High-volume V2O5 film anode material for lithium ion battery

A lithium-ion battery, V2O5 technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of reducing the symmetry of spinel structure, low specific capacity and energy density, poor charge-discharge cycle performance, etc., to improve the application Value, ease of process, effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

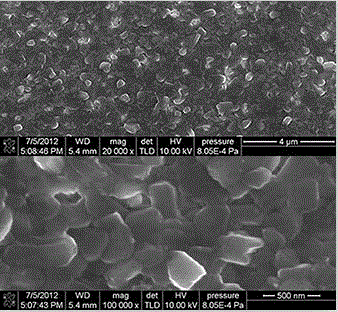

[0021] A high-capacity V for Li-ion batteries 2 o 5 The preparation method of thin film cathode material is as follows:

[0022] (1) Preparation of vanadium pentoxide sol: take 3mL of 30% hydrogen peroxide (H 2 o 2 ) solution in a 25 mL beaker, and then accurately weighed 0.146 g of vanadium pentoxide (V 2 o 5 ) powder into a beaker, fully and slowly stir at room temperature to make V 2 o 5 The powder is completely dissolved, then add 2 mL of deionized water and continue to stir until a stable reddish-brown sol is formed;

[0023] (2) Prepare V with a concentration of 0.008mol / L 2 o 5 Sol: Add the above V 2 o 5 The sol was fixed to 100ml to obtain V with a concentration of 0.008 mol / L 2 o 5 Sol;

[0024] (3) Pretreatment of the Pt substrate: completely immerse the Pt sheet to be treated in hydrogen peroxide for 10 minutes, then rinse it with deionized water and dry it naturally;

[0025] (4) Prepare V 2 o 5 Membrane electrode: Use a pipette to measure 10 μL of ...

Embodiment 2

[0034] A high-capacity V for Li-ion batteries 2 o 5 The specific steps of the preparation method of the thin film cathode material are the same as in Example 1, wherein:

[0035] In step (2), this embodiment is to prepare V with a concentration of 0.016mol / L 2 o 5 Sol: Add the above V 2 o 5 The sol was fixed to 50ml to obtain V with a concentration of 0.016 mol / L 2 o 5 Sol.

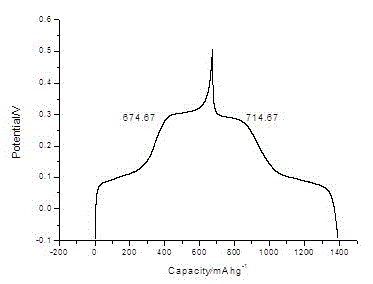

[0036] V with a concentration of 0.016mol / L 2 o 5 Sol prepared V 2 o 5 The constant current charge and discharge capacity curve of the thin film cathode material under the condition of mass current density of 400mA / g is as follows: Figure 7 shown.

Embodiment 3

[0038] A high-capacity V for Li-ion batteries 2 o 5 The specific steps of the preparation method of the thin film cathode material are the same as in Example 1, wherein:

[0039] In step (2), this embodiment is to prepare V with a concentration of 0.0054mol / L 2 o 5 Sol: Add the above V 2 o 5 The sol is fixed to 150ml, and the concentration of V obtained is 0.0054 mol / L 2 o 5 Sol.

[0040] V with a concentration of 0.0054mol / L 2 o 5 Sol prepared V 2 o 5 The constant current charge and discharge capacity curve of the thin film cathode material under the condition of mass current density of 400mA / g is as follows: Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com