Coating structure applicable to high-voltage charge-discharge and manufacturing method of coating structure

A coating structure and manufacturing method technology, applied to battery electrodes, structural parts, circuits, etc., can solve the problems of energy density decline, fast capacity decay, cycle performance degradation, etc., and achieve high-temperature storage performance improvement, good cycle and safety performance , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

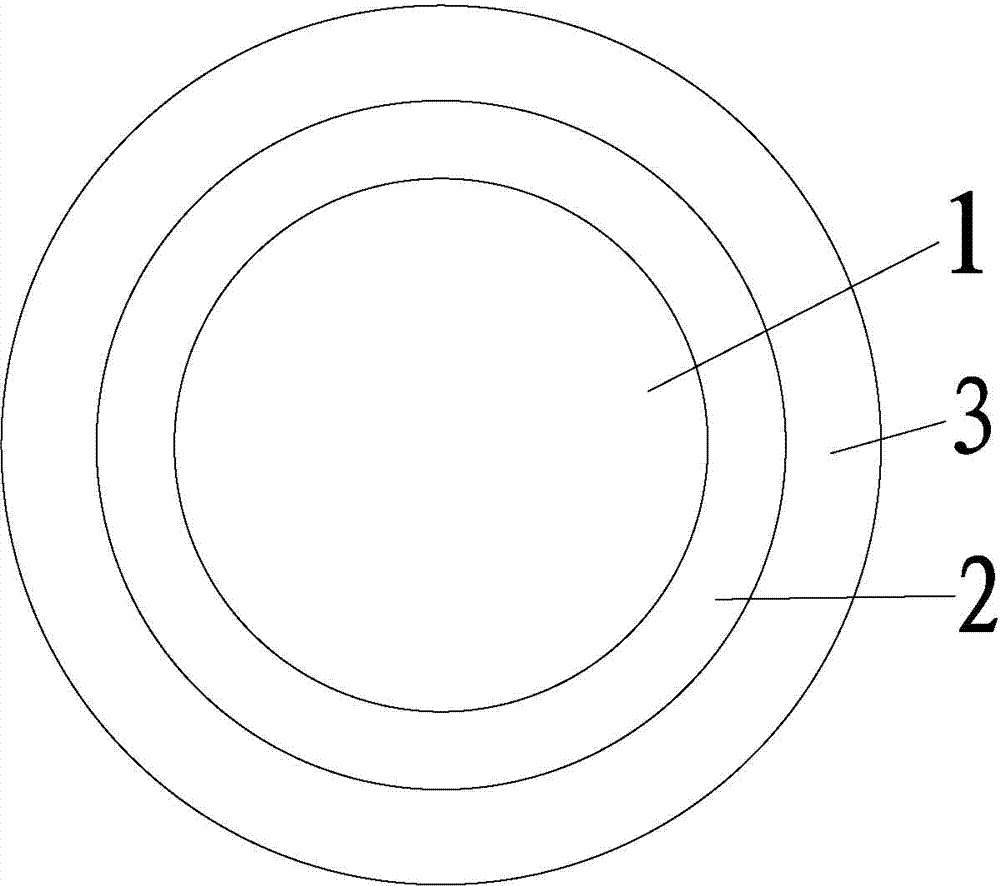

[0023] Example 1 ,Such as figure 1 As shown, a coating structure suitable for high-voltage charging and discharging includes a positive electrode material layer 1 of ternary lithium nickel cobalt manganese, and the surface of the positive electrode material layer 1 is coated with TiO 2 The first metal oxide layer 2 and Al 2 o 3 The second metal oxide layer 3, with TiO 2 The first metal oxide layer 2 is coated on the surface of the positive electrode material layer 1, with Al 2 o 3 A second metal oxide layer 3 coated with TiO 2 The outer surface of the first metal oxide layer 2, with TiO 2 The weight of the first metal oxide layer 2 accounted for with TiO 2 The first metal oxide layer 2 and has Al 2 o 3 40% of the total weight of the second metal oxide layer 3 .

[0024] The manufacturing method of the above cladding structure, the steps include:

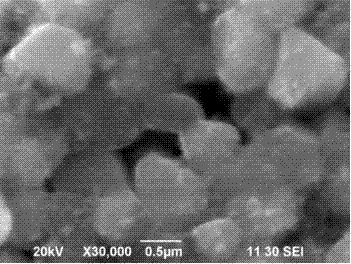

[0025] (1) First, add the positive electrode material 1 of ternary lithium nickel cobalt manganese into 4.7 g of titan...

Embodiment 2

[0029] Example 2 , the difference from Example 1 is that it is a coating structure suitable for high-voltage charging and discharging, and the surface of the positive electrode material layer 1 is coated with TiO 2 The first metal oxide layer 2 and ZrO 2 The second metal oxide layer 3, with TiO 2 The first metal oxide layer 2 is coated on the surface of the positive electrode material layer 1, with ZrO 2 A second metal oxide layer 3 coated with TiO 2 The outer surface of the first metal oxide layer 2, with TiO 2 The weight of the first metal oxide layer 2 accounted for with TiO 2 The first metal oxide layer 2 and has ZrO 2 45% of the total weight of the second metal oxide layer 3 .

[0030] The manufacturing method of the above cladding structure, the steps include:

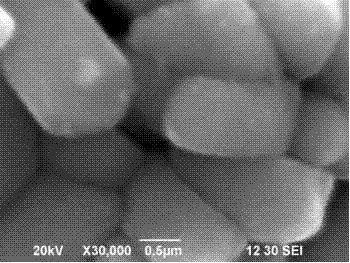

[0031] (1) First add the positive electrode material of ternary lithium nickel cobalt manganese to 5.4 g of TiCl 4 and 75 ml of methanol stirring solvent, after stirring for 4h, suction filtration, evapora...

Embodiment 3

[0036] Example 3 , the difference from Example 2 is that it is a coating structure suitable for high-voltage charging and discharging, and the surface of the positive electrode material layer 1 is coated with Al 2 o 3 The first metal oxide layer 2 and ZrO 2 The second metal oxide layer 3, with Al 2 o 3 The first metal oxide layer 2 is coated on the surface of the positive electrode material layer 1, with ZrO 2 The second metal oxide layer 3 is coated with Al 2 o 3 The outer surface of the first metal oxide layer 2, with Al 2 o 3 The weight of the first metal oxide layer 2 accounts for Al 2 o 3 The first metal oxide layer 2 and has ZrO 2 55% of the total weight of the second metal oxide layer 3 .

[0037] The manufacturing method of the above cladding structure, the steps include:

[0038] (1) Firstly, the positive electrode material of ternary lithium nickel cobalt manganese was added to 2.7 g of aluminum nitrate and 300 ml of industrial alcohol stirring solvent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com