Patents

Literature

37results about How to "Improve first-week efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

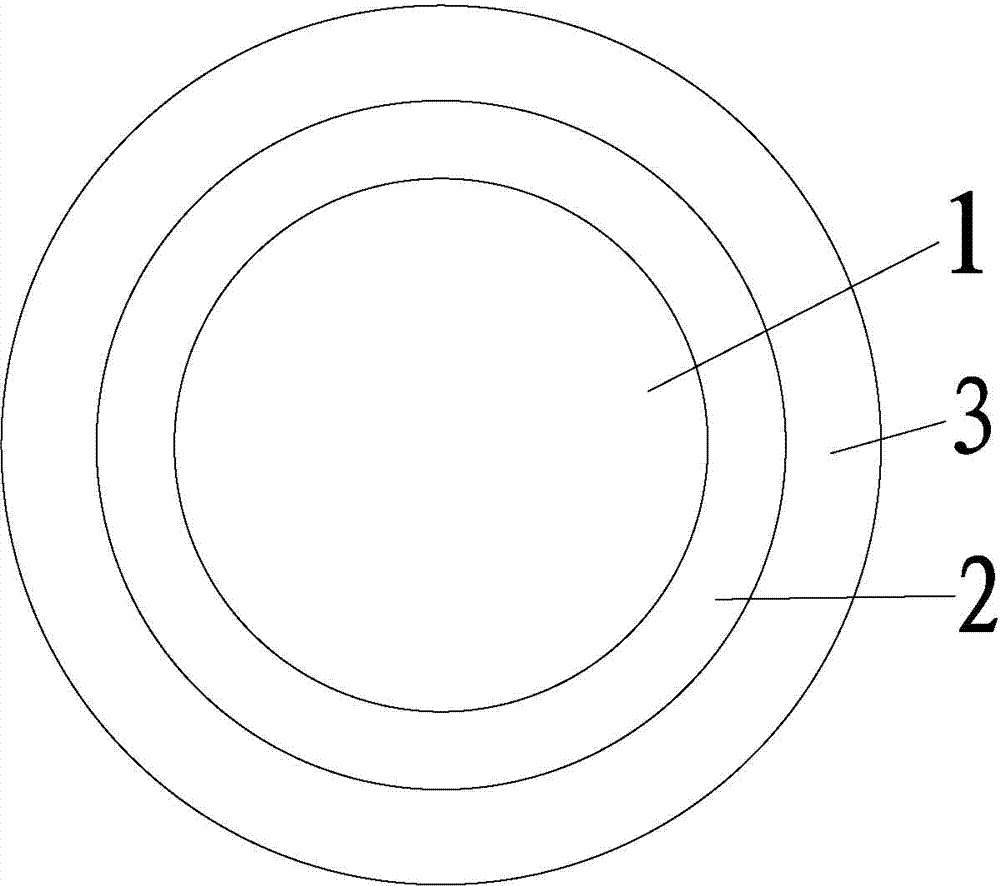

Coating structure applicable to high-voltage charge-discharge and manufacturing method of coating structure

ActiveCN102931384AImprove efficiencyInhibit corrosionCell electrodesElectrical batteryCharge and discharge

The invention relates to the technical field of lithium ion batteries, in particular to a coating structure applicable to high-voltage charge-discharge and a manufacturing method of the coating structure. A first metal oxide layer and a second metal oxide layer coat the surface of a cathode material layer, the first metal oxide layer coats the surface of the cathode material layer, the second metal oxide layer coats the outer surface of the first metal oxide layer, and the weight of the first metal oxide layer occupies 40 to 70 percent of the total weight of the first metal oxide layer and the second metal oxide layer. The coating structure contains active substances, so the first charge-discharge efficiency of a material is improved; by a surface ceramic oxide layer, corrosion of hydrogen fluoride (HF), release of metal ions and extraction of active oxygen are well inhibited; and a lithium ion secondary battery with the structure is applicable to charge-discharge at high voltage of more than 4.30 V, high in energy density, high in cycle performance and high in safety performance, and high-temperature storage performance is greatly improved.

Owner:DONGGUAN AMPEREX TECH

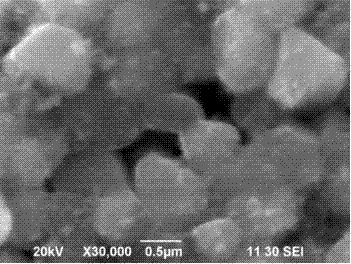

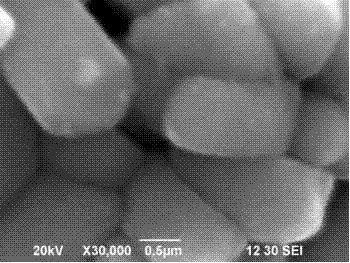

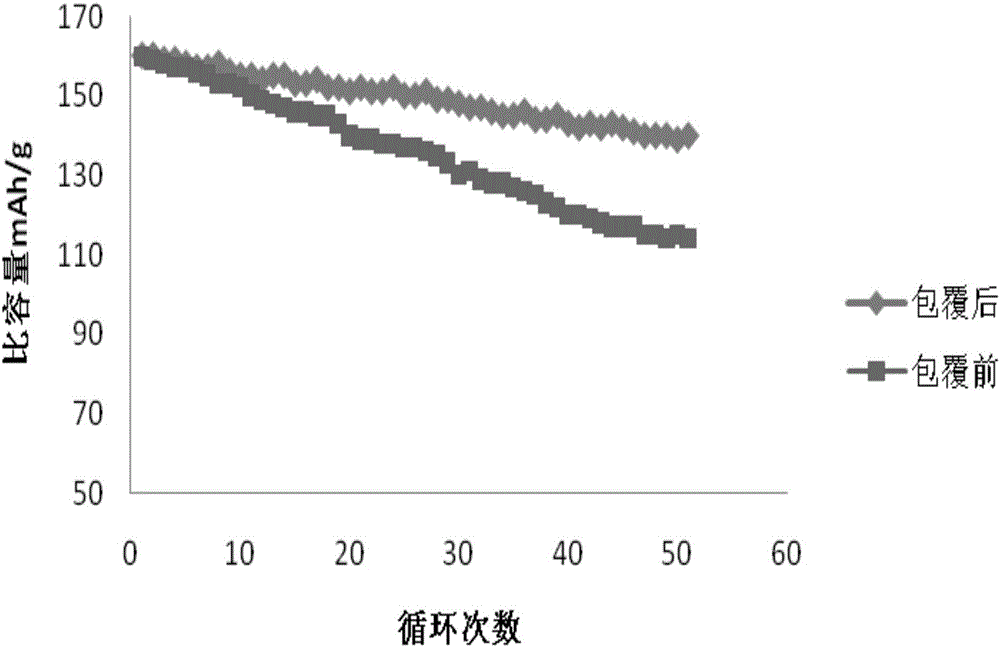

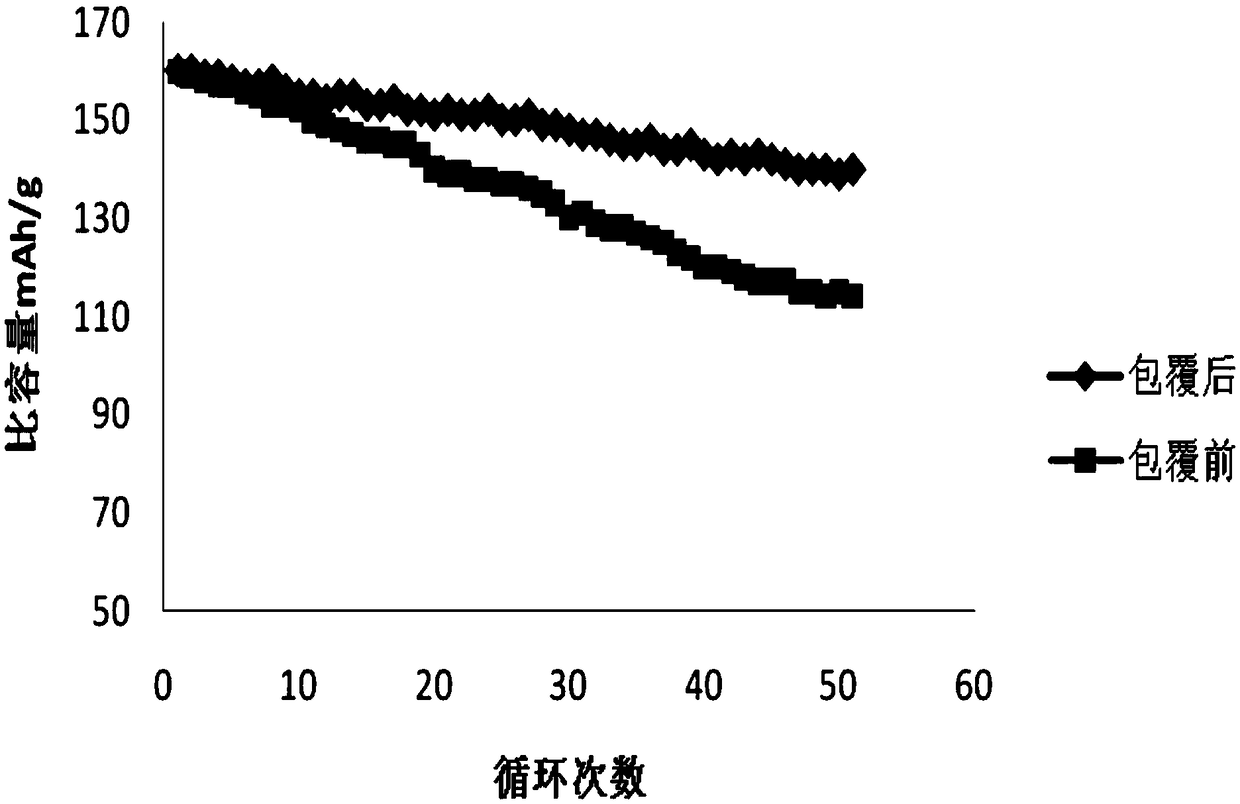

Modified nickel, cobalt and lithium manganite three-element material and preparation method thereof

ActiveCN106299320AImprove cycle performanceLittle changeCell electrodesSecondary cellsCyclic processLithium

The invention provides a modified nickel, cobalt and lithium manganite three-element material and a titanium dioxide layer compounded on the surface of the nickel, cobalt and lithium manganite three-element material. The titanium dioxide layer is creatively compounded on the surface of the nickel, cobalt and lithium manganite three-element material, the surface microstructure change of the NCM three-element material in the first-time charging process is effectively decreased, and the first-cycle efficiency is improved. In addition, due to the fact that titanium dioxide serves as a shell layer and form a core-shell structure with the NCM material, only lithium ions can pass through the titanium dioxide layer, and nickel and manganese ions cannot pass through, dissolution of Ni and Mn in the three-element material in the cycling process is reduced, and the cycle performance of the three-element material is optimized.

Owner:GREE ELECTRIC APPLIANCES INC

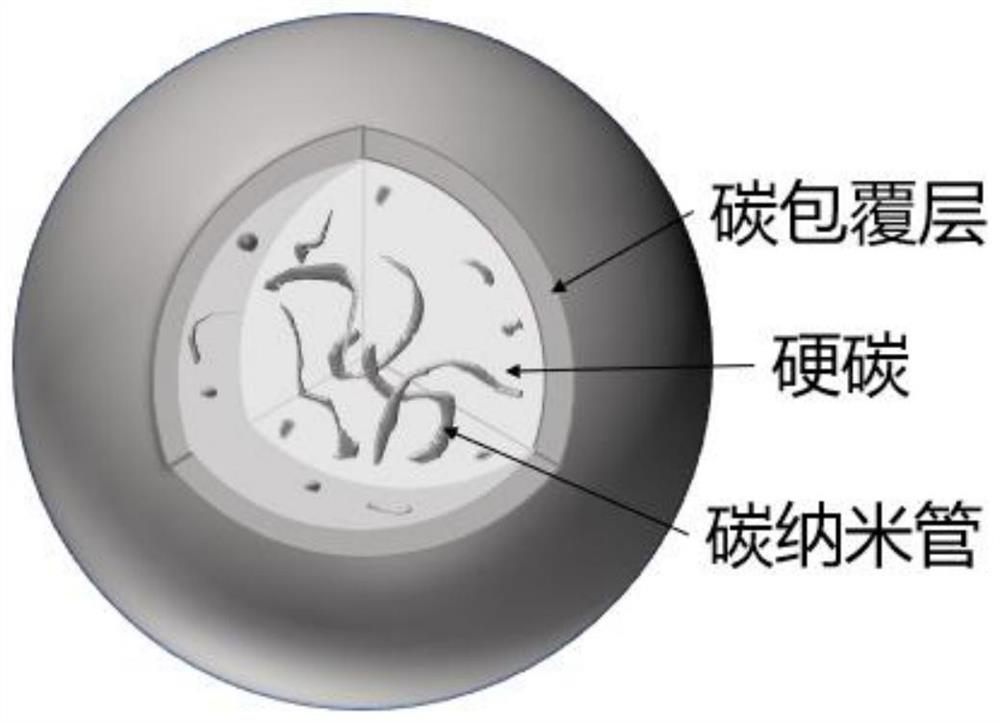

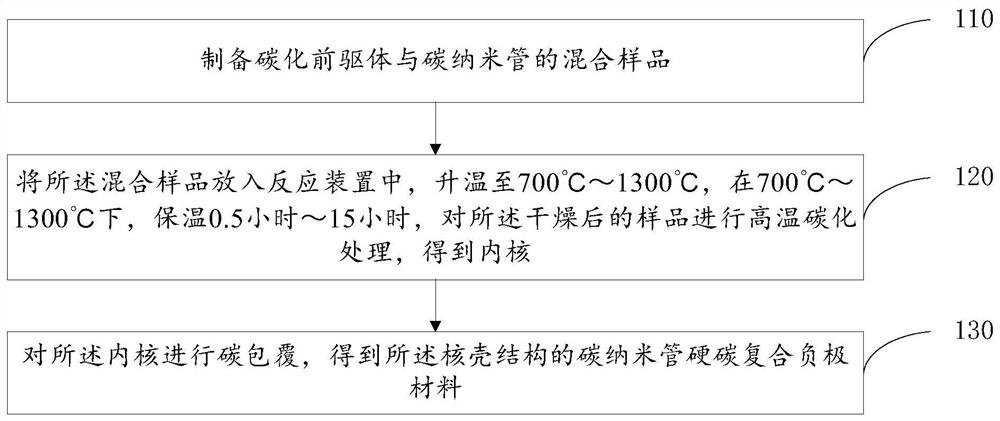

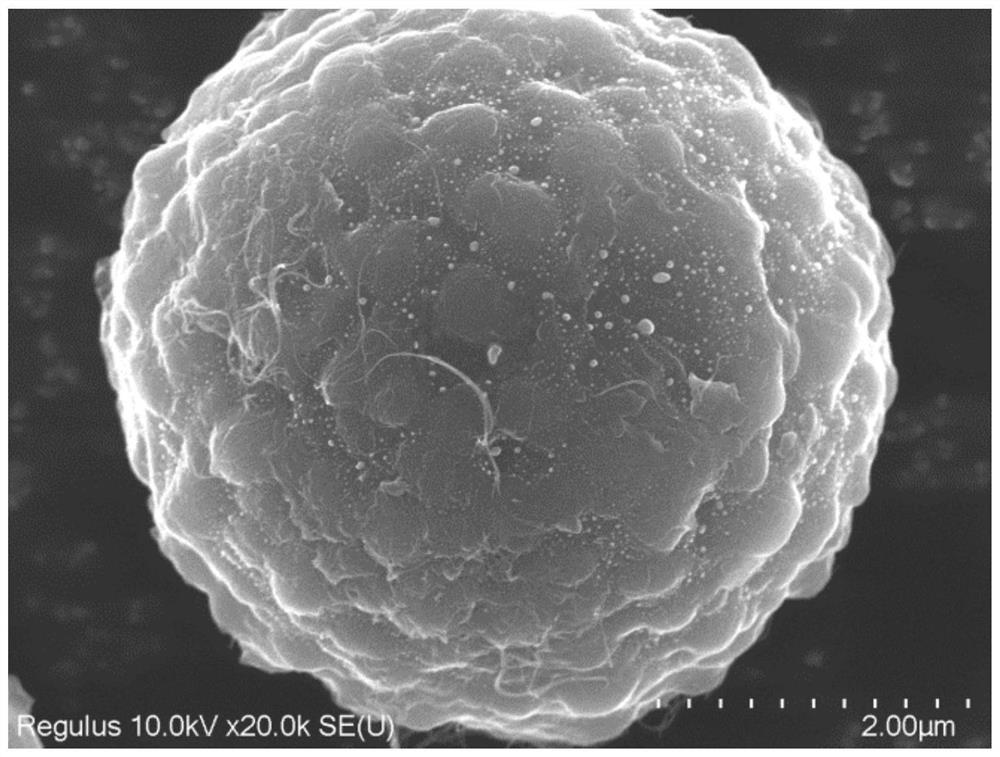

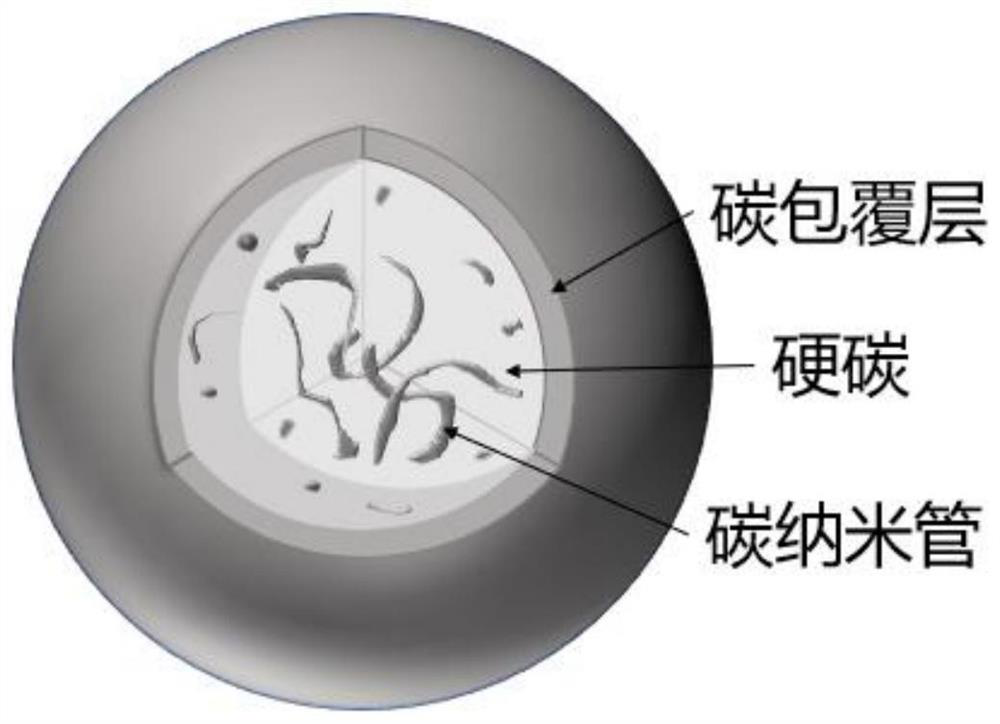

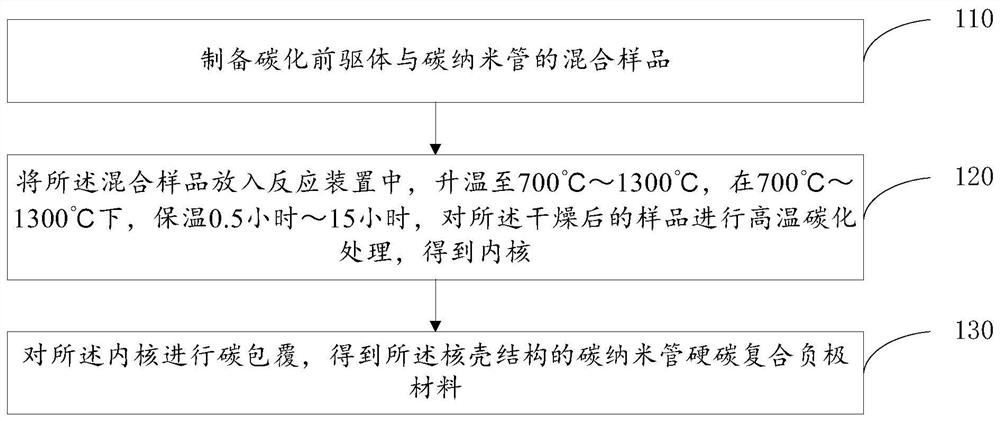

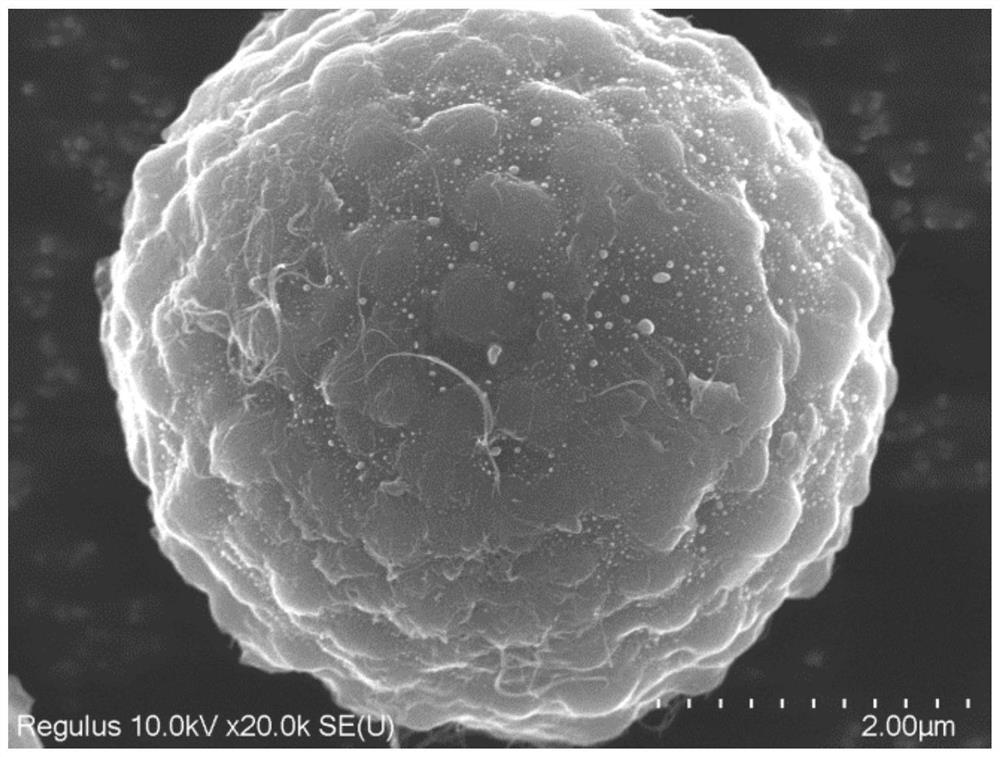

Carbon nanotube hard carbon composite negative electrode material with core-shell structure and preparation method and application

ActiveCN113328068AImprove first-week efficiencySmall specific surface areaCell electrodesSecondary cellsEpoxyCarbon composites

The embodiment of the invention relates to a carbon nanotube hard carbon composite negative electrode material with a core-shell structure and a preparation method and application. The size range of the carbon nanotube hard carbon composite negative electrode material is 1-50 mum, and the carbon nanotube hard carbon composite negative electrode material is composed of an inner core and a carbon coating layer coating the inner core; the inner core comprises a first phase and a second phase; the first phase is a hard carbon material prepared by taking one or a combination of several of glucose, cane sugar, polyvinylpyrrolidone, starch polyvinylidene fluoride, novolac epoxy resin or polyvinyl chloride as a carbonization precursor, the size range is 1-40 mum, and the Raman spectrum Id / Ig range is 0.7-0.9; the second phase is a carbon nanotube, and the size of the second phase is 1-50 nm; the carbon coating layer is prepared by a gas phase method, a liquid phase method or a solid phase method, and the Raman spectrum Id / Ig range is 0.7-1.3; in the carbon nanotube hard carbon composite negative electrode material, the mass fraction of the first phase to the second phase to the carbon coating layer is equal to (0, 100%) to (0, 60%) to (0, 40%).

