Aqueous binder and lithium battery containing the binder

A water-based adhesive, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high toxicity, pollute the environment, volatile, etc., and achieve the effect of improving the efficiency of the first week and improving the cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

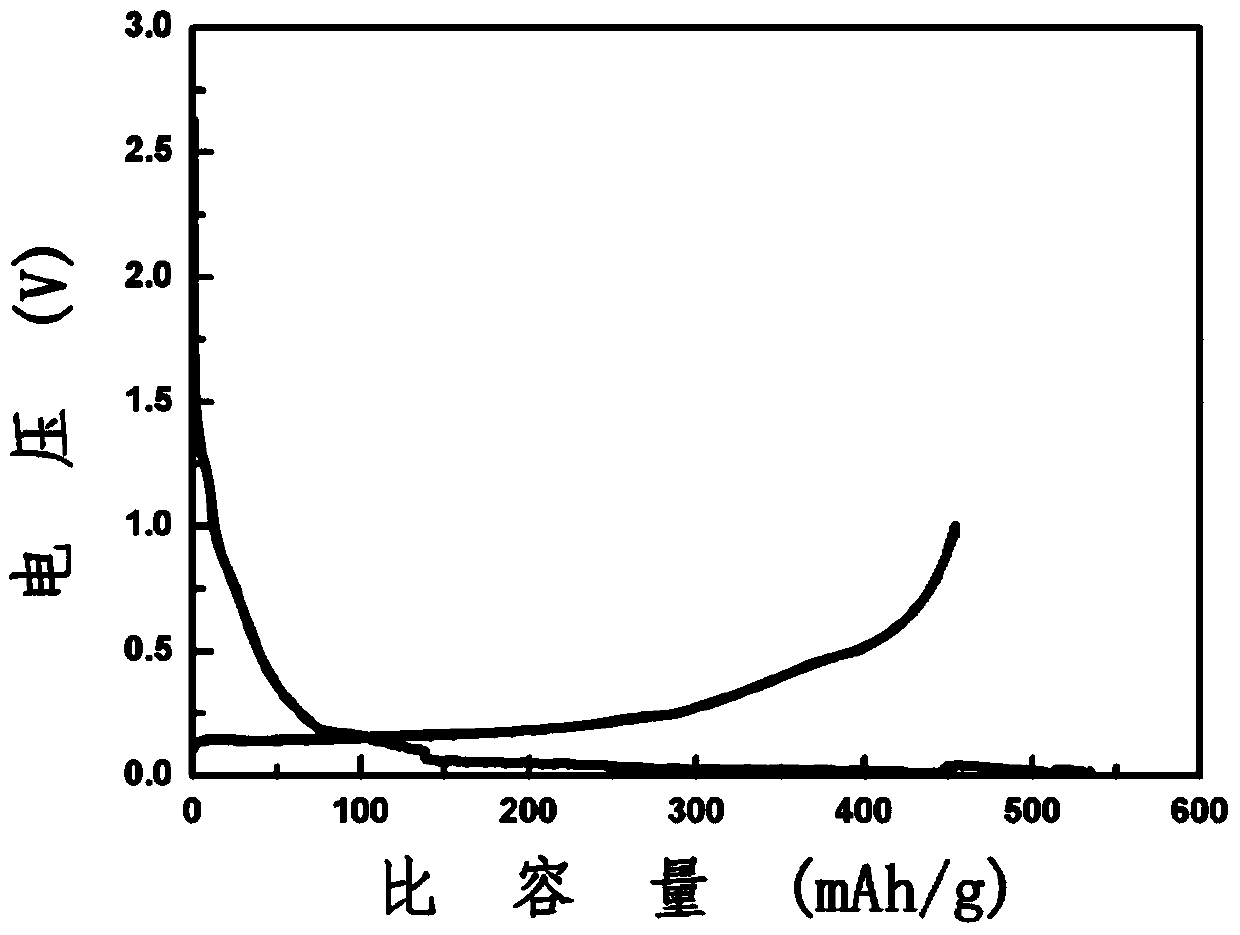

[0032] Take 0.5g of polyglutamic acid (molecular weight: 1,000,000) and put it in 10g of deionized water. Use a magnetic stirrer to stir for about 1 hour. After it is completely dissolved, add 0.2 g of a conductive agent (Super-P), continue to stir for 2 hours, and finally add 9.3 g of a silicon-carbon composite with a specific capacity of 450mAh / g, stir for 8 hours, and mix the obtained The paste was coated on copper foil with a thickness of 200 μm. Then place it in an air-blast oven at 80°C to dry, punch and weigh it, store it in a vacuum oven at 120°C for 24 hours, transfer it to a glove box to assemble it into a button cell, and let it rest for 12 hours.

[0033] The electrochemical performance test of the obtained button battery was carried out with the battery test system CT 2001A produced by Wuhan Landian Company. The discharge cut-off voltage of the test conditions was 0.005V, the charge cut-off voltage was 1V, and the charge-discharge rate was 0.5C.

