A kind of sulfur/nitrogen/silicon co-doped graphite composite negative electrode material and preparation method thereof

A technology of negative electrode material and composite material, applied in the field of sulfur/nitrogen/silicon co-doped graphite composite negative electrode material and its preparation, can solve the problems of poor lithium ion conductivity, easy agglomeration, poor consistency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

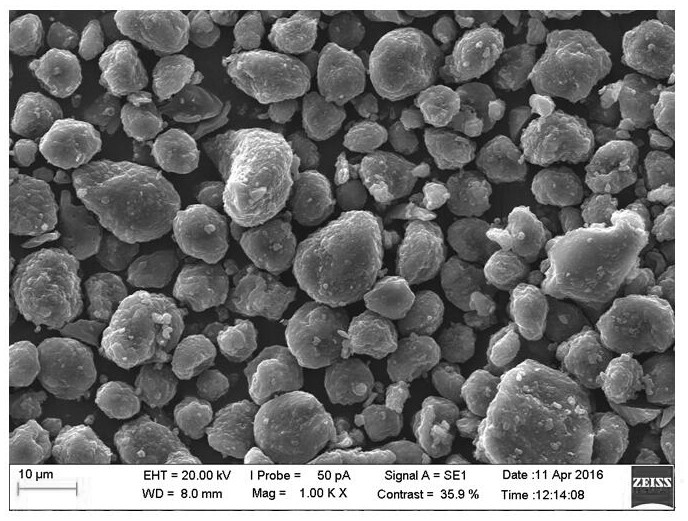

Image

Examples

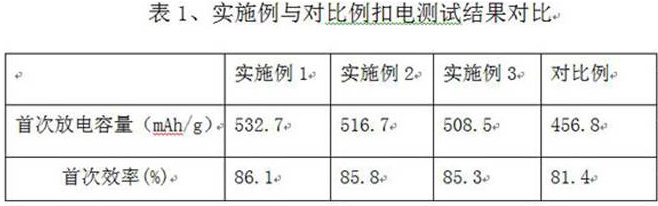

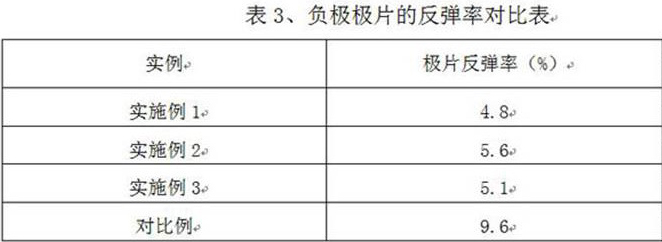

Embodiment 1

[0017] 1) Add 3g of mercaptoethylamine and 3g of melamine cyanurate to 500g of ethylene glycol, stir well and then add 100g of artificial graphite, filter, transfer to a tube furnace, and heat in an argon atmosphere Raise the temperature to 350°C and keep it warm for 3 hours, then cool down to room temperature in an argon atmosphere to obtain graphite composite material A;

[0018] 2) Afterwards, nano-silicon (particle size 100nm) was implanted into the surface layer of graphite composite material A by bombardment with high-speed particle beam. -4 Pa; the injection temperature is 300°C, and the time is 30min; after that, carbonization is carried out at 800°C for 2h to obtain a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material.

Embodiment 2

[0020] 1) Weigh 1g of 3-mercapto-1-propylamine and 1g of pentaerythritol melamine phosphate, add it to 500g of benzyl alcohol, stir well, add 100g of artificial graphite and stir evenly, after filtering, transfer to a tube furnace, and heat in an argon atmosphere , heated up to 200°C, and kept for 6 hours, and then cooled down to room temperature in an argon atmosphere to obtain graphite composite material A;

[0021] 2) Afterwards, nano-silicon (particle size: 50nm) is implanted into the surface layer of graphite composite material A by bombardment with high-speed particle beams, wherein: the high-speed particle injection atmosphere is selected from oxygen; the gas flow rate is 5 sccm, and the air pressure is 2×10 -4 Pa; the injection temperature is 100°C, and the time is 60min; after that, carbonization is carried out at 800°C for 2h to obtain a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material.

Embodiment 3

[0023] 1) Weigh 5g of 2-mercaptopyrimidine and 5g of ammonium pyrophosphate and add it to 500g of propanol, stir evenly, add 100g of artificial graphite, stir evenly, filter, transfer to a tube furnace, and heat in an argon atmosphere , heated up to 500°C, and kept for 1 hour, and then cooled down to room temperature in an argon atmosphere to obtain graphite composite material A;

[0024] 2) After that, nano-silicon (particle size 200nm) is implanted into the surface layer of graphite composite material A by bombardment with high-speed particle beams, wherein: high-speed particle injection is selected from nitrogen; the gas flow rate is 60 sccm, and the air pressure is 5×10 -4 Pa; the implantation temperature is 500°C, and the time is 10min; after that, carbonization is carried out at 800°C for 2h to obtain a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com