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

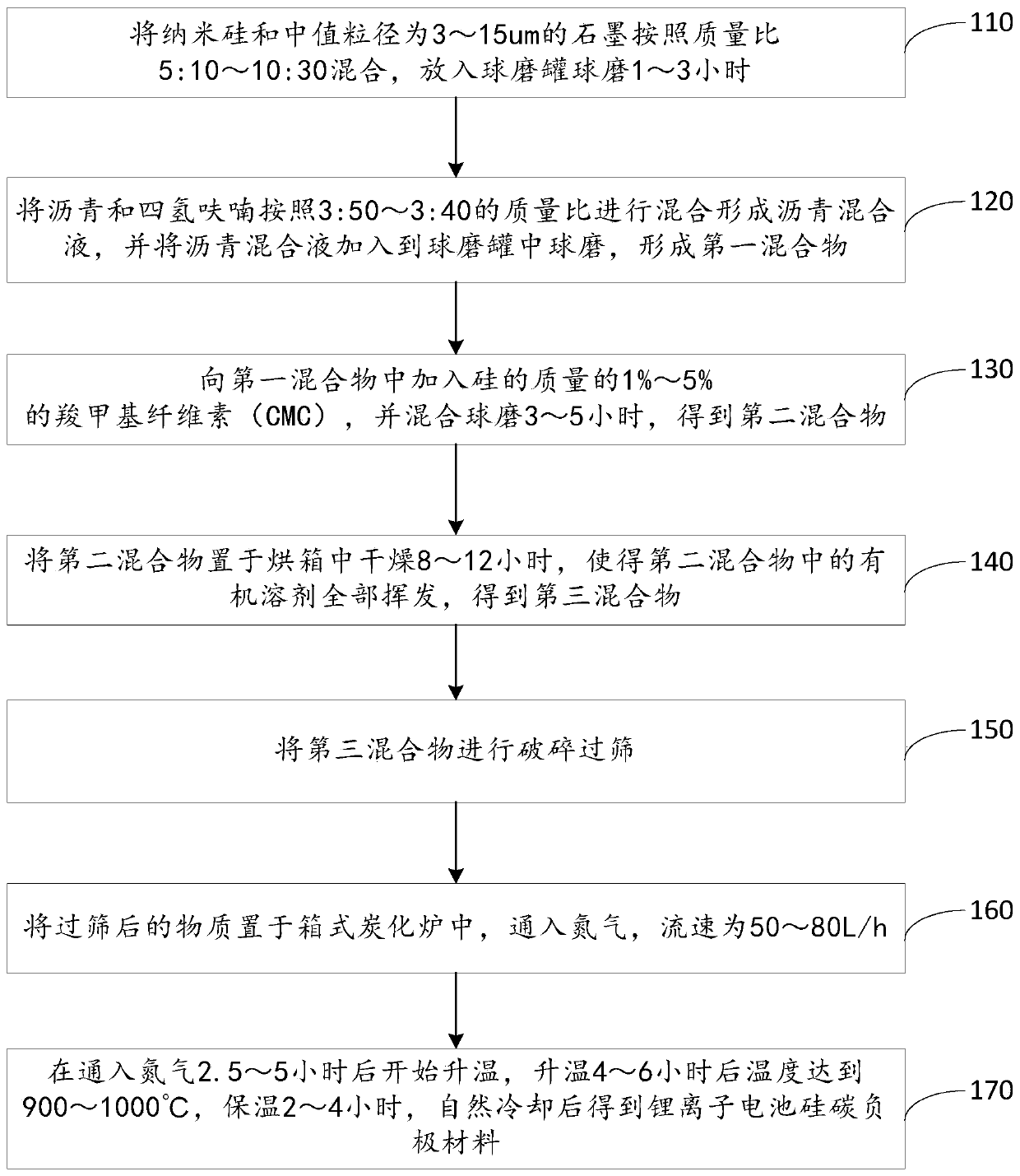

Lithium battery silicon-carbon negative electrode material, negative electrode material and lithium battery

PendingCN110723721AIncrease gram capacityImprove first-week efficiencyMaterial nanotechnologyCell electrodesOrganosolvLithium-ion battery

The embodiments of the invention relate to a method for preparing a lithium battery silicon-carbon negative electrode material, a negative electrode material and a lithium battery. The method comprises: mixing nanometer silicon and graphite with a median particle size of 3-15 [mu]m according to a certain mass ratio, and carrying out ball milling for 1-3 h; mixing asphalt and tetrahydrofuran according to a mass ratio of 3:50-3:40 to form an asphalt mixed solution, and adding the asphalt mixed solution into a ball milling tank, and carrying out ball milling to form a first mixture, wherein a mass ratio of the asphalt mixed solution to the silicon to the graphite is 20:5:10-40:10:30; adding carboxymethyl cellulose CMC accounting for 1-5% of the mass of the silicon, and carrying out mixed ballmilling for 3-5 h to obtain a second mixture; drying in a drying oven for 8-12 h to completely volatilize the organic solvent in the second mixture, and then crushing and sieving; and putting the sieved substance into a box-type carbonization furnace, introducing nitrogen at a flow rate of 50-80 L / h, heating after 2.5-5 h, and keeping the temperature at 900-1000 DEG C for 2-4 h after heating for4-6 h; and naturally cooling to obtain the lithium battery silicon-carbon negative electrode material.

Owner:溧阳紫宸新材料科技有限公司

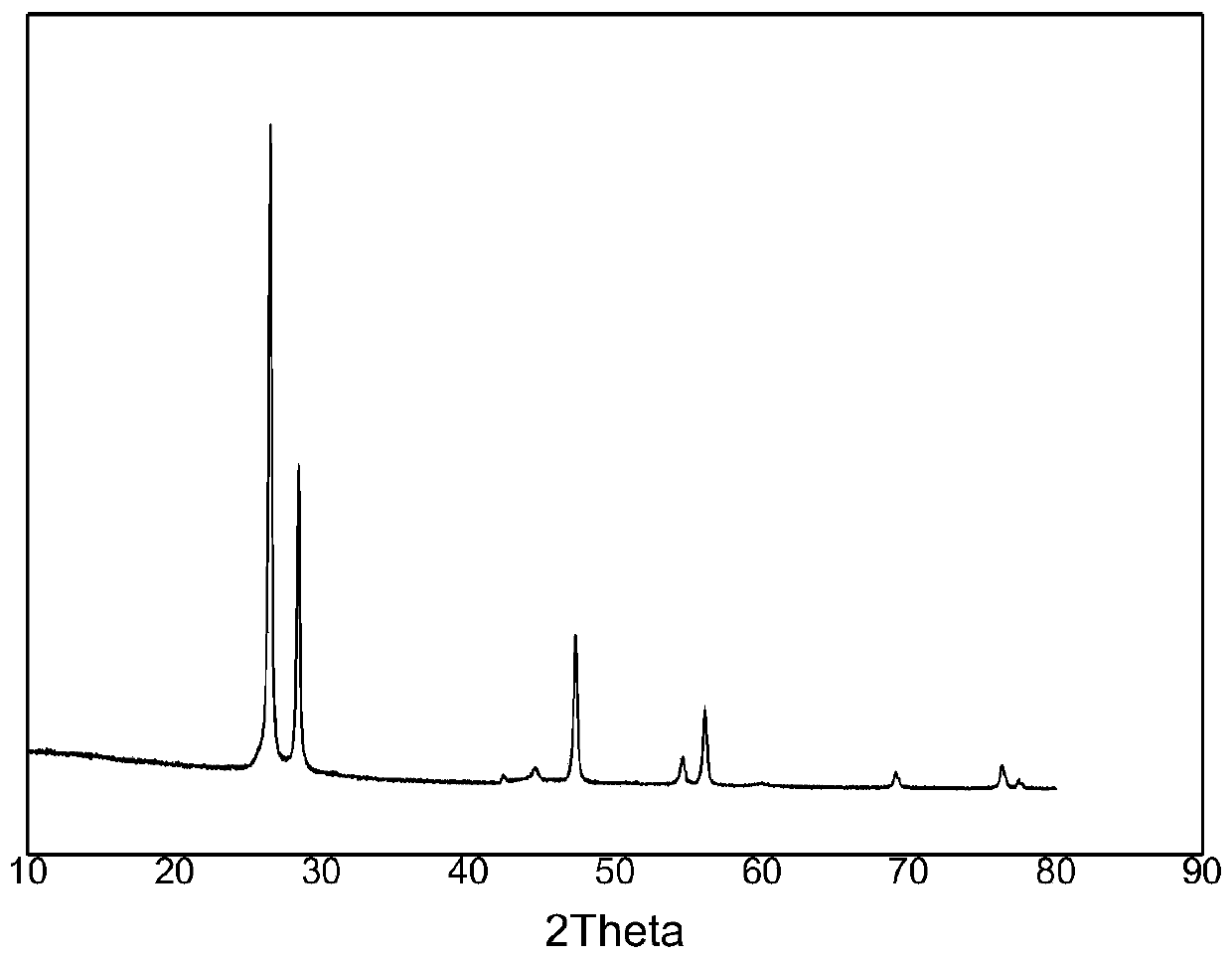

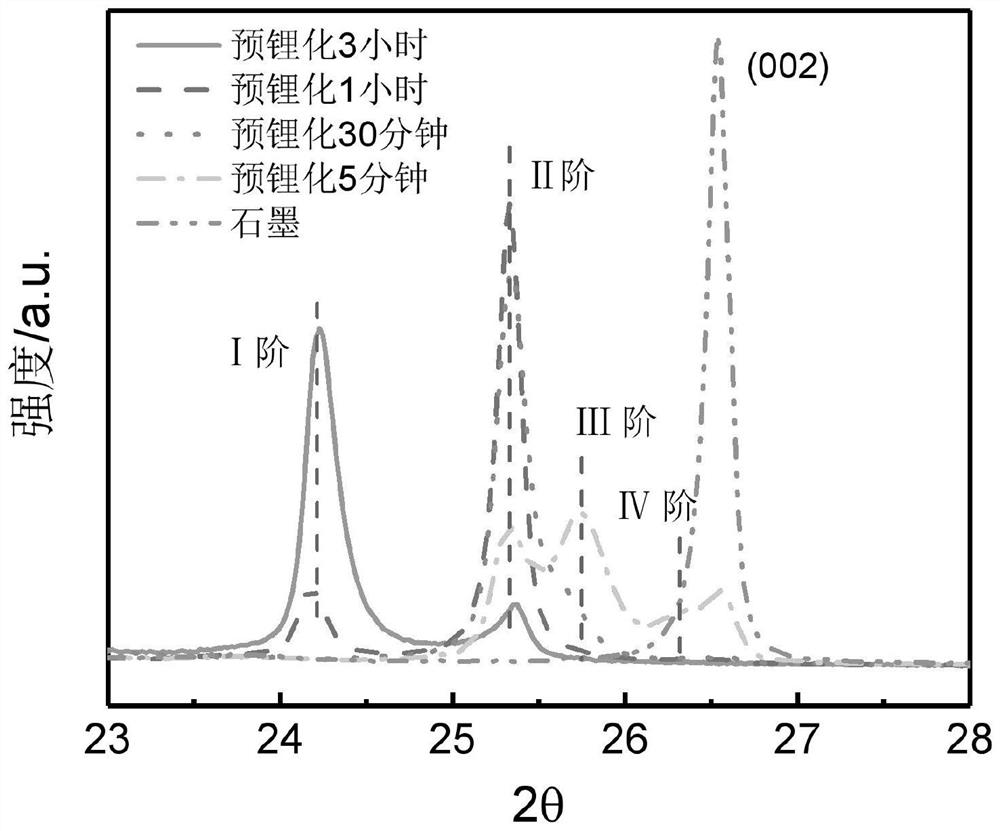

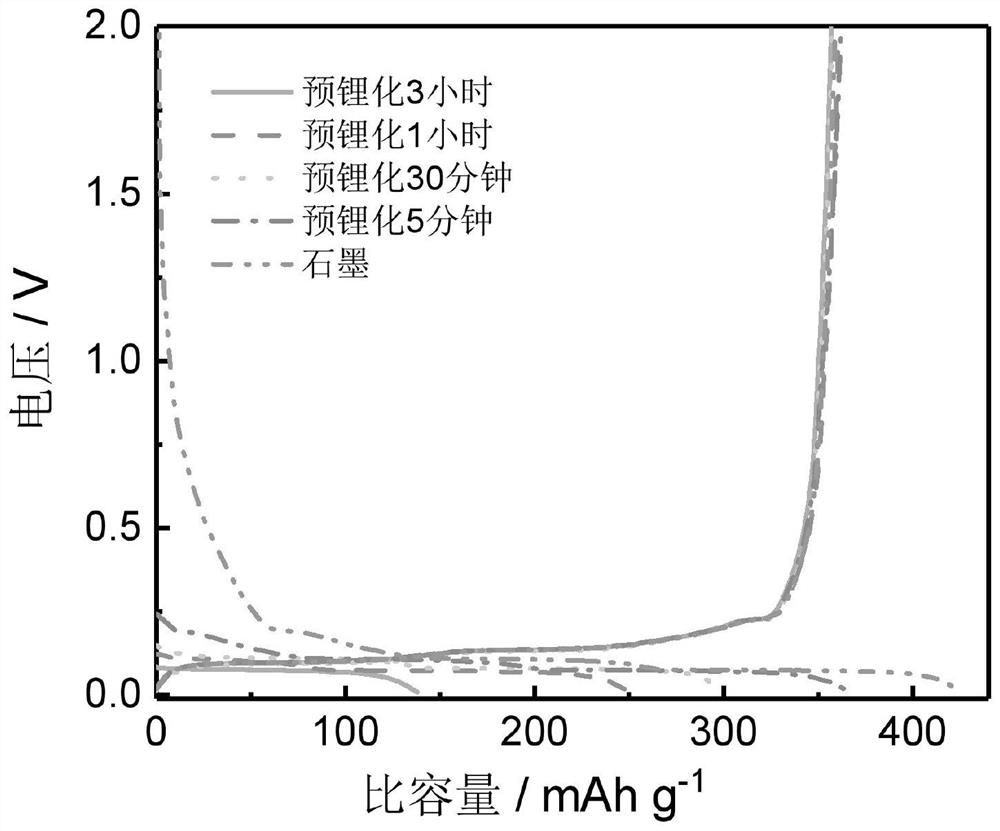

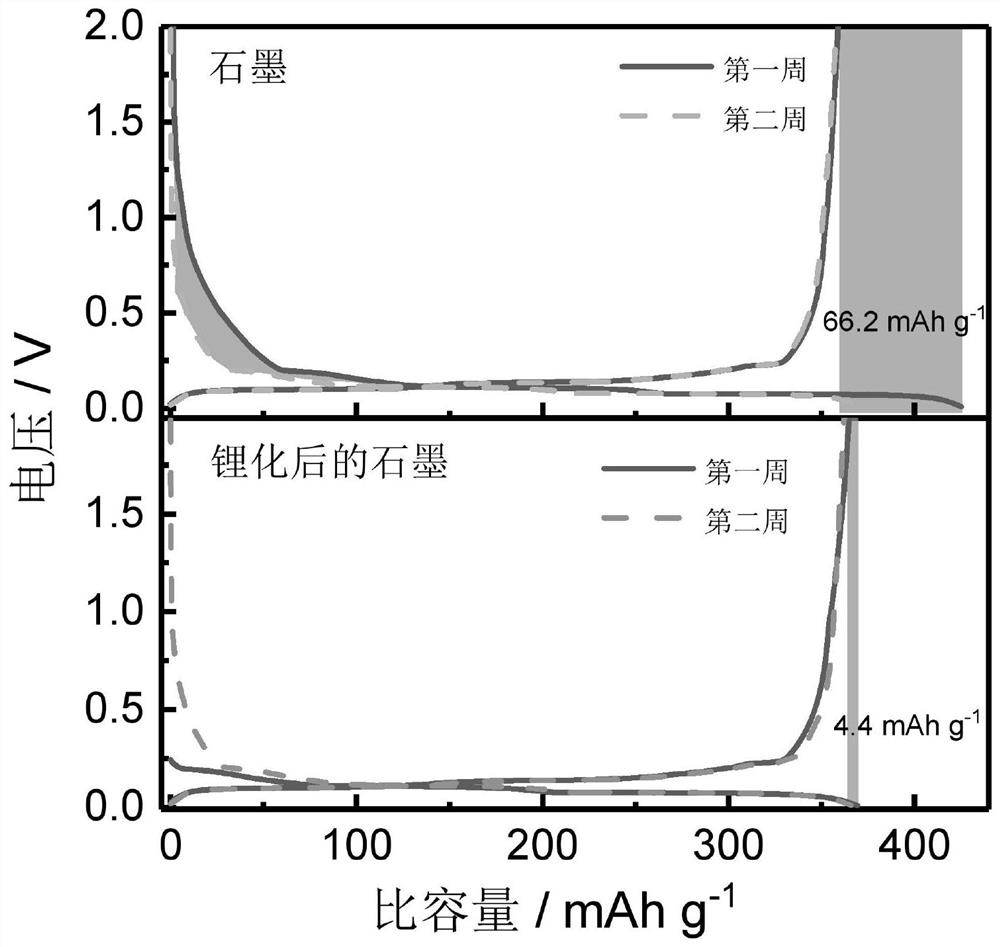

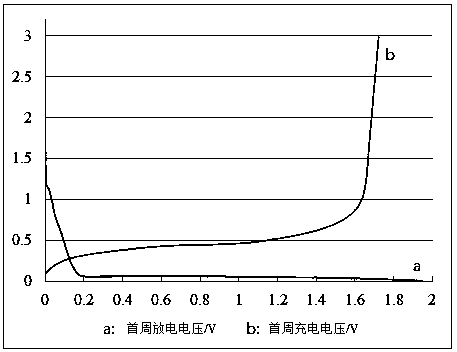

Chemical pre-lithiation method for graphite electrode of lithium ion battery

ActiveCN112490394AElectrochemical performance does not affectImprove first-week efficiencyGraphiteSecondary cellsGraphite electrodeElectrical battery

The invention discloses a chemical pre-lithiation method for a graphite electrode of a lithium ion battery. The chemical pre-lithiation method comprises the following steps: dissolving a lithiation reagent containing anion free radicals into monobasic ether to obtain a lithiation reagent solution with the concentration of 0.001-10 mol / L; and carrying out contact reaction on the prepared graphite negative plate of the lithium ion battery and a lithiation reagent solution for 1s to 48h, washing and drying to obtain the pre-lithiated graphite electrode. According to the invention, the free radical anion lithiation reagent with mild property is selected, and the graphite negative electrode material of the lithium ion battery is chemically pre-lithiated in a relatively safe chemical environment, so that the first week efficiency of the graphite electrode is improved, and the energy density of the whole battery is further improved. The used monobasic ether solvent is compatible with the graphite negative electrode, so that the phenomenon that the electrochemical performance of the graphite negative electrode is damaged by co-embedding or stripping and the like is avoided; the solution system is high in reducibility, the lithiation process is rapid, and the electrochemical performance of the electrode is not influenced.

