Preparation method for hollow carbon-coated nano-silicon composite graphite material

A composite graphite and composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of inability to be used alone, fast capacity decay, poor stability of intercalation and delithiation, etc. Stable and reversible lithium intercalation and deintercalation, good cycle performance, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing a hollow carbon-coated nano-silicon composite graphite material, comprising the following steps:

[0021] 1) Dissolve a certain amount of surfactant in absolute ethanol, add silicon nanoparticles at 35-45°C and stir for 1.5h; then heat to 70-85°C, add a certain amount of 2,4-dihydroxybenzoic acid and the catalyst, stirring at a constant temperature within the range of 70-85°C for 2 hours; then adding a certain amount of formaldehyde solution, and reacting for 30-36 hours to obtain a suspension, which is filtered, washed, and dried to obtain composite microspheres; wherein, the The surfactant is polyethylene glycol-polypropylene glycol-polyethylene glycol triblock copolymer; the catalyst is L-lysine.

[0022] 2) Dispersing the composite microspheres in step 1) in a mixed solution of absolute ethanol and deionized water, stirring and dispersing at a constant temperature of 75-85° C. for 3-4 hours, to obtain nano-silicon coated...

Embodiment 1

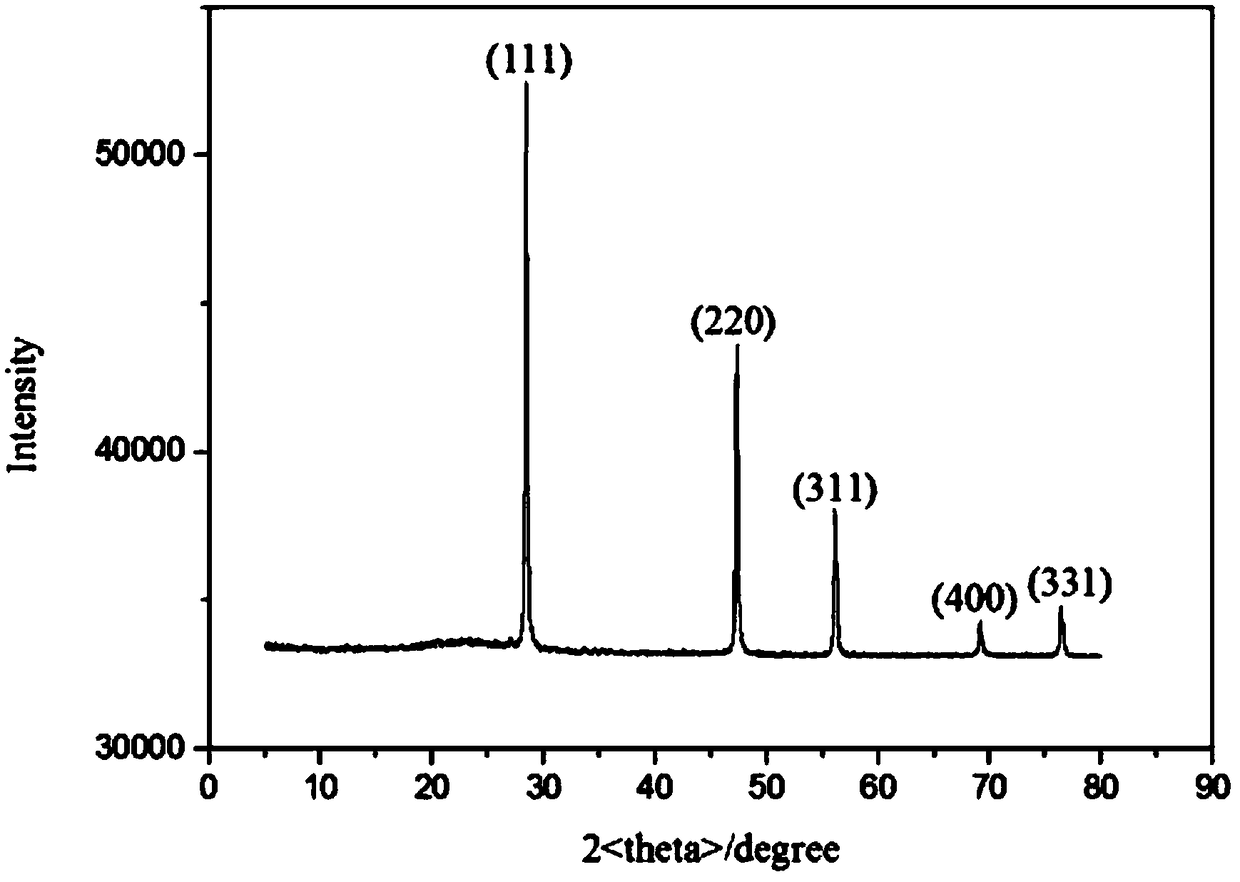

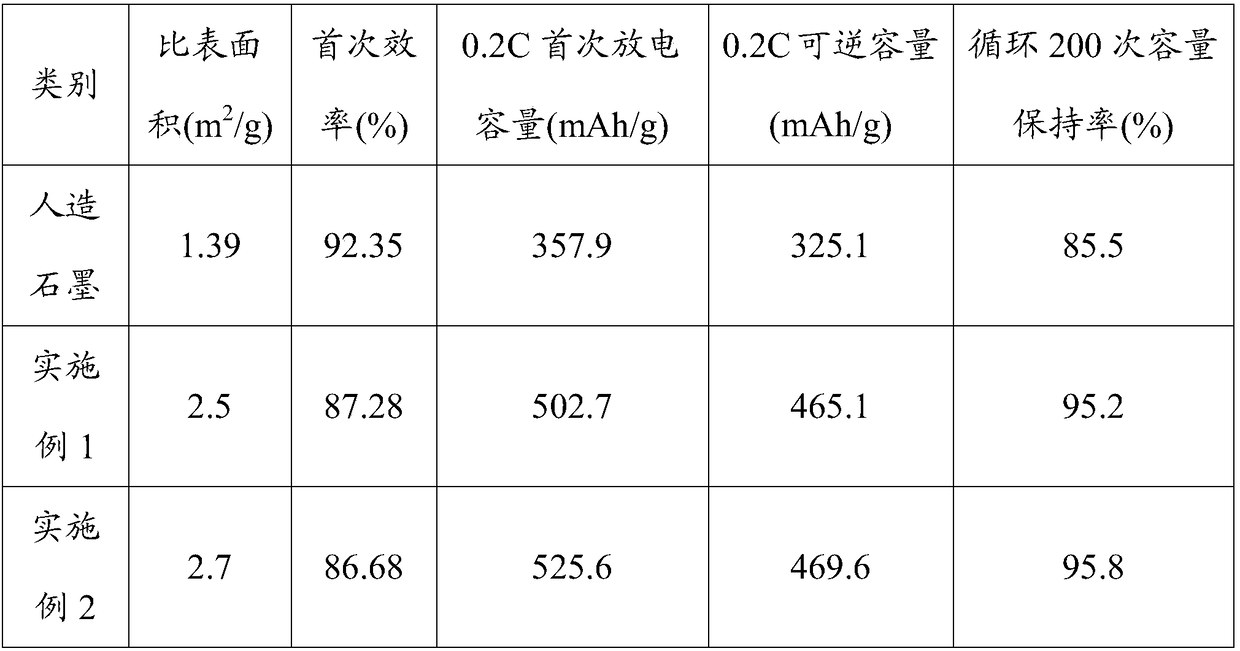

[0028] Dissolve 6-30g of surfactant (polyethylene glycol-polypropylene glycol-polyethylene glycol triblock copolymer) in 300-600ml of absolute ethanol, add 2-6g of silicon nanoparticles at 40°C and stir for 1.5h ; Then heat to 80°C, add 20~60g of 2,4-dihydroxybenzoic acid and 2~5g of L-lysine, stir