Lithium ion battery anode material and preparation method thereof, lithium ion battery anode piece and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficulty in meeting the needs for preparing high energy density lithium ion batteries, low specific capacity of negative electrode materials, etc., to achieve high energy density, The effect of high specific capacity and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The conductive agent may be a commonly used conductive agent for preparing lithium-ion batteries. In this embodiment, the conductive agent is graphite, carbon black or carbon fiber. The binder is polyvinylidene fluoride or epoxy resin. The organic solvents include N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), N-2-methylpyrrolidone (NMP), acetone, tetrahydrofuran (THF) and methanol one or more of them.

[0038] The anode material of a lithium ion battery provided by the first aspect of the embodiment of the present invention has high capacity, high rate performance, and stable structure, is not easy to react with the electrolyte, and does not agglomerate, so that the lithium ion battery can finally have a higher High energy density and good cycle stability.

[0039] In a second aspect, an embodiment of the present invention provides a method for preparing a negative electrode material for a lithium ion battery, comprising the following steps:

[0040] mixin...

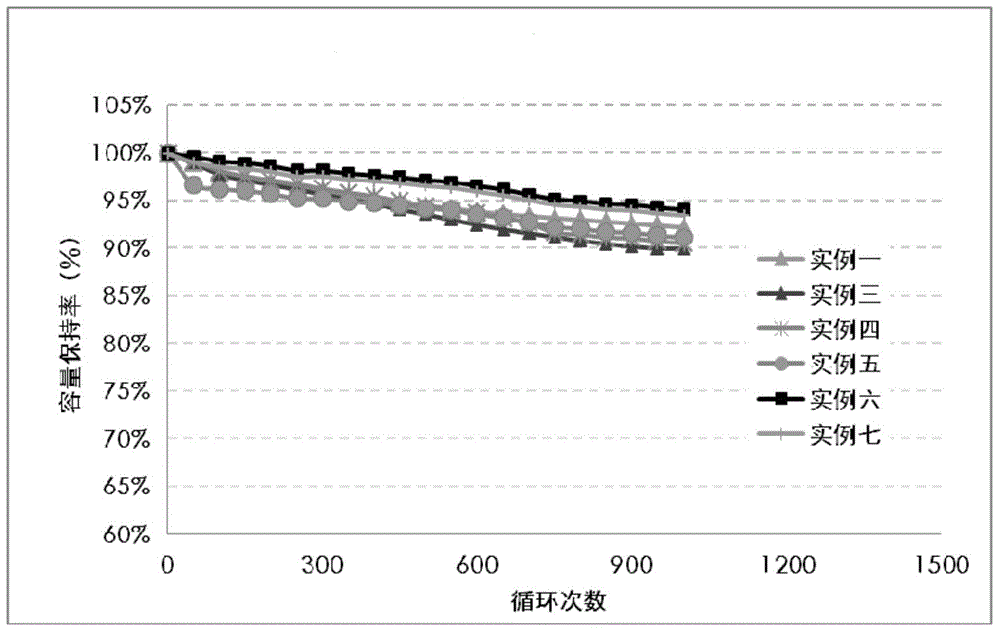

Embodiment 1

[0056] A preparation method for a lithium ion battery negative electrode material, comprising the following steps:

[0057] Add 25.0g polyvinylidene fluoride (PVDF) to 500g N-2-methylpyrrolidone (NMP), add 25.0g conductive graphite after stirring for 4 hours, add Li 4 Ti 5 o 12 360.0g, add Fe after stirring for 4 hours 2 o 3 90.0 g, stirred for 4 hours to obtain the lithium ion battery negative electrode material. Among them, the temperature in the four stirring processes is 30° C., and the stirring speed is 2500 rpm in rotation and 30 rpm in revolution.

[0058] Preparation of Lithium-ion Battery Negative Electrode

[0059] Take the above-mentioned lithium-ion battery negative electrode material and coat it on a perforated aluminum foil with a coating weight of 6.5g / cm 2 (excluding aluminum foil), put the electrode in an oven and bake the electrode at 100-120°C, roll the baked and dried electrode sheet to obtain a negative electrode sheet with a thickness of 0.085mm, an...

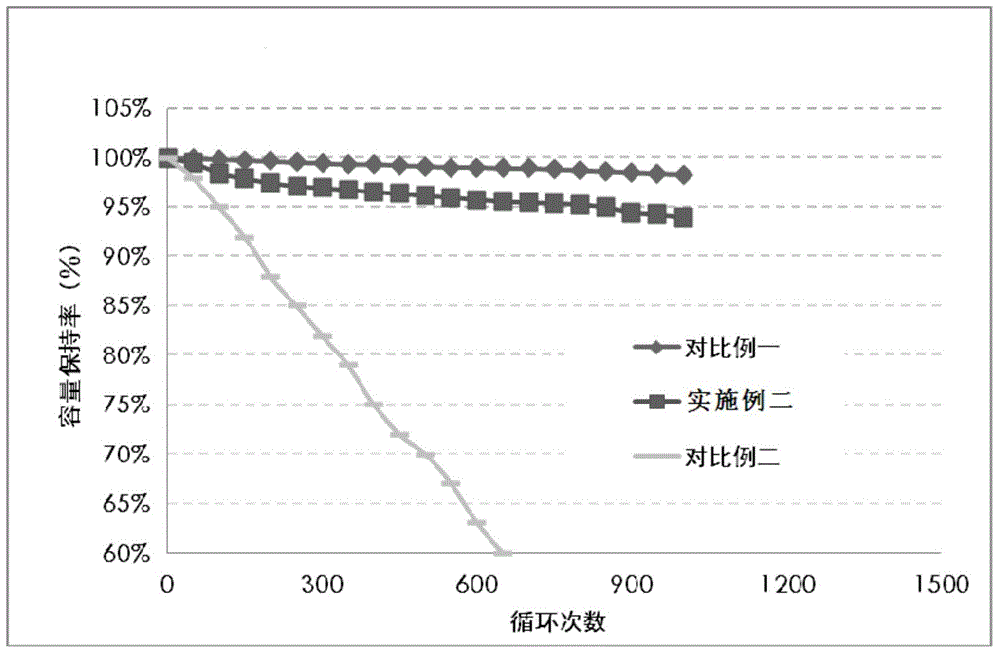

Embodiment 2

[0065] A preparation method for a lithium ion battery negative electrode material, comprising the following steps:

[0066] Add 21.4g polyvinylidene fluoride (PVDF) to 500g N-2-methylpyrrolidone (NMP), add 42.9g conductive carbon black after stirring for 1 hour, add Li 4 Ti 5 o 12 162.9 g, after stirring for 1 hour, Co 3 o 4 8.6g, stirred for 3 hours to obtain the lithium ion battery negative electrode material. The temperature in the four stirring processes was 30° C., and the stirring speed was 3500 rpm for rotation and 40 rpm for revolution.

[0067] Preparation of Lithium-ion Battery Negative Electrode

[0068] Take the above-mentioned lithium-ion battery negative electrode material and coat it on a perforated aluminum foil with a coating weight of 10.8g / cm 2 (without aluminum foil), put the electrode in an oven and bake the electrode at 100-120°C, roll the baked and dried electrode sheet to obtain a negative electrode sheet with a thickness of 0.128mm, and finally c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com