A method for preparing nickel-manganese spinel cathode material by magnetic field texturing

A positive electrode material and spinel technology, which is applied in the field of preparing nickel-manganese spinel positive electrode material by magnetic field texture, can solve the problems of nickel-manganese spinel capacity decay and poor cycle performance, and achieve the effect of prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

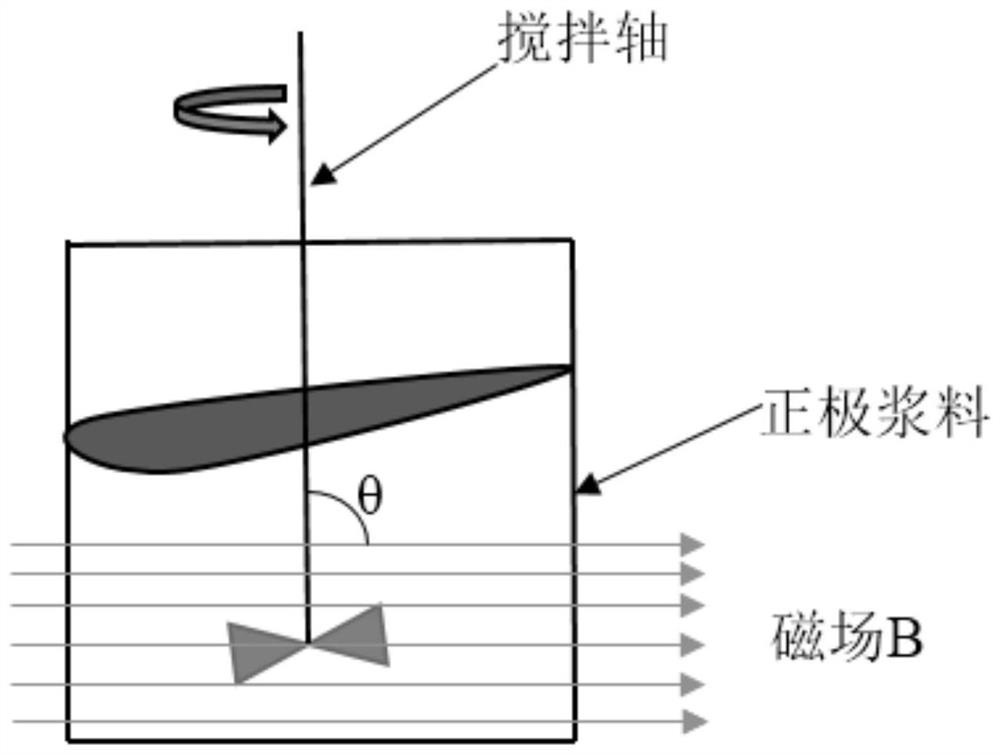

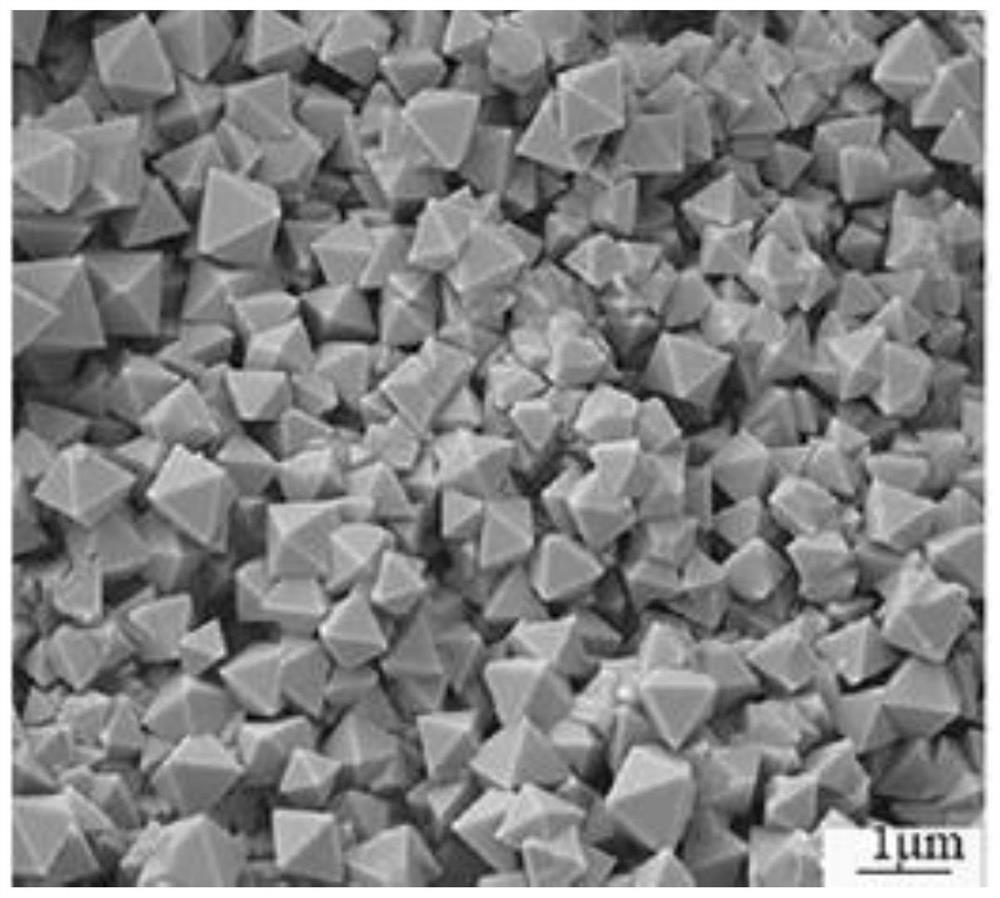

Embodiment 1

[0064] Dissolve nickel nitrate and manganese nitrate in deionized water at a molar ratio of 1:3 to prepare a salt solution with a metal ion concentration of 0.35 mol / L. Ammonia water is used as a complexing agent, and the three components are introduced into the reactor with equal volumes by a peristaltic pump. The reaction temperature is controlled at 55±0.5°C, the pH value is 10±0.2, and the stirring speed is 1000r / min. After reacting for 12 hours, the obtained precipitate was washed with deionized water three times, and then dried at 120° C. for 24 hours under a nitrogen protective atmosphere. The obtained precursor was uniformly mixed with lithium carbonate according to the molar ratio Li / Me=1.2, and calcined in a high-temperature furnace at 1050° C. for 8 hours. The obtained massive splits are crushed and screened, mixed with binder and conductive agent to make positive electrode slurry, and an external magnetic field with a strength of 10T is applied during the stirring ...

Embodiment 2

