A slurry mixing process for lithium-ion battery composite graphite negative electrode

A lithium-ion battery, composite graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low first efficiency, and achieve the effects of improving compaction density, stable performance, and increasing battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

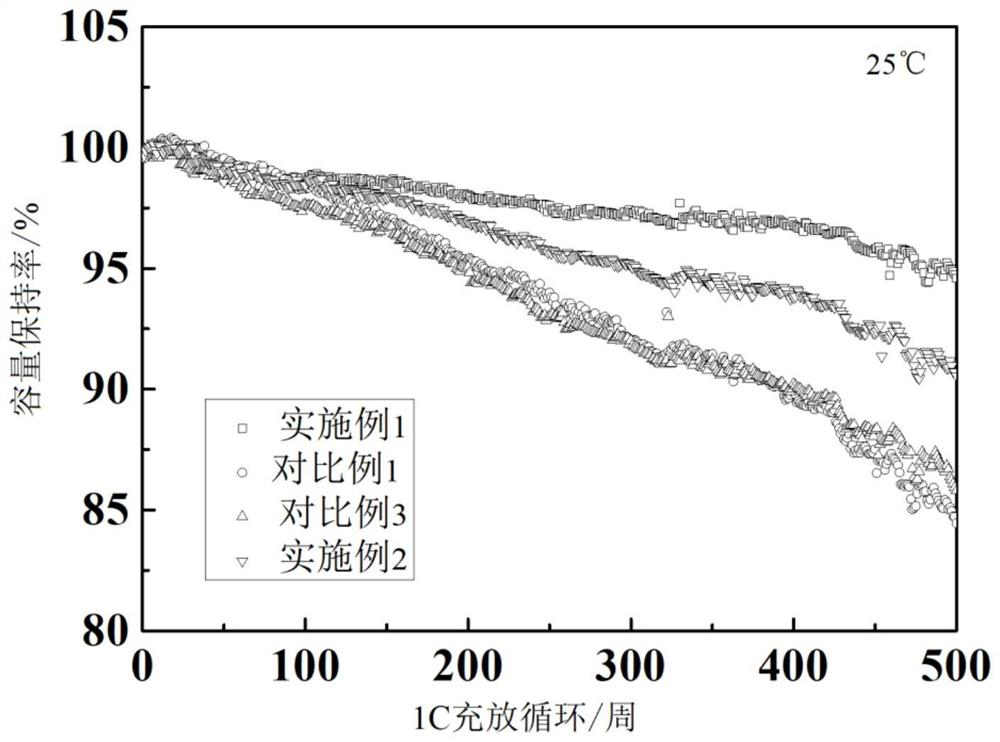

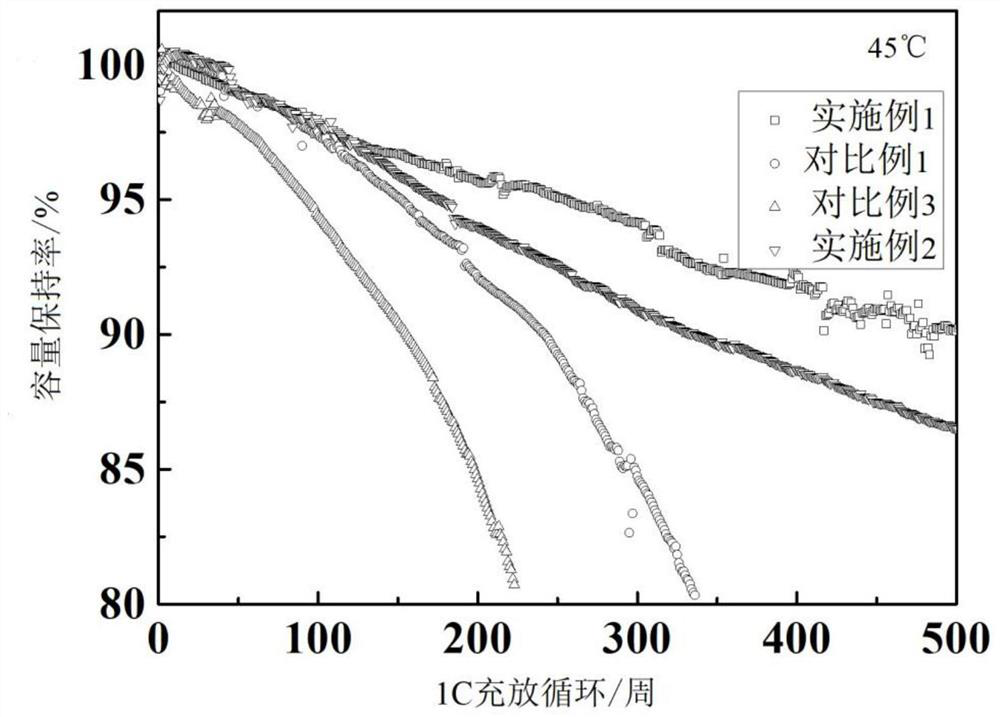

Examples

Embodiment 1

[0034] The lithium-ion battery positive pole in the present embodiment adopts NCM622 (LiNi 0.6 co 0.2 mn 0.2 o 2 ), the negative electrode graphite is mixed with natural graphite and artificial graphite, wherein the mass ratio of natural graphite and artificial graphite is 3:7.

