Formation method of lithium-ion battery

A lithium-ion battery and a formation method technology, applied in the field of formation of lithium-ion batteries, can solve the problems of large internal resistance, poor rate performance, increased lithium ion consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

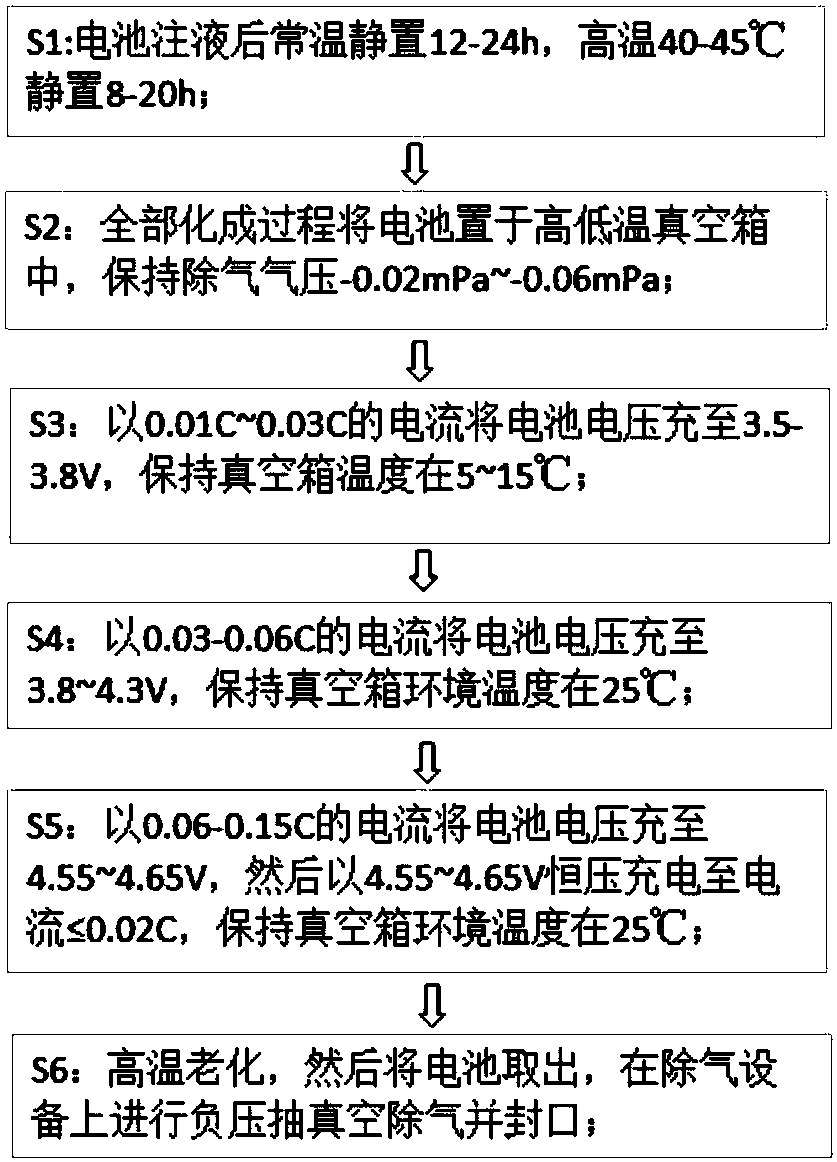

Method used

Image

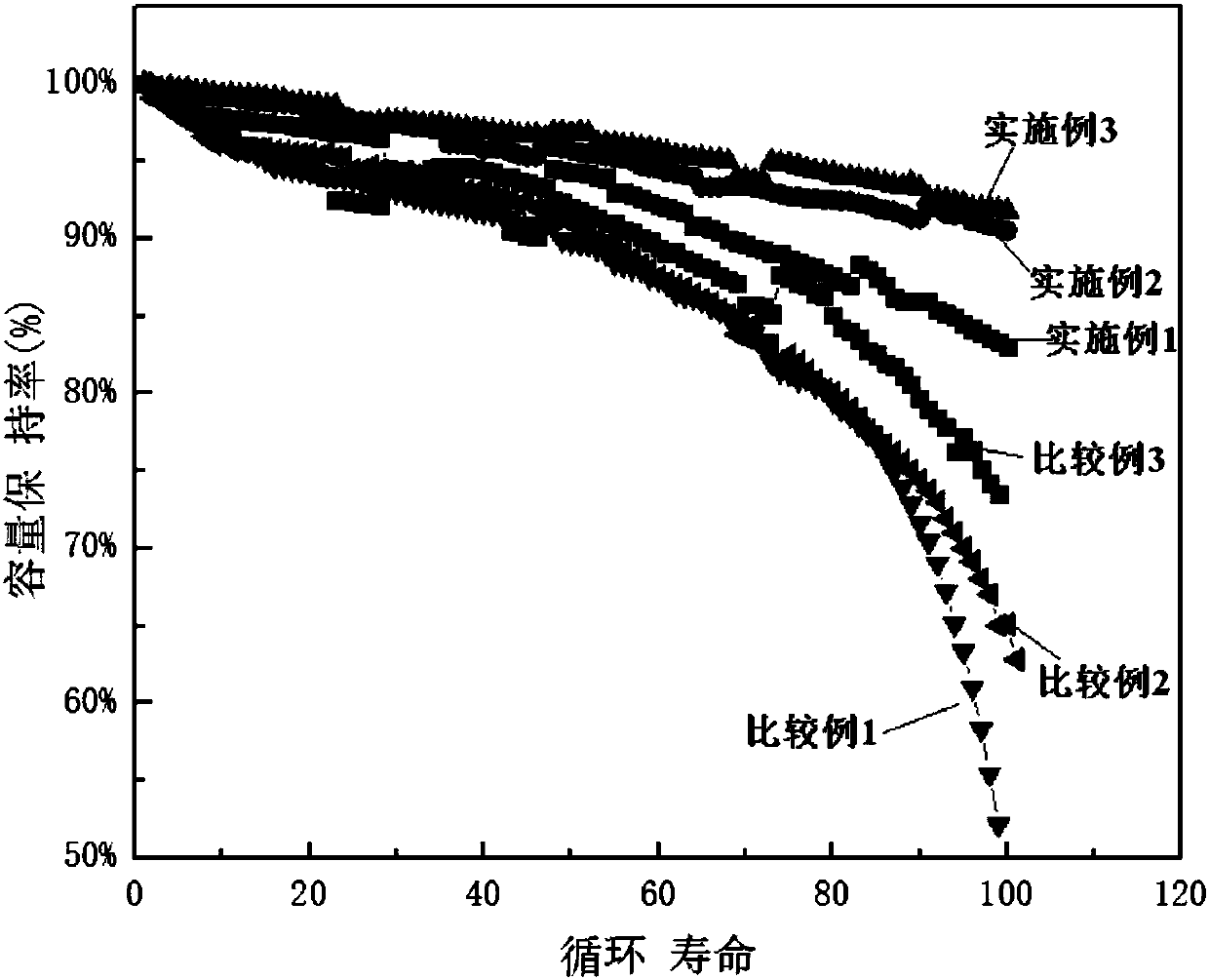

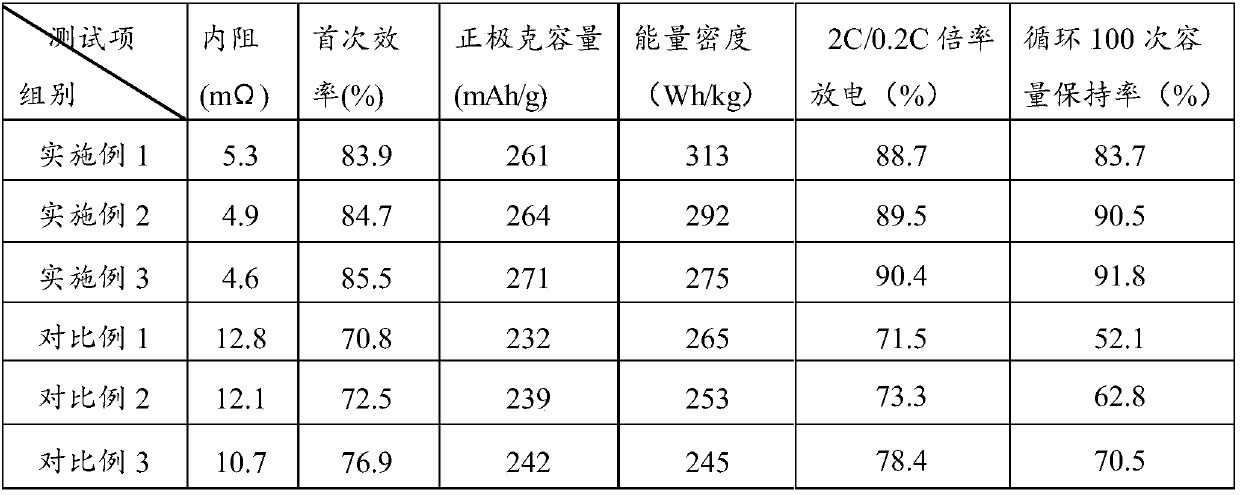

Examples

Embodiment 1

[0060] The lithium ion battery that present embodiment provides, its manufacture method is:

[0061] The mass ratio of the positive electrode is: lithium-rich manganese-based material: conductive carbon black: conductive graphite: polyvinylidene fluoride = 96:1.5:0.5:2; polyvinylidene fluoride is dissolved in N-methylpyrrolidone solvent to prepare 8 % glue, then add conductive graphite and conductive carbon black, add lithium-rich manganese-based materials after the dispersion is complete, until the slurry is evenly mixed and dispersed, add N-methylpyrrolidone to adjust the viscosity to 5000-8000cp, and then mix the slurry The material is evenly coated on the aluminum foil with a thickness of 15μm, and the density of both sides of the coating is 36mg / cm 2 , and rolled and cut to obtain the positive electrode sheet.

