A kind of silicon-containing porous amorphous alloy lithium-ion battery negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the field of electrochemical power supply, can solve the problems of complex process, difficult to realize industrial production, high cost, etc., achieve the effect of small volume change, prevent concentration polarization, and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The composite material was obtained by chemical corrosion method, and the electrochemical performance test was carried out as the negative electrode material of lithium ion battery.

[0032] 1. The FeCuNbSiB amorphous powder obtained by high-energy ball milling is corroded by chemical etching, and the specific composition is Fe73.5Cu1Nb3Si13.5B9 (atomic percentage), thereby obtaining silicon-containing porous amorphous alloy-1, wherein the content of Si element is 50.94at% , the B content is 33.96 at%, the Cu content is 3.7 at%, and the Nb content is 11.3 at%.

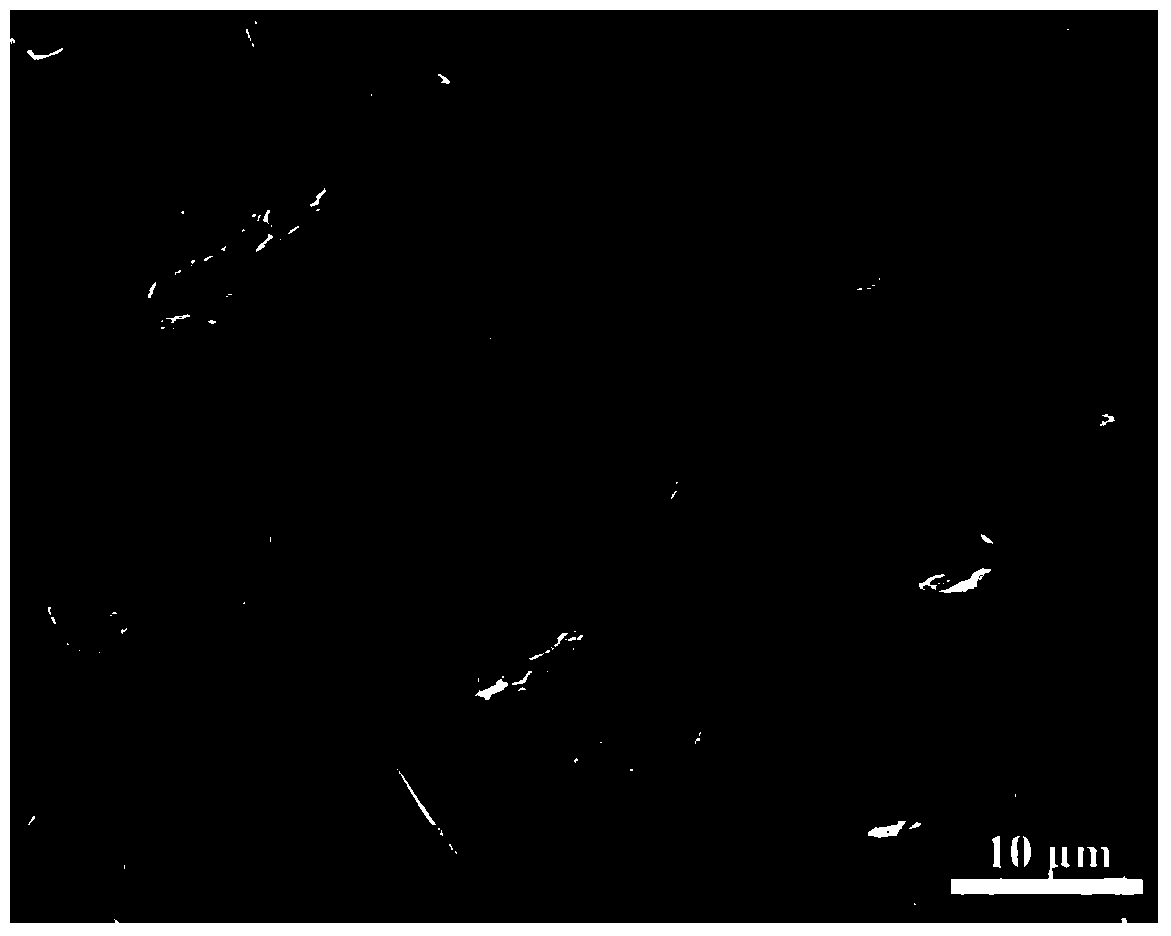

[0033] 2. Add the selected raw material, FeCuNbSiB amorphous powder obtained by high-energy ball milling, into the dilute hydrochloric acid prepared in the beaker, and stir with a glass rod while adding. In this example, dilute hydrochloric acid is configured with a ratio of 4:1 between deionized water and concentrated hydrochloric acid. The concentration of concentrated hydrochloric acid used is 12mol / L. The am...