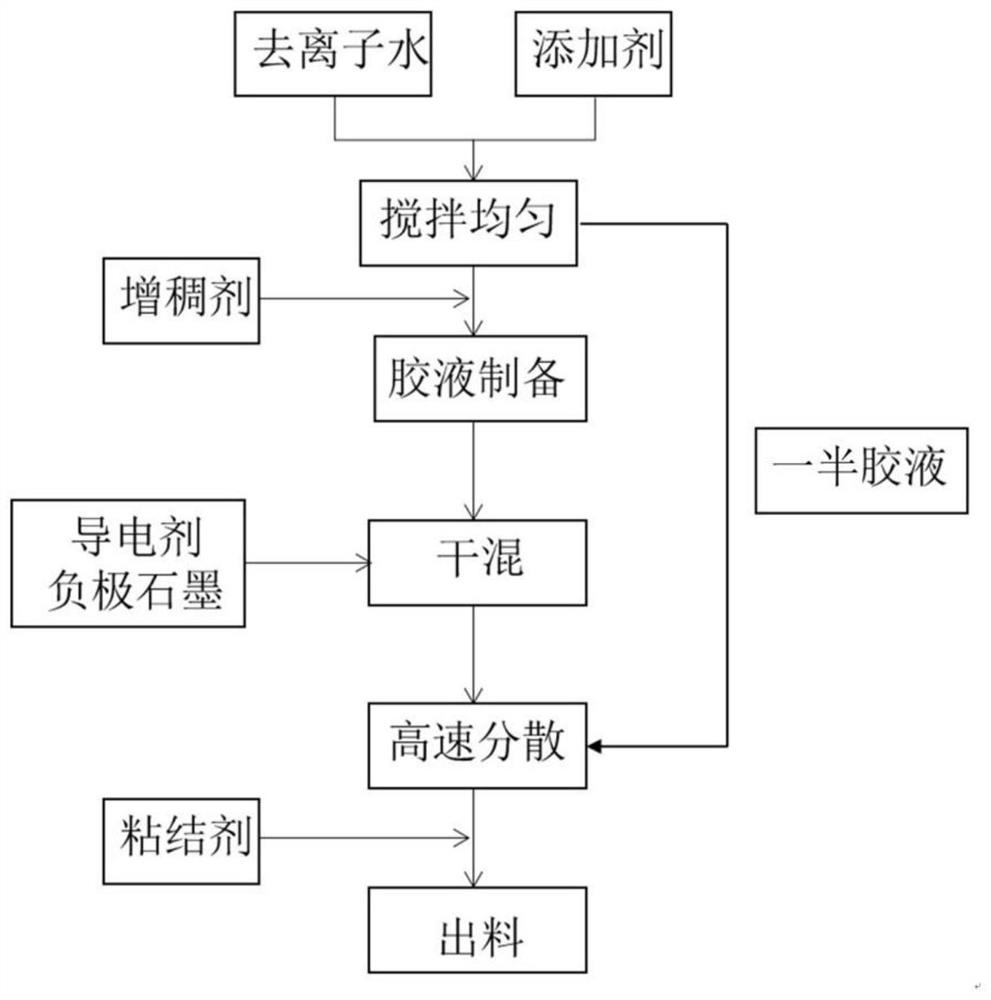

[0035] Among them, the negative electrode mixing process adopts the following steps:

[0036] (1) 1.746gCH 3 COOH was added into deionized water and stirred until dissolved to obtain an additive solution;

[0037] (2) 2.06g CMC (carboxymethyl cellulose) is added in the additive solution, is 1.6% to make glue solution according to solid content, and glue solution is divided into two equal parts for subsequent use;

[0038] (3) Add 1.98g of conductive agent SP, 45g of natural graphite and 105g of artificial graphite into half of the glue in step (2), and dry mix to prepare slurry 1;

[0039] (4) Add the other half of the glue in step (2) to the slurry 1 in step (3), and after high-speed dispersion...

Embodiment 2

[0043] The lithium-ion battery positive pole in the present embodiment adopts NCM622 (LiNi 0.8 co 0.1 mn 0.1 o 2 ), the negative electrode graphite is mixed with natural graphite and artificial graphite, wherein the mass ratio of natural graphite and artificial graphite is 4:6.

[0044] Among them, the negative electrode mixing process adopts the following steps:

[0045] (1) 4.41g Add deionized water and stir until dissolved to obtain an additive solution;

[0046] (2) 2.65g CMC is added in the additive solution, is 1.5% to make glue solution by solid content, and glue solution is divided into two equal parts for subsequent use;

[0047] (3) 4.1g of conductive agent SP, 82g of natural graphite and 123g of artificial graphite were added to half of the glue solution in step (2), and after dry mixing, slurry 1 was obtained;

[0048] (4) Add the other half of the glue solution in step (2) to the slurry 1 in step (3), and after high-speed dispersion, prepare slurry 2;

[0...

Embodiment 3

[0052] The lithium-ion battery positive pole in the present embodiment adopts NCM622 (LiNi 0.8 co0.1 mn 0.1 o 2 ), the negative electrode graphite is mixed with natural graphite and artificial graphite, wherein the mass ratio of natural graphite and artificial graphite is 1:9.

[0053] Among them, the negative electrode mixing process adopts the following steps:

[0054] (1) 4.50g Add deionized water and stir until dissolved to obtain an additive solution;

[0055] (2) 3.55g CMC is added in the additive solution, is 1.5% to make glue solution by solid content, and glue solution is divided into two equal parts for subsequent use;

[0056] (3) Add 4.3g of conductive agent SP, 25g of natural graphite and 225g of artificial graphite into half of the glue in step (2), and dry mix to prepare slurry 1;

[0057] (4) Add the other half of the glue solution in step (2) to the slurry 1 in step (3), and after high-speed dispersion, prepare slurry 2;

[0058] (5) Join the 15.46g bin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com