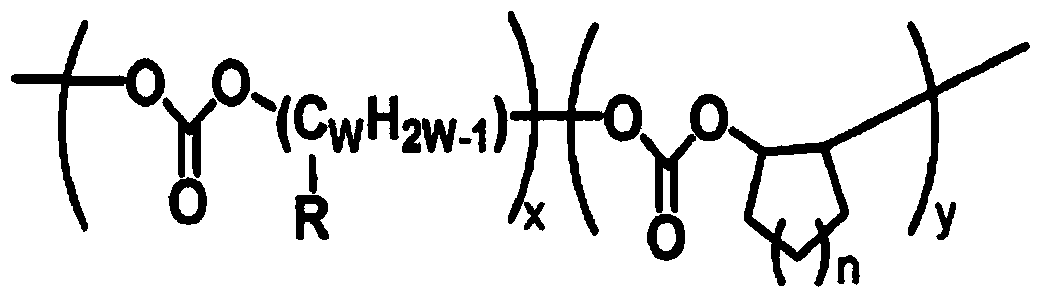

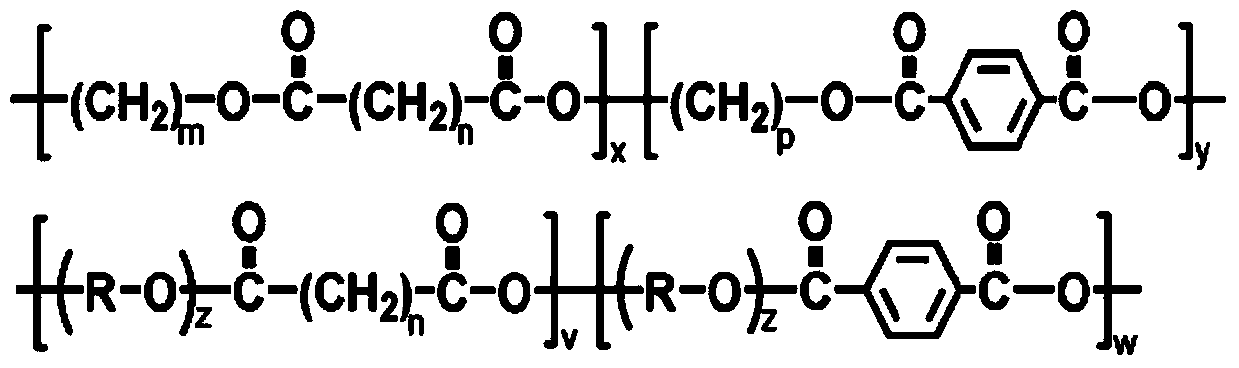

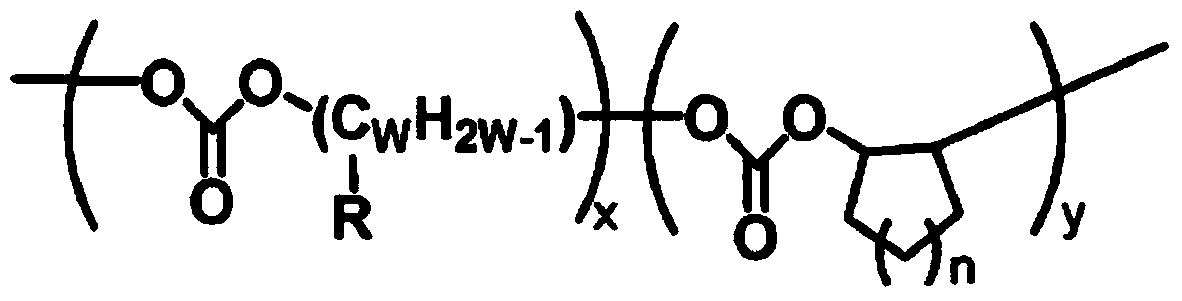

Eco-friendly poly(alkylene carbonate) resin composition for high-transparency and high-gloss sheet

A technology of alkylene carbonate and resin composition, applied in the field of eco-friendly poly(alkylene carbonate) resin composition for highly transparent and high-gloss sheets, capable of solving insufficient flexibility, expense burden, high cost And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Based on 100 parts by weight of poly(propylene carbonate) resin (SK New Technology Co., Ltd.), 20 parts by weight of linear low density polyethylene (FT400, SK New Technology Co., Ltd.), 5 parts by weight of toughening agent (DAIFATTY-101, DAIHACHI Co., Ltd.), 0.1 parts by weight of a compatibilizer based on polypropylene (BP401, Honam Petrochemical Company), and 1 part by weight of a lubricant (stearic acid, OCI Company) are input in a Henschel mixer (Henschel mixer), and then mixed for 20 minute. The wet-blended mixture was fed into a compounding extruder at 150° C. for granulation. Through a kneading process (mixing roll and warming roll) and calendering process, a sheet semi-finished product is made, and then through a printing, primer and surface treatment process, and a lamination process, thereby preparing a sheet (including a film). However, in the case of 20 parts by weight of the toughening agent, a kneading type mixer was used, and after performing a kneadin...

Embodiment 1-1 to 1-7

[0098] Sheets were prepared by controlling the content of linear low density polyethylene used in the components of Example 1 to 0, 5, 10, 20, 50, 75 and 100 parts by weight, respectively. The results of the physical property measurements are then listed in Table 1.

[0099] Table 1

[0100]

[0101] When a strength improver for linear low density polyethylene is used in the poly(propylene carbonate) resin of the present invention, compared with polyvinyl chloride resin or polyolefin resin, mechanical properties such as tensile strength and tear strength and dimension Stability is greatly improved and exhibits better elongation. When the linear low density polyethylene is used in an amount of 100 parts by weight or less based on 100 parts by weight of the poly(propylene carbonate) resin, high transparency is exhibited. When its content is more than 100 parts by weight, opacity increases and cold resistance decreases. In addition, even when the content of the strength impro...

Embodiment 1-8 to 1-28

[0103] Sheets were prepared by using SKflex from SK New Technology Co., Ltd., DAIFATTY-101 from Japan DAIHACHI Co., Ltd., and acrylate from LG Chem Co., Ltd. as toughening agents in the components of Example 1, and their content Respectively controlled at 0, 1, 2.5, 5, 10, 20 and 50 parts by weight. Then the physical property measurement results are listed in Tables 2-4.

[0104] Table 2

[0105]

[0106] table 3

[0107]

[0108] Table 4

[0109]

[0110]

[0111] Tougheners used to mitigate the hard and brittle characteristics of poly(propylene carbonate) resins do not affect the physical properties of the sheet until the level of toughener is 50 parts by weight. If its content is more than 50 parts by weight, mechanical strength, especially dimensional stability may deteriorate, but transparency may improve. Even when the amount of toughener used is 1 / 3 times that of phthalate plasticizer used in polyvinyl chloride resin, the desired physical properties can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com