[0067] Dissolve nickel sulfate and manganese sulfate in deionized water at a molar ratio of 1:3 to prepare a salt solution with a metal ion concentration of 0.8mol / L. At the same time, prepare the same volume and concentration of sodium hydroxide as a precipitant, 0.6mol / L Ammonia water was used as a complexing agent, and the three components were introduced into the reactor with equal volumes by a peristaltic pump. The reaction temperature was controlled at 70±0.5°C, the pH value was 9.7±0.2, and the stirring speed was 800r / min. After reacting for 7 hours, the obtained precipitate was washed with deionized water three times, and then dried at 120° C. for 24 hours under an argon protective atmosphere. The obtained precursor was uniformly mixed with lithium carbonate according to the molar ratio Li / Me=1.02, and calcined in a high-temperature furnace at 900° C. for 13 hours. The resulting massive splits are crushed and sieved, mixed with a binder and a conductive agent to make a...

Embodiment 3

[0070] Dissolve nickel acetate and manganese acetate in deionized water at a molar ratio of 1:3 to prepare a salt solution with a metal ion concentration of 0.6mol / L. Ammonia water is used as a complexing agent, and the three components are introduced into the reactor with equal volumes by a peristaltic pump. The reaction temperature is controlled at 40±0.5°C, the pH value is 10.8±0.2, and the stirring speed is 1200r / min. After reacting for 16 hours, the obtained precipitate was washed with deionized water three times, and then dried at 120° C. for 24 hours under a nitrogen protective atmosphere. The obtained precursor was uniformly mixed with lithium carbonate according to the molar ratio Li / Me=0.9, and calcined in a high-temperature furnace at 700° C. for 18 hours. The obtained massive splits are crushed and sieved, mixed with a binder and a conductive agent to make a positive electrode slurry, and an external magnetic field with a strength of 6T is applied during the stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com