Lithium ion battery negative electrode material and preparation method thereof as well as lithium ion battery negative electrode plate and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost, low energy density of lithium-ion batteries, and low specific capacity of negative electrode materials, and achieve high rate performance and high capacity, less responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A kind of preparation method of negative electrode material of lithium ion battery

[0077] Add 25.0g polyvinylidene fluoride (PVDF) to 500g N-2-methylpyrrolidone (NMP), add 25.0g graphite conductive agent after stirring for 4 hours, add lithium titanate Li after stirring for 2 hours 4 Ti 5 o 12 360.0g, stirred for 4 hours, then added 90.0g of FeS material, stirred for 4 hours to obtain a stable mixed negative electrode slurry, which is the negative electrode material for lithium ion batteries. Wherein, the temperature during stirring is 30° C., and the stirring speed is 2500 rpm for rotation and 30 rpm for revolution.

[0078] Preparation of Lithium-ion Battery Negative Electrode

[0079] Take the above-mentioned lithium ion battery negative electrode material slurry, and coat it on the perforated aluminum foil, and the coating weight is 8.66g / cm 2 (without aluminum foil), bake the electrode in an oven at 100-120°C, roll the baked and dried electrode sheet to obtai...

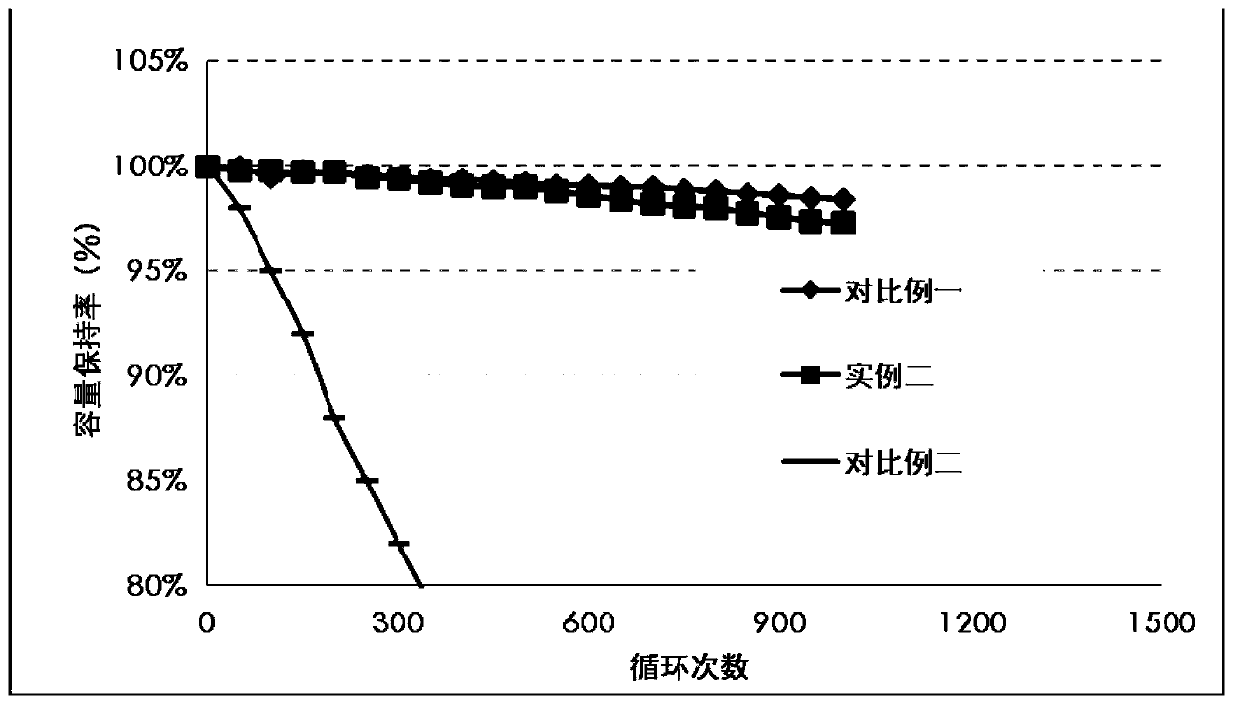

Embodiment 2

[0084] A kind of preparation method of negative electrode material of lithium ion battery

[0085] Add 21.4g polyvinylidene fluoride (PVDF) to 500g N-2-methylpyrrolidone (NMP), add 42.9g carbon black conductive agent after stirring for 1 hour, add lithium titanate Li after stirring for 2 hours 4 Ti 5 o 12 162.9g, stirred for 1 hour, then added 8.6g of FeS material, stirred for 3 hours to obtain a stable mixed negative electrode slurry, which is the negative electrode material for lithium ion batteries. Wherein, the temperature during stirring is 30° C., and the stirring speed is 3500 rpm for rotation and 40 rpm for revolution.

[0086] Preparation of negative electrode sheet for lithium ion battery

[0087] Take the above-mentioned lithium ion battery negative electrode material slurry, and coat it on the perforated aluminum foil, and the coating weight is 12.01g / cm 2 (without aluminum foil), bake the electrode in an oven at 100-120°C, roll the baked and dried electrode sh...

Embodiment 3

[0091] A kind of preparation method of negative electrode material of lithium ion battery

[0092] Add 36.7g polyvinylidene fluoride (PVDF) to 500g N,N-dimethylformamide (DMF), stir for 2 hours, add 61.1g carbon fiber, stir for 3 hours, add lithium titanate Li 4 Ti 5 o 12308.0g, stirred for 1 hour, then added 205.3g of NiS material, stirred for 4 hours to obtain a stable mixed negative electrode slurry, which is the negative electrode material for lithium ion batteries. Wherein, the temperature during stirring is 30° C., and the stirring speed is 3000 rpm for rotation and 50 rpm for revolution.

[0093] Preparation of Lithium-ion Battery Negative Electrode

[0094] Take the above-mentioned lithium ion battery negative electrode material slurry, and coat it on the perforated aluminum foil, and the coating weight is 9.04g / cm 2 (without aluminum foil), bake the electrode in an oven at 100-120°C, roll the dried electrode sheet to obtain a negative electrode sheet with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com