Preparation method of sodium-nitrogen in-situ doped ternary material

A technology of in-situ doping and ternary materials, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of high nickel ternary material capacity, decreased cycle performance rate performance, and low tap density of ternary materials It is unfavorable for industrial processing, affects the stability of crystal structure, etc., and achieves the effect of improving cycle stability, improving cycle and rate performance, and improving the stability of layered structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of sodium nitrogen in-situ doped nickel cobalt lithium manganate ternary material, lithium hydroxide, sodium carbonate, Ni 0.6 co 0.2 mn 0.2 (OH) 2 Weigh it according to the molar ratio of 1:0.05:1 and use a high-mixer to mix for 15 minutes. After mixing evenly, sinter at 800°C. During the sintering process, 10L / min of oxygen and 0.2L / min of high-purity ammonia are introduced at the same time. After 10 hours, after natural cooling, the sodium nitrogen in-situ doped nickel cobalt lithium manganate ternary material Li 0.95 Na 0.05 (Ni 0.6 co 0.2 mn 0.2 )N 0.002 o 1.998 .

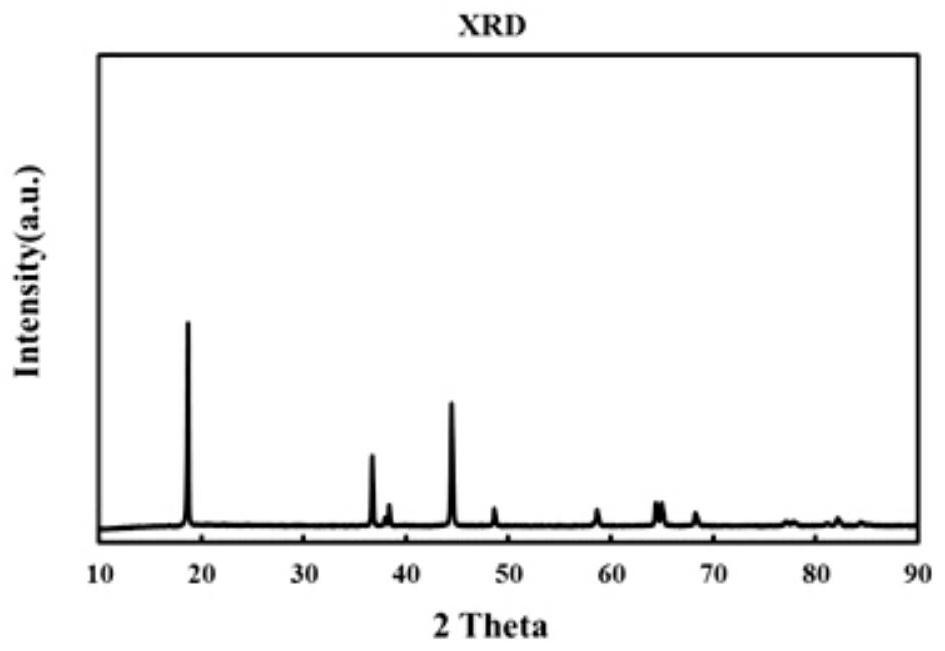

[0026] The sodium nitrogen in-situ doped nickel cobalt lithium manganese oxide ternary material Li prepared in Example 1 0.95 Na 0.05 (Ni 0.6 co 0.2 mn 0.2 )N 0.002 o 1.998 Carry out XRD scanning, can see from the XRD data of XRD figure that the sample prepared by this method has good crystal phase, no impurity peak. The diffraction peaks on the XRD pattern ...