Owner:EVE ENERGY CO LTD

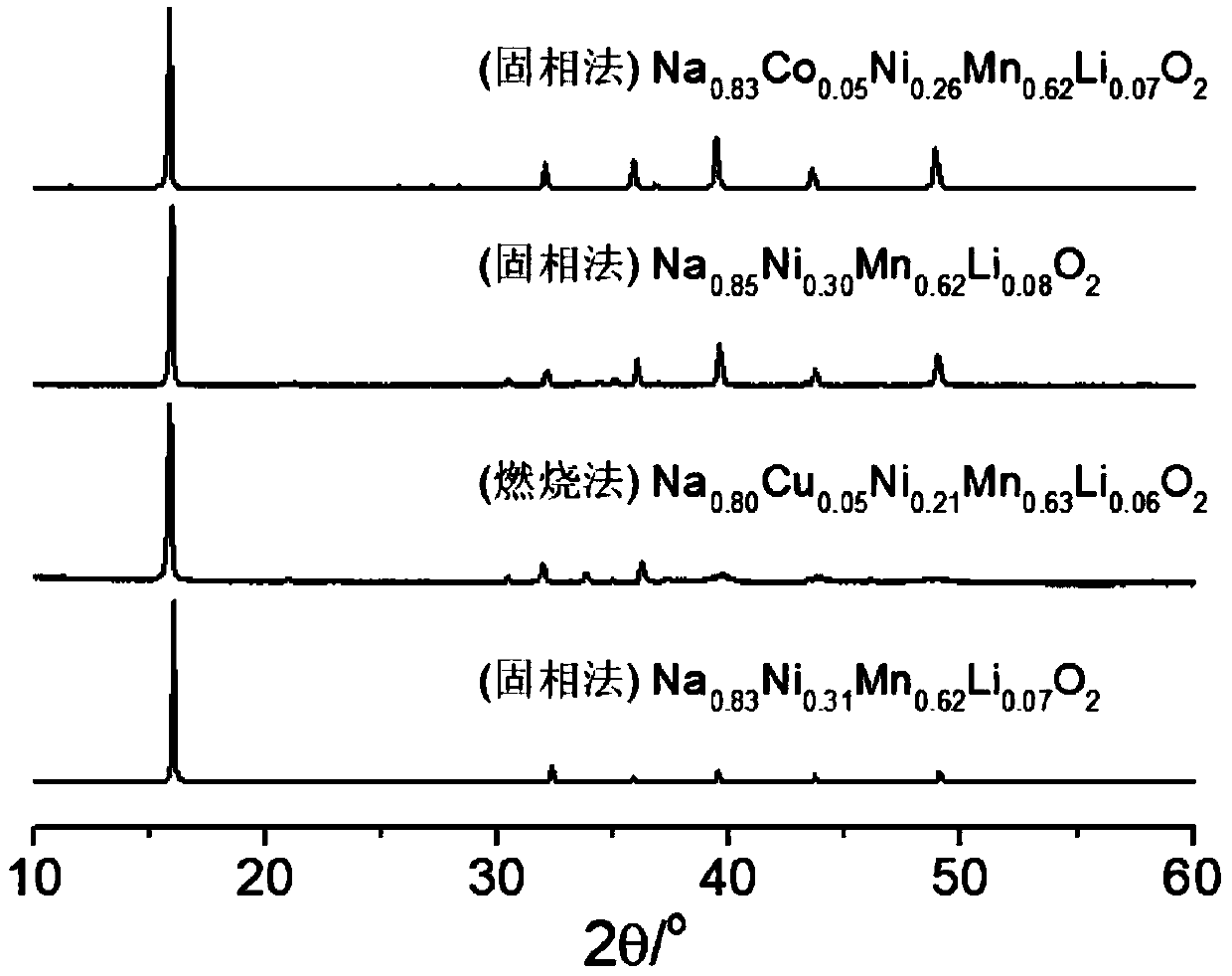

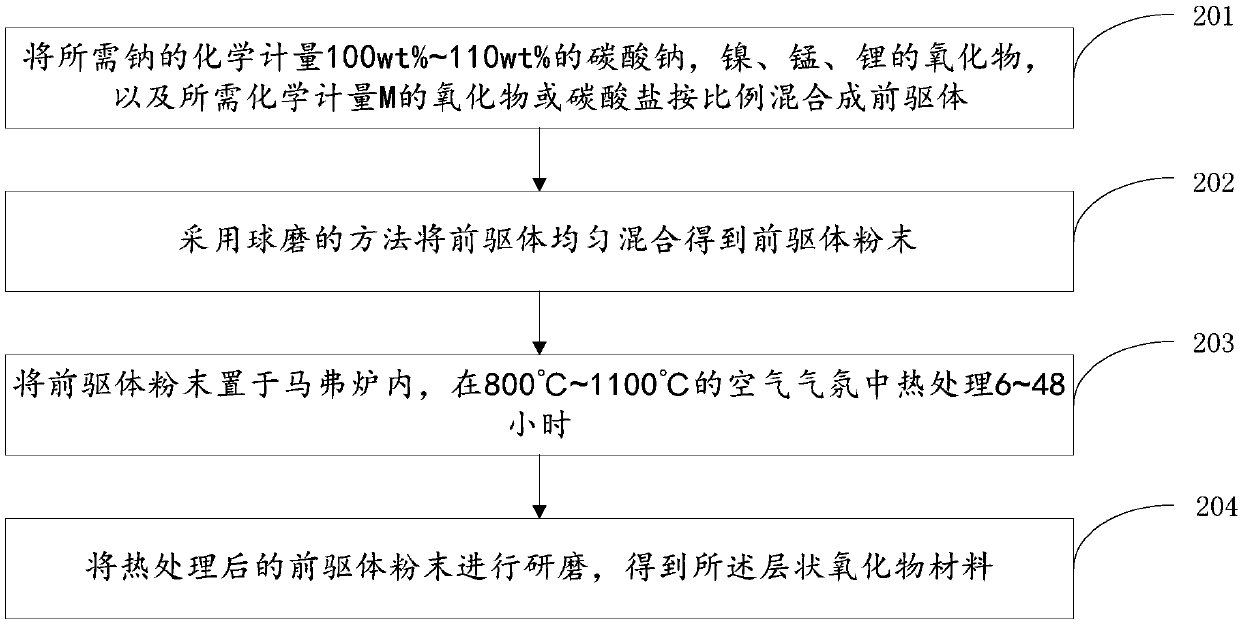

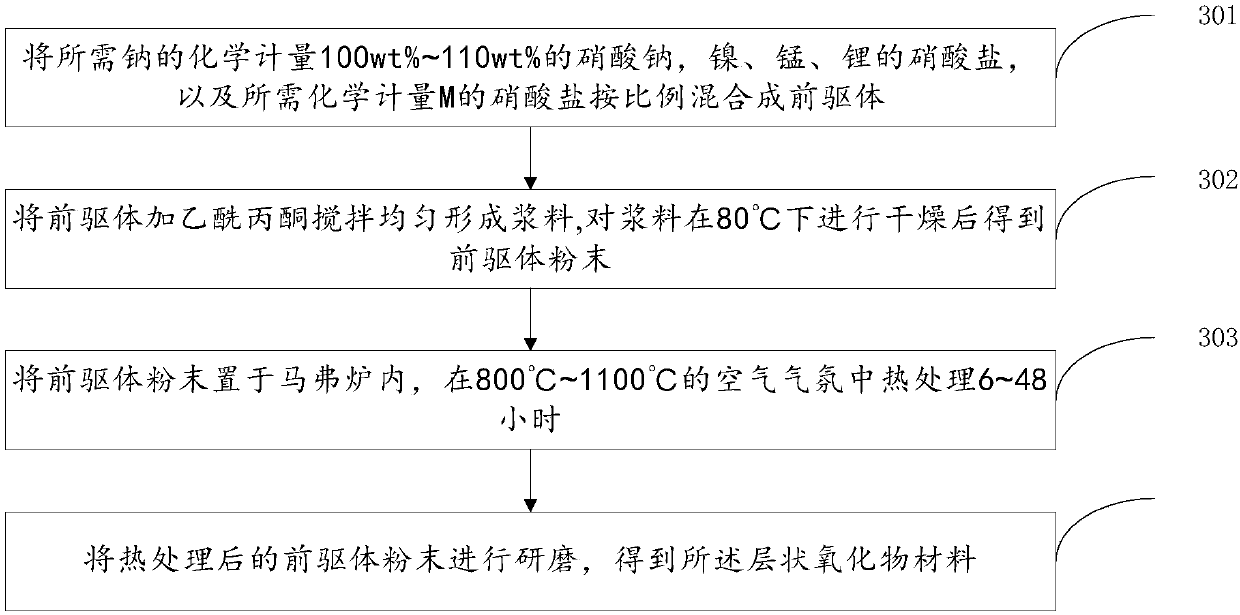

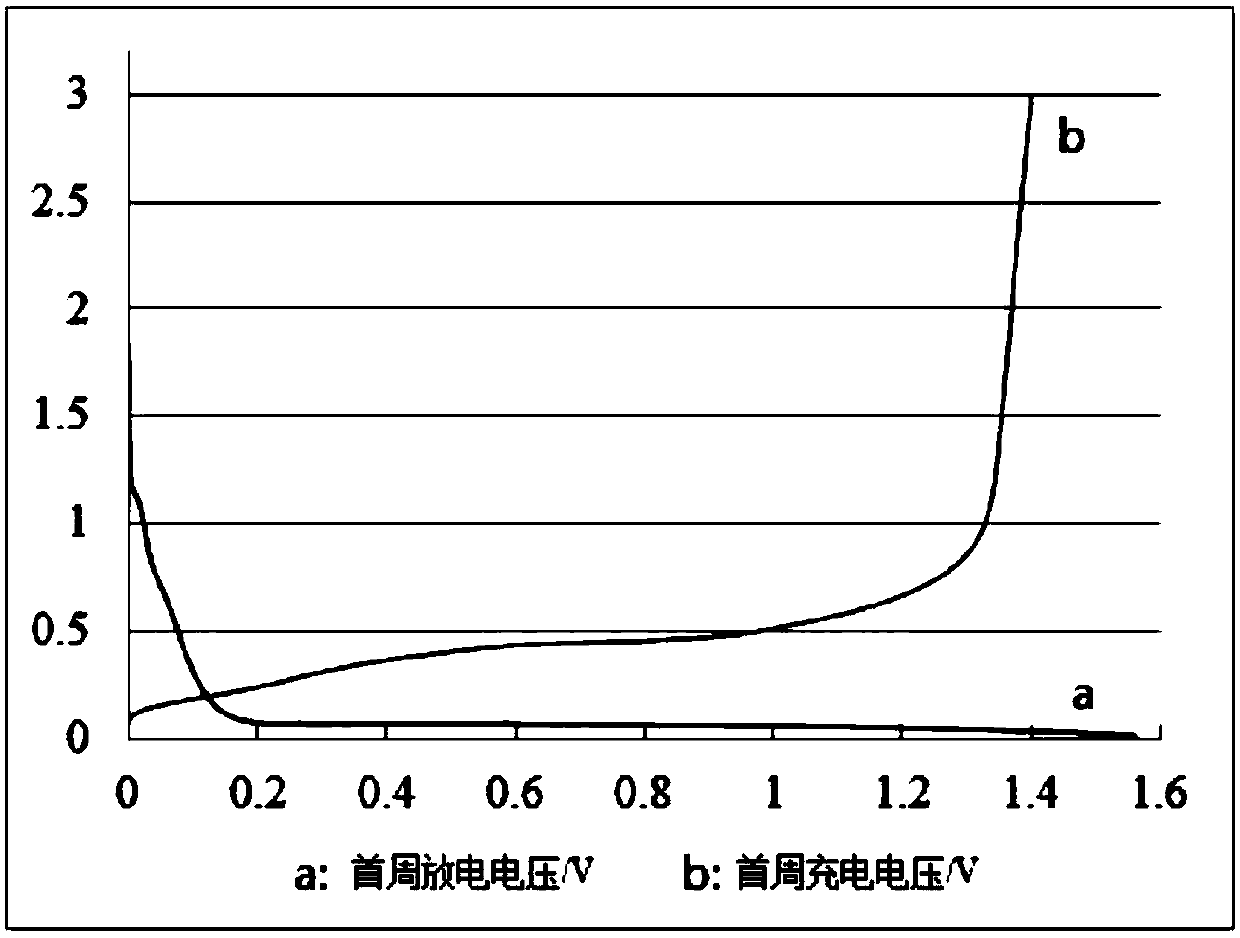

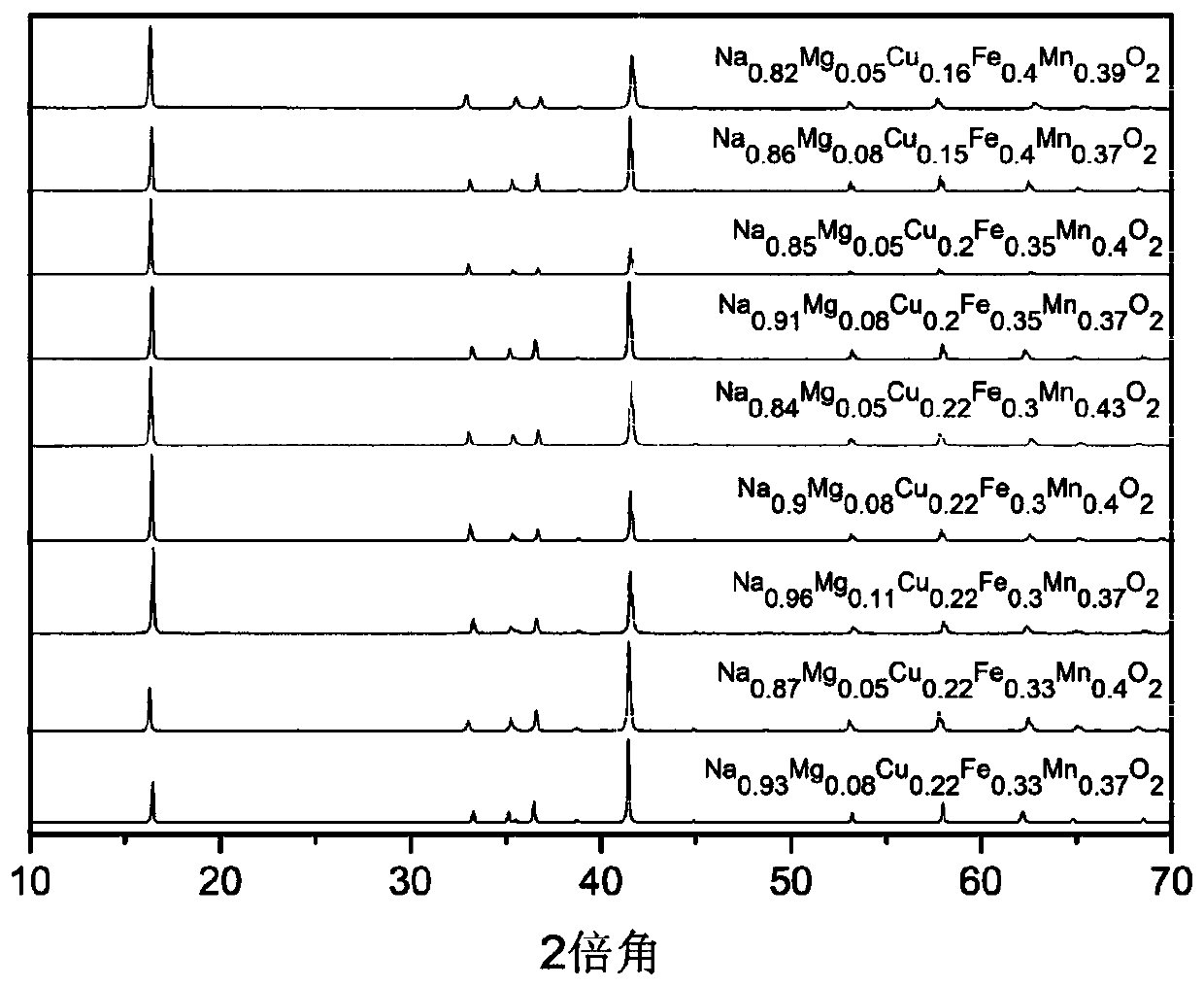

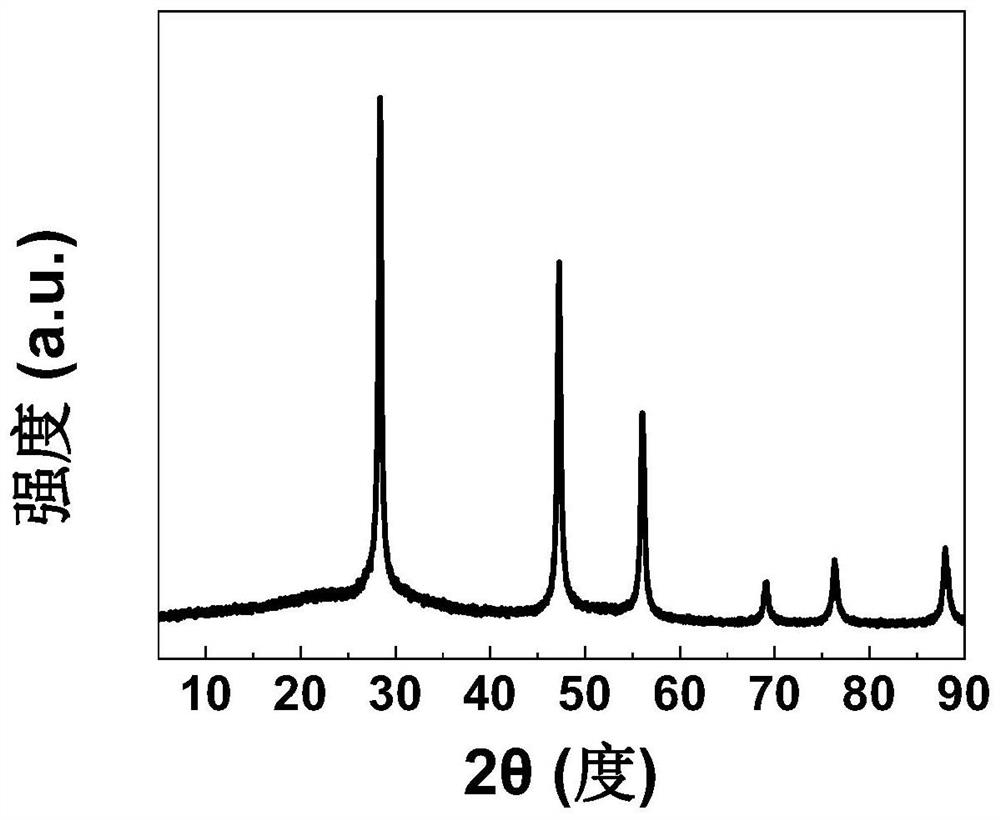

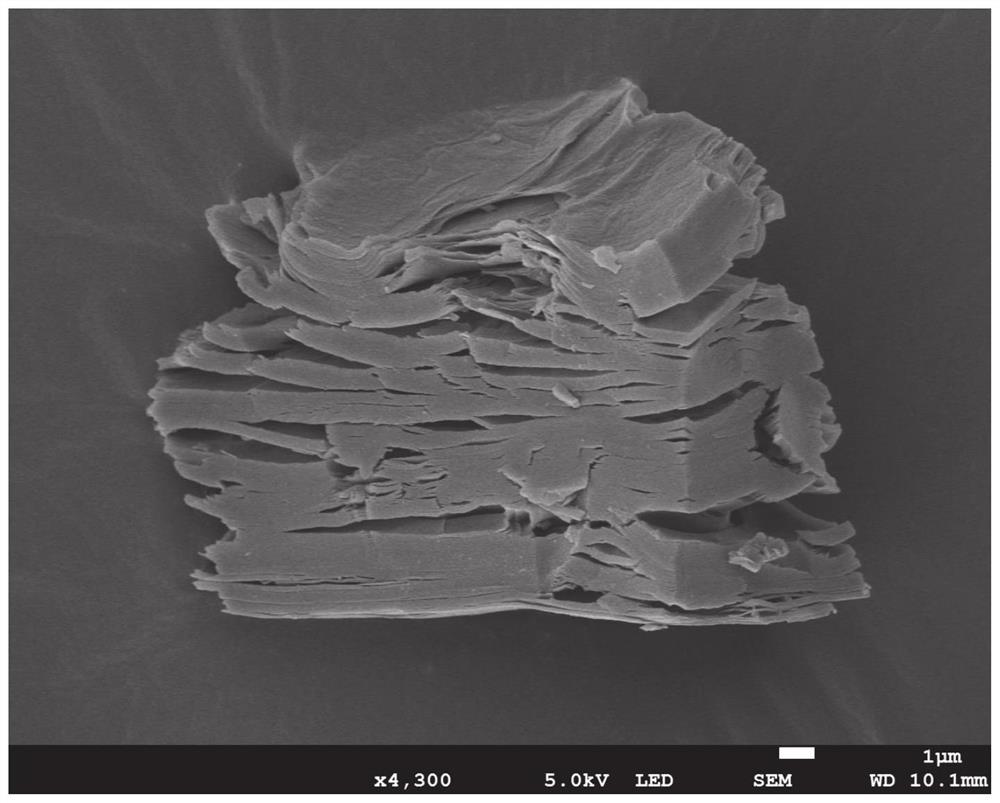

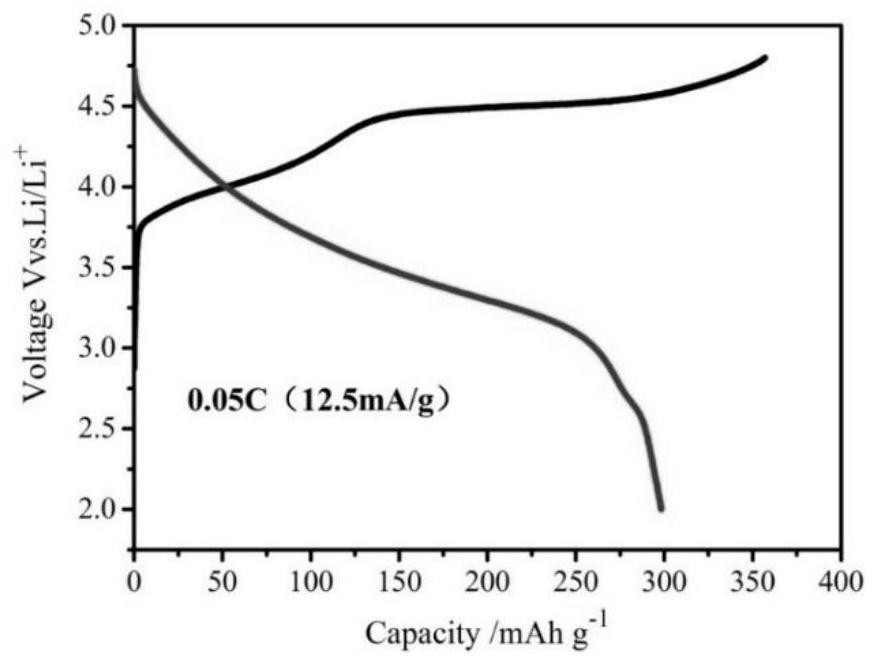

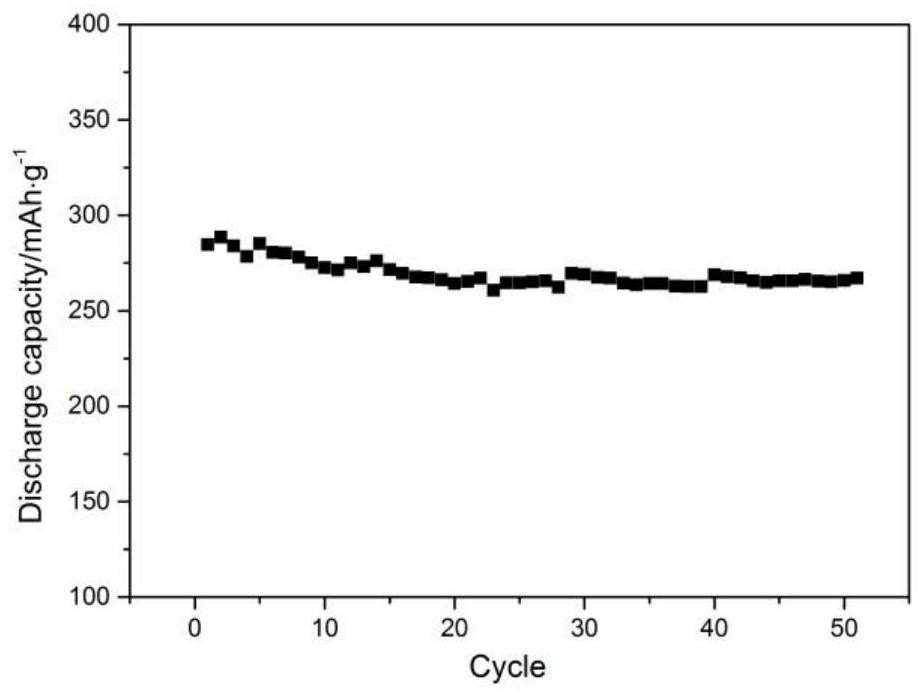

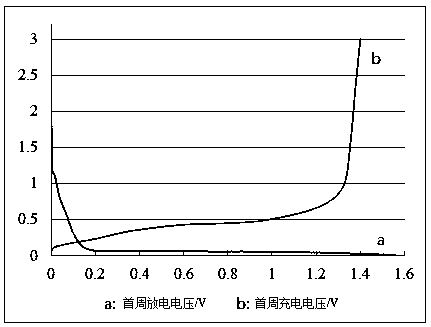

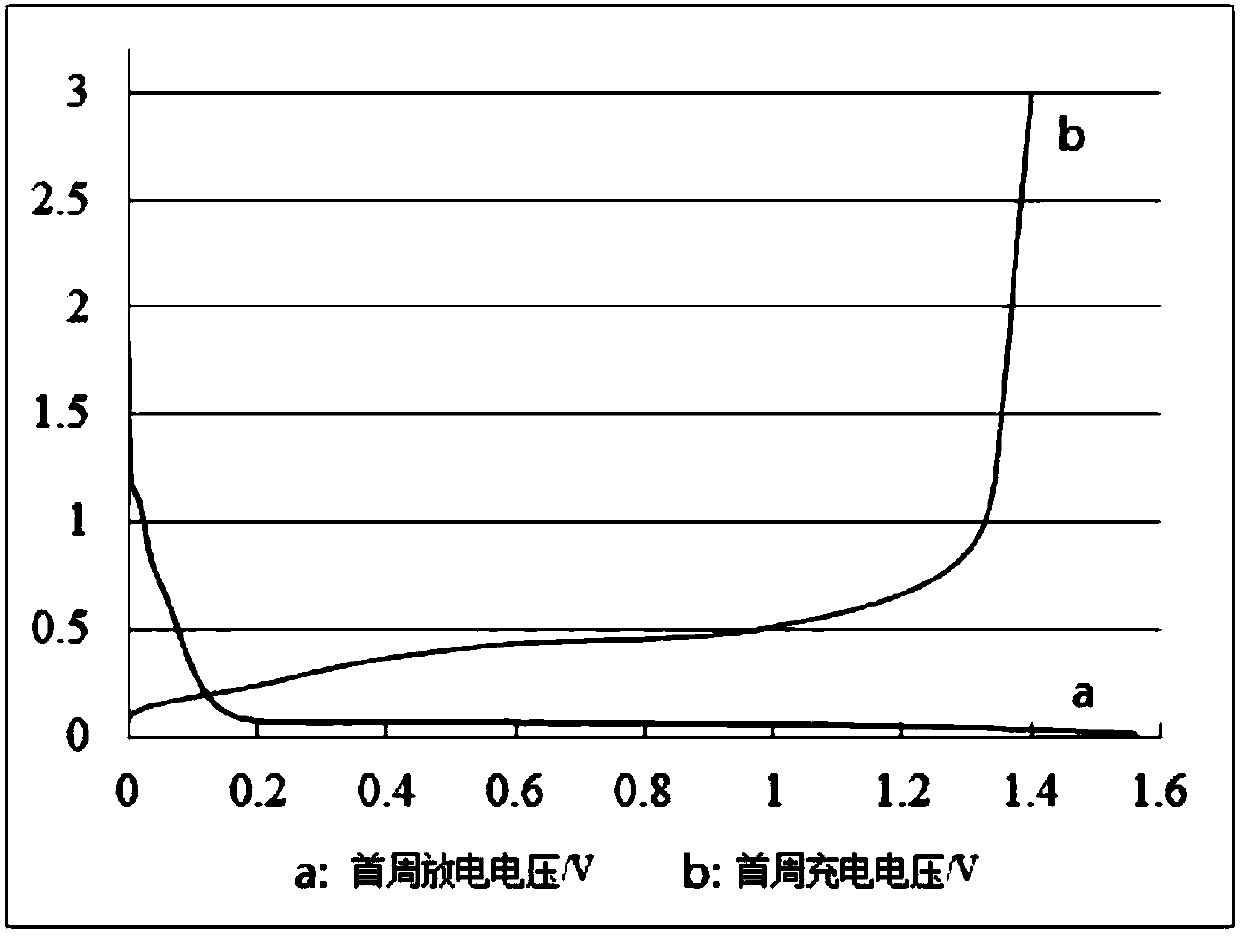

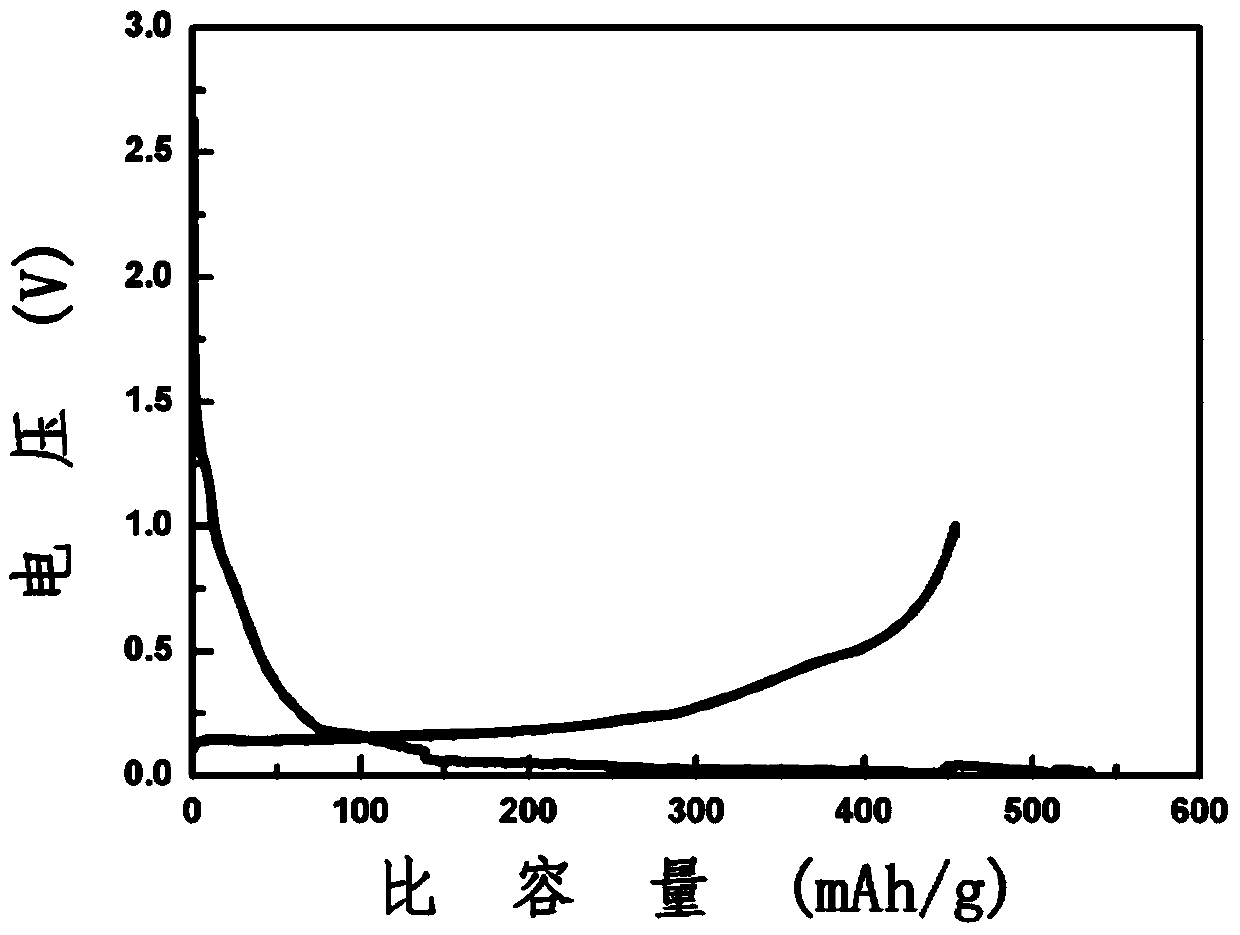

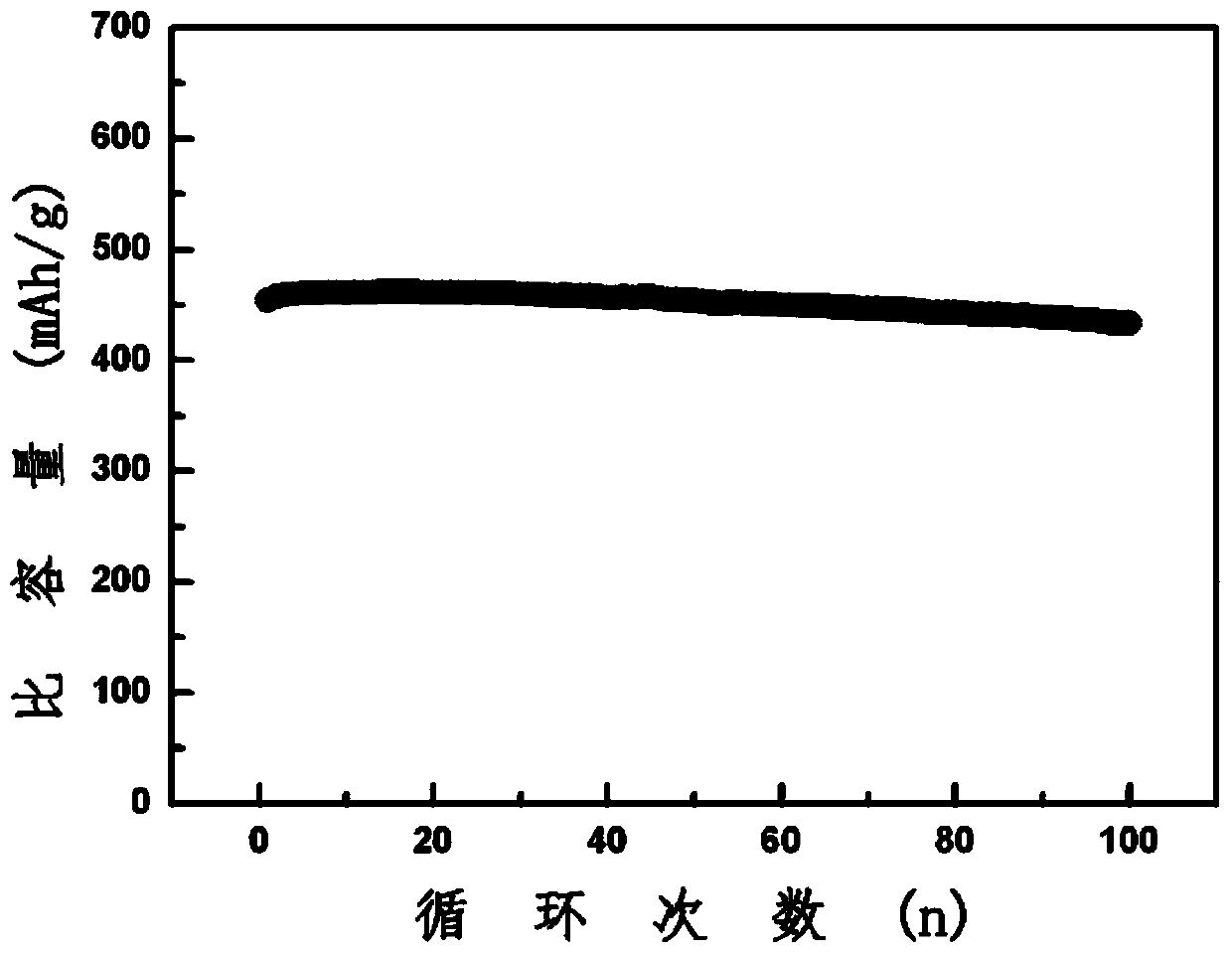

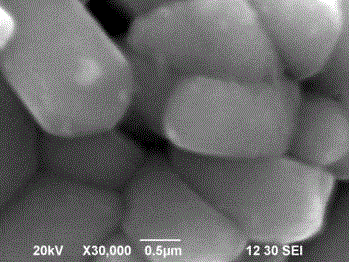

Pure cation valence-variable P2-phase layered oxide material with high sodium content, preparation method and application

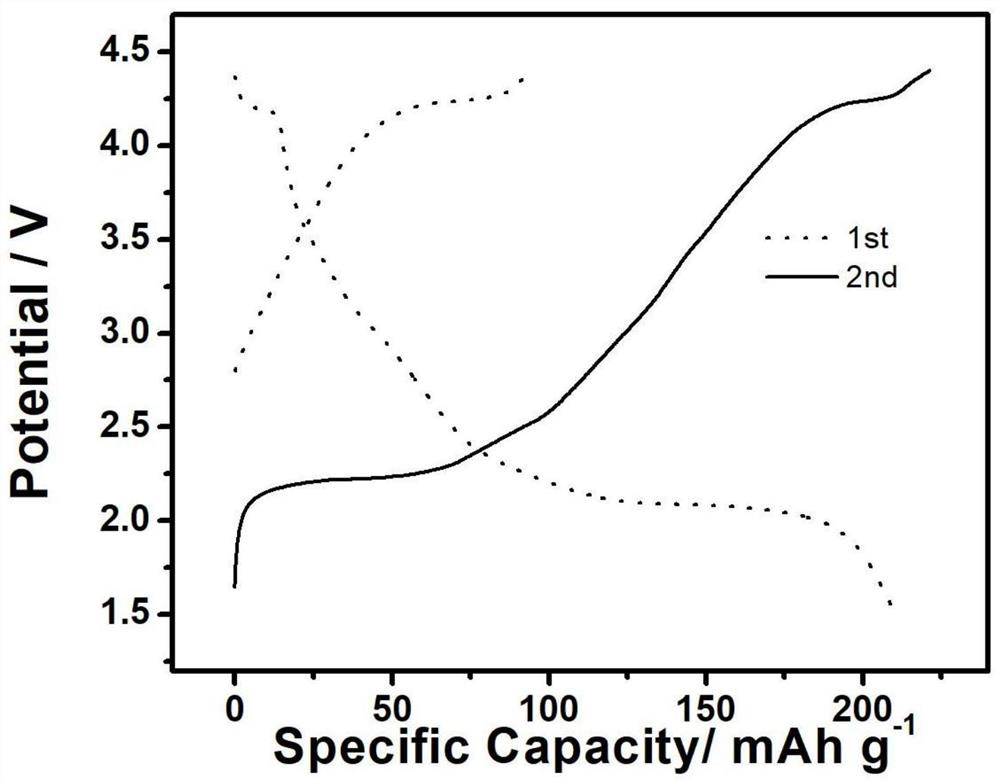

InactiveCN111162250AIncrease abundanceImprove first-week efficiencyCell electrodesSecondary cellsCrystal structureCharge compensation

The invention discloses a pure cation valence-variable P2-phase layered oxide material with high sodium content as well as a preparation method and application thereof. The chemical general formula ofthe material is Nax [LiiNijMnkMy] O2 + beta, and li, Ni, Mn and M jointly occupy the position of transition metal ions in the crystal structure, wherein M is an element