A secondary battery electrode material containing intrinsic vacancies and battery

A technology for secondary batteries and electrode materials, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of limited selection range, low material capacity, and high cost, achieve high energy density, improve specific capacity, and improve electrodes. The effect of material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example is used to illustrate that Na containing intrinsic vacancies 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 The preparation process, structural characteristics and performance for sodium metal secondary batteries.

[0040] Its preparation method can mainly be carried out according to the following steps.

[0041] First NaOH and MnO 2 Mix and grind evenly at a molar ratio of 2:3, then place the above mixture in a muffle furnace, sinter at 400°C for 24 hours in an air atmosphere, cool down to room temperature and take it out for later use to obtain Na 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 .

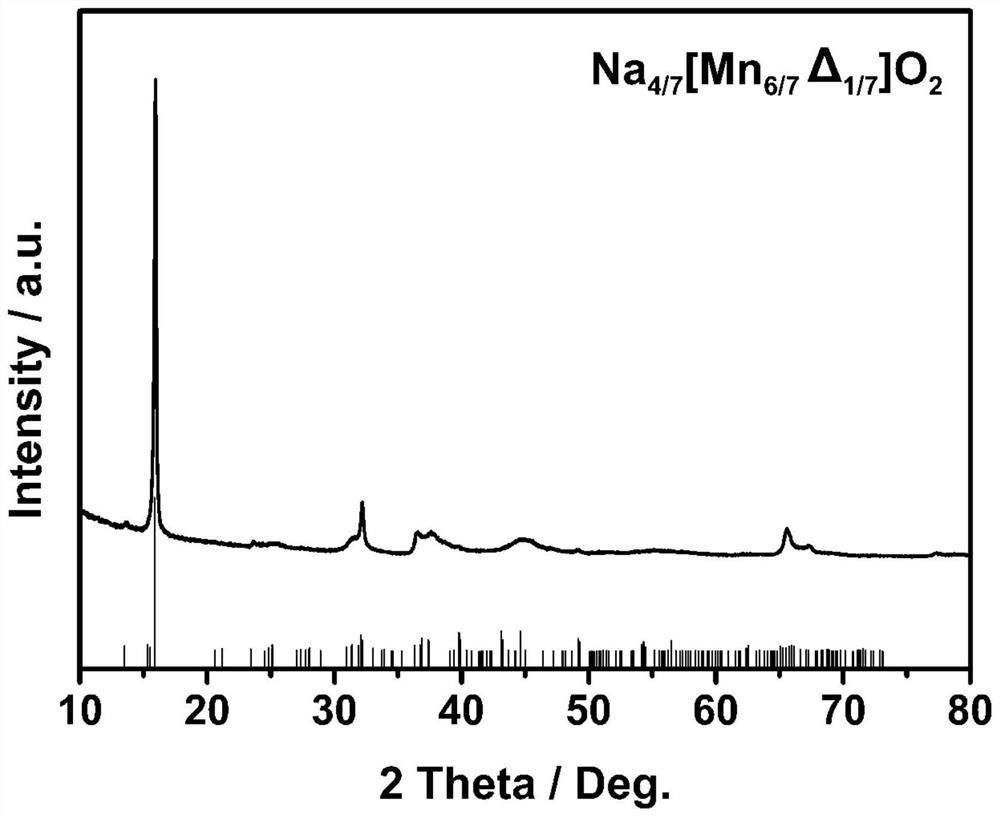

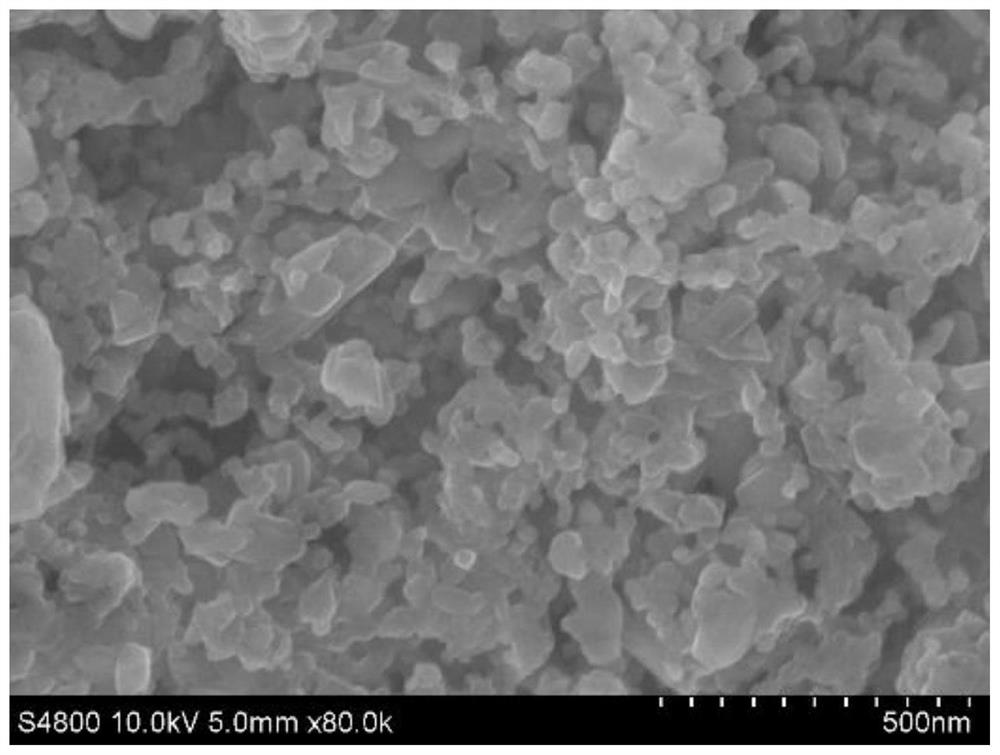

[0042] figure 1 with figure 2 respectively for the prepared Na 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 XRD patterns and SEM pictures of the materials. It can be seen from the figure that there are vacancies occupied by manganese sites in the material structure.

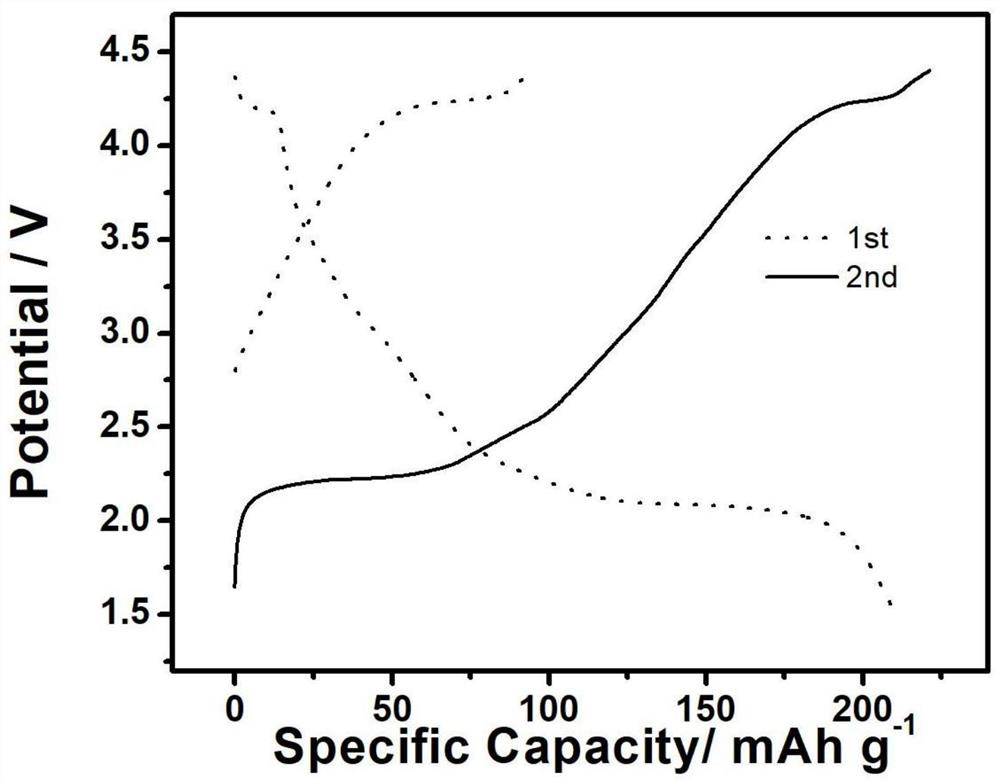

[0043] Na prepared in this example 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 The material is the positive electrode, the metal sodium is the negative electrode, an...

Embodiment 2

[0050] This example is used to illustrate that Na containing intrinsic vacancies 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 Preparation process and properties for sodium metal secondary batteries.

