Composite cathode material of low-temperature lithium ion battery, cathode plate of low-temperature lithium ion battery, preparation method thereof, and lithium ion battery

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low initial efficiency and energy density, improve the quantity and transmission rate, easy to obtain raw materials, and improve the first discharge. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

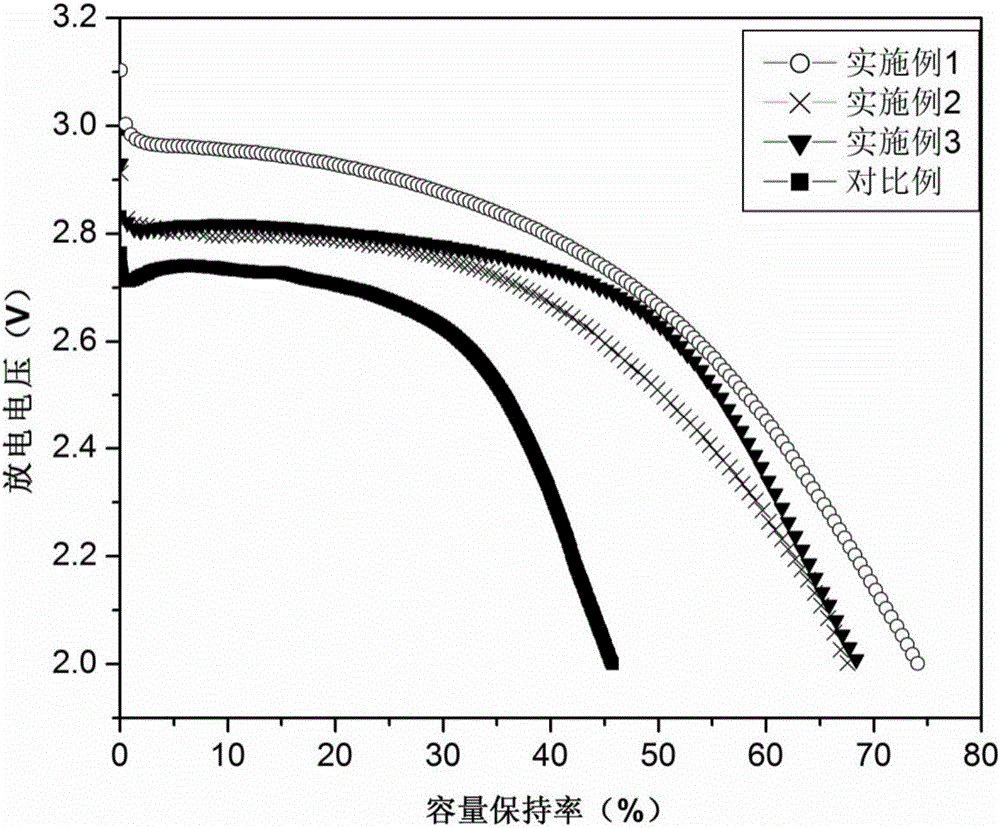

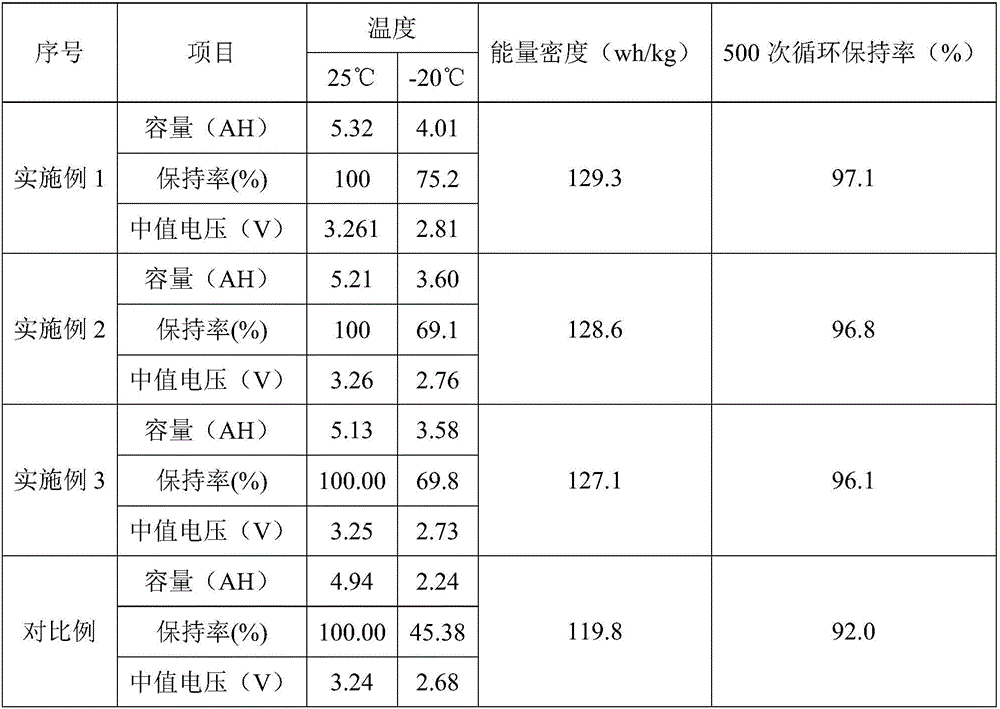

Embodiment 1

[0033] The low-temperature lithium-ion battery composite positive electrode material of this embodiment is composed of components in the following mass ratio: lithium iron phosphate: carbon nanotube / polypropylene composite material: carbon nanofiber: lithium carbonate = 92:1.5:1.5:1.

[0034] The positive electrode sheet of the low-temperature lithium-ion battery of this embodiment includes aluminum foil and a conductive layer and an active material layer that are sequentially coated on the surface of the aluminum foil along the direction away from the aluminum foil. The conductive layer is composed of components with the following mass ratio: graphene: carbon nanotubes : binder=15:3:8; the active material layer is composed of components in the following mass ratio: lithium iron phosphate: carbon nanotube / polypropylene composite material: carbon nanofiber: lithium carbonate: binder=92: 1.5:1.5:1:4; The binder is composed of the following components in weight percentage: polyacr...

Embodiment 2

[0041] The low-temperature lithium-ion battery composite cathode material of this embodiment is composed of components in the following mass ratio: lithium iron phosphate: carbon nanotube / polypropylene composite material: carbon nanofiber: lithium carbonate = 90:2:2:1.