[0034] see test...

Embodiment 2

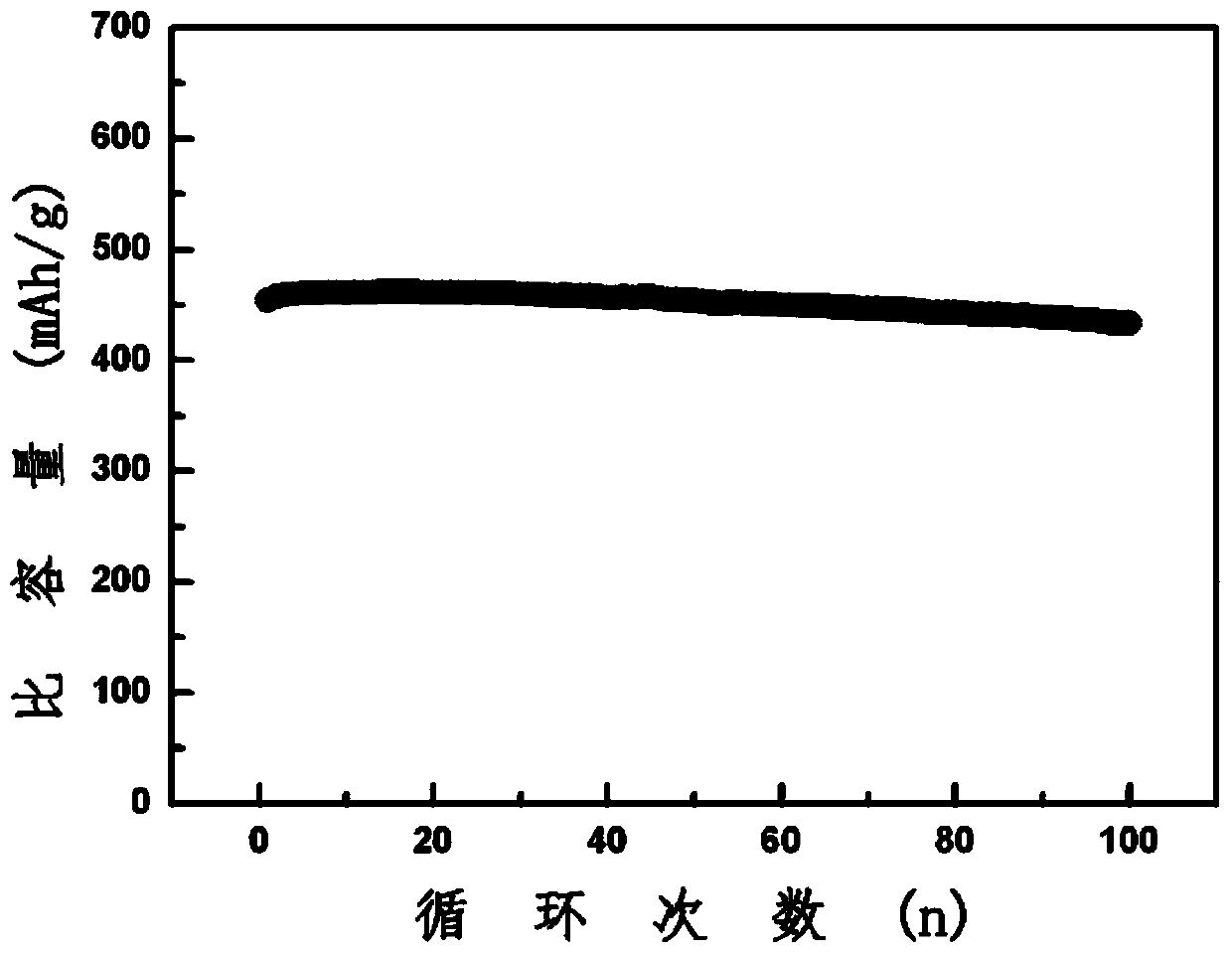

[0036] Take 0.5 g of lithium polyglutamate (molecular weight: 1,000,000) and place it in 10 g of deionized water. Use a magnetic stirrer to stir for about 1 hour. After it is completely dissolved, add 0.2 g of a conductive agent (Super-P), continue to stir for 2 hours, and finally add 9.3 g of a silicon-carbon composite with a specific capacity of 450mAh / g, stir for 8 hours, and mix the obtained The paste was coated on copper foil with a thickness of 200 μm. Then place it in an air-blast oven at 80°C to dry, punch and weigh it, store it in a vacuum oven at 120°C for 24 hours, transfer it to a glove box to assemble it into a button cell, and let it rest for 12 hours.

[0037] The electrochemical performance test of the obtained button battery was carried out with the battery test system CT 2001A produced by Wuhan Landian Company. The discharge cut-off voltage of the test conditions was 0.005V, the charge cut-off voltage was 1V, and the charge-discharge rate was 0.5C.