Embodiment 2

[0042] The silicon-containing porous amorphous alloy-1 prepared in Example 1 was used as an active material to prepare a battery pole piece, and the battery was assembled with metal lithium as a counter electrode. The battery preparation method and battery assembly conditions are the same as in Example 1, and the test conditions are: charge and discharge voltage range 0.03-1.5V, charge and discharge 20 cycles at a rate of 0.1C. Image 6 In order to prepare the electrode with silicon-containing porous amorphous alloy-1 as the active material, the cycle performance curve and the coulombic efficiency diagram of the battery assembled with lithium metal as the counter electrode. It can be seen that this material has a good capacity retention effect.

Embodiment 3

[0044] The silicon-containing porous amorphous alloy-2 was obtained by chemical corrosion method, and its electrochemical performance was tested as an anode material for lithium-ion batteries. The difference from Example 1 is that in the etching process, the required amount of concentrated hydrochloric acid is calculated and used based on the corrosion of three quarters of the Fe in the FeCuNbSiB amorphous powder. The preparation and testing process are the same as in Example 1.

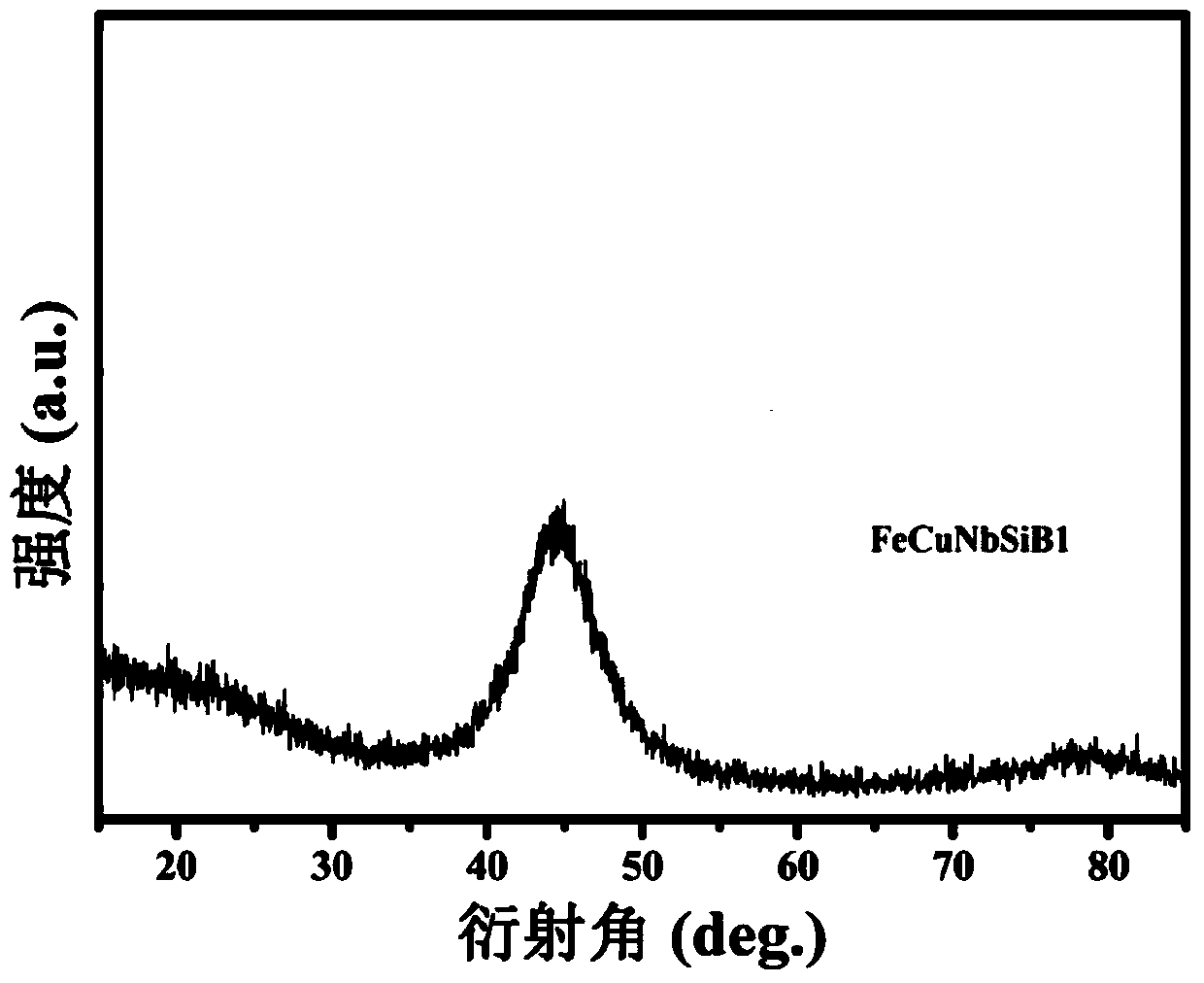

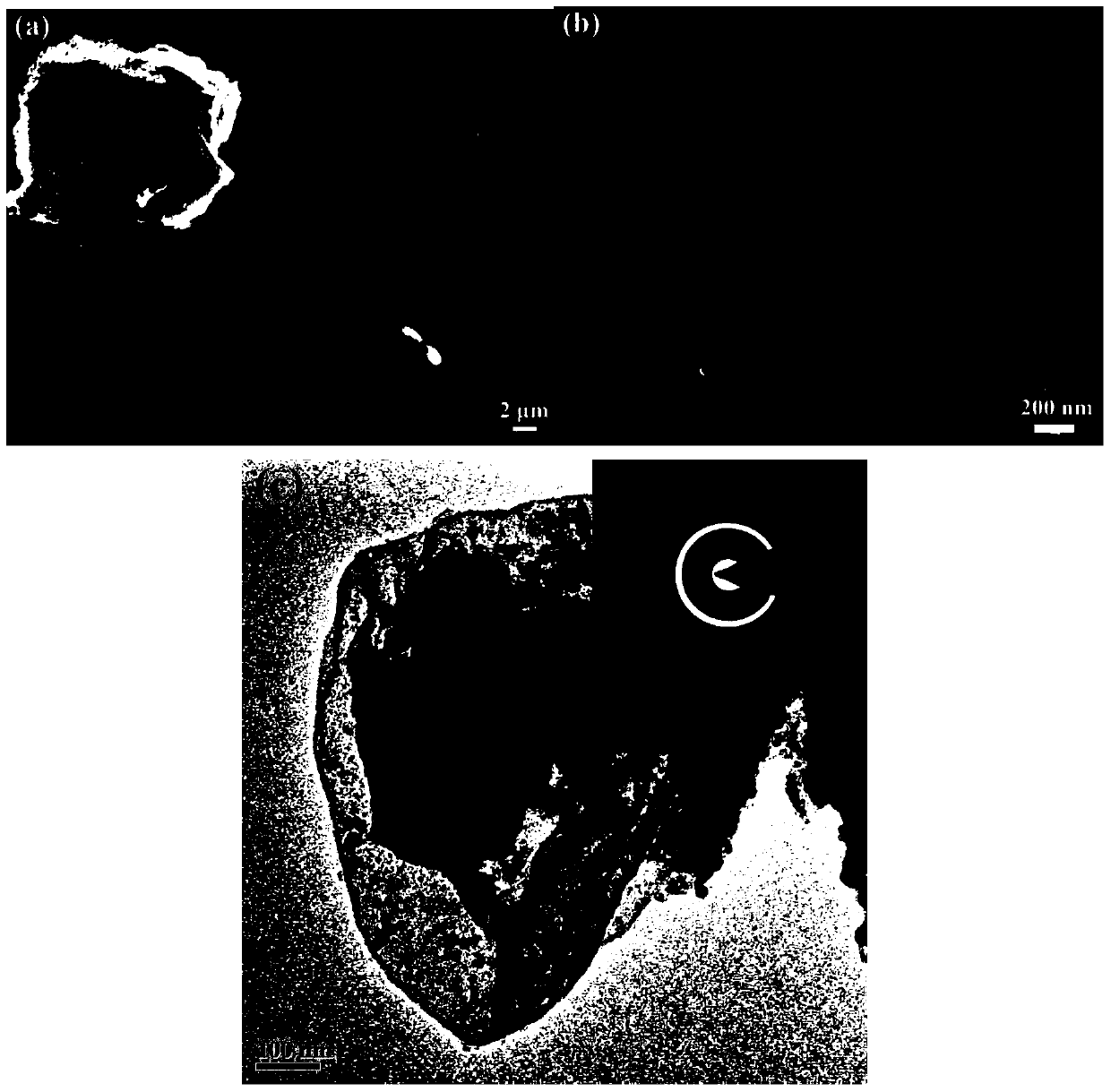

[0045] In the silicon-containing porous amorphous alloy-2 prepared in this example, the content of Si element is 30.1 at%, the content of B is 20.1 at%, the content of Cu is 2.2 at%, and the content of Nb is 6.7 at%. Its XRD pattern is as Figure 7 As shown, it is a typical amorphous diffuse scattering peak, but a small amount of crystalline phase is formed. The pore size formed by corrosion in this porous material is 200nm, and the particle size is ≦10μm. The electrochemical test results show that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com