Alumina-modified graphene lithium ion battery anode material and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low storage capacity and low cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

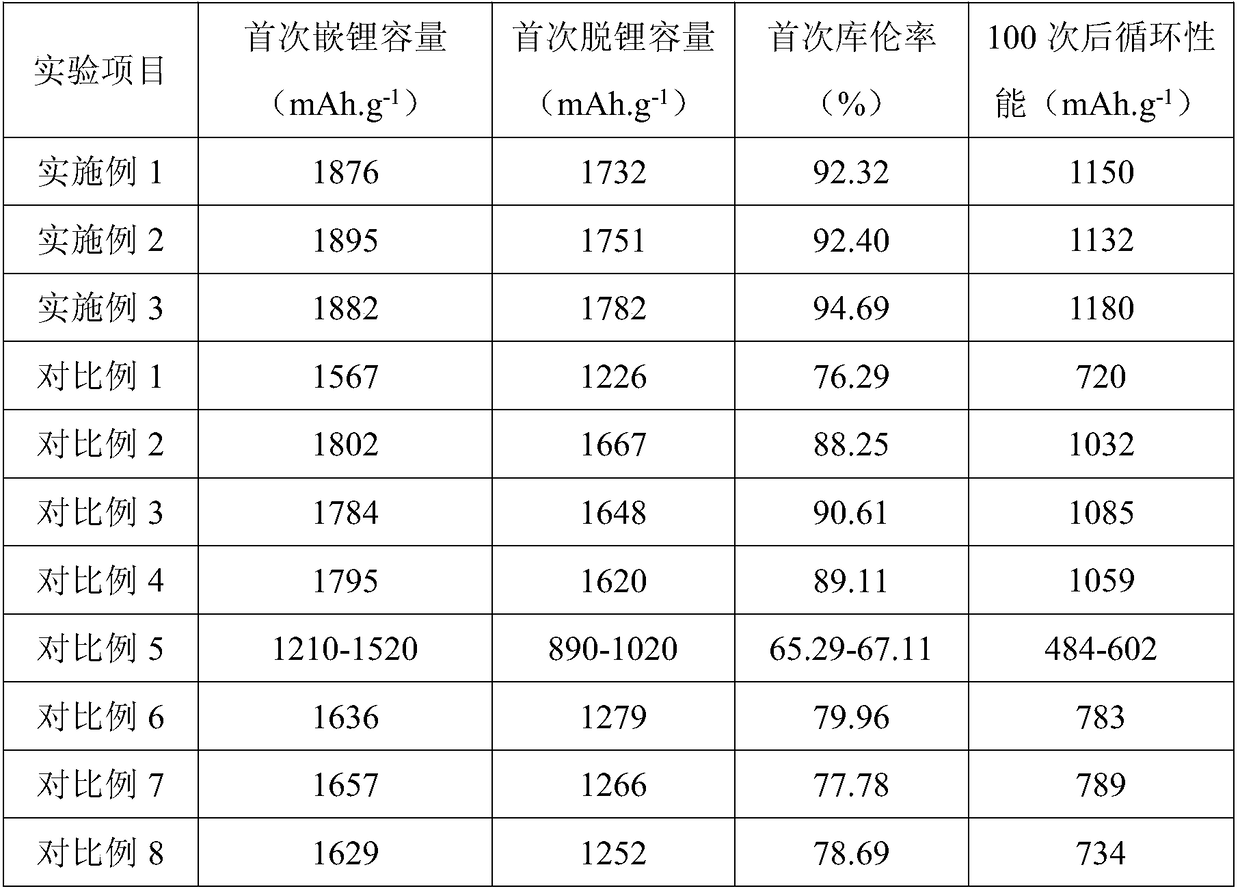

Examples

preparation example Construction

[0029] The preparation method of the graphene lithium ion battery negative electrode material of described aluminum oxide modification, comprises the following steps:

[0030] S1: Mix nano-silicon powder and graphene and perform ultrasonic treatment, then add carbon fiber and acid-treated carbon nanotubes and stir evenly to obtain graphene containing silicon / carbon; during the ultrasonic treatment, the frequency of the ultrasonic wave is 25 -30KHz, the treatment time is 30-40min; the acid-treated carbon nanotubes are added to the concentration of 20%-30% hydrochloric acid and mixed uniformly, and dried under the condition of 40-60°C. The mass ratio of hydrochloric acid to carbon nanotubes is (1-2): (4-6);

[0031] S2: Mix ethylene carbonate with composite graphene containing silicon / carbon, stir magnetically at room temperature for 10-12h, let it stand for 2-6h, then place it in a high-temperature furnace, rapidly raise the temperature to 800-1000°C, and heat it under argon U...

Embodiment 1

[0035] A graphene lithium-ion battery negative electrode material modified by alumina, comprising the following raw materials in parts by weight: 20 parts of nano-silicon powder, 60 parts of carbon fiber, 20 parts of graphene, 18 parts of carbon nanotubes, and 3 parts of ethylene carbonate , 12 parts of aluminum oxide, and 1 part of polyacrylic acid.

[0036] Preferably, the particle size of the nano silicon powder is 15nm.

[0037] The preparation method of the graphene lithium ion battery negative electrode material of described aluminum oxide modification, comprises the following steps:

[0038] S1: Mix nano-silicon powder and graphene and perform ultrasonic treatment, then add carbon fiber and acid-treated carbon nanotubes and stir evenly to obtain graphene containing silicon / carbon; during the ultrasonic treatment, the frequency of the ultrasonic wave is 25KHz , the treatment time is 40min; the acid-treated carbon nanotubes are that the carbon nanotubes are added to a co...

Embodiment 2

[0043] A graphene lithium-ion battery negative electrode material modified by alumina, in parts by weight, comprising the following raw materials: 15 parts of nano silicon powder, 50 parts of carbon fiber, 30 parts of graphene, 15 parts of carbon nanotube, 7 parts of ethylene carbonate , 15 parts of aluminum oxide, 3 parts of polyacrylic acid.

[0044] Preferably, the particle size of the nano silicon powder is 10nm.

[0045] The preparation method of the graphene lithium ion battery negative electrode material of described aluminum oxide modification, comprises the following steps:

[0046] S1: Mix nano-silicon powder and graphene and perform ultrasonic treatment, then add carbon fiber and acid-treated carbon nanotubes and stir evenly to obtain graphene containing silicon / carbon; during the ultrasonic treatment, the frequency of the ultrasonic wave is 30KHz , the treatment time is 35min; the acid-treated carbon nanotubes are that the carbon nanotubes are added to a concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com