for doping and substituting atransition metal site and is one or more of Cu <2+>, Mg <2+>, Mn <2+>, Zn <2+>, Al <3+>, B <3+>, Zr <4+> and Ti <4+>, and x, y, i, j, k and beta are mole percentages of the corresponding elements respectively; the relationship among x, y, i, j, k and beta satisfies y+i+j+k=1, and x +my+i+2j+4k=2 (2 + beta); 0.8<= x<= 0.85; 0<i<= 0.1; 0<j<= 0.4; 0<k <=0.65; -0.05<= beta<=0.05; m is a valence stateof M, and the space group of the layered oxide material is P63 / mmc or P63 / mcm. The material is used as a positive electrode active material of a sodium ion secondary battery, and the charge compensation is completely realized by obtaining and losing electrons by transition metal cations in the charging and discharging process, so that the structural change caused by the participation of anions invalence change is effectively inhibited, and the cycling stability of the material is greatly improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

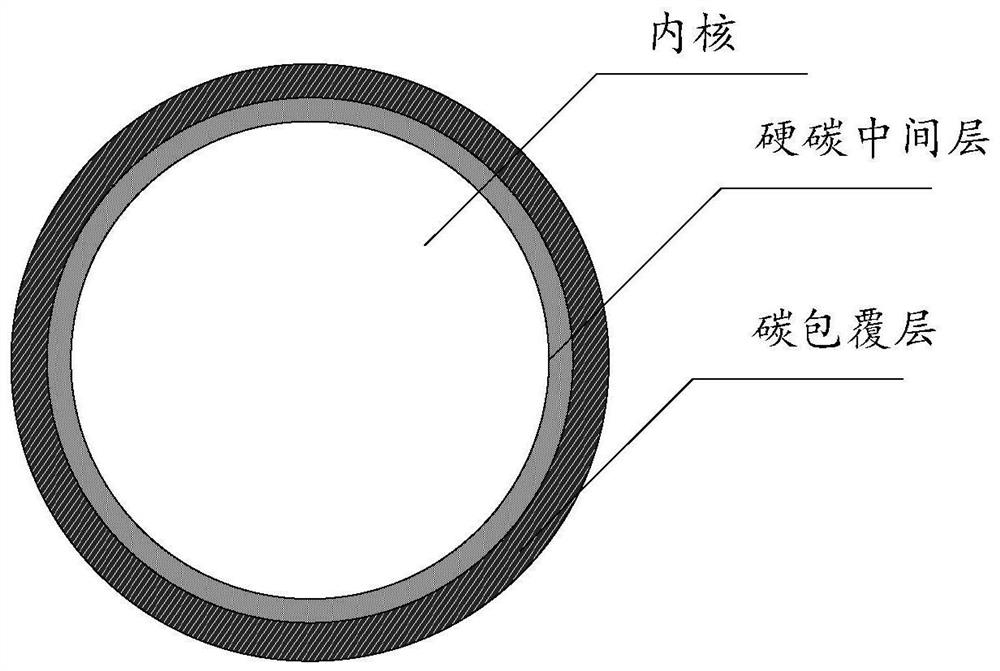

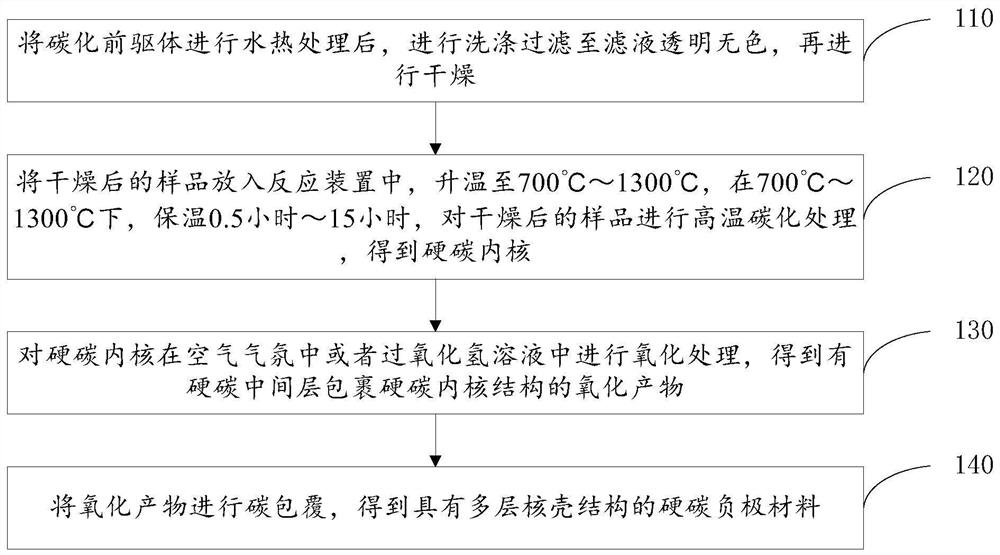

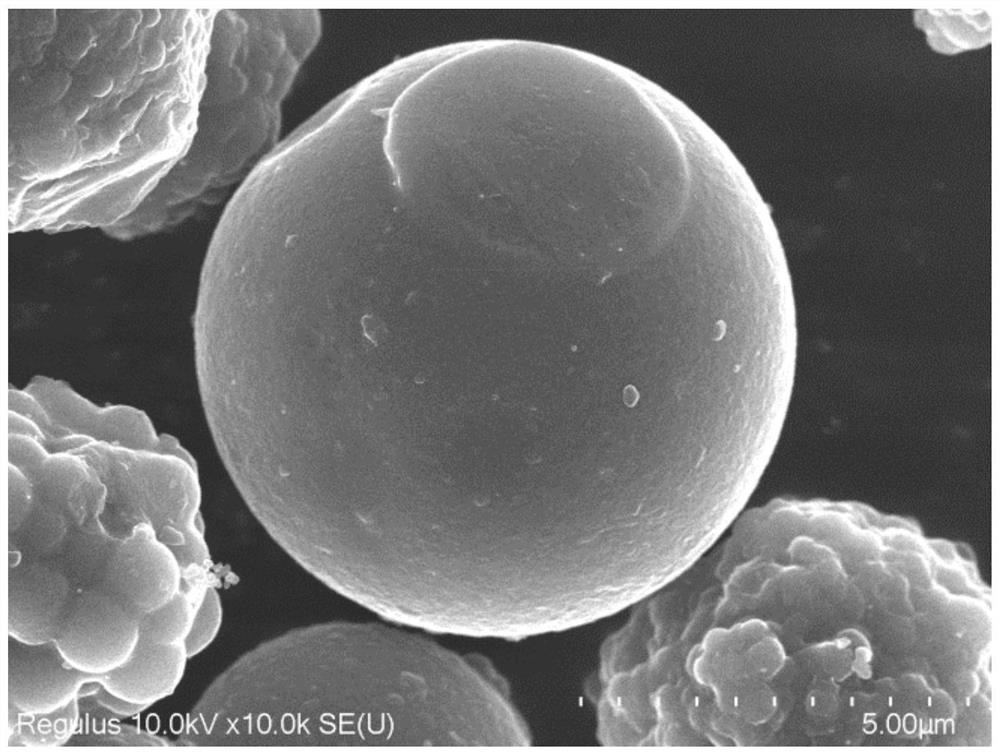

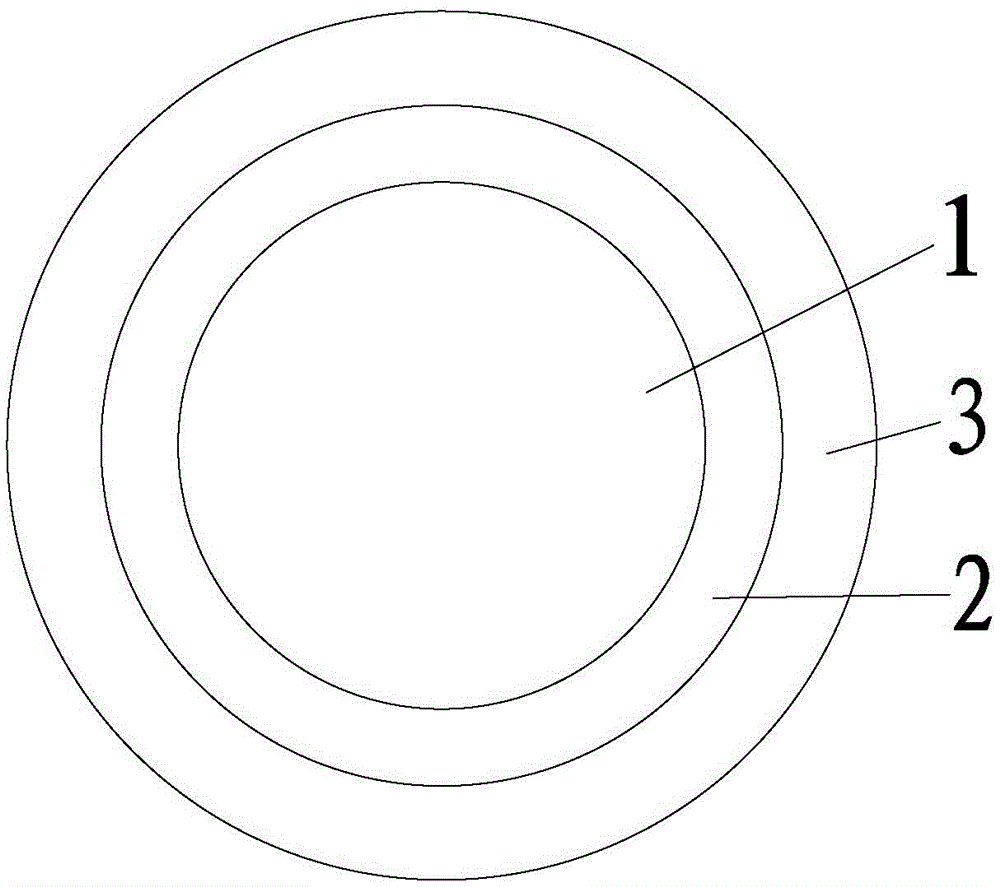

Hard carbon negative electrode material with multilayer core-shell structure and preparation method and application thereof

