A lithium-ion carbon-based supercapacitor

A supercapacitor, lithium ion technology, applied in the field of electrochemical energy storage devices, can solve the problems of low power density, high power density, low energy density, etc., and achieve the effects of good safety performance, long life and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

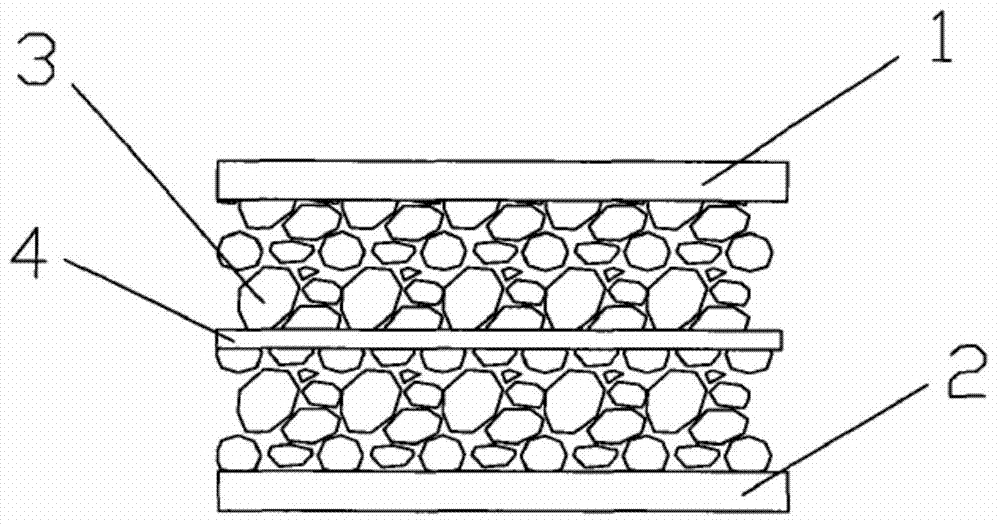

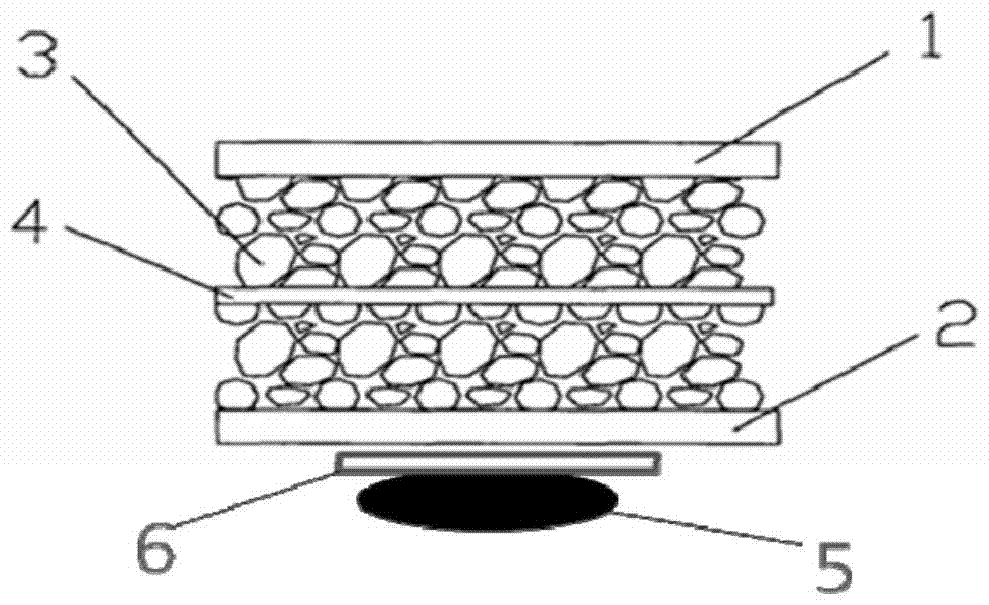

[0024] Activated carbon, conductive agent sp and binder polytetrafluoroethylene are weighed according to the ratio of mass ratio 85:10:5, activated carbon, conductive agent sp are placed in a clean and dry beaker, and (V 异丙醇 :V 水 =3:1) isopropanol solution, and keep stirring to make it wet to a paste, then add 60wt% polytetrafluoroethylene emulsion dropwise for mixing, after stirring for 0.5h, place it in a vacuum drying oven at a constant temperature of 80°C After 1 hour, take it out and put it in a muffle furnace at 285°C to heat it at a constant temperature for 5-8 minutes, then take it out for later use. Weigh the above-mentioned processed electrode material, put it into an agate mortar and grind it into a thin slice with a smooth surface, place the thin slice on the top of the circular nickel sheet collector with a thickness of 9um to 25um, and press it with a tablet press at 10Mpa to form a positive electrode material. Electrode 1.

[0025] Weigh graphite, conductive a...

Embodiment 2

[0029] Activated carbon, conductive agent sp and binder polytetrafluoroethylene are weighed according to the ratio of mass ratio 85:10:5, activated carbon, conductive agent sp are placed in a clean and dry beaker, and (V 异丙醇 :V 水 =3:1) isopropanol solution, and keep stirring to make it wet to a paste, then add 60wt% polytetrafluoroethylene emulsion dropwise for mixing, after stirring for 0.5h, place it in a vacuum drying oven at a constant temperature of 80°C After 1 hour, take it out and put it in a muffle furnace at 285°C to heat it at a constant temperature for 5-8 minutes, then take it out for later use. Weigh the above-mentioned processed electrode material, put it into an agate mortar and grind it into a thin slice with a smooth surface, place the thin slice on the top of the circular nickel sheet collector with a thickness of 9um to 25um, and press it with a tablet press at 10Mpa to form a positive electrode material. Electrode 1.

[0030] Weigh graphite, conductive a...

Embodiment 3

[0034] Activated carbon, conductive agent sp and binder polytetrafluoroethylene are weighed according to the ratio of mass ratio 85:10:5, activated carbon, conductive agent sp are placed in a clean and dry beaker, and (V 异丙醇 :V 水 =3:1) isopropanol solution, and keep stirring to make it wet to a paste, then add 60wt% polytetrafluoroethylene emulsion dropwise for mixing, after stirring for 0.5h, place it in a vacuum drying oven at a constant temperature of 80°C After 1 hour, take it out and put it in a muffle furnace at 285°C to heat it at a constant temperature for 5-8 minutes, then take it out for later use. Weigh the above-mentioned processed electrode material, put it into an agate mortar and grind it into a thin slice with a smooth surface, place the thin slice on the top of the circular nickel sheet collector with a thickness of 9um to 25um, and press it with a tablet press at 10Mpa to form a positive electrode material. Electrode 1.

[0035] Weigh graphite, conductive age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com