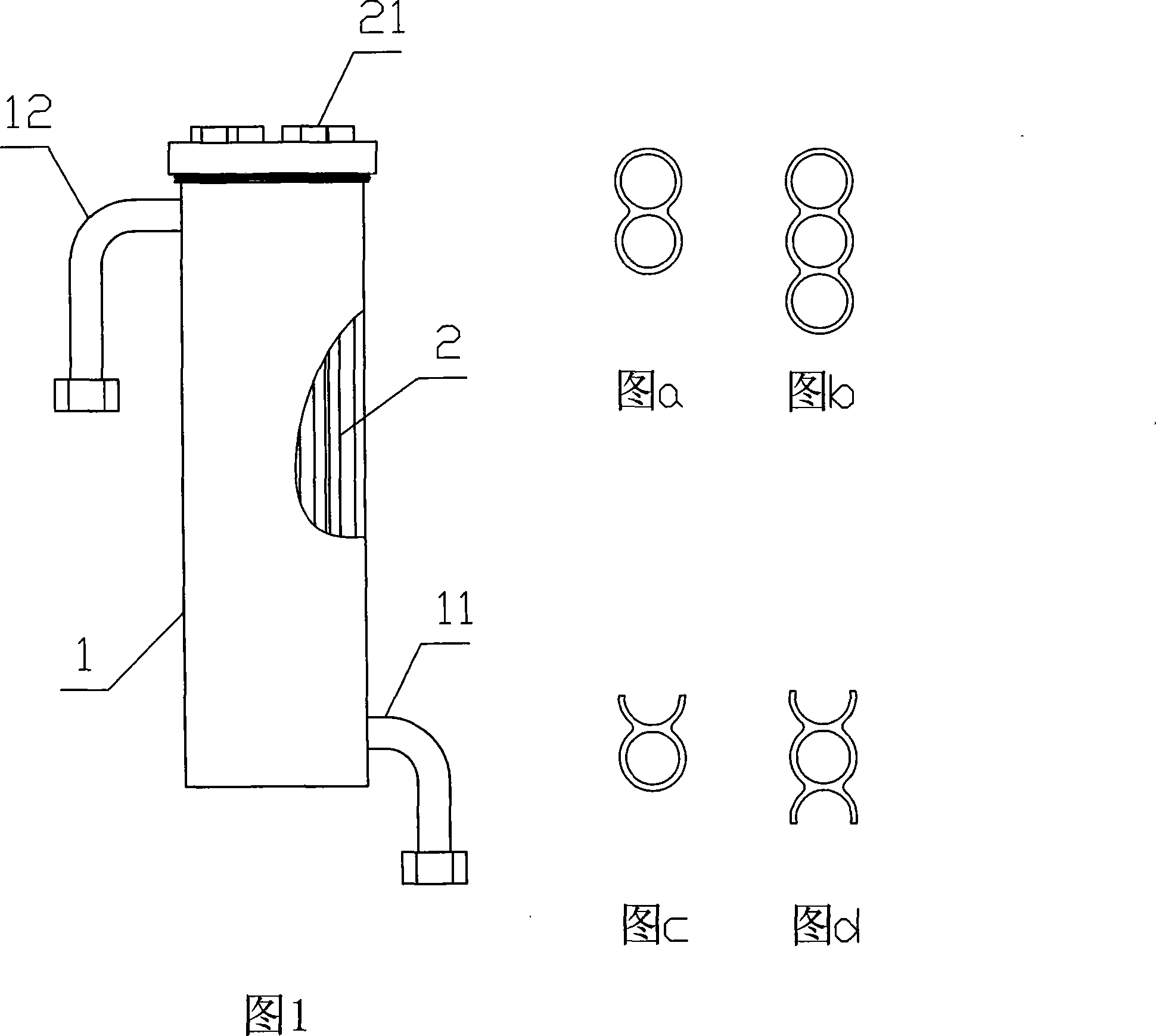

[0054] Referring to Fig. 2a and Fig. 2b, a heater for an electric water heater proposed by the present invention includes a heat exchange body and an electric heating tube 2. A metal pipe is used as the fluid passage pipe 1, and the two ends of the heating pipe 3 are cut off to leave pipe joints 11 and 12 at both ends of the fluid passage pipe 1, and a straight electric heating pipe 2 is installed in the heating pipe 3 to form a single heating straight pipe structure.

[0055] The method of use is as follows: the electrodes 21 at both ends of the electric heating tube 2 are connected to the control circuit, the pipe joints 11 and 12 are respectively connected to the running water pipe and the shower or the faucet, and the water heater function is realized by the switch and the temperature control device on the control circuit.

Embodiment 2

[0057]Referring to Fig. 3a and Fig. 3b, a heater for an electric water heater proposed by the present invention includes a heat exchanging body and an electric heating tube 2, the heat exchanging body is a conjoined three-metal tube, and one of the metal tubes is used as a fluid passage tube 1, The other two metal pipes are used as the heating pipe 3, and the two ends of the heating pipe 3 are cut off to leave the pipe joints 11 and 12 at the two ends of the fluid channel pipe 1, and the electric heating pipe 2 is installed in the heating pipe 3 to form a double parallel heating straight pipe structure.