InactiveCN113328067AImprove first-week efficiencyImprove lithium intercalation capacityNegative electrodesSecondary cellsEpoxyCarbon coating

The embodiment of the invention relates to a hard carbon negative electrode material with a multilayer core-shell structure and a preparation method and application thereof. The size range of the hard carbon negative electrode material is 1-50 mum, and the hard carbon negative electrode material is composed of a hard carbon inner core, a hard carbon middle layer and a carbon coating layer; the hard carbon inner core is a hard carbon material prepared by taking one or more of glucose, cane sugar, polyvinylpyrrolidone, starch polyvinylidene fluoride, novolac epoxy resin or polyvinyl chloride as a carbonization precursor; the size range is 1-40 mum, and the Raman spectrum Id / Ig range is 0.7-0.9; the hard carbon middle layer is a hard carbon porous oxide layer, the porosity is 1%-80%, the pore size is 0.005-2 um, and the Raman spectrum Id / Ig range is 0.8-1.5; the carbon coating layer is prepared by a gas phase method, a liquid phase method or a solid phase method, and the Raman spectrum Id / Ig range is 0.7-1.3; in the hard carbon negative electrode material, the mass fraction of the hard carbon inner core to the hard carbon middle layer to the carbon coating layer is equal to (0, 100%) to (0, 50%) to (0, 30%).

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

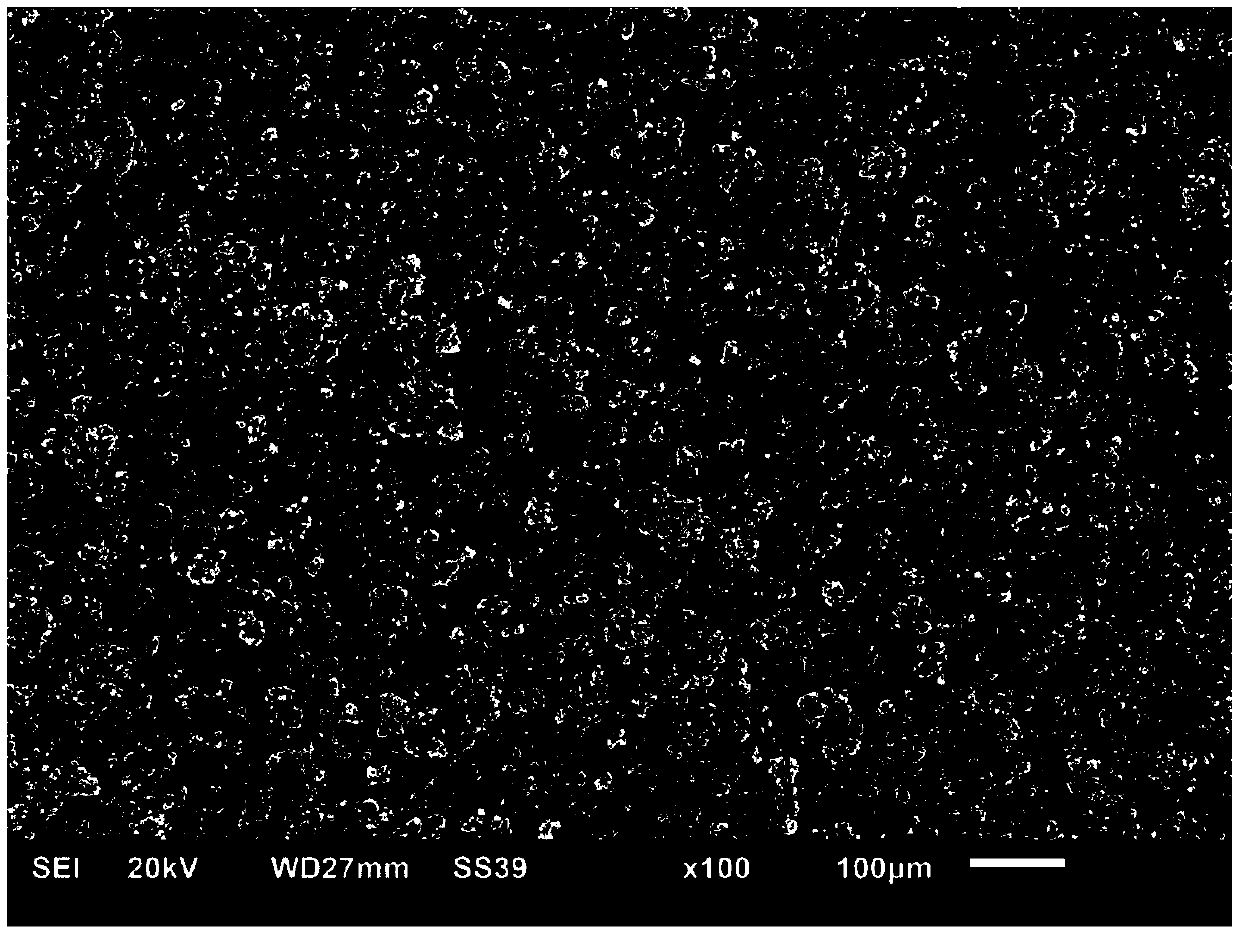

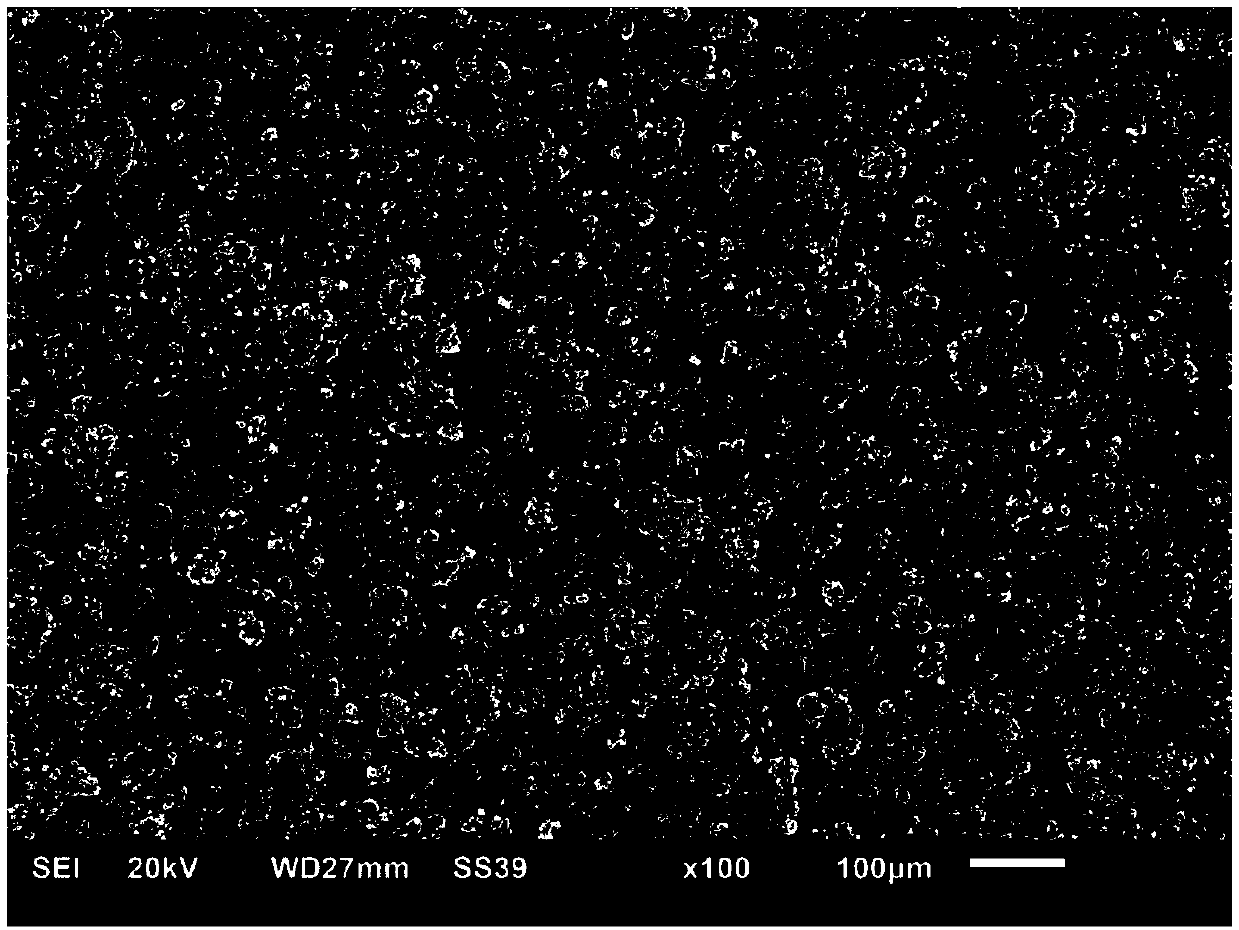

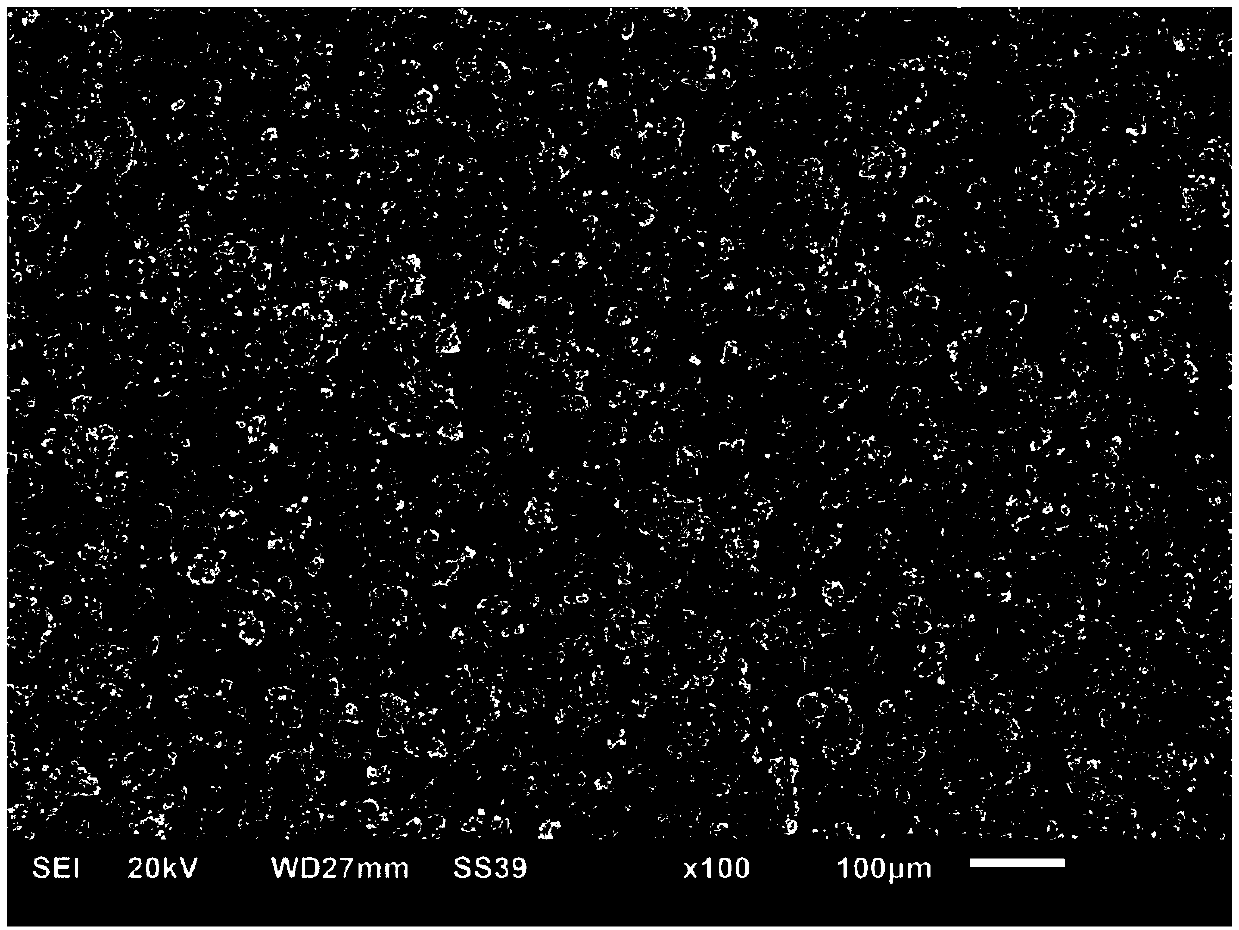

Copper-aluminum-silicon alloy nano cathode material of lithium battery and preparation method thereof

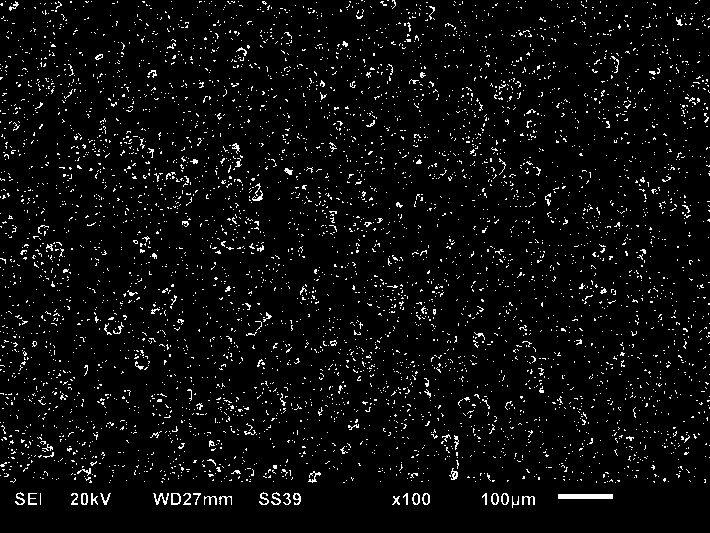

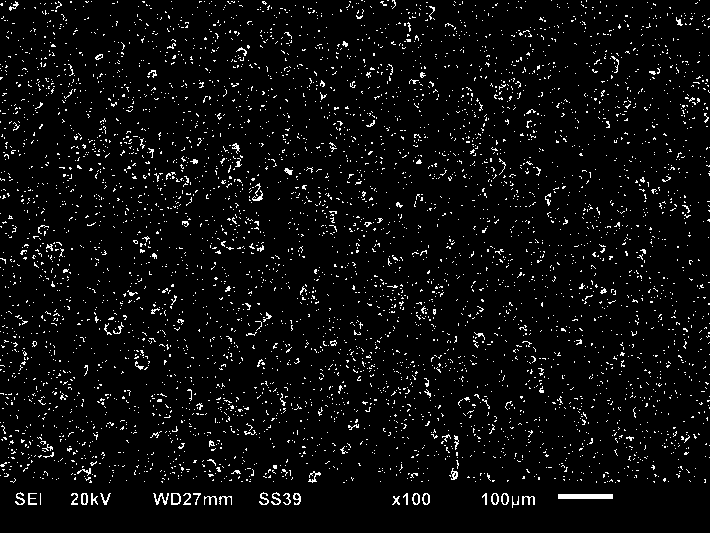

ActiveCN107790712AUnique structureImprove conductivityMaterial nanotechnologyTransportation and packagingSilicon alloyNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nano cathode material of a lithium battery and a preparation method thereof, and belongs to the technical field of cathode materials of the lithium battery. The adopted technical scheme is that the copper-aluminum-silicon alloy nano cathode material of the lithium battery comprises the following raw materials in parts by weight: 42 to 46 parts of silicon, 50 to 58 parts of copper, 5 to 15 parts of aluminum and 0 to 3 parts of impurities; the copper-aluminum-silicon alloy nano cathode material integrally comprises a multi-defect structurewith pores, shrinkage cavities, shrinkage porosities, dislocation, vacancy and holes; and the particle size is smaller than or equal to 80 <mu>m. The copper-aluminum-silicon alloy nano cathode material can be applied to the technical field of cathode materials of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

