Titanium dioxide (B) negative electrode material with improved performance and preparation method thereof

A technology of titanium dioxide and negative electrode materials, which is applied in the direction of negative electrodes, active material electrodes, battery electrodes, etc., can solve the problems that the energy density of batteries cannot be further greatly improved, the cycle performance of graphite is poor, and the lithium intercalation capacity of graphite is low, so as to improve lithium intercalation space, improvement of cycle performance, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

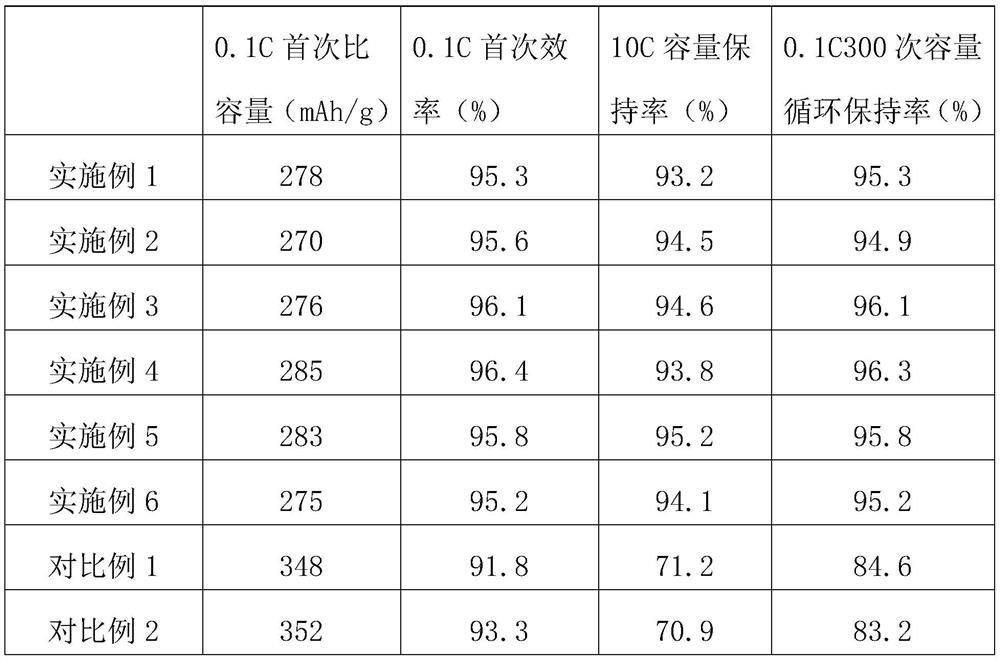

Examples

preparation example Construction

[0022] The present invention also discloses a method for preparing a titanium dioxide (B) negative electrode material with improved properties, comprising the following steps:

[0023] (1) Mixing: immerse the titanium dioxide (B) in an ethanol solvent of ethyl orthosilicate, stir and sonicate for 0.5-2 hours to prepare a mixed solution.

[0024] (2) Roasting: Evaporate the mixed solution prepared in (1) to dryness in a water bath at 60-90°C, put it in an oven for drying, and then place it in a muffle furnace. The temperature is raised to 500-1000°C at a rate of °C / min, high-temperature roasting is carried out, and the temperature is kept for 2-5 hours to obtain surface-modified titanium dioxide (B).

[0025] (3) Dispersion: disperse the surface-modified titanium dioxide (B), graphite, lithium source, dopant, and carbon source in ethanol, and ultrasonicate for 1-4 hours to obtain a mixed slurry.

[0026] (4) Grinding: Grinding the mixed slurry obtained in (3) for 1-5 hours wit...

Embodiment 1

[0032] A titanium dioxide (B) negative electrode material with improved properties, comprising the following raw materials by weight: 130 parts of titanium dioxide (B), 20 parts of tetraethyl orthosilicate, 100 parts of graphite, 100 parts of lithium source, 5 parts of doped Miscellaneous agent, 28 parts of carbon source, 35 parts of ionic liquid; The ionic liquid is N-methylbutylpyrrolidine bistrifluoromethanesulfonimide salt and N-methylbutylpiperidine bistrifluoromethanesulfonyl imide salt.

[0033] A method for preparing a titanium dioxide (B) negative electrode material with improved properties, comprising the following steps:

[0034] (1) Mixing: immerse titanium dioxide (B) in ethanol solvent of ethyl orthosilicate, stir and sonicate for 2 hours to prepare a mixed solution.

[0035] (2) Roasting: Evaporate the mixed solution prepared in (1) to dryness in a water bath at 80°C, put it in an oven for drying, and then place it in a muffle furnace. Raise the temperature to...

Embodiment 2

[0042] A titanium dioxide (B) negative electrode material with improved properties, comprising the following raw materials by weight: 155 parts of titanium dioxide (B), 40 parts of tetraethyl orthosilicate, 60 parts of graphite, 130 parts of lithium source, 7 parts of doped Miscellaneous agent, 35 parts of carbon source, 45 parts of ionic liquid; The ionic liquid is 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt and 1-ethyl-3-methylimidazole tetrafluoro borate.

[0043] A method for preparing a titanium dioxide (B) negative electrode material with improved properties, comprising the following steps:

[0044](1) Mixing: immerse titanium dioxide (B) in an ethanol solvent of ethyl orthosilicate, stir and sonicate for 0.5 h to obtain a mixed solution.

[0045] (2) Roasting: Evaporate the mixed solution prepared in (1) to dryness in a 60°C water bath, put it in an oven for drying, and then place it in a muffle furnace. Raise the temperature to 1000° C., perform hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com