Embodiment 3

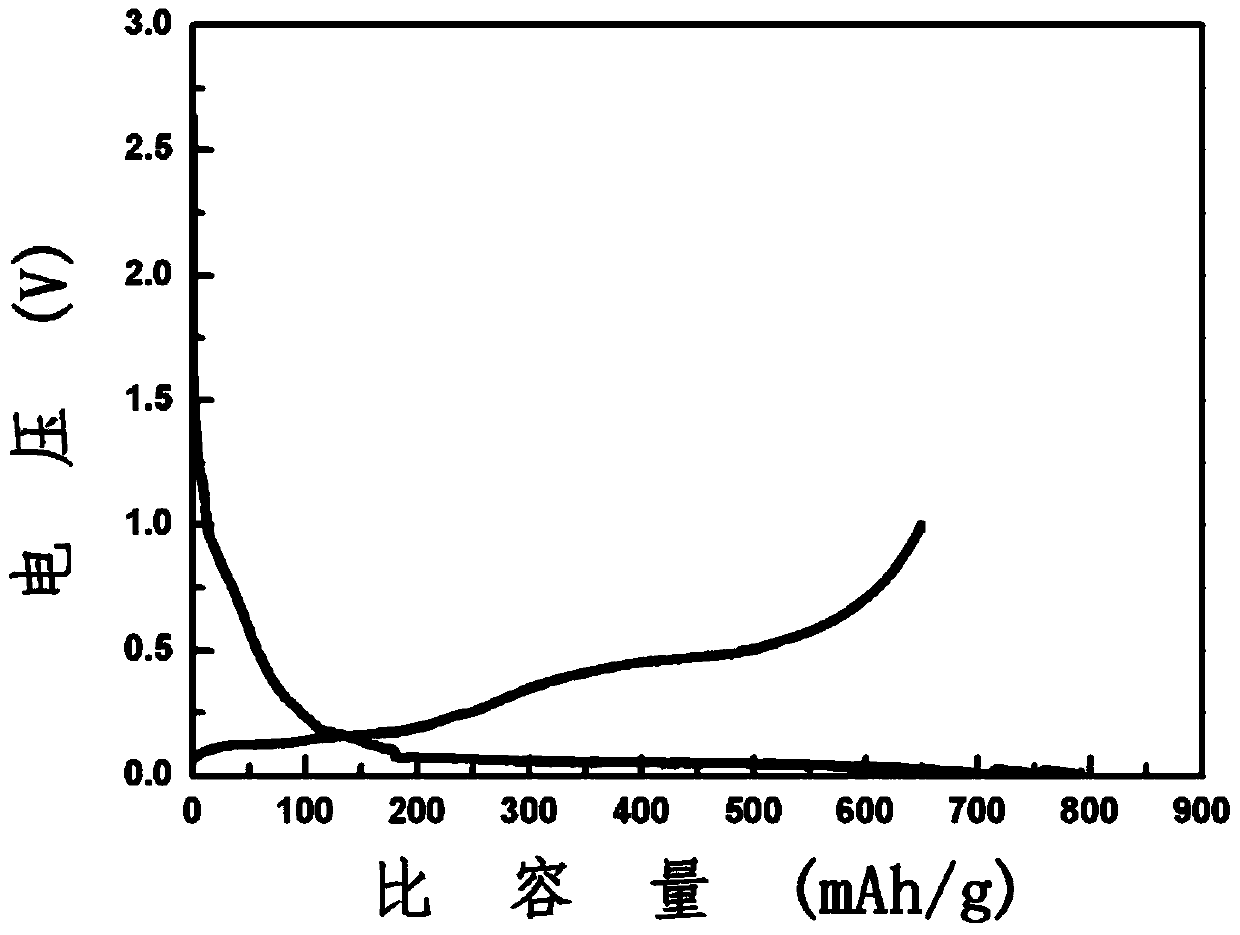

[0039] Take 0.5 g of sodium polyglutamate (molecular weight: 1,000,000) and place it in 10 g of deionized water. Use a magnetic stirrer to stir for about 1 hour. After it is completely dissolved, add 0.2 g of a conductive agent (Super-P), continue to stir for 2 hours, and finally add 9.3 g of a silicon-carbon composite with a specific capacity of 450mAh / g, stir for 8 hours, and mix the obtained The paste was coated on copper foil with a thickness of 200 μm. Then place it in an air-blast oven at 80°C to dry, punch and weigh it, store it in a vacuum oven at 120°C for 24 hours, transfer it to a glove box to assemble it into a button cell, and let it rest for 12 hours.

[0040] The electrochemical performance test of the obtained button battery was carried out with the battery test system CT 2001A produced by Wuhan Landian Company. The discharge cut-off voltage of the test conditions was 0.005V, the charge cut-off voltage was 1V, and the charge-discharge rate was 0.5C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com