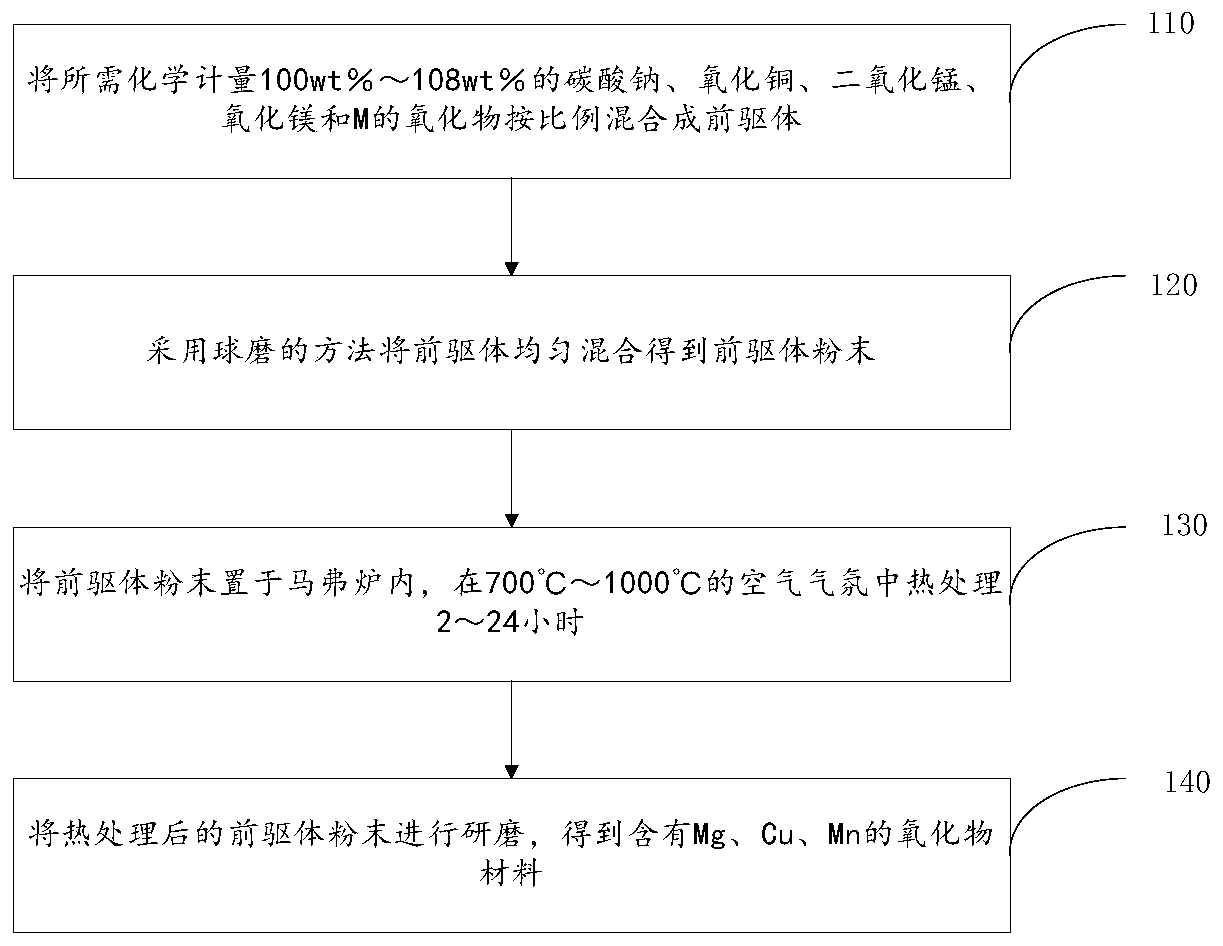

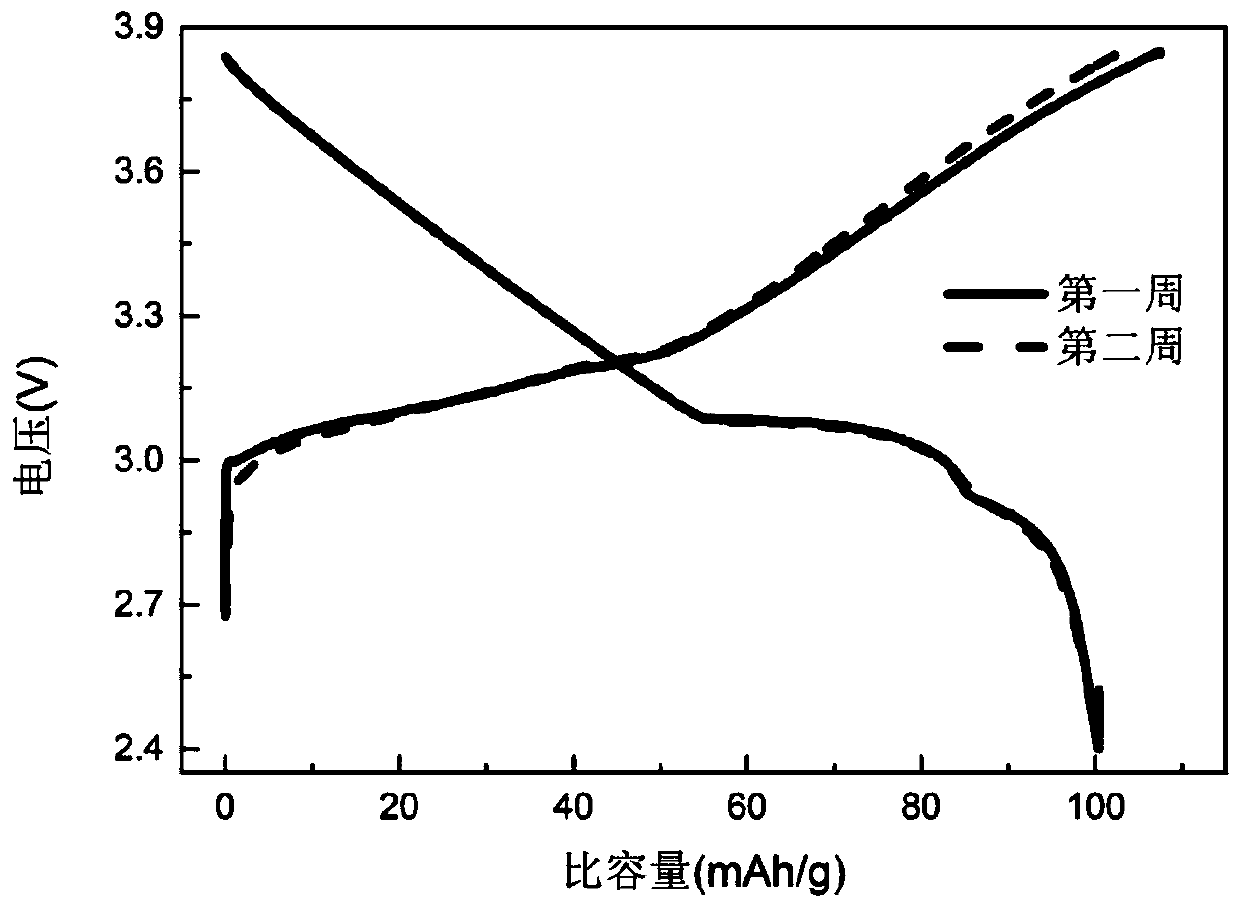

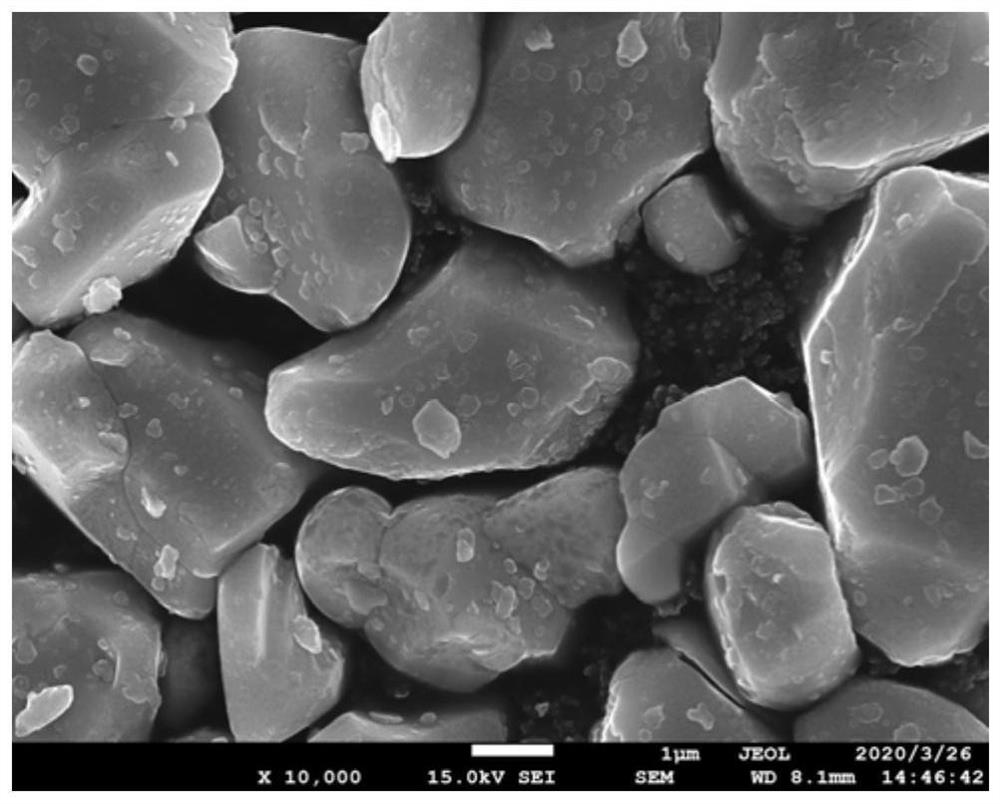

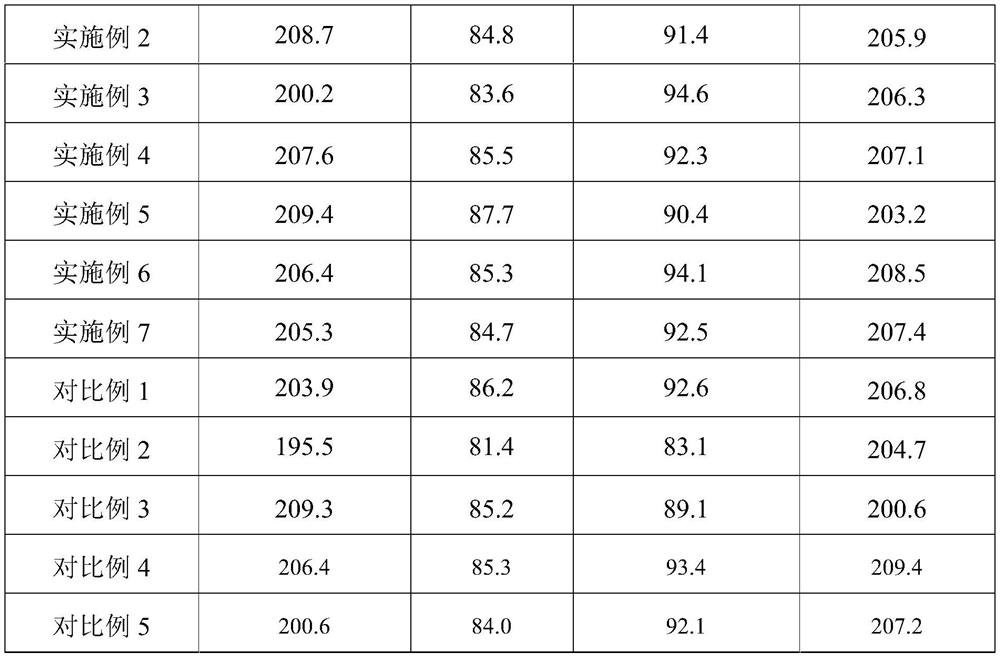

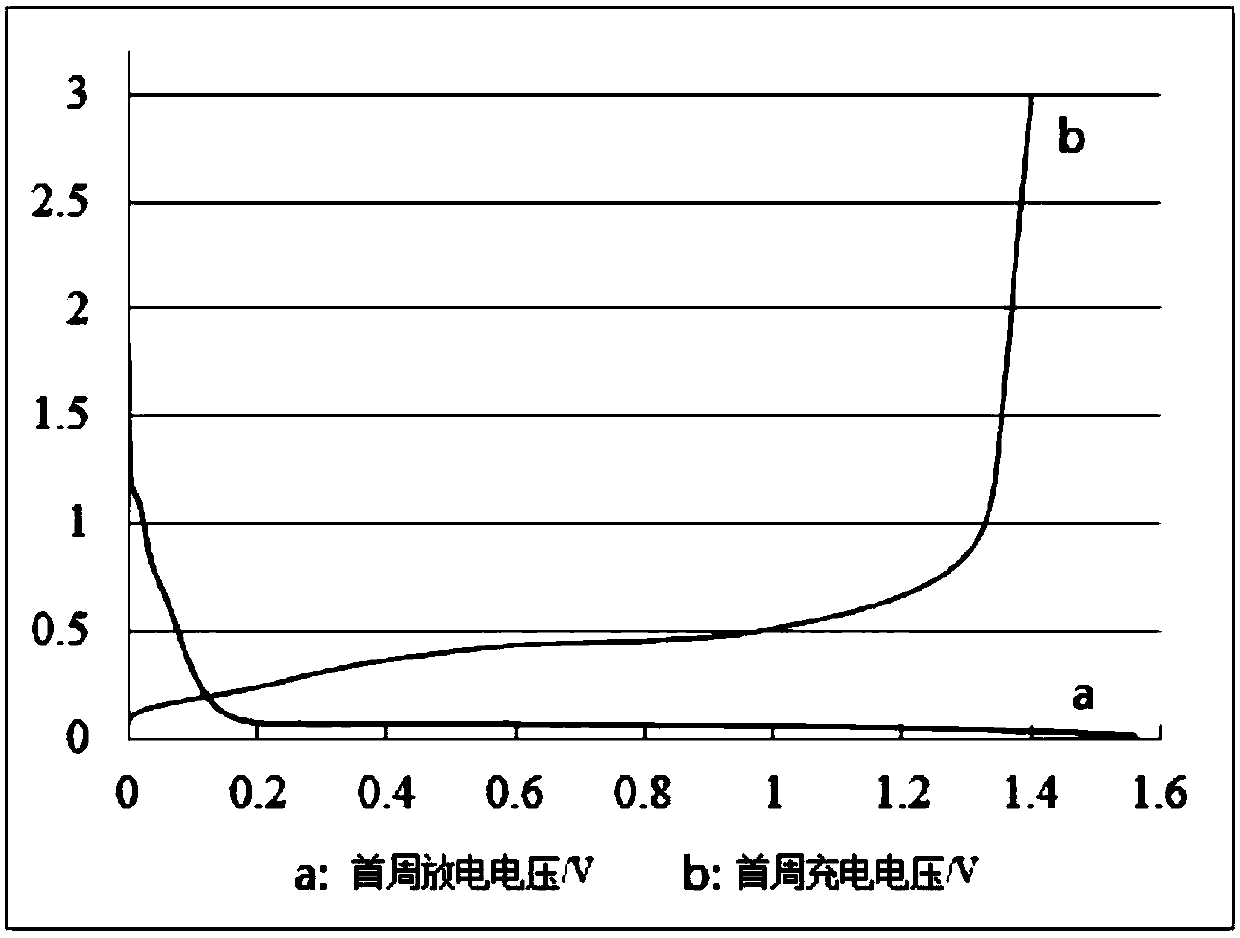

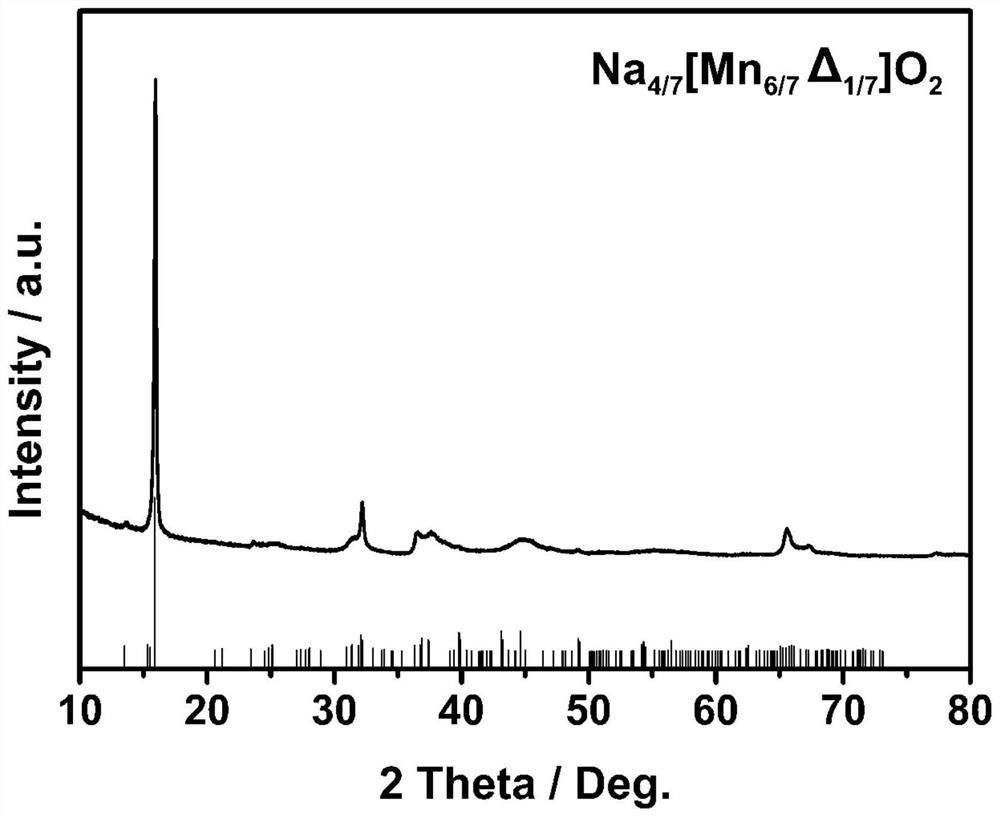

Magnesium compound material and preparation method and application thereof

InactiveCN111900377AImprove first-week efficiencyImprove cycle performanceCell electrodesSecondary cellsBattery cellElectrode material

The invention relates to a magnesium compound material and a preparation method and application thereof, the magnesium compound material comprises MgxMyO2, M comprises one or more of Cu, Ni, Zn, Ti, Mn or Fe, X is greater than or equal to 0.1 and less than or equal to 2, and Y is greater than or equal to 0.1 and less than or equal to 2; the pH value of the magnesium compound material is 7-9; the magnesium compound material is one or more of a spherical shape, an ellipsoidal shape, a cobblestone shape or an irregular shape; and the magnesium compound material is used as a secondary battery positive electrode material or an active material additive for a secondary battery positive electrode.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for preparing copper-aluminum-silicon alloy powder by water atomization and application of method

ActiveCN107732190AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesMolten stateSilicon alloy

The invention relates to a method for preparing copper-aluminum-silicon alloy powder by water atomization and application of the method, and belongs to the technical field of preparation of a lithiumbattery negative electrode material. The invention provides a high-performance lithium battery copper-aluminum-silicon alloy nanometer negative electrode material prepared by employing a water atomization method and application of the copper-aluminum-silicon alloy nanometer negative electrode material. The method comprises the steps of 1, starting a tundish system of an atomization system, whereinthe inner diameter of a tundish nozzle selects 6-14 millimeters; 2, adjusting a tapping temperature of molten-state copper-aluminum-silicon alloy to be 1,300-1,700 DEG C; and 3, pouring liquid-statemetal to a tundish, adjusting water atomization pressure to be 300-450Mpa, and performing water atomization powder preparation, wherein the copper-aluminum-silicon alloy comprises the constituents based on parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of other impurity. The method can be widely applied to the field of preparation of the lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy material and application thereof

InactiveCN107732191AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesLithium electrodeCopper

The invention relates to a copper-aluminum-silicon alloy material and application thereof, and belongs to the technical field of alloy material. The defect of the prior art is overcome, and a high-performance copper-aluminum-silicon alloy material of a lithium battery and application of the copper-aluminum-silicon alloy material are provided. The copper-aluminum-silicon alloy material provided bythe technical scheme comprises the following constituents based on parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurity. The copper-aluminum-silicon alloy material can be widely applied to the field of a lithium ion battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of negative electrode material

InactiveCN107732196AUnique microstructureReasonable particle size distributionMaterial nanotechnologyCell electrodesDislocationNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the negative electrode material, and belongs to the technical field of the negative electrode material of the lithium battery. According to the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the negative electrode material provided by the invention, a technical scheme is adopted as follows: the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials in parts by weight: 27.5-32 parts of silicon, 58-63 parts of copper, 9-11 parts of aluminum and 0-5 parts of impurities; and the overall alloy nanomaterial comprises a multi-defect organization structure of air pores, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain diameter is less than or equal to 80[mu]m. The inventioncan be applied to the technical field of the negative electrode material of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of negative electrode material

InactiveCN107732197AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesSilicon alloyNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the negative electrode material, and belongs to the technical field of the negative electrode material of the lithium battery. According to the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the negative electrode material provided by the invention, a technical scheme is adopted as follows: the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials in parts by weight: 37-42 parts of silicon, 55-62 parts of copper, 4-15 parts of aluminum and 0-3 parts of impurities; and the overall alloy nanomaterial comprises a multi-defect organization structure of air pores, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain diameter is less than or equal to 80[mu]m. The invention can be applied to the technical field of the negative electrode material of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminium-silicon alloy nano negative electrode material of lithium battery and preparation method thereof

InactiveCN107779661AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesSilicon alloyCopper

The invention discloses a copper-aluminium-silicon alloy nano negative electrode material of a lithium battery and a preparation method thereof, and belongs to the technical field of lithium battery negative electrode materials. The used technical solution is as follows: the copper-aluminium-silicon alloy nano negative electrode material of the lithium battery is formed by the following raw materials by weight: 22-27.5 parts of silicon, 60-70 parts of copper, 0.5-5 parts of aluminium, and 0-5 parts of impurities; and the alloy nano material contains multi-defect tissue structures of pore, contraction cavity, shrinkage porosity, dislocation, vacancy and cavity, and the particle size is less than or equal to 80 um. The copper-aluminium-silicon alloy nano negative electrode material can be applied to the technical field of the lithium battery negative electrode materials.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

A kind of modified nickel cobalt lithium manganese oxide ternary material and preparation method thereof

ActiveCN106299320BImprove cycle performanceLittle changeCell electrodesSecondary cellsCyclic processManganate

The invention provides a modified nickel, cobalt and lithium manganite three-element material and a titanium dioxide layer compounded on the surface of the nickel, cobalt and lithium manganite three-element material. The titanium dioxide layer is creatively compounded on the surface of the nickel, cobalt and lithium manganite three-element material, the surface microstructure change of the NCM three-element material in the first-time charging process is effectively decreased, and the first-cycle efficiency is improved. In addition, due to the fact that titanium dioxide serves as a shell layer and form a core-shell structure with the NCM material, only lithium ions can pass through the titanium dioxide layer, and nickel and manganese ions cannot pass through, dissolution of Ni and Mn in the three-element material in the cycling process is reduced, and the cycle performance of the three-element material is optimized.