[0062] Negative electrode mass ratio is: silicon-carbon composite material (the ratio of silicon is 15%): conductive carbon black: conductive graphite: sodium ca...

Embodiment 2

[0074] The lithium ion battery that present embodiment provides, its manufacture method is:

[0075] Positive sheet production is exactly the same as embodiment 1.

[0076] The mass ratio of the negative electrode is: silicon-carbon composite material: conductive carbon black: conductive graphite: sodium carboxymethyl cellulose: styrene-butadiene rubber = 95: 1.5: 1.5: 2; the thickener sodium carboxymethyl cellulose is dissolved in deionized Prepare 2.5% glue solution in water, then add conductive carbon black, add silicon-carbon composite material (the proportion of silicon is 7%) in batches several times after dispersion is complete, add binder styrene-butadiene rubber emulsion after mixing evenly, add water to adjust When the viscosity reaches 2000-4000cp, the mixed slurry is evenly coated on a copper foil with a thickness of 8 μm. The surface density of the coating is calculated by corresponding to 4% excess capacity of the positive electrode, and the negative electrode sh...

Embodiment 3

[0088] The lithium ion battery that present embodiment provides, its manufacture method is:

[0089] Positive sheet production is exactly the same as embodiment 1.

[0090] The negative electrode mass ratio is: artificial graphite material: conductive carbon black: conductive graphite: sodium carboxymethyl cellulose: styrene-butadiene rubber = 95: 1.5: 1.5: 2; the thickener sodium carboxymethyl cellulose is dissolved in deionized water Prepare a 2.5% glue solution, then add conductive carbon black, add artificial graphite in batches several times after the dispersion is complete, add the binder styrene-butadiene rubber emulsion after mixing evenly, add water to adjust the viscosity to 2000-4000cp, and then put the mixed The slurry is uniformly coated on a copper foil with a thickness of 8 μm, and the coating area density is calculated by corresponding to an excess capacity of 8% of the positive electrode, and the negative electrode sheet is obtained by rolling and cutting.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com