[0042] The positive electrode sheet of the low-temperature lithium-ion battery of this embodiment includes aluminum foil and a conductive layer and an active material layer that are sequentially coated on the surface of the aluminum foil along the direction away from the aluminum foil; the conductive layer is composed of the following mass ratio components: graphene: carbon nanotubes : binder=10:1:5; the active material layer is composed of components in the following mass ratio: lithium iron phosphate: carbon nanotube / polypropylene composite material: carbon nanofiber: lithium carbonate: binder=90: 2:2:1:5; The binder is composed of the following components by weight percentage: polyacrylic acid 30%, polyacryl...

Embodiment 3

[0049] The low-temperature lithium-ion battery composite positive electrode material of this embodiment is composed of components in the following mass ratio: lithium iron phosphate: carbon nanotube / polypropylene composite material: carbon nanofiber: lithium hydroxide=94:1:1:0.5.

[0050] The positive electrode sheet of the low-temperature lithium-ion battery of this embodiment includes aluminum foil and a conductive layer and an active material layer that are sequentially coated on the surface of the aluminum foil along the direction away from the aluminum foil. The conductive layer is composed of components with the following mass ratio: graphene: carbon nanotubes : binder=20:5:10; the active material layer is composed of components in the following mass ratio: lithium iron phosphate: carbon nanotube / polypropylene composite material: carbon nanofiber: lithium hydroxide: binder=94 : 1: 1: 0.5: 3.5; The binder is composed of the following components in weight percentage: polyac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com