Owner:GREE ELECTRIC APPLIANCES INC

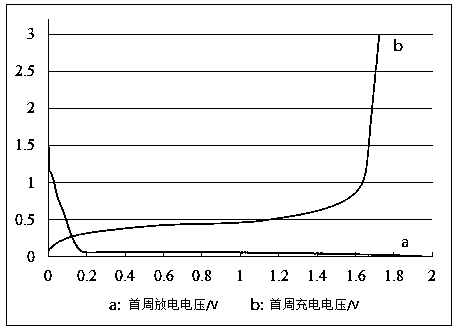

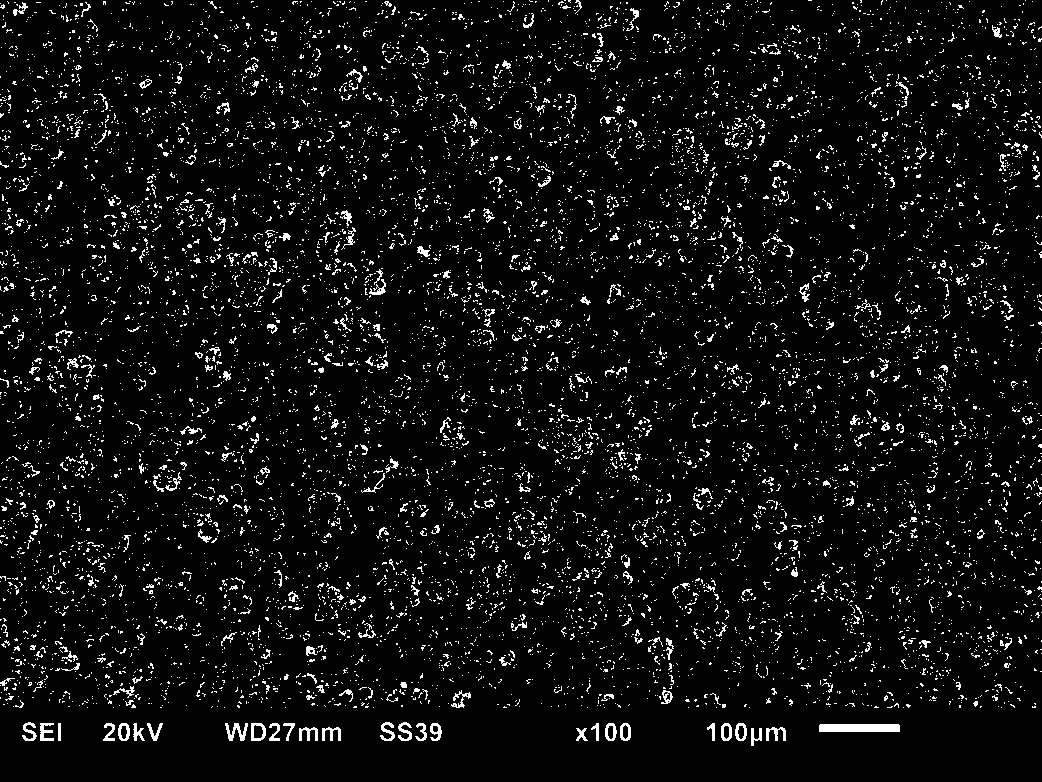

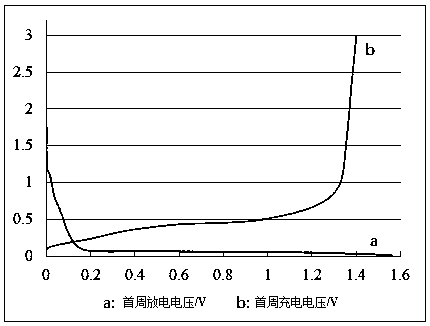

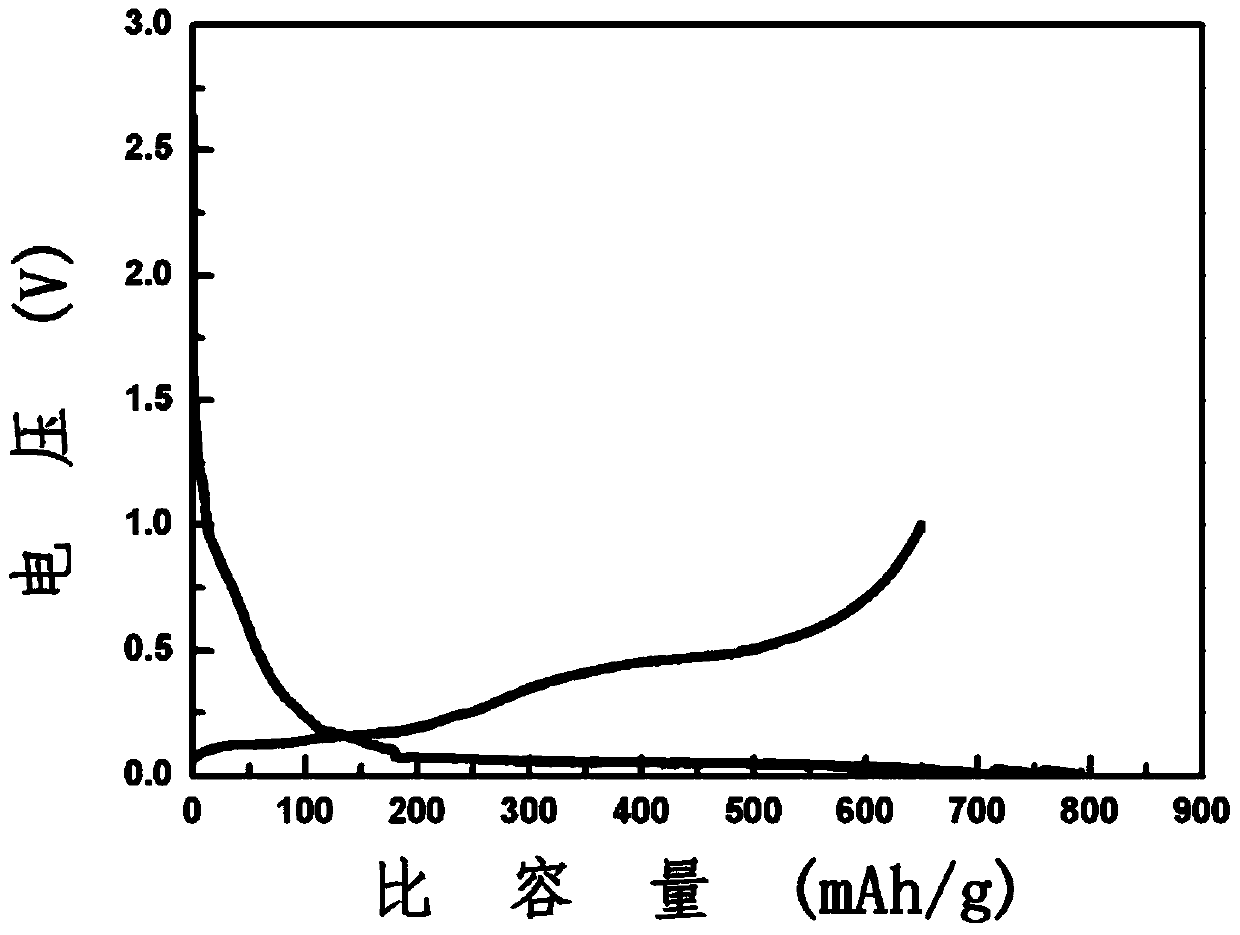

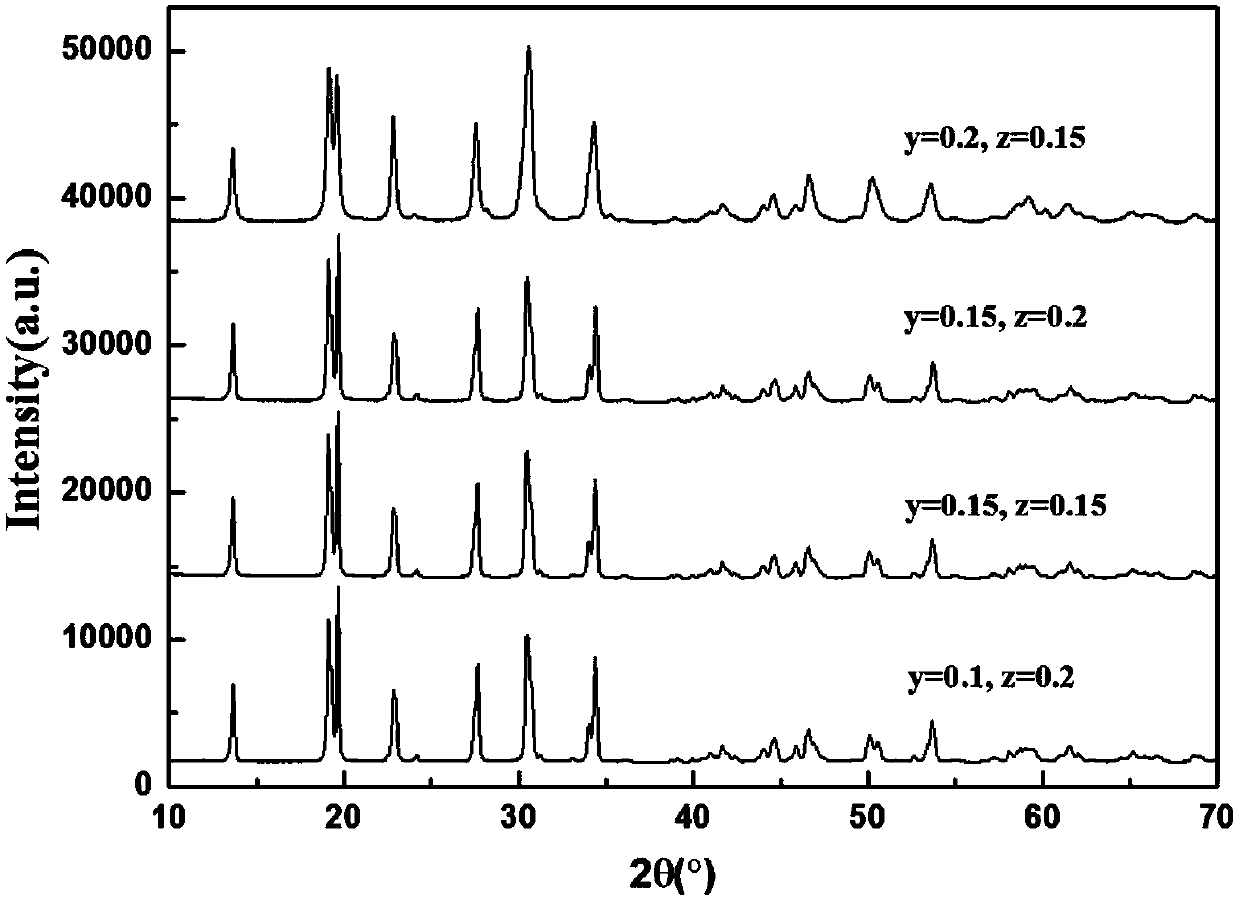

Oxide material containing Mg, Cu and Mn and preparation method and application of oxide material

ActiveCN111525120AEasy to makeImprove first-week efficiencyCell electrodesLi-accumulatorsPhysical chemistryMaterials science

The invention discloses an oxide material containing Mg, Cu and Mn and a preparation method and an application of the oxide material. The chemical general formula of the oxide material is Na(0.8+alpha)MgxCuyM(1-x-y-z)MnzO2+beta, M is an element for doping and substituting a transition metal site and specifically comprises one or more of Fe<3+>, Zn<2+>, Ni<2+>, Li<+>, Al<3+>, B<3+> and Ti<4 +>, thevalence of a transition metal element Mn in the chemical general formula is +4, alpha, x, y, z and beta are mole percentages of corresponding elements respectively, the relationship among alpha, x, y, z, and beta satisfies (0.8+alpha)+2x+2y+4z+m(1-x-y-z) =2(2+beta) and 0< = (1-x-y-z), 0.02<= alpha <=0.2, x > 0, y > 0, z > 0, -0.02 <= beta<= 0.02, m is the valence state of M, 1<= m<= 4, the oxidematerial is an O3-phase layered oxide material, and the space group is R3<->m

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Coated modified high-nickel positive electrode material as well as preparation method and application thereof

InactiveCN112349892AImprove thermal stabilityImprove first week efficiencyCell electrodesHeat stabilityAluminium oxides

The invention relates to a coated modified high-nickel positive electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: takingurea as a precipitant, adding the precipitant into a mixed solution of a dispersion liquid of the high-nickel positive electrode material and an aluminum source solution, heating at 50-55 DEG C, reacting uniformly, precipitating, and calcining to obtain the coated modified high-nickel positive electrode material. According to the method, urea is adopted as the precipitant, OH- is uniformly released in the heating reaction process, then uniform coating of aluminum oxide is achieved on the surface of the high-nickel positive electrode material, and the obtained coated and modified high-nickel positive electrode material has high thermal stability, long cycle life and good safety.

Owner:EVE HYPERPOWER BATTERIES INC

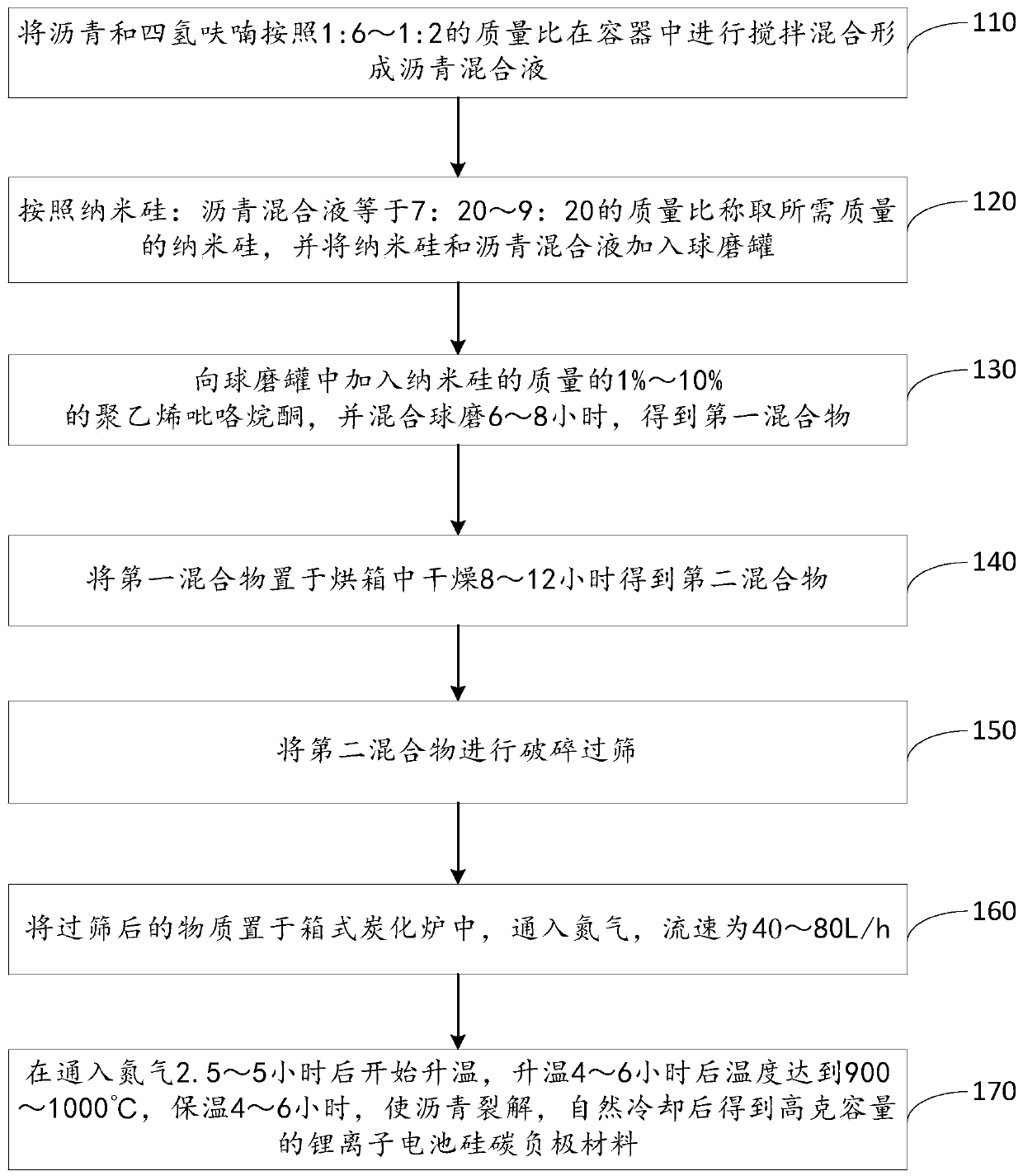

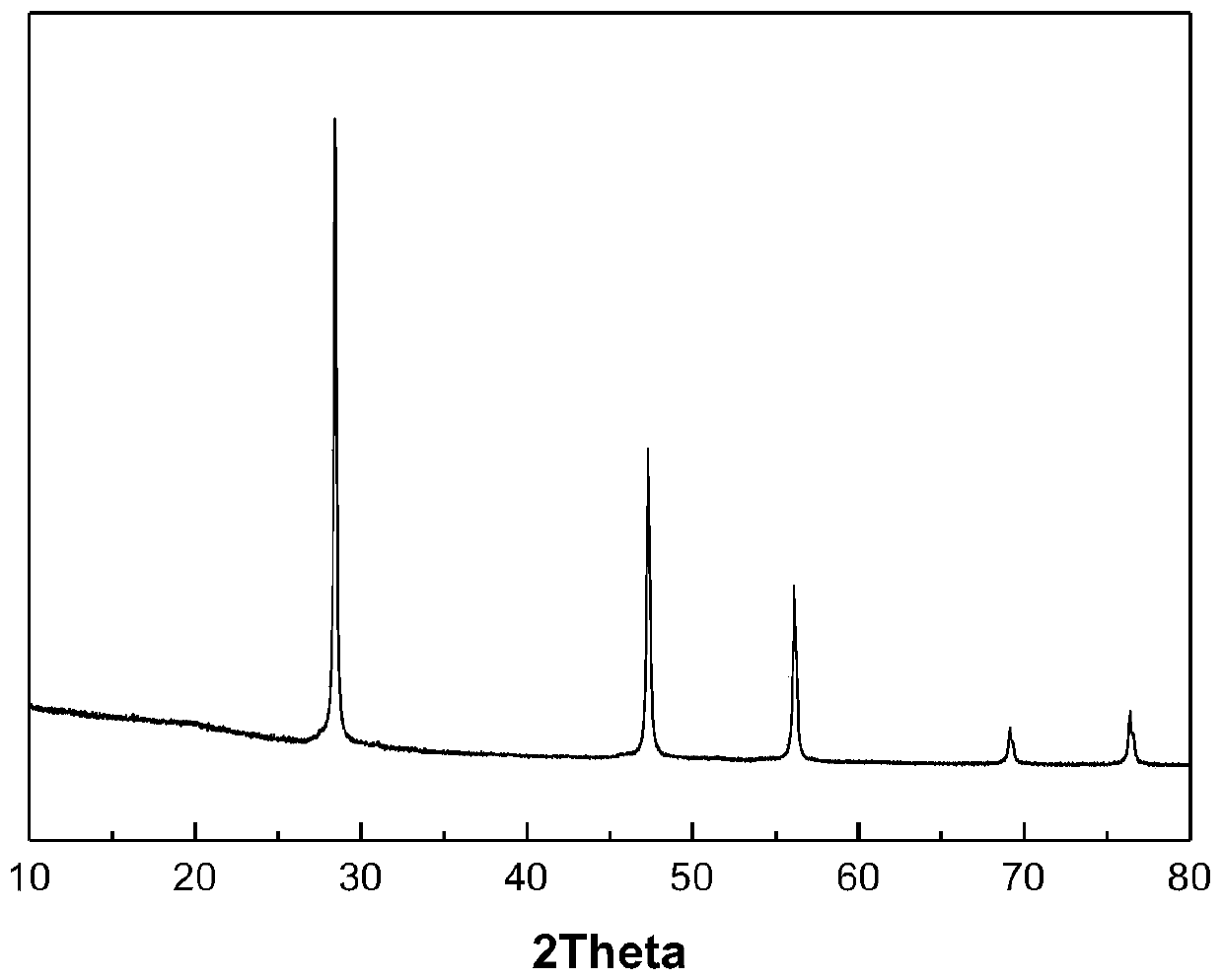

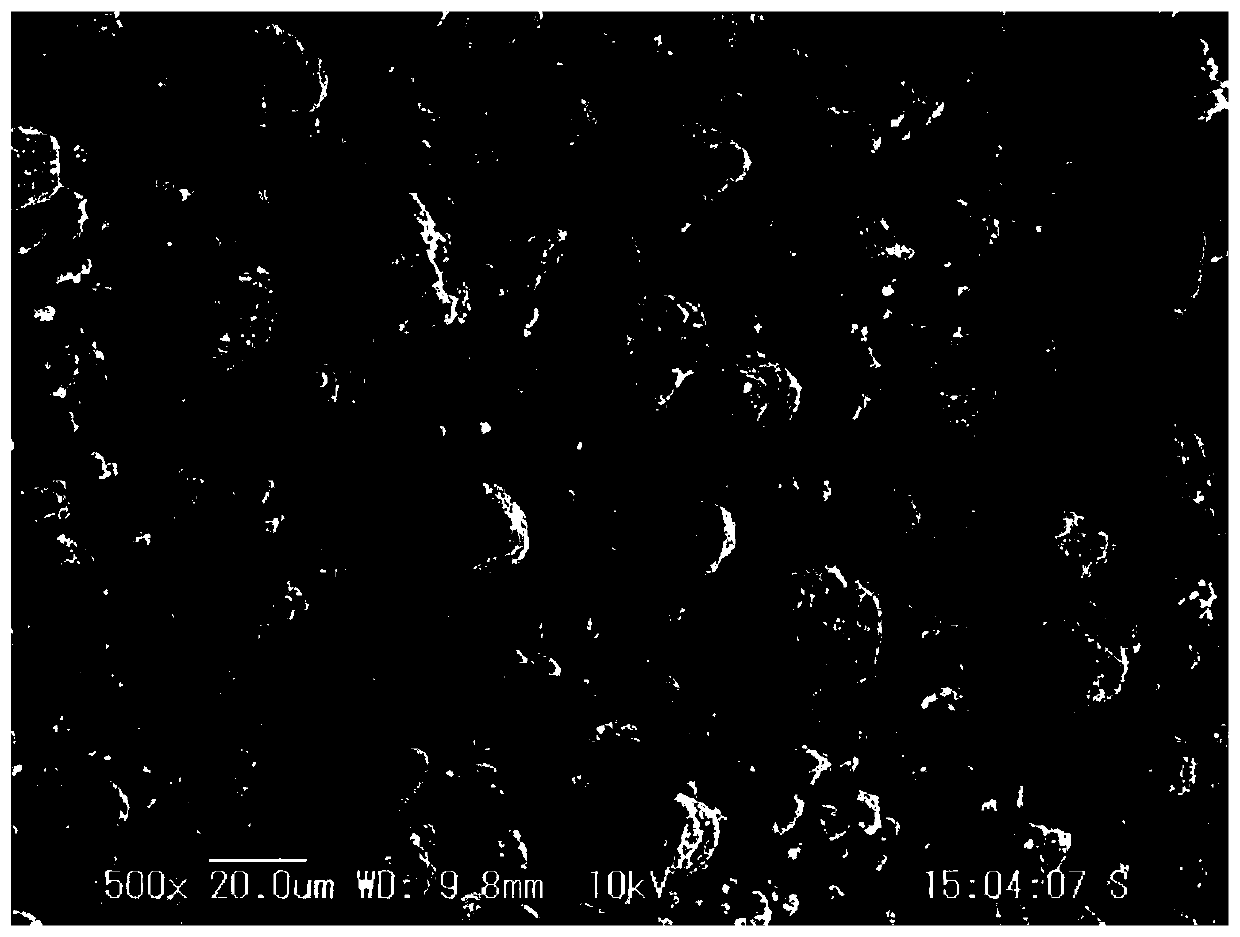

High-gram-capacity lithium ion battery silicon-carbon negative electrode material, and preparation method and lithium battery thereof

PendingCN110877903AImprove first-week efficiencyImprove performanceSiliconNegative electrodesLithium-ion batteryTetrahydrofuran

The embodiment of the invention relates to a high-gram-capacity lithium ion battery silicon-carbon negative electrode material, and a preparation method and a lithium battery thereof. The preparationmethod comprises the following steps: asphalt and tetrahydrofuran are stirred and mixed in a container according to a mass ratio of 1:6 to 1:2 to form an asphalt mixed solution; nano-silicon with therequired mass is weighed according to a mass ratio of the nano-silicon to the asphalt mixed solution of 7:20 to 9:20, and the nano-silicon and the asphalt mixed solution are added into a ball millingtank; polyvinylpyrrolidone (PVP) accounting for 1-10% of the mass of the nano-silicon is added into the ball milling tank, and mixing and ball-milling are carried out for 6-8 h to obtain a first mixture; the first mixture is placed in an oven and is dried for 10-12 h to obtain a second mixture; the second mixture is crushed and sieved; the sieved substance is placed in a box-type carbonization furnace, and nitrogen is introduced at a flow rate of 40-80 L / h; and the temperature is raised 2.5-5 h after nitrogen introduction, and reaches 900-1000 DEG C 3-6 h later, the temperature is kept at 900-1000 DEG C for 4-6 h to crack the asphalt, and the cracked asphalt is naturally cooled to obtain the lithium ion battery silicon-carbon negative electrode material.