at 80°C for 2h; then add 15~30ml of formaldehyde solution, react for 30h A khaki suspension is obtained, and after filtering, washing and drying, composite microspheres are obtained. The obtained composite microspheres were dispersed in a mixed solution of absolute ethanol and deionized water with a volume ratio of 3:1, and stirred and dispersed at a constant temperature of 80°C for 3.5 hours to obtain nano-silicon coated with carbon microspheres. Carbon microspheres coated nano-silicon in H 2 with N 2 Under the mixed atmosphere of 650 ° C constant temperature carbonization treatment for 1 h, the hollow carbon microsphere-coated nano-silicon particle composite material was obtaine...

Embodiment 2

[0031] Dissolve 6-30g of surfactant (polyethylene glycol-polypropylene glycol-polyethylene glycol triblock copolymer) in 300-600ml of absolute ethanol, add 2-6g of silicon nanoparticles at 45°C and stir for 1.5h ; Then heat to 85°C, add 20~60g of 2,4-dihydroxybenzoic acid and 2~5g of L-lysine, stir at 85°C for 2h; then add 15~30ml of formaldehyde solution, react for 32h A khaki suspension is obtained, and after filtering, washing and drying, composite microspheres are obtained. The obtained composite microspheres were dispersed in a mixed solution of absolute ethanol and deionized water with a volume ratio of 3:1, and stirred and dispersed at a constant temperature of 85°C for 3.5 hours to obtain nano-silicon coated with carbon microspheres. Carbon microspheres coated nano-silicon in H 2 with N 2 Carbonization treatment at 670°C for 1 hour under a mixed atmosphere of 670°C to obtain a hollow carbon microsphere-coated nano-silicon particle composite material.

[0032] The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com