Special graphene conductive agent for lithium battery

A technology of graphene and conductive agent, applied to battery electrodes, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of reducing the mechanical properties of conductive agents, unfavorable conductive agent applications, and reducing resin content, etc., to achieve Excellent performance, easy operation of preparation steps, and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

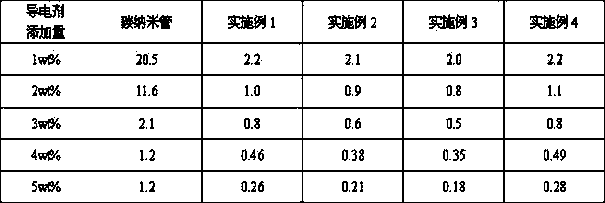

Examples

Embodiment 1

[0015] In this embodiment, the mass parts of each raw material are as follows: 8 parts of graphene, 16 parts of acrylic resin, 32 parts of water, 6 parts of BYK wetting and dispersing agent, and 5 parts of tricarboxymethylpropane glycidyl ether. The preparation steps are as follows:

[0016] (1) Mix 8 parts of graphene with 12 parts of water to infiltrate the graphene to obtain a graphene premix;

[0017] (2) Mix 16 parts of acrylic resin with 20 parts of water to swell the resin to obtain a resin premix;

[0018] (3) Mix the graphene premix with the resin premix, add 6 parts of BYK wetting and dispersing agent, and 5 parts of tricarboxymethylpropane glycidyl ether, and stir evenly to obtain a finished product.

Embodiment 2

[0020] In this embodiment, the mass parts of each raw material are as follows: 13 parts of graphene, 22 parts of acrylic resin, 43 parts of ethanol, 8 parts of BYK wetting and dispersing agent, and 4 parts of tricarboxymethyl propane glycidyl ether. The preparation steps are as follows:

[0021] (1) Mix 13 parts of graphene with 15 parts of ethanol to infiltrate the graphene to obtain a graphene premix;

[0022] (2) Mix 22 parts of acrylic resin with 28 parts of ethanol to swell the resin to obtain a resin premix;

[0023] (3) Mix the graphene premix with the resin premix, add 8 parts of BYK wetting and dispersing agent, 4 parts of tricarboxymethylpropane glycidyl ether, and stir evenly to obtain a finished product.

Embodiment 3

[0025] In this embodiment, the mass parts array of each raw material is as follows: 18 parts of graphene, 28 parts of alkyd resin, 50 parts of acetone, 5 parts of BYK wetting and dispersing agent, and 8 parts of tricarboxymethyl propane glycidyl ether. The preparation steps are as follows:

[0026] (1) Mix 18 parts of graphene with 20 parts of acetone to infiltrate the graphene to obtain a graphene premix;

[0027] (2) Mix 28 parts of alkyd resin with 30 parts of acetone to swell the resin to obtain a resin premix;

[0028] (3) Mix the graphene premix with the resin premix, add 5 parts of BYK wetting dispersant and 8 parts of tricarboxymethylpropane glycidyl ether, and stir evenly to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com