Embodiment 2

[0028] A kind of preparation method of sodium nitrogen in-situ doped nickel cobalt lithium manganate ternary material, lithium hydroxide, sodium carbonate, Ni 0.8 co 0.1 mn 0.1 (OH) 2Weigh it according to the molar ratio of 1:0.04:1 and use a high-mixer to mix it for 15 minutes. After mixing evenly, sinter at 730°C. During the sintering process, 20L / min of oxygen and 0.2L / min of high-purity ammonia are introduced at the same time. After 12 hours, after natural cooling, the sodium nitrogen in-situ doped nickel cobalt lithium manganate ternary material Li 0.96 Na 0.04 (Ni 0.8 co 0.1 mn 0.1 )N 0.002 o 1.998 .

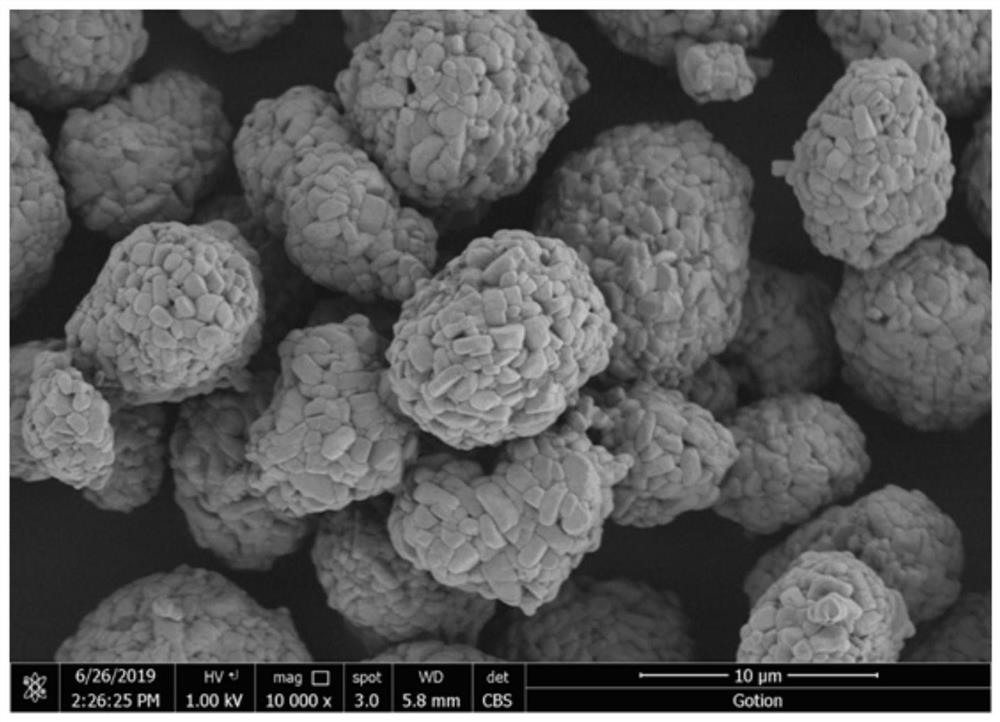

[0029] The sodium nitrogen in-situ doped nickel cobalt lithium manganese oxide ternary material Li prepared in Example 2 0.96 Na 0.04 (Ni 0.8 co 0.1 mn 0.1 )N 0.002 o 1.998 SEM scanning analysis is carried out, and the SEM test results from the SEM image show that the sample prepared by this method has a good secondary spherical structure, the ternary mater...

Embodiment 3

[0031] A kind of preparation method of sodium nitrogen in-situ doped nickel cobalt lithium manganate ternary material, lithium hydroxide, sodium carbonate, Ni 0.6 co 0.2 mn 0.2 (OH) 2 Weigh it according to the molar ratio of 1:0.05:1 and use a high-mixer to mix for 15 minutes. After mixing evenly, sinter at 850°C. During the sintering process, 10L / min of oxygen and 0.1L / min of high-purity ammonia are introduced at the same time. After 15 hours, after natural cooling, the sodium nitrogen in-situ doped nickel cobalt lithium manganate ternary material Li 0.95 Na 0.05 (Ni 0.6 co 0.2 mn 0.2 )N 0.001 o 1.999 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com