[0058] The method of use is the same as the examples.

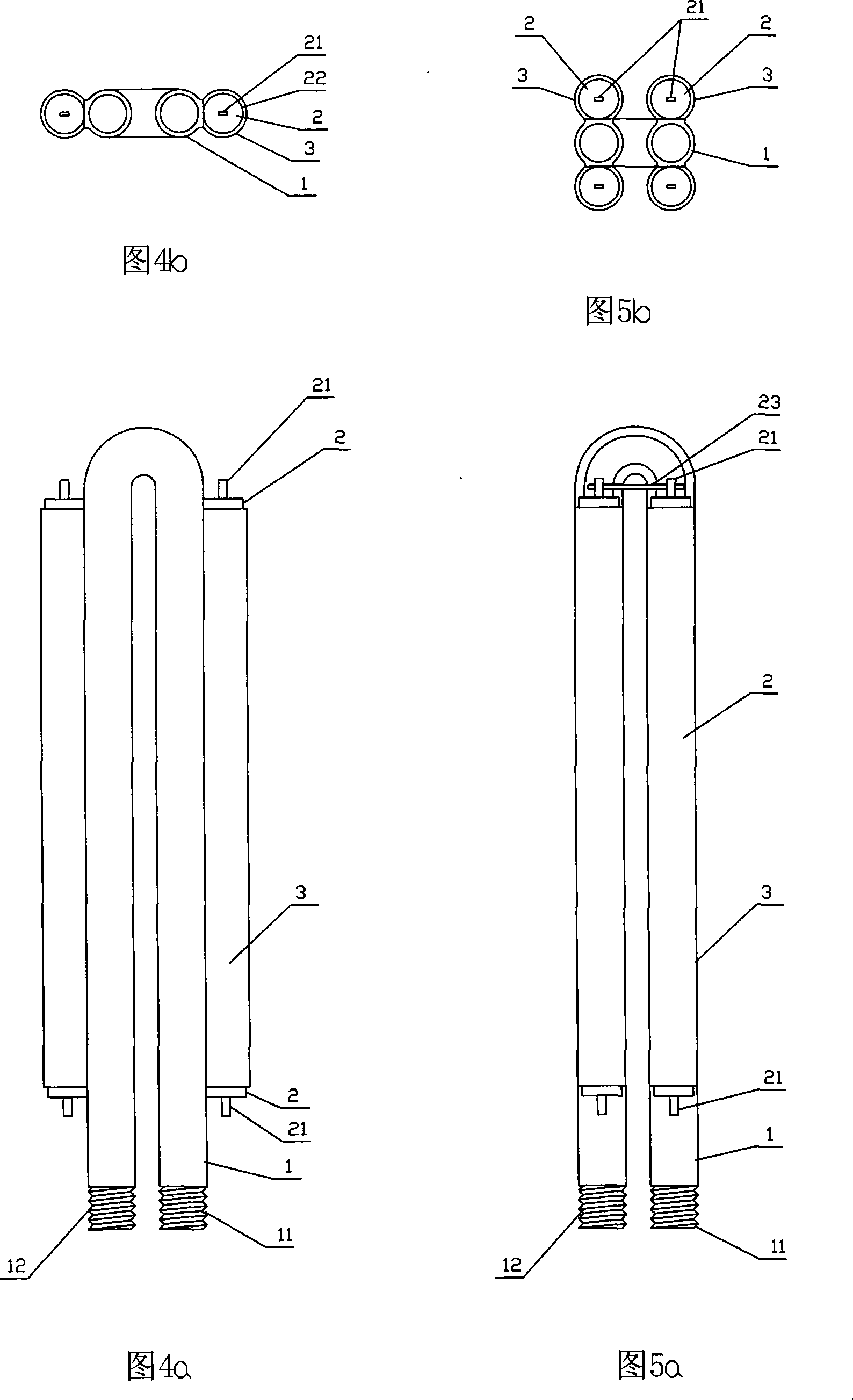

Embodiment 3

[0060] Referring to Figure 4a and Figure 4b, a heater for an electric water heater proposed by the present invention includes a heat exchange body and an electric heating tube 2. The structure of the heat exchange body is the same as that of Embodiment 1, which is a connected bimetallic tube, one of which The metal pipe is used as the heating pipe 3, and the other metal pipe is used as the fluid passage pipe 1. Cut off the two ends of the heating pipe 3 so that the pipe joints 11 and 12 are left at the two ends of the fluid passage pipe 1, and cut off a section in the middle of the heating pipe 3. , the fluid channel tube 1 is bent into a U-shaped tube structure, and two straight electric heating tubes 2 are respectively installed in the segmented heating tubes 3 to form a double-string heating U-shaped tube structure.

[0061] The method of use is the same as the examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com