A cathode material -- SiC for a lithium ion battery and a lithium ion secondary battery using such material

A negative electrode material and secondary battery technology, applied in the field of new energy materials, can solve the problems of limited lithium-ion battery capacity, poor cycle stability, high volume change rate, etc., and achieve good application prospects, stable cycle performance, and good safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

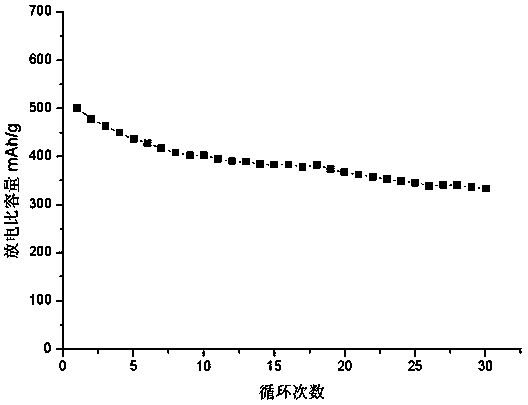

Embodiment 1

[0011] Example 1 SiC, conductive carbon black, and PVDF were mixed in a mass ratio of 80:10:10, coated on a current collector and dried in vacuum at 120°C for 12 hours to make a positive electrode of a lithium battery. A button battery is assembled with a lithium metal sheet as the negative electrode, 1M LiPF6 as the electrolyte, and a polypropylene microporous membrane as the diaphragm. The electrochemical performance test of the lithium-ion secondary battery made of SiC negative electrode material was carried out, and the charging and discharging voltage setting range was 0.1V~2.0V. The electrochemical performance of this example product is shown in Table 1.

Embodiment 2

[0012] Example 2 SiC, acetylene black, and polyvinyl alcohol were mixed in a mass ratio of 90:5:5, coated on a current collector and dried in vacuum at 120°C for 12 hours to make a lithium battery negative electrode. A button battery is assembled with lithium iron phosphate as the positive electrode, 1M LiPF6 as the electrolyte, and a polypropylene microporous membrane as the diaphragm. The electrochemical performance test of the lithium-ion secondary battery made of SiC negative electrode material was carried out, and the charging and discharging voltage setting range was 0.1V~2.0V. The electrochemical performance of this example product is shown in Table 1.

Embodiment 3

[0013] Example 3 SiC, activated carbon fiber, and polyethylene were mixed in a mass ratio of 85:10:5, coated on a current collector and dried in vacuum at 120°C for 12 hours to make a lithium battery negative electrode. A button battery is assembled with lithium manganate as the positive electrode, 1M LiPF6 as the electrolyte, and polypropylene microporous membrane as the separator. The electrochemical performance test of the lithium-ion secondary battery made of SiC negative electrode material was carried out, and the charging and discharging voltage setting range was 0.1V~2.0V. The electrochemical performance of this example product is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com