[0051] In this example Na 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 The preparation method is with embodiment 1.

[0052]When assembling a sodium-ion secondary battery, pyrolytic carbon is used as the negative electrode, and Na 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 As the positive electrode, 1mol L dissolved in EC and DMC (volume ratio 1:1) -1 NaPF 6 The solution is an electrolyte, and a sodium ion secondary battery is assembled in dry air.

[0053] Electrochemical tests were performed on the sodium-ion secondary battery: the test voltage of the sodium-ion secondary battery was 1.4-4.0V, and other test conditions were the same as in Example 1. Electrochemical performance test results show that the charging capacity in the first week is 200mAh·g -1 , The capacity retention rate was 95% after 20 weeks of circulation.

Embodiment 3

[0055] This example is used to illustrate that Na containing intrinsic vacancies 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 It is used in the preparation process and performance of metallic lithium secondary batteries.

[0056] In this example Na 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 The preparation method is with embodiment 1.

[0057] When assembling metal lithium secondary batteries, metal lithium is used as the negative electrode, and Na 4 / 7 (Mn 6 / 7 Δ 1 / 7 )O 2 As the positive electrode, 1mol L dissolved in EC and DMC (volume ratio 1:1) -1 LiPF 6 The solution is an electrolyte, and a lithium metal secondary battery is assembled in a glove box filled with argon.

[0058] Electrochemical testing was performed on the metal lithium secondary battery: the test voltage range of the metal lithium secondary battery was 2.0-4.4V, and other test conditions were the same as in Example 1. Electrochemical performance test results show that the charging capacity in the first week is 180mAh·g -1 , The capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com