Lithium silicon alloy and preparation method and application thereof

A lithium-silicon alloy and alloy technology, applied in the field of materials, can solve the problems of limited efficiency and volume change in the first week, and achieve the effect of simple and easy preparation method, small volume change and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A lithium-silicon alloy material, the preparation method is as follows:

[0028] Take 10g of calcium silicide alloy, heat-treat at 900°C for 2 hours by vacuum distillation method, and obtain two-dimensional silicon material;

[0029] Two-dimensional silicon is coated on copper foil and assembled into a lithium-ion battery. The electrolyte is 1M LiPF6 / EC+DEC, and the current density is 100mA g -1 , the discharge voltage is 0.01V, and after the discharge is completed, a two-dimensional lithium-silicon alloy can be obtained.

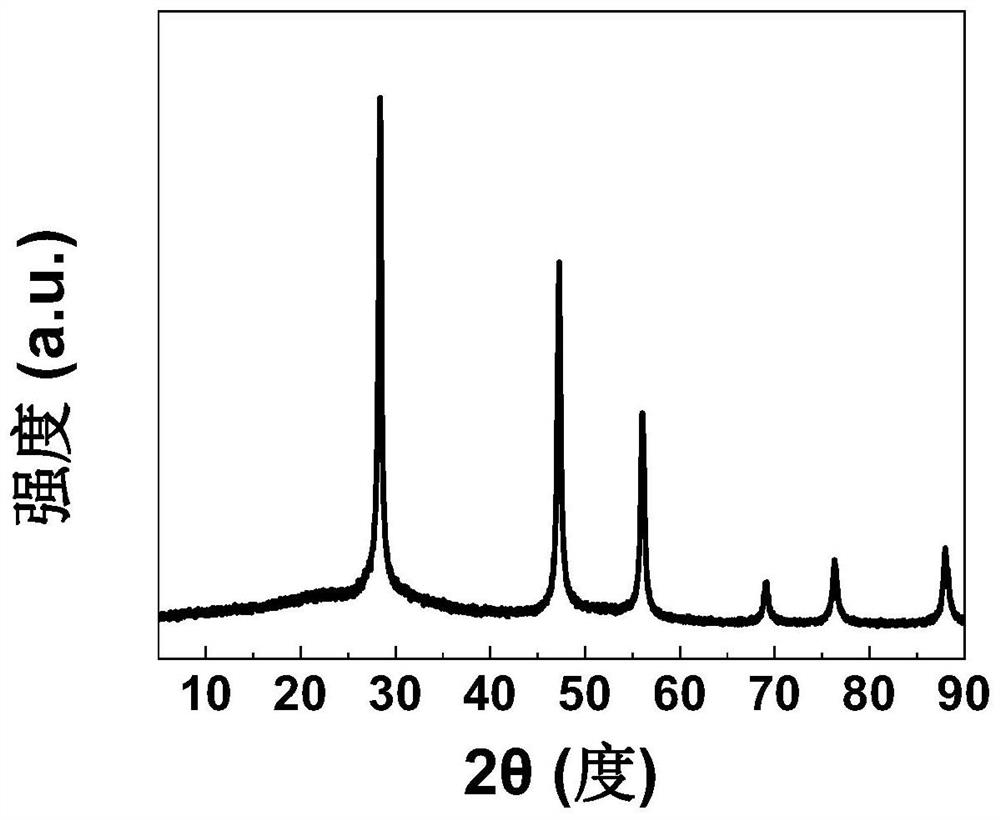

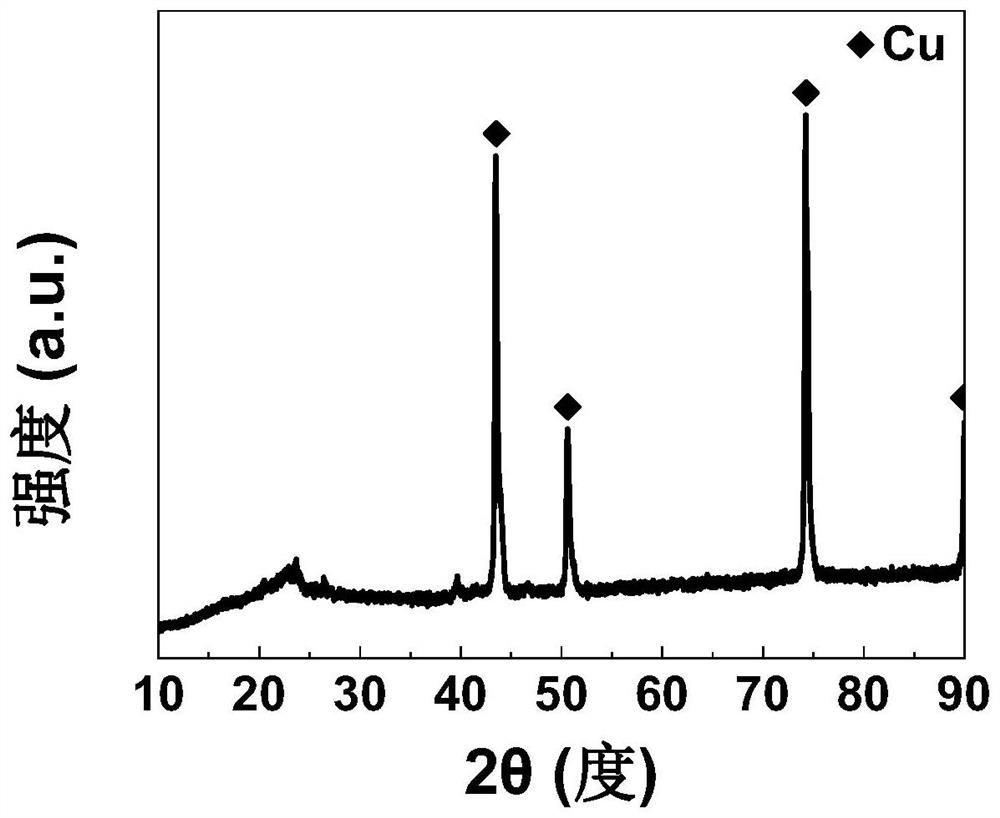

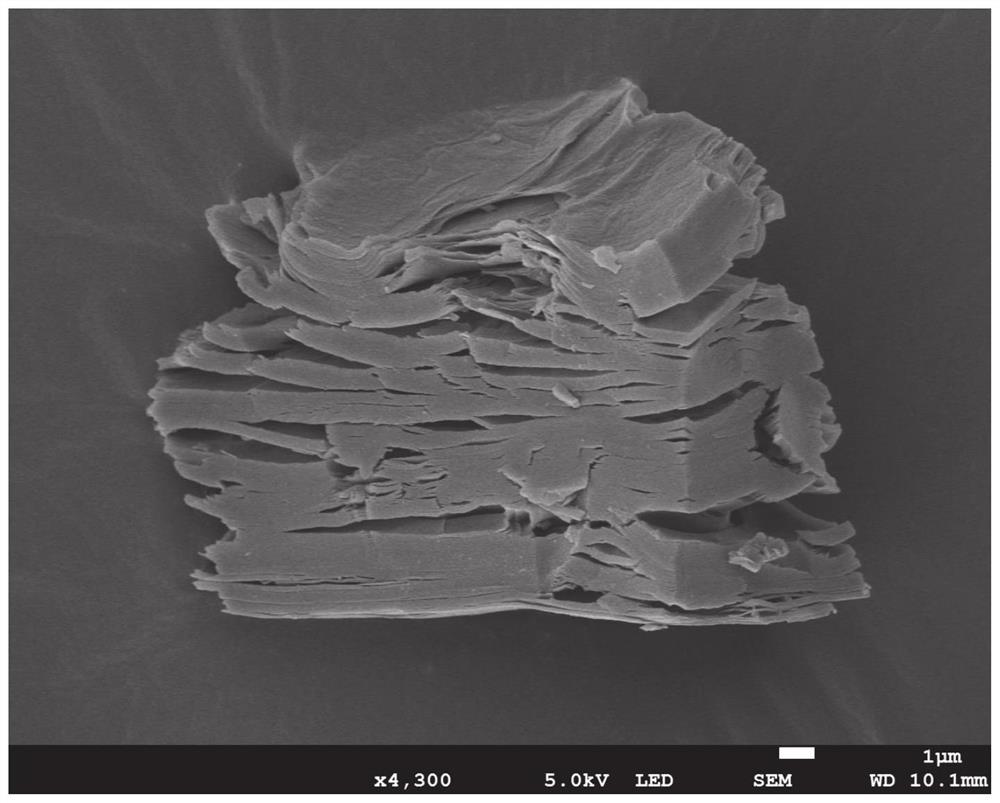

[0030] The two-dimensional silicon material obtained in the preparation method was analyzed by figure 1 It can be seen from the XRD pattern that no other miscellaneous peaks appear in the figure, indicating that elemental silicon was successfully prepared from calcium silicide alloy by vacuum distillation. And from image 3 It can be clearly seen from the SEM image that the synthesized two-dimensional silicon material presents an obvious layered s...

Embodiment 2

[0033] A lithium-silicon alloy material, the preparation method is as follows:

[0034] Take 10g of magnesium silicide alloy and heat-treat it at 800°C for 2 hours by vacuum distillation to obtain porous silicon material;

[0035] Porous silicon is coated on copper foil and assembled into a lithium-ion battery. The electrolyte uses 1M LiPF 6 / EC+DEC, the current density is 100mA·g -1 , the discharge voltage is 0.01V, and the porous lithium-silicon alloy can be obtained after the discharge is completed.

Embodiment 3

[0037] A lithium-silicon alloy material, the preparation method is as follows:

[0038] Take 10g of calcium silicide alloy and heat-treat it at 800°C for 5 hours by vacuum distillation to obtain a two-dimensional silicon material;

[0039] Two-dimensional silicon is coated on copper foil and assembled into a lithium-ion battery. The electrolyte uses 1M LiPF 6 / EC+DEC, the current density is 200mA·g -1 , the discharge voltage is 0.01V, and after the discharge is completed, a two-dimensional lithium-silicon alloy can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com