Owner:溧阳紫宸新材料科技有限公司

Vibration aging treatment method of copper-aluminum-silicon nano alloy material and application of vibration aging treatment method

InactiveCN107760921AStress reliefImprove performance consistencySecondary cellsNegative electrodesAlloyCopper

The invention discloses a vibration aging treatment method of a copper-aluminum-silicon nano alloy material and application of the vibration aging treatment method, and belongs to the technical fieldof lithium battery cathode material preparation. To overcome defects of the prior art, the invention provides the vibration aging treatment method of the copper-aluminum-silicon nano alloy material and application of the vibration aging treatment method. According to the technical scheme, the vibration aging treatment method is implemented after a step of vacuum drying after steps of blending, smelting, powdering, separation and screening, dried copper-aluminum-silicon nano alloy powder is subjected to vibration aging treatment, an electromagnetic vibration aging instrument is adopted, the electromagnetic vibration efficiency is 3000-5000Hz, and the vibration time is 24-150 hours; a copper-aluminum-silicon nano alloy comprises the following components in parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurities, and the particle size of the alloy is less than or equal to 80mu m. The vibration aging treatment method can be widely applied to the field of lithium battery cathode materials.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

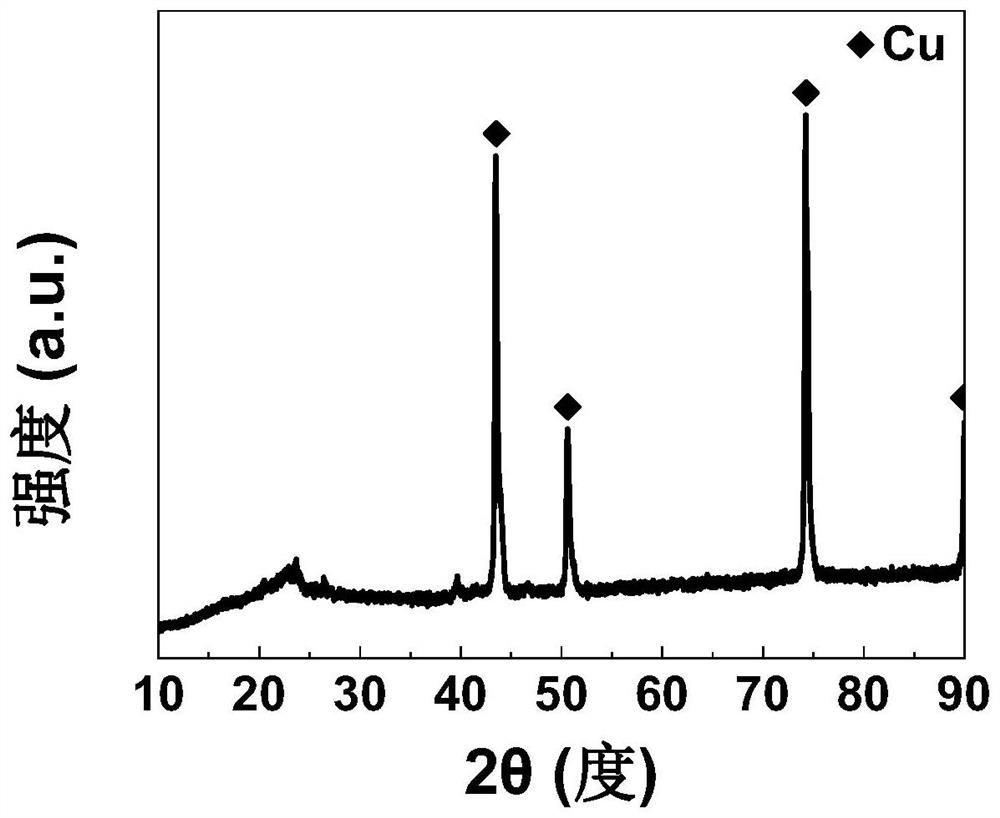

Lithium silicon alloy and preparation method and application thereof

PendingCN114122374AEasy to prepareUniform structureCell electrodesFinal product manufactureLithium electrodeMetallurgy

The invention relates to a lithium-silicon alloy and a preparation method and application thereof. The lithium-silicon alloy can be prepared by assembling and discharging a conventional lithium ion battery; in the lithium-silicon alloy prepared by the invention, the microstructure is two-dimensional layered / three-dimensional porous, so that the volume change in the circulation process can be buffered. In addition, lithium is embedded in advance in the discharging process, so that the first-cycle efficiency is high; in the process, the lithium-silicon alloy is synthesized by an electrochemical method, so that the structure is extremely uniform.

Owner:SHANDONG UNIV

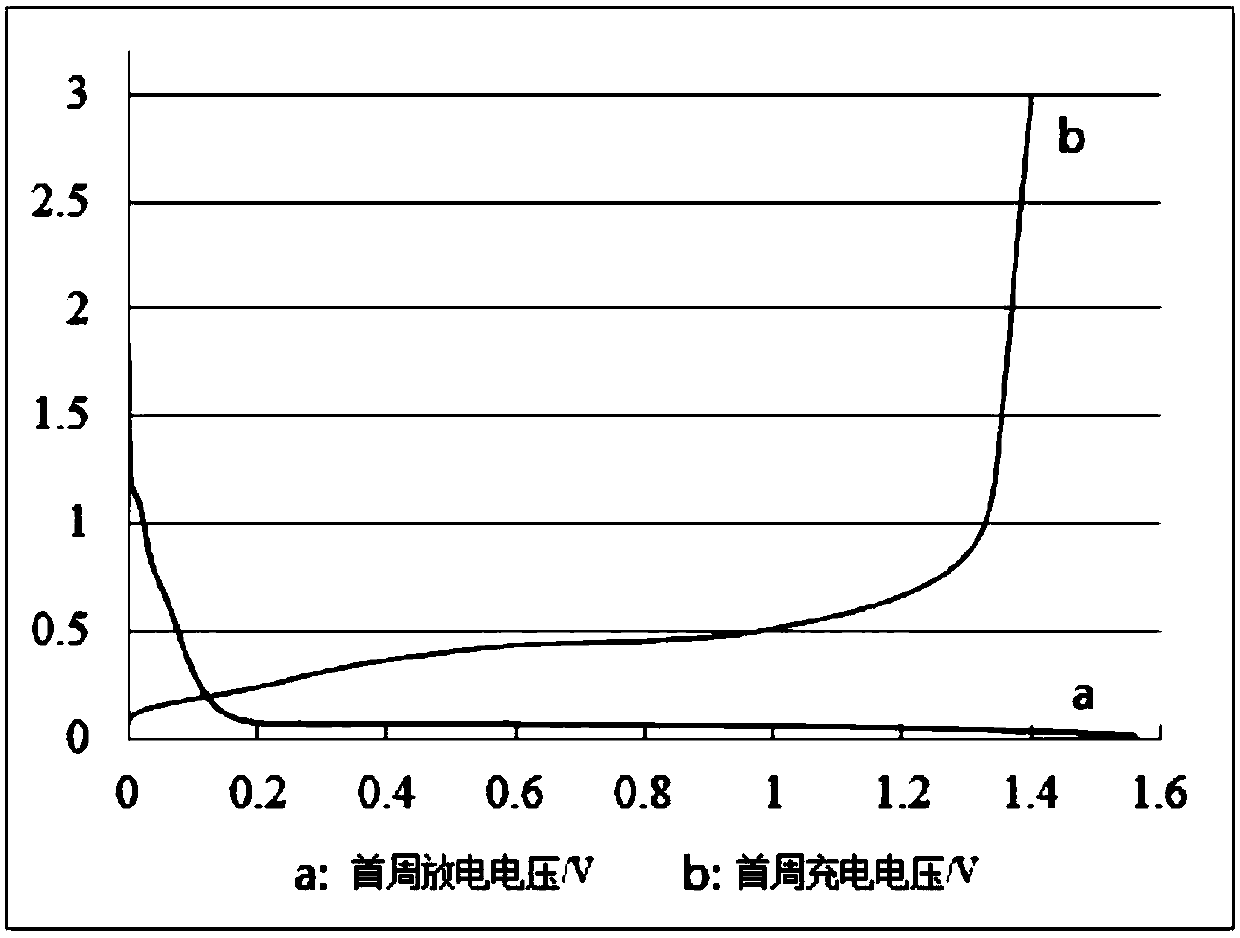

A kind of preparation method of lithium-rich manganese-based solid solution cathode material co-doped with anion

InactiveCN109860509BEvenly dopedInhibit side effectsElectrode manufacturing processesSecondary cellsElectrical batteryManganese

A method for preparing an anion co-doped lithium-rich manganese-based solid solution cathode material. The invention belongs to the field of cathode materials for lithium ion batteries. The soluble metal salt and soluble phosphate of the present invention are dissolved in secondary deionized water to prepare a mixture solution; the polymer is dissolved in absolute ethanol to prepare a polymer solution. Then the polymer solution and the mixture solution are mixed evenly, and the precursor is prepared by using an electrospinning device. Finally, the obtained precursor and the fluoride are uniformly mixed according to the molar ratio, and roasted in an oxygen environment to obtain an anion co-doped lithium-rich manganese-based solid solution positive electrode material. The preparation method of the invention is simple, the reaction process is fast and simple, the phosphate radical of the positive electrode material is added through the precursor, and the doping is more uniform. "Oxygen loss" during the process improves the efficiency of the first cycle, and the polyanion effectively stabilizes the structure of the positive electrode material and improves the cycle stability of the material.

Owner:CHINA ELECTRIC POWER RES INST +3

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of copper-aluminum-silicon alloy nanometer negative electrode material

InactiveCN107706386AUnique structureImprove conductivityCell electrodesSilicon alloyNickel–lithium battery

The invention relates to a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material, and belongs to the technical field of a lithium battery negative electrode material. The invention provides a high-performance copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and a preparation method of the high-performance copper-aluminum-silicon alloy nanometer negative electrode material. The copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials based on parts by weight: 32-39 parts of silicon, 54-59 parts of copper, 1-8 parts of aluminum and 0-5 parts of impurity, the whole alloy nanometer material comprises a multi-defect tissue structure of air holes, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain is smaller than orequal to 80 micrometers. The copper-aluminum-silicon alloy nanometer negative electrode material can be applied to the technical field of a lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of copper-aluminum-silicon alloy nanometer negative electrode material

InactiveCN107732189AUnique structureImprove conductivityCell electrodesDislocationNickel–lithium battery

The invention relates to a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material, and belongs to the technical field of a lithium battery negative electrode material. The invention provides a high-performance copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material. The copper-aluminum-silicon alloy nanometer negative electrodematerial of the lithium battery comprises the following raw materials based on parts by weight: 50-70 parts of silicon, 20-40 parts of copper, 0.5-10 parts of aluminum and 0-5 parts of impurity, thealloy nanometer material integratedly comprises a multi-defect tissue structure of air holes, shrinkage holes, shrinkage porosity, dislocation, vacancies and holes, and the grain size is smaller thanor equal to 80 micrometers. The copper-aluminum-silicon alloy nanometer negative electrode material can be applied to the technical field of the lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Carbon coating treatment method for copper-aluminum-silicon nano alloy material and application of carbon coating treatment method

InactiveCN107732198AUnique structureReasonable particle size distributionCell electrodesCarbon coatingSilicon alloy

The invention provides a carbon coating treatment method for a copper-aluminum-silicon nano alloy material and an application of the carbon coating treatment method, belongs to the technical field ofpreparation of negative electrode materials for lithium batteries, and provides a carbon coating treatment method for treating a copper-aluminum-silicon nano alloy material and an application of the carbon coating treatment method to overcome the disadvantages of the prior art. According to the adopted technical scheme, the carbon coating treatment method is carried out through vacuum drying afterthe steps of burdening, smelting, milling, separating and screening, and comprises the steps of firstly preparing dried copper-aluminum-silicon alloy powder, a carbonaceous material and water at theratio in parts by weight of (80-100):(1-2):(8-11); stirring the raw materials evenly, putting the mixture into a vacuum heat treatment furnace, carrying out heat preservation at 600-800 for 2-4h and carrying out carbon coating treatment, wherein the vacuum degree is smaller than or equal to 0.02Pa; and finally carrying out furnace cooling to below 80 DEG C and drawing a charge. The copper-aluminum-silicon nano alloy is prepared from the following components in parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurities; and the particlesizes are smaller than or equal to 80 microns. The carbon coating treatment method can be widely applied to the field of the negative electrode materials for the lithium batteries.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Aqueous binder and lithium battery containing the binder

ActiveCN106992299BImprove first-week efficiencyImprove efficiencyCell electrodesSecondary cellsPhysical chemistryPolyglutamic acid

The invention relates to a waterborne binder and a lithium battery containing the same. The binder comprises a component A and a component B, wherein the component A comprises one or more selected from a group consisting of polyglutamic acid as shown in a formula I which is defined in the specification and derivatives thereof; the mass fraction of the component A is 0.01 to 100%; and mass fraction of the component B is 0 to 99.99%. The binder is water-soluble, green and environment-friendly and can improve the first-cycle efficiency and cycle performance of the lithium battery. The lithium battery containing the binder has higher first-cycle efficiency and longer cycle performance.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

A coating structure suitable for high-voltage charging and discharging and its manufacturing method

ActiveCN102931384BImprove first-week efficiencyIncrease energy densityCell electrodesHigh energyPhysical chemistry

Owner:DONGGUAN AMPEREX TECH

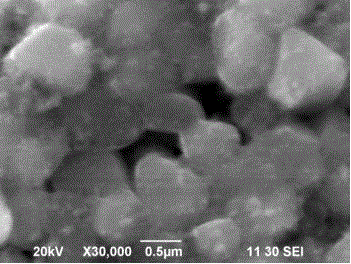

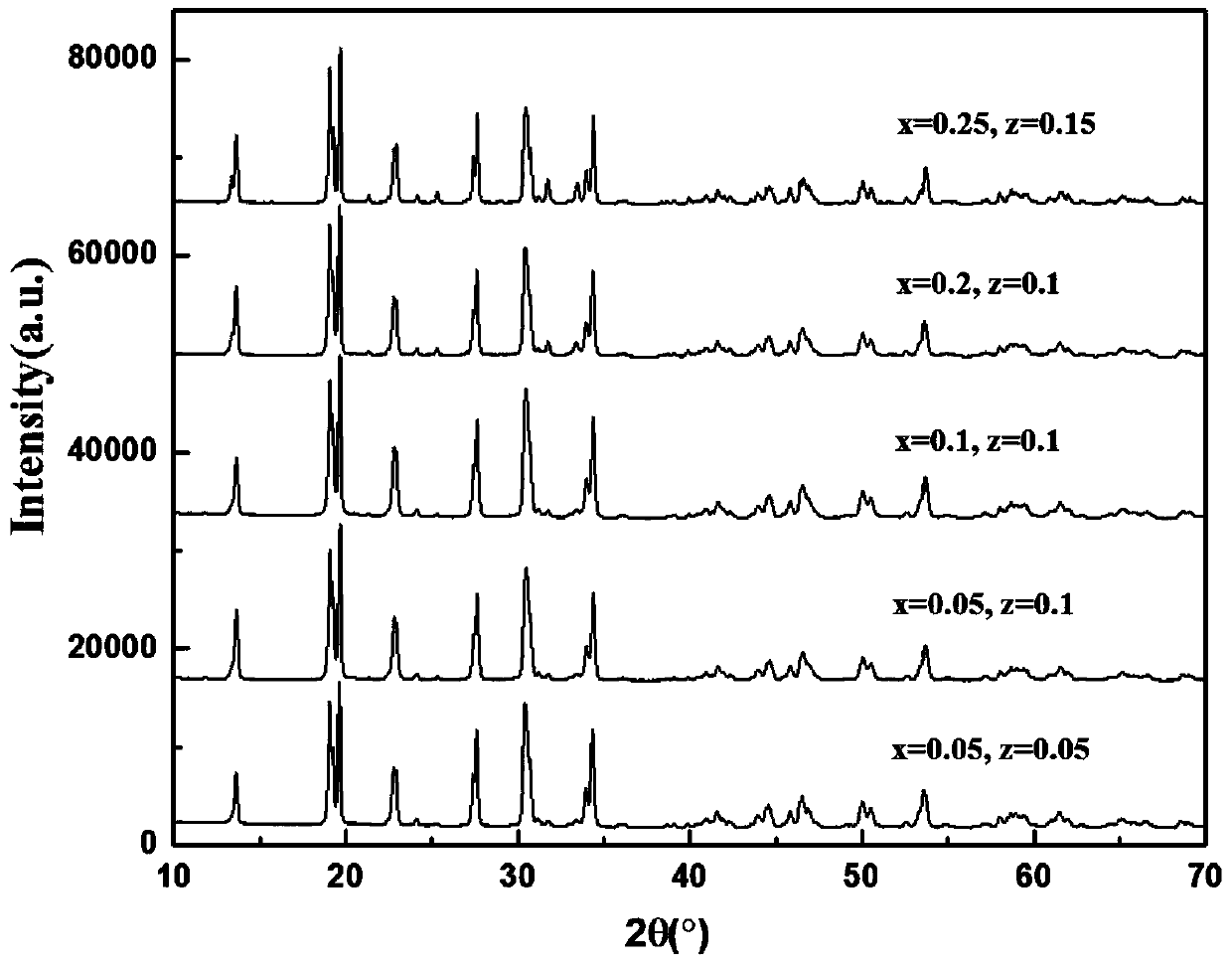

A secondary battery electrode material containing intrinsic vacancies and battery

ActiveCN109616648BBroaden your optionsHigh specific capacityNon-aqueous electrolyte accumulatorsCell electrodesAlkaline earth metalElectrical battery

The invention discloses a secondary battery electrode material containing intrinsic vacancies and a battery. The general chemical structure formula of the secondary battery electrode material containing intrinsic vacancies is A x (M y Δ w )B z ; wherein, A is an alkali metal or alkaline earth metal cation; M is a metal or non-metal cation, and the atomic number of M is greater than that of A; ; B is an anion or an anion group; in the general chemical structure formula, 0<x≤10, 0<y<10, 0<w<10, 0<z≤10; in the spatial structure of the secondary battery electrode material In the polyhedral layer composed of M cations and B anions or anion groups, there are intrinsic M vacancies Δ formed by some M cation sites not being occupied by any ions.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

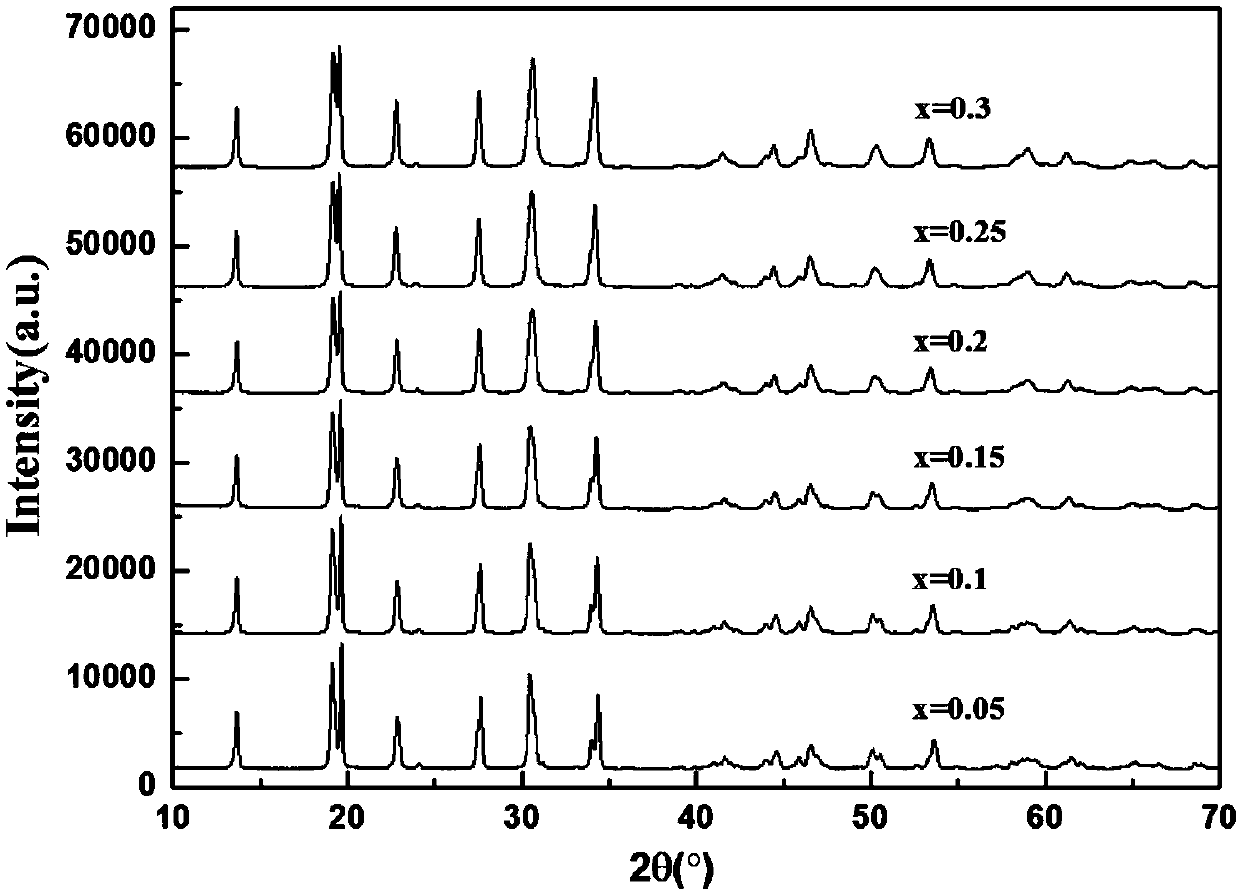

Nasicon type sodium ion solid electrolyte material and preparation method thereof

ActiveCN105742698BSimple preparation processRaw materials are cheap and easy to getNon-aqueous electrolyte accumulatorsAlkaline earth metalSi doped

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Carbon nanotube hard carbon composite negative electrode material with core-shell structure, preparation method and application

ActiveCN113328068BImprove first-week efficiencySmall specific surface areaCell electrodesSecondary cellsEpoxyCarbon composites

The embodiment of the present invention relates to a carbon nanotube hard carbon composite negative electrode material with a core-shell structure and its preparation method and application. The outer carbon coating is composed of; the inner core includes a first phase and a second phase; One or several combinations of these are hard carbon materials prepared from carbonized precursors, with a size range of 1um to 40um, and a Raman spectrum Id / Ig range of 0.7 to 0.9; the second phase is carbon nanotubes, with a size of 1nm to 50nm; the carbon coating layer is prepared by gas phase method, liquid phase method or solid phase method, and the range of Raman spectrum Id / Ig is 0.7~1.3; in the carbon nanotube hard carbon composite negative electrode material, according to the mass Score, first phase: second phase: carbon coating = (0, 100%]: (0, 60%]: (0, 40%].

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

Method for preparing copper-aluminum-silicon alloy powder by using ultrasonic gas atomization and application of method

InactiveCN107737939AUnique structureImprove conductivityCell electrodesSecondary cellsMolten stateSilicon alloy

The invention discloses a method for preparing copper-aluminum-silicon alloy powder by using ultrasonic gas atomization and application of the method, and belongs to the technical field of preparationof anode materials for lithium batteries. The method provides a copper-aluminum-silicon alloy anode nanomaterial for preparing the high-performance lithium batteries by using an ultrasonic gas atomization method and application of the method. According to the technical scheme, the method comprises the following steps that firstly, a tundish system of an atomization device is started, and the inner diameter of a tundish discharging spout is phi 6-14 mm; secondly, the tapping temperature of a copper-aluminum-silicon alloy in a molten state is adjusted to be 1300-1700 DEG C; and thirdly, liquidmetal is poured into a tundish, the flow rate of supersonic airflow is adjusted to be 2-2.5 mach. the pulse frequency of the supersonic airflow is 80-100 KHz, airflow pressure is 10-50 Mpa, and powdermaking through ultrasonic gas atomization is conducted. The method for preparing the copper-aluminum-silicon alloy powder by using ultrasonic gas atomization can be widely applied to the field of preparation of the anode materials